Gelatin extraction system

A gelatin and glue tank technology, applied in the preparation of animal glue or gelatin, etc., can solve the problems of inability to directly bag and transport, increase the pressure of sewage system, easy to stink and pollute the environment, etc., achieve a small footprint, reduce colloid Loss, the effect of large throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

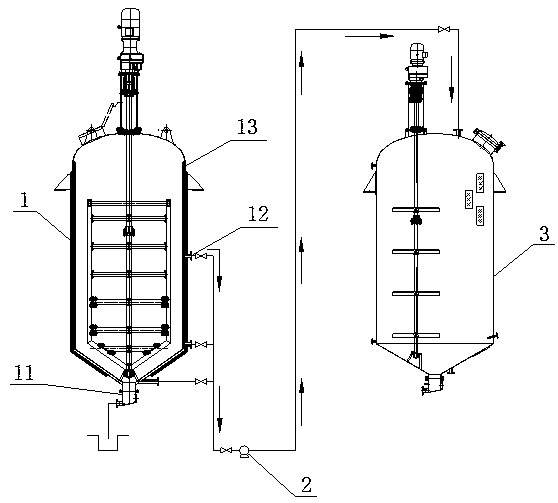

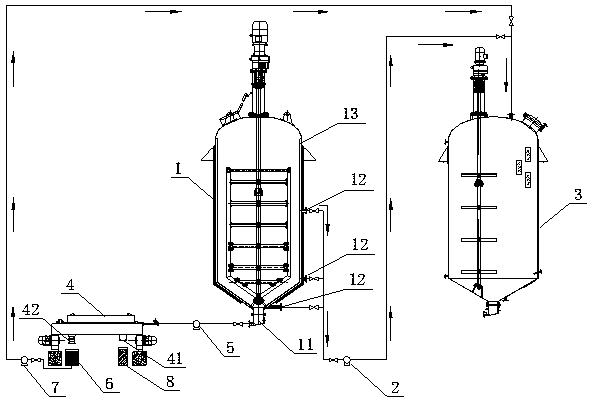

[0014] This embodiment proposes a gelatin extraction system that can reduce the loss of glue solution and facilitate the treatment of solids.

[0015] Such as figure 2 As shown, the gelatin extraction system of this embodiment includes a gelatin extraction tank 1, a gel delivery pump 2, and a clarification tank 3. The gel delivery pump 2 is respectively connected to the liquid outlet 12 of the gelatin extraction tank 1 and the liquid inlet of the clarification tank 3. The key is that the gelatin extraction system also includes a horizontal centrifuge 4, a solids conveying pump 5, a liquid recovery tank 6 and a liquid recovery pump 7. The inlet of the centrifuge 4 is connected to the lifting pump through the solids conveying pump 5 The solids outlet 11 of the glue tank 1 is connected, and the liquid outlet 42 of the centrifuge 4 is connected to the liquid recovery tank 6 which is also connected to the liquid inlet of the clarification tank 3 through the liquid recovery pump 7.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com