Composite floor slab supporting system with universal ball adjusting devices and installing method

A technology of superimposing floor slabs and adjusting devices, which is applied in the processing of building materials, formwork/template/work frame, and on-site preparation of building components, etc., can solve the change of scaffolding support performance, affect the normal progress of construction, and increase construction costs. and other problems, to achieve the effect of improving the utilization rate and service life, improving convenience and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

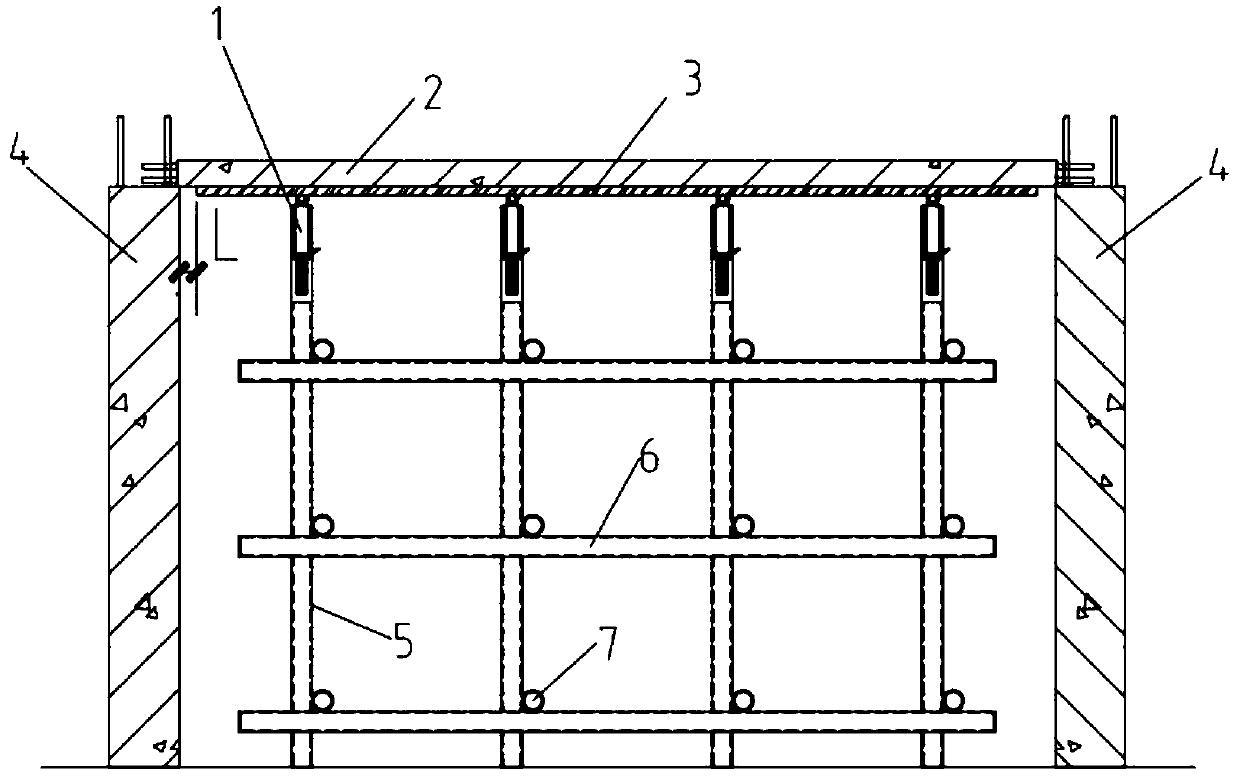

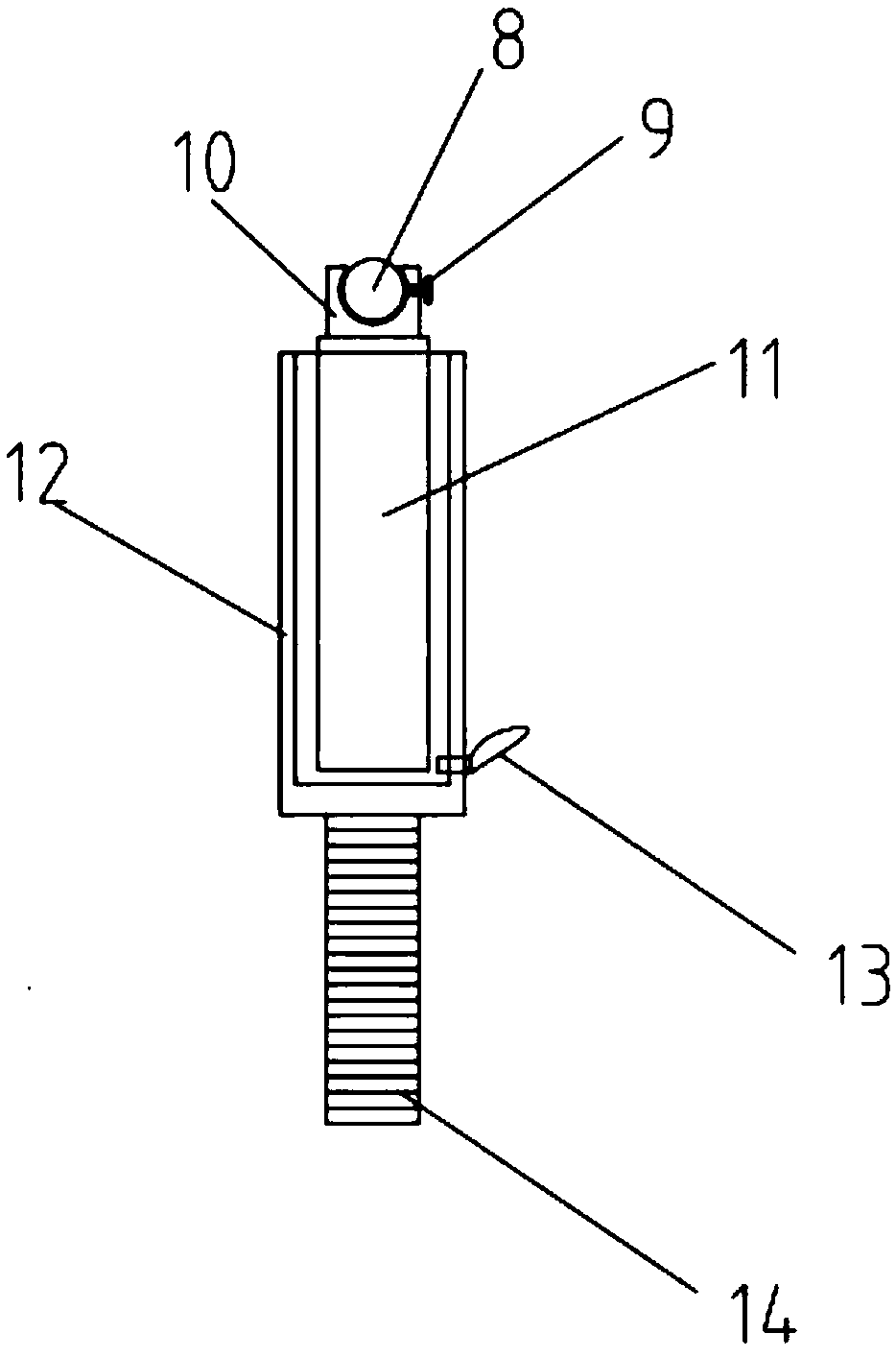

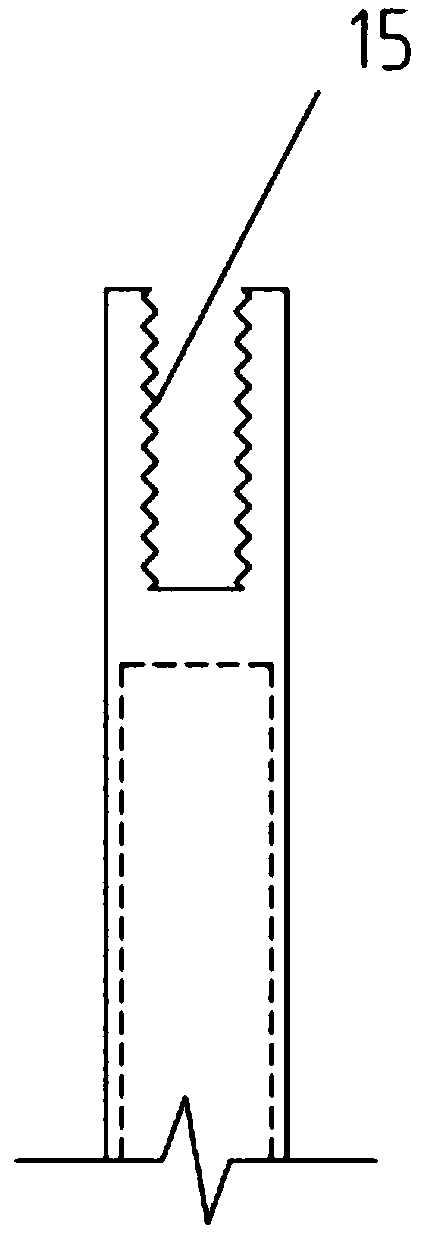

[0023] A support system and installation method for a composite floor with a universal ball adjustment device involved in this embodiment is realized through the following technical scheme: vertically placed vertical rods 5 intersect with horizontal rods 6 extending left and right, and vertical rods 7 extending forward and backward Connected to form a scaffold system that can be adjusted and moved in three directions. A universal ball adjustment device 1 for adjusting balance and stability is movable on the upper end of each vertical pole 5. The upper part of the universal ball adjustment device 1 is horizontally arranged to be useful To support and install the formwork 3 of the laminated floor 2, the left and right sides of the laminated floor 2 are vertically provided with prefabricated shear walls 4, and the positions of the formwork 3 and the laminated floor 2 can be precisely adjusted by adjusting the universal ball device 1, so that the left and right ends of the laminate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com