Method for separating cannabidiol by using continuous chromatographic system

A continuous chromatography and cannabidiol technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as unfavorable industrial production, large environmental pollution, and high solvent consumption, and achieve low labor intensity and high product quality. The effect of high recovery rate and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for separating cannabidiol utilizing a continuous chromatographic system, said method comprising the steps of:

[0033] Step 1, reflux extraction:

[0034] Take marijuana flowers and leaves, crush them and extract them under heat reflux with an ethanol solution with a mass concentration of 60%, and then concentrate the obtained extract under reduced pressure to obtain a concentrated liquid extract; the total content of cannabidiol and tetrahydrocannabinol is 15%. 12% cannabidiol and 3% THC;

[0035] Step 2. Configure the solution:

[0036] Dissolve the concentrated liquid extract obtained in step 1 in an ethanol mobile phase with a mass fraction of 65%, and configure it as a raw material solution with a concentration of 100 mg / mL;

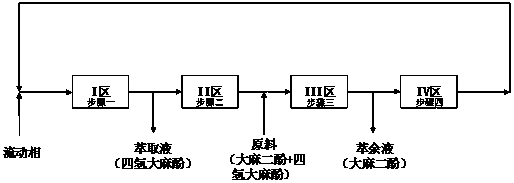

[0037] Step three, separation:

[0038] The mobile phase described in step 2 and the obtained raw material solution are continuously sent into the continuous chromatography system, and the cannabidiol solution is continuously col...

Embodiment 2

[0046] A method for separating cannabidiol utilizing a continuous chromatographic system, said method comprising the steps of:

[0047] Step 1, reflux extraction:

[0048] Take marijuana flowers and leaves, crush them and extract them under heat reflux with an ethanol solution with a mass concentration of 65%, and then concentrate the obtained extract under reduced pressure to obtain a concentrated liquid extract; the total content of cannabidiol and tetrahydrocannabinol is 15%, 12% cannabidiol and 3% THC;

[0049] Step 2. Configure the solution:

[0050] Dissolve the concentrated liquid extract obtained in step 1 in the acetone mobile phase with a mass fraction of 65%, and configure it as a raw material solution with a concentration of 300 mg / mL;

[0051] Step three, separation:

[0052]The mobile phase described in step 2 and the obtained raw material solution are continuously sent into the continuous chromatography system, and the cannabidiol solution is continuously col...

Embodiment 3

[0060] A method for separating cannabidiol utilizing a continuous chromatographic system, said method comprising the steps of:

[0061] Step 1, reflux extraction:

[0062] Take marijuana flowers and leaves, crush them and extract them under reflux with ethanol solution with a mass concentration of 100%, and then concentrate the obtained extract under reduced pressure to obtain a concentrated liquid extract; the total content of cannabidiol and tetrahydrocannabinol is 15%, 12% cannabidiol and 3% THC;

[0063] Step 2. Configure the solution:

[0064] The concentrated liquid extract obtained in step 1 is dissolved in the acetonitrile mobile phase with a mass fraction of 55%, and is configured into a raw material solution with a concentration of 600mg / mL;

[0065] Step three, separation:

[0066] The mobile phase described in step 2 and the obtained raw material solution are continuously sent into the continuous chromatography system, and the cannabidiol solution is continuousl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap