Integrated active air inlet grille front end frame

A front-end frame and air intake grille technology, which is applied in the power unit, the arrangement of the cooling combination of the power unit, the vehicle safety arrangement, etc., can solve the problems of many tooling procedures, large number of parts, low efficiency, etc., and improve the installation structure. , The installation structure is simple, and the cost is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

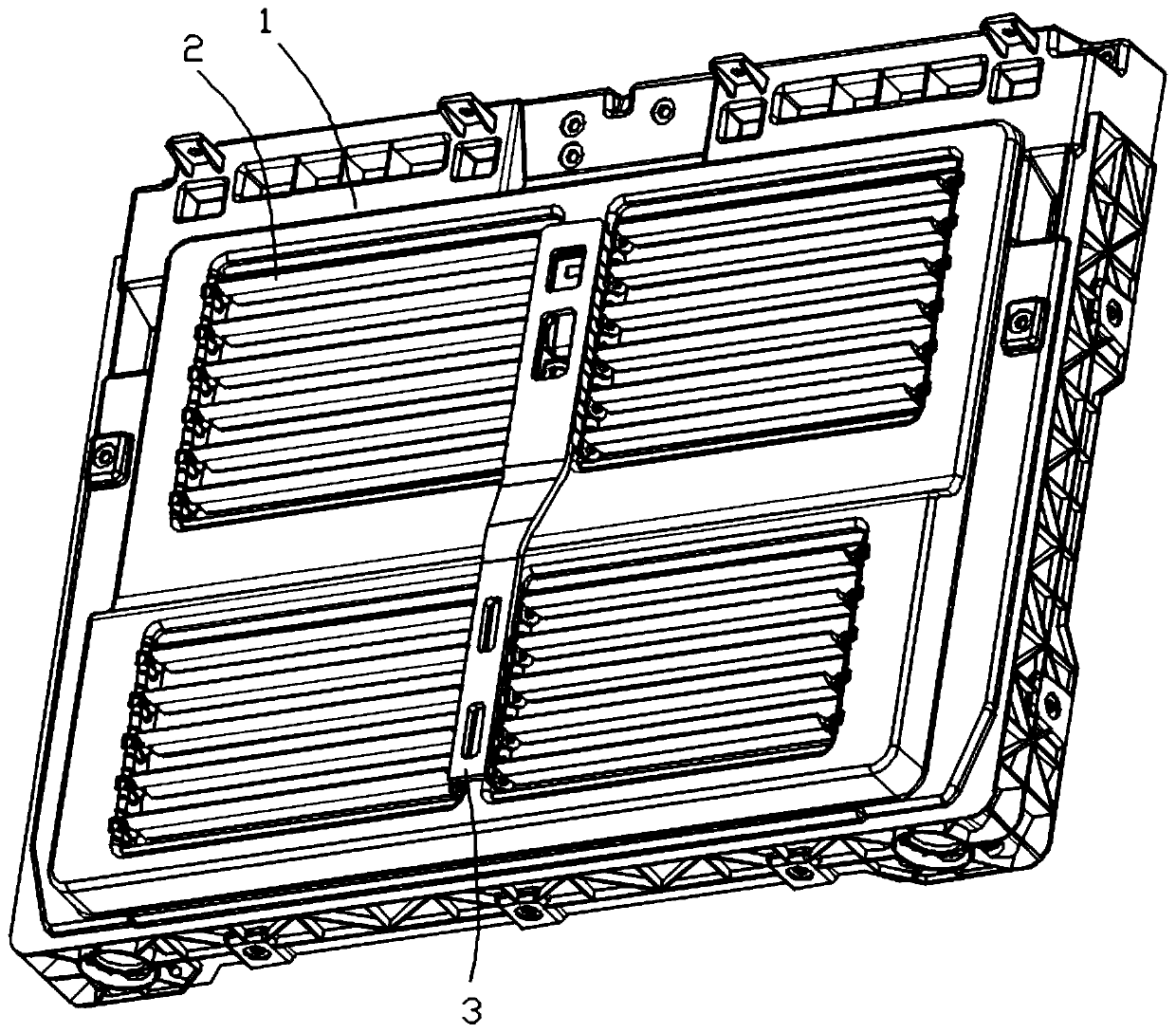

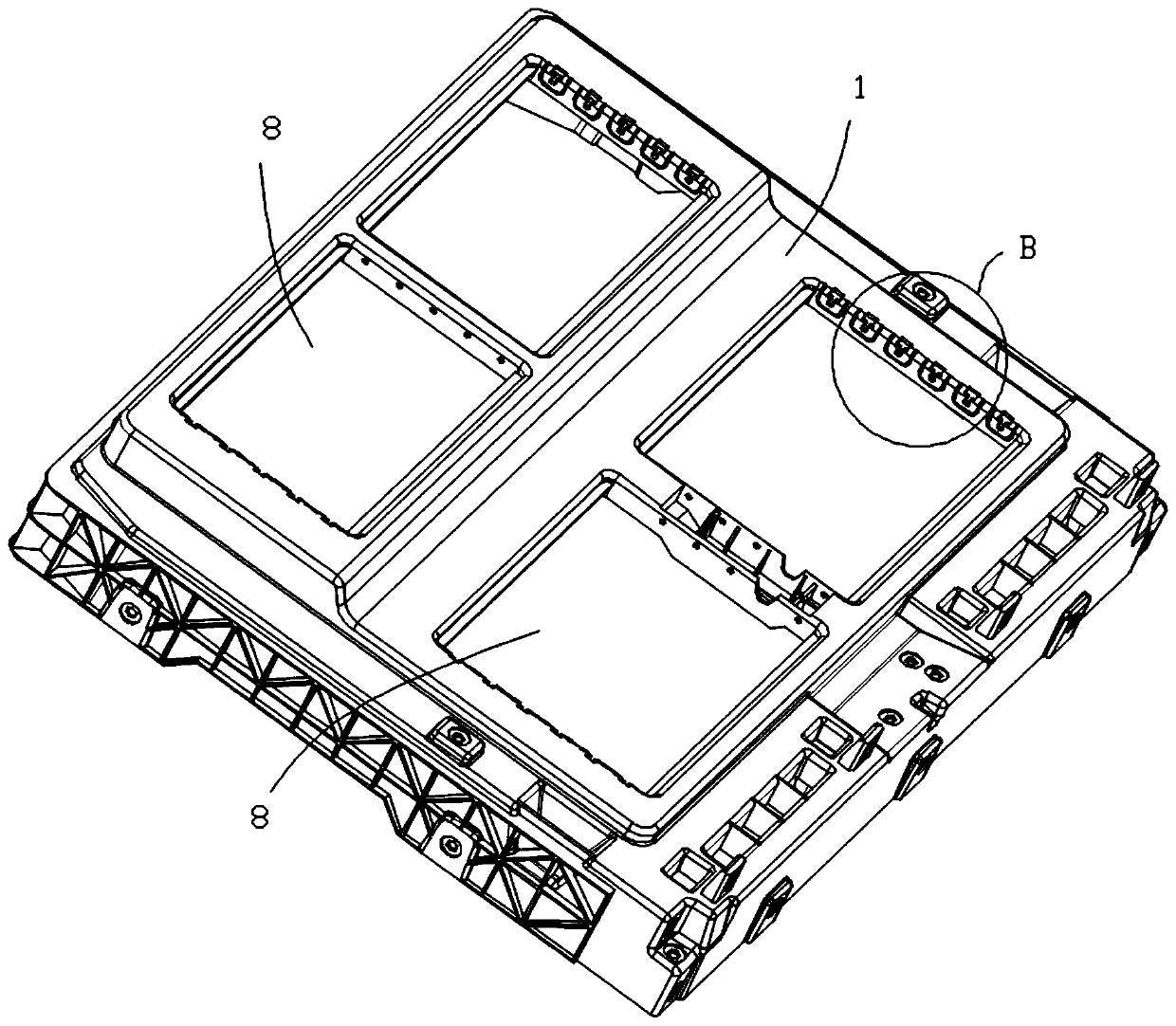

[0038] Such as Figure 1-Figure 6 As shown, this embodiment provides a front frame of an integrated active air intake grille, which includes a front frame body 1 , blades 2 and a blade driving device.

[0039] Wherein, at least one air intake channel 8 is opened on the front frame body 1 , and a plurality of blades 2 are respectively arranged in each air intake channel 8 . In this embodiment, the front-end frame body 1 is preferably an integrated structure. After the blade 2 and the blade driving device are installed on the front-end frame, the integrated structure of the three can be installed on the vehicle as a whole. Exemplary, figure 2 It shows the situation that there are 4 intake passages 8, which are arranged in two rows up and down, each row has 2 intake passages 8, the middle part of the front frame body 1 is the middle frame, and the intake passages 8 are distributed on both sides of the middle frame .

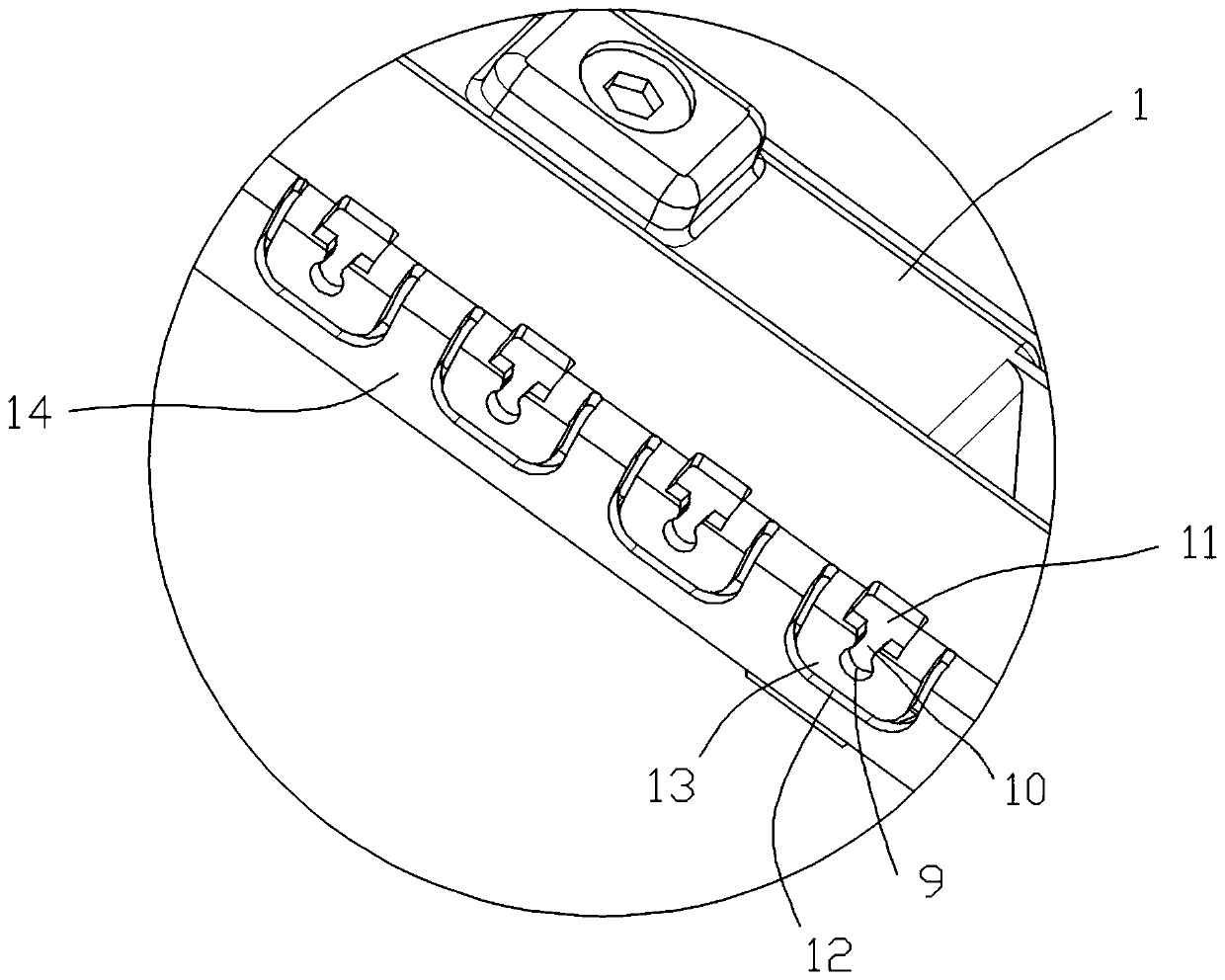

[0040] In this embodiment, the blade driving device is ins...

Embodiment 2

[0052] This embodiment provides a front-end frame of an integrated active air intake grille. Compared with Embodiment 1, the main difference of this embodiment is:

[0053] Such as Figure 7 As shown, the gap is a continuous gap formed between the elastic clips 13 on the inner wall 14 of the air intake passage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com