A kind of moss inhibitor for concrete

An inhibitor and concrete technology, which is applied in the field of chemical building materials, can solve the problems that the moss and algae on the concrete surface are not well controlled, reduce the friction coefficient of the parasite surface, endanger the surrounding water body and atmospheric environment, etc., and achieve good hydrophobicity and Thermal stability, good self-cleaning effect, good superhydrophobic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

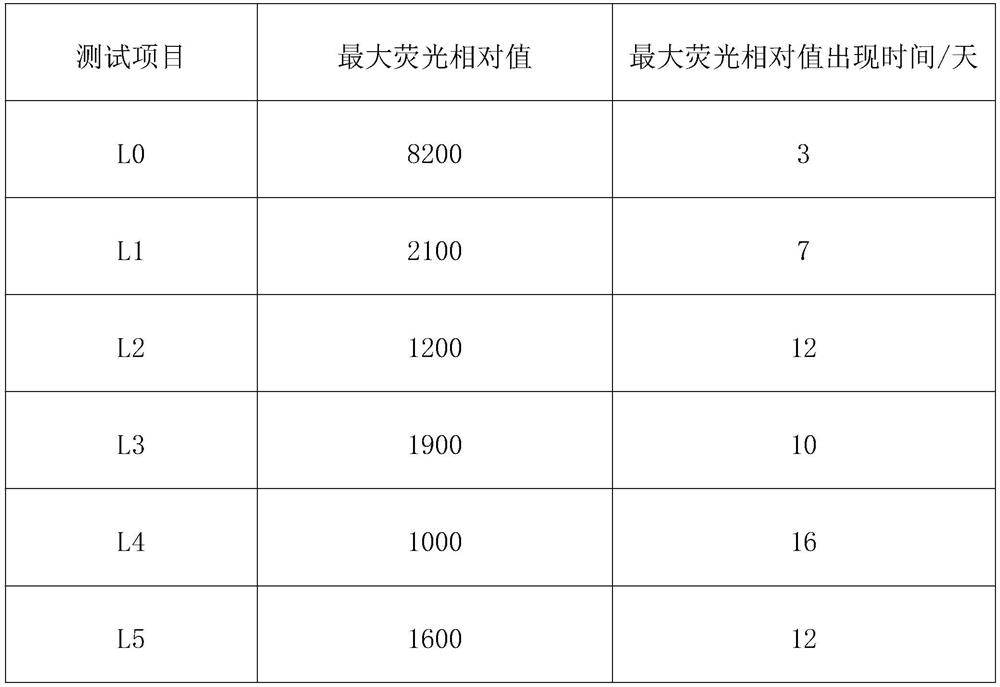

Embodiment 1

[0023] A moss algae inhibitor 15g for concrete, made of the following raw materials in mass percentage: nano-titanium dioxide 0%, thiazolinone 0%, nano-silver bactericide 0%, alloy powder 68.10%, silane 9.10%, modified nano-silicon Sodium acid hydrophobic material 17.30%, water-based nano inorganic mineral emulsion 5.50%.

[0024] After the above-mentioned raw materials are weighed in proportion, they are put into a mortar mixer and stirred for 120 seconds, so that the raw materials are uniformly mixed to obtain the finished material L1.

Embodiment 2

[0026] A moss algae inhibitor 15g for concrete, made of the following raw materials in mass percentage: 40.00% of nano-titanium dioxide, 6.70% of thiazolinone, 8.20% of nano-silver fungicide, 40.00% of alloy powder, 5.10% of silane, modified nano-silicon Sodium acid hydrophobic material 0%, water-based nano inorganic mineral emulsion 0%.

[0027] After the above-mentioned raw materials are weighed in proportion, they are put into a mortar mixer and stirred for 120 seconds, so that the raw materials are uniformly mixed to obtain the finished material L2.

Embodiment 3

[0029] A moss algae inhibitor 15g for concrete, made of the following raw materials in mass percentage: 31.70% of nano-titanium dioxide, 6.00% of thiazolinone, 12.70% of nano-silver fungicide, 31.70% of alloy powder, 5.30% of silane, modified nano-silicon Sodium acid hydrophobic material 6.3%, water-based nano inorganic mineral emulsion 6.3%.

[0030] After the above-mentioned raw materials are weighed in proportion, they are put into a mortar mixer and stirred for 120 seconds, so that the raw materials are uniformly mixed to obtain the finished material L3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com