Online dual-track high-speed jet dispensing machine

A high-speed jetting and dispensing machine technology, applied in the field of dispensing machines, can solve the problems of high requirements on camera and compensation accuracy, large vibration of the parts to be dispensed, and difficulty in synchronization of belts, and achieves high dispensing efficiency and dispensing. The process is precise and the effect of maintaining tension is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following is attached Figure 1-6 The present invention is described in further detail.

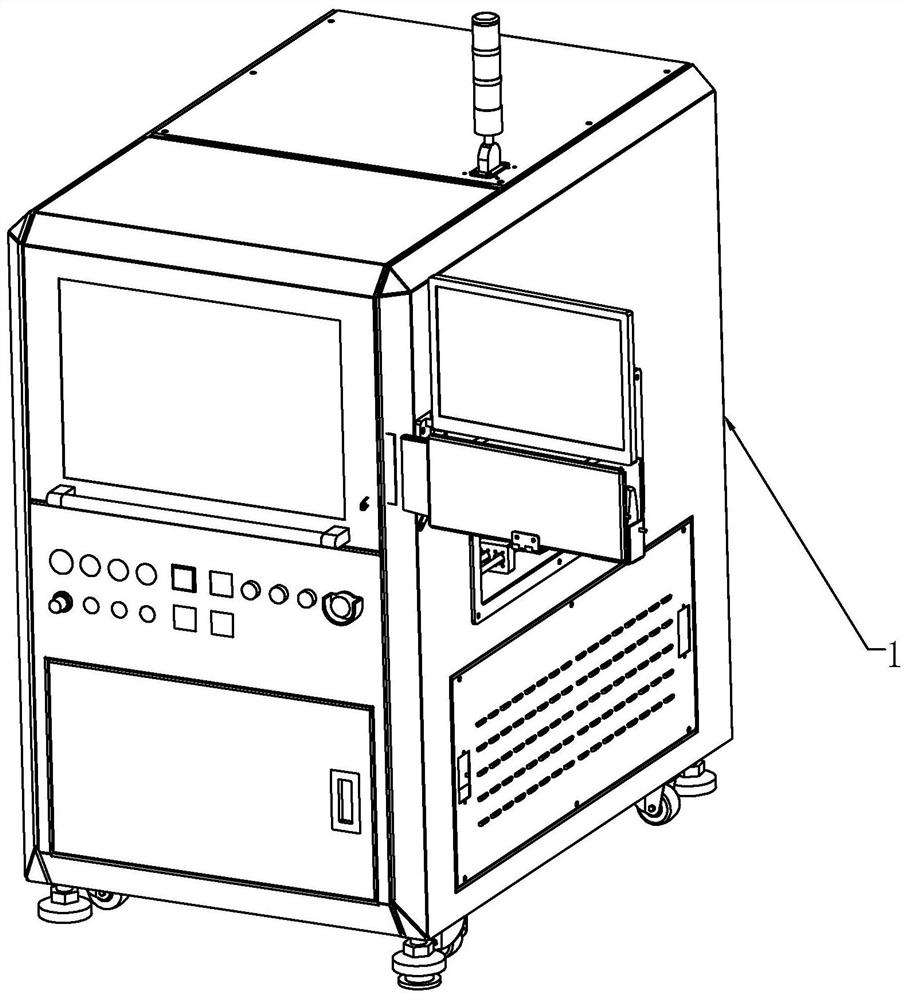

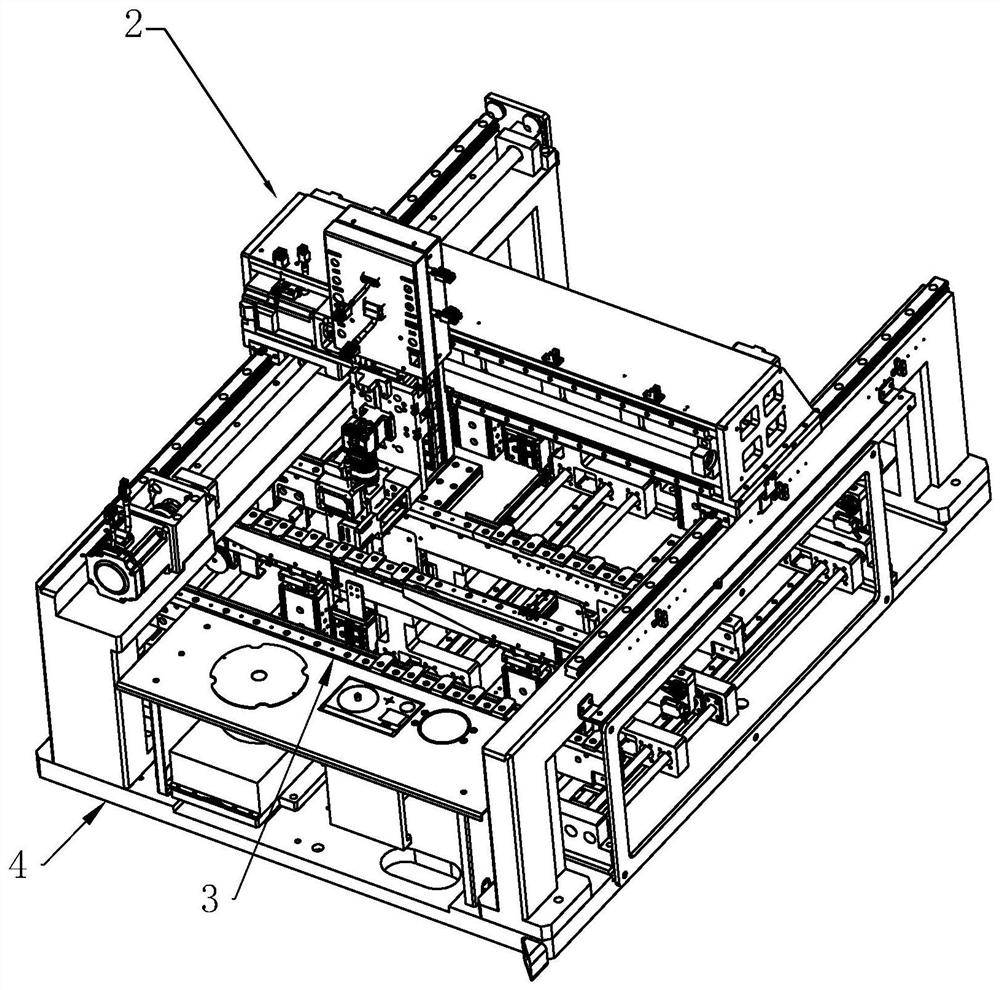

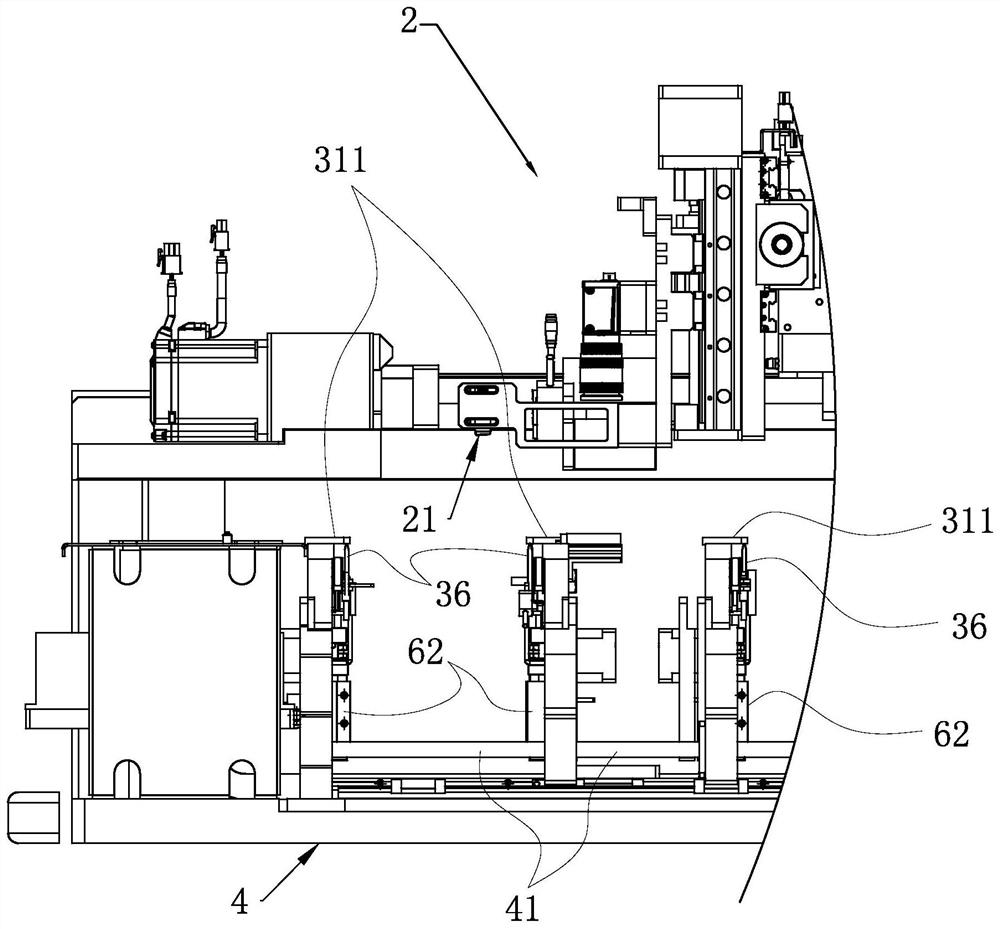

[0042] Online dual-track high-speed jet dispensing machine, such as figure 1 and figure 2 As shown, it includes a housing 1 and a three-axis mechanism 2 installed in the housing 1, and a dispensing nozzle 21 is installed on the three-axis mechanism 2 (see image 3 ), the lower part of the three-axis mechanism 2 is provided with a mounting plate 4, and a conveying mechanism 3 is installed on the mounting plate 4; Figure 5 As shown, the conveying mechanism 3 is made up of two rail groups arranged side by side, and each rail group includes two transfer rails 31 arranged side by side for conveying the parts to be dispensed, guide wheels 32 arranged at both ends of the transfer rail 31 and a set The abutment wheel 33 below the transmission track 31, the drive wheel 34 is also arranged below the transmission track 31, and the conveyor belt 35 surrounds the top of the transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com