A kind of multiple organic wastewater treatment system

A technology for organic wastewater treatment and biological treatment, applied in multi-stage water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The air reaction rate declines and other problems, so as to achieve the effect of sufficient aeration treatment and increase the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

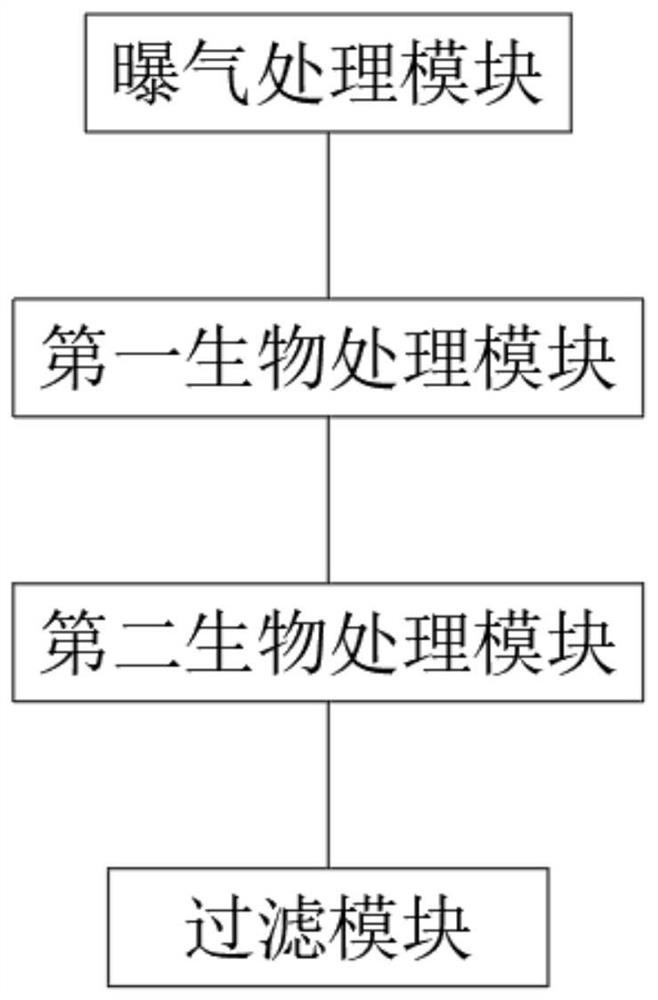

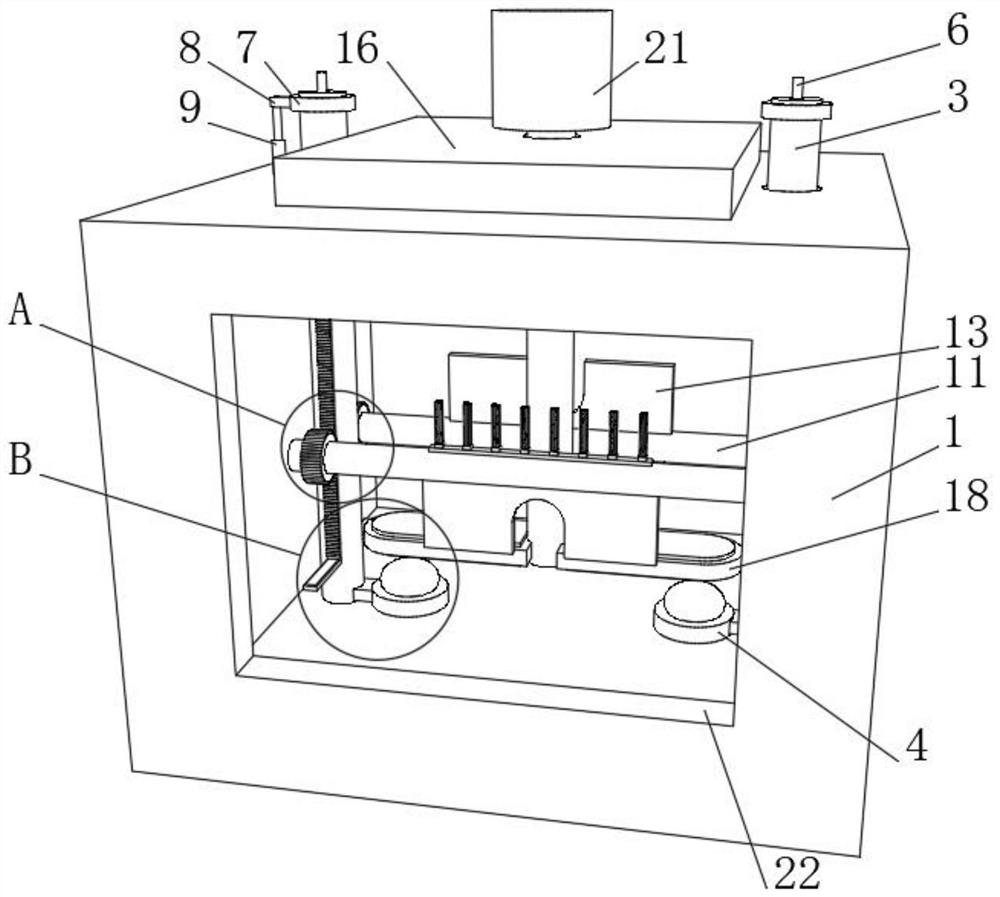

[0037] see Figure 1-8 , a diversified organic wastewater treatment system, including an aeration treatment module, the aeration treatment module is connected to a first biological treatment module, the first biological treatment module is connected to a second biological treatment module, and the second biological treatment module is connected to a filtration module .

