Constant temperature water mixing valve

A thermostatic mixing valve and valve body technology, applied in valve details, multi-port valves, valve devices, etc., can solve the problems of difficult adjustment, high motor power, complex structure, etc., to achieve fast response, small driving force, Accurate temperature adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

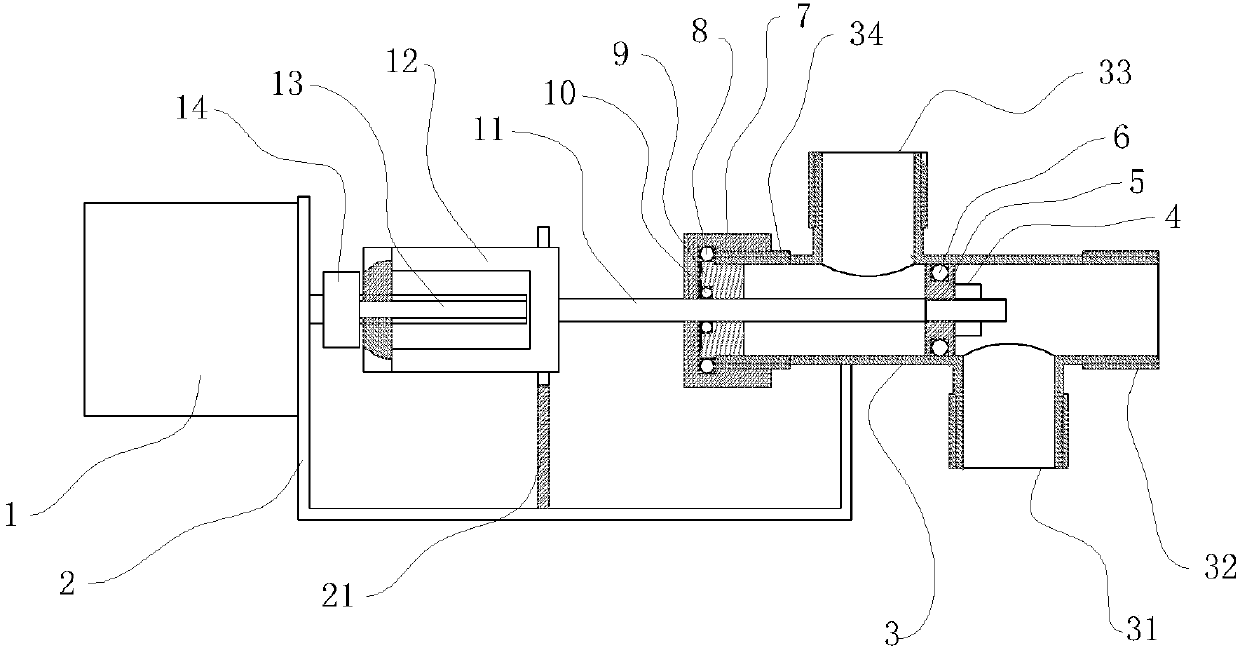

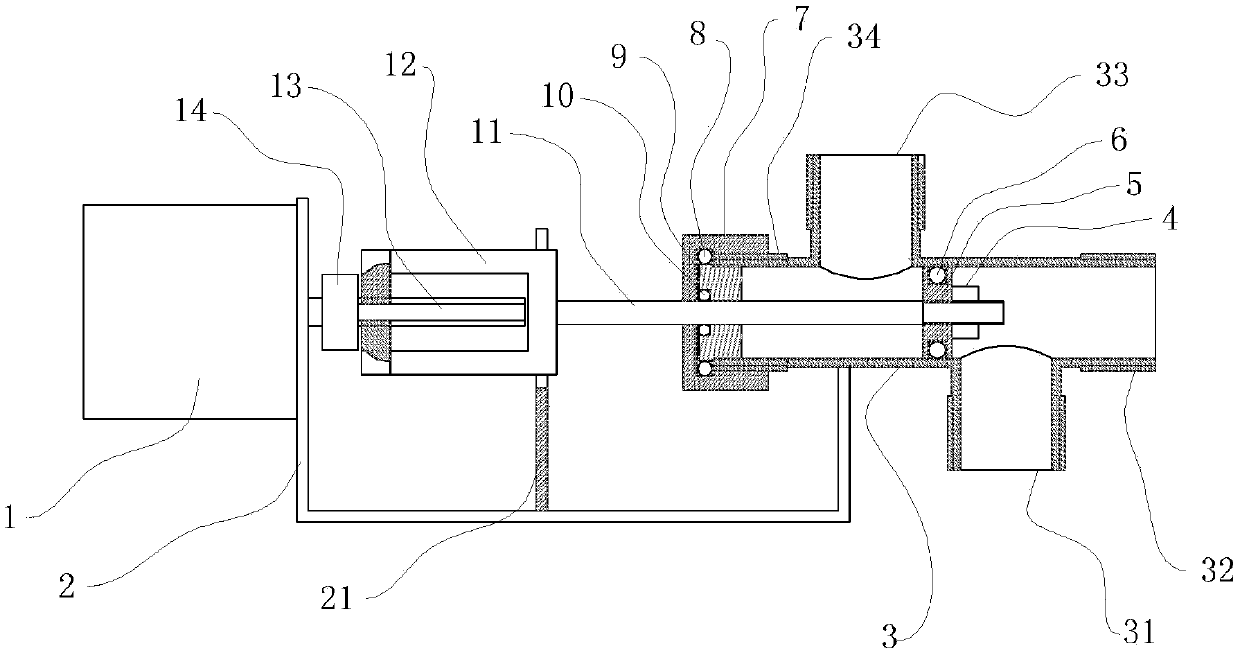

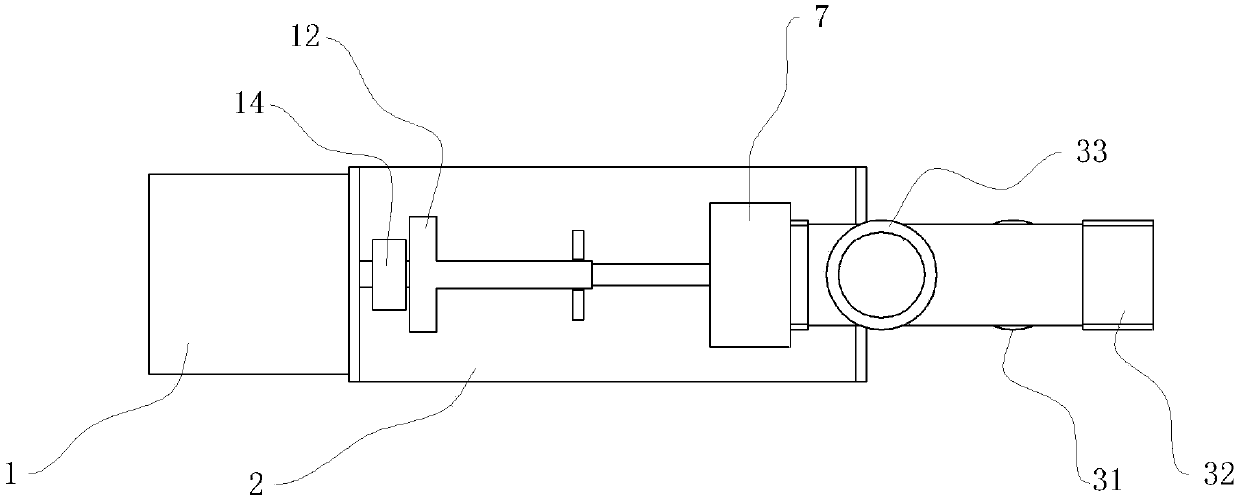

[0013] refer to figure 1 , a thermostatic water mixing valve of the present invention includes a stepper motor 1, a bracket 2, and a valve body 3, the valve body 3 is provided with four threaded ports, the port 32 is a hot water pipe port, and the port 33 is a cold water pipe port , the interface 31 is the water outlet of the mixing valve, the inside of the valve body 3 is a cylindrical surface, the valve core 5 is fixed on the valve stem 11, and the components composed of the valve core 5 and the valve stem 11 form a sliding fit with the inner surface of the valve body 3 , The spool 5 is also provided with an annular groove, the sealing ring 6 is stuck in the annular groove, the right side of the spool 5 is provided with a locking nut 4, and the locking nut locks the spool 5 by the screw thread at the right end of the valve stem.

[0014] The valve body 3 is fixed on the bracket 2, the interface 34 on the valve body 3 is provided with a sealing nut 7, the valve stem 11 passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com