An electromagnetically driven urea pump OBD diagnosis method

A technology of electromagnetic drive and diagnostic method, which is applied in the direction of diagnostic devices of exhaust treatment devices, engine components, combustion engines, etc., can solve problems such as high cost of pressure sensors, increased system costs, and difficulty in distinguishing failures of pressure build-up, etc., to achieve cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

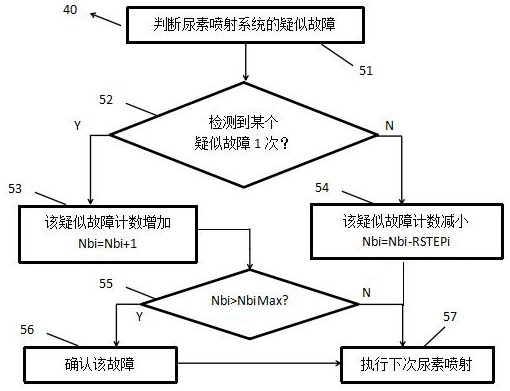

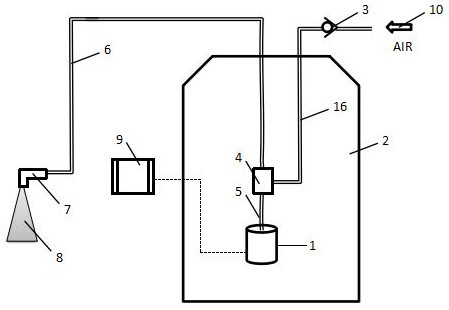

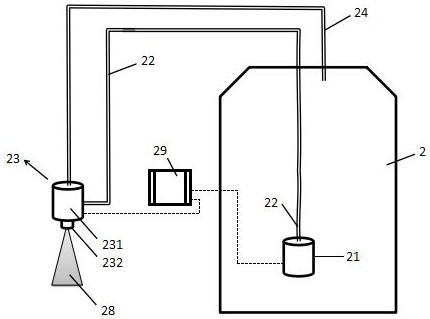

[0034] For such as figure 1 The electromagnetically driven plunger metering pump and its metering system faults in the air-assisted SCR system shown in the figure, using the OBD diagnosis method of the present invention, can judge whether the metering pump is stuck, empty pump, air circuit or injection pipe by detecting T3 Jam fault.

[0035] Such as figure 1 and Figure 4 As shown, the relationship between T3 and T1 can be determined in advance when the metering pump 1 pumps liquid normally, the check valve 3, the air pipe 16, the injection pipe 6, the mixing chamber 4, the liquid outlet pipe 5 and the air-assisted nozzle 7 are also normally unblocked. , the T3 measured during each T1 operation when the pump is working should basically satisfy this predetermined relationship, as shown in the attached Figure 4 Shown in the curve L0 in. But if ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com