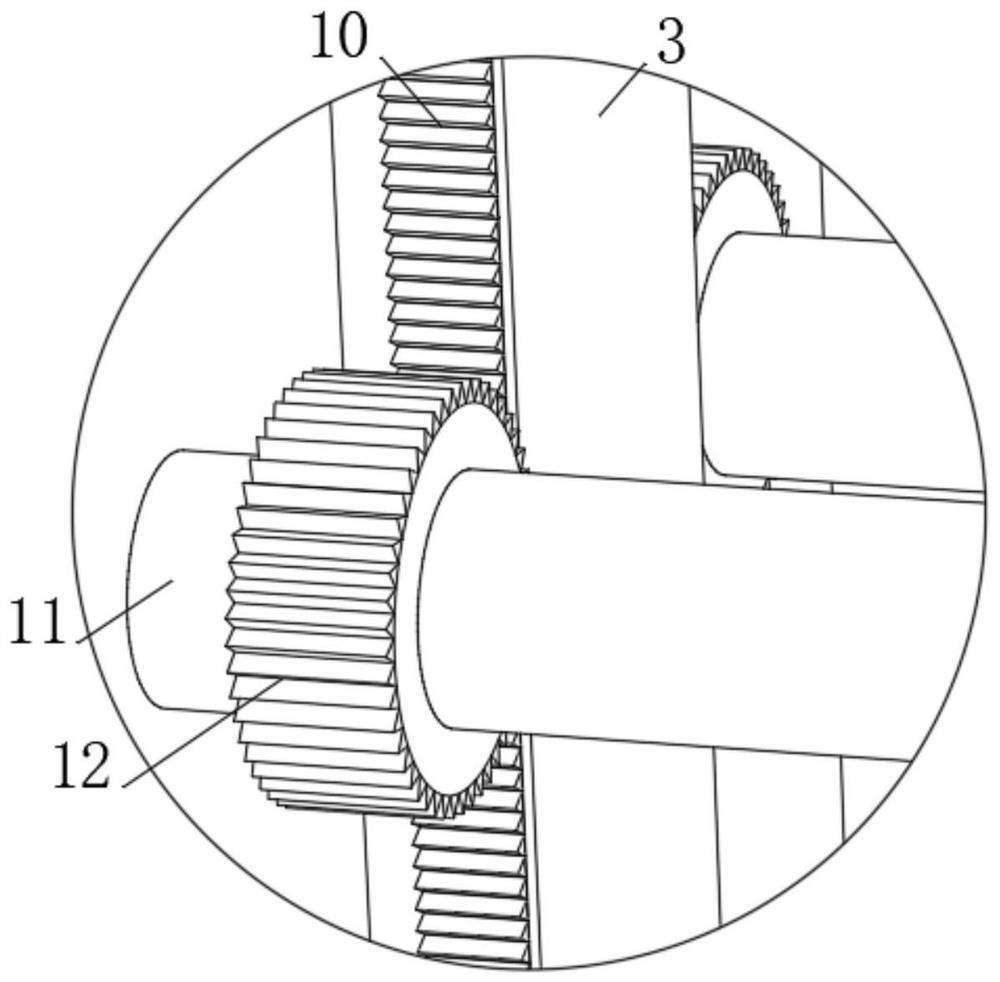

[0038] The aeration treatment module includes an aeration tank. A pair of through-holes 2 are drilled at the upper end of the aeration tank 1, and an outer protection cylinder 3 is inserted into the through-hole 2. The ends of the two outer protection cylinders 3 that are close to each other are fixedly connected to an aeration disc. 4. The aeration pan 4 is located in the aeration tank 1, and the outer protection cylinder 3 has an installation cavity 5. The outer end of the aeration pan 4 is installed with a rubber tube 6, and the end of the rubber tube 6 far away from the aeration pan 4 is connected to the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com