Solid-state coupling patch for measurement of ultrasonic flowmeter and preparation method of solid-state coupling patch

A coupling patch and flowmeter technology, applied in the field of solid-state coupling patch and its preparation, can solve the problems of oil coupling agent polluting the environment, affecting measurement results, and collision scratches on the probe surface, so as not to cause secondary pollution, The operation is convenient and hygienic, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

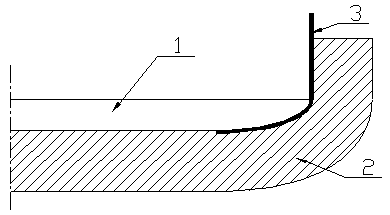

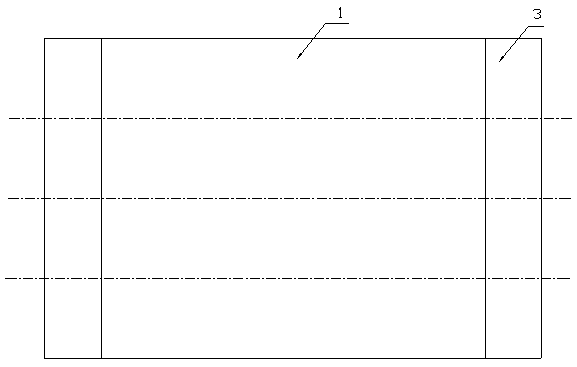

[0024] see figure 1 and figure 2 , the solid-state coupling patch 1 of the present invention is composed as follows by mass percentage: 20%-40% water-soluble polymer gel, 15%-30% adhesive, 35%-40% glycerol, and the rest is ionized water. The water-soluble polymer gel is polymerized from cyclopentasiloxane and polydimethylsiloxane. The adhesive is a silicone adhesive.

[0025] In this embodiment, the solid coupling patch 1 is composed as follows in mass percentage: 20% water-soluble polymer gel, 15% adhesive, 40% glycerol and 25% deionized water.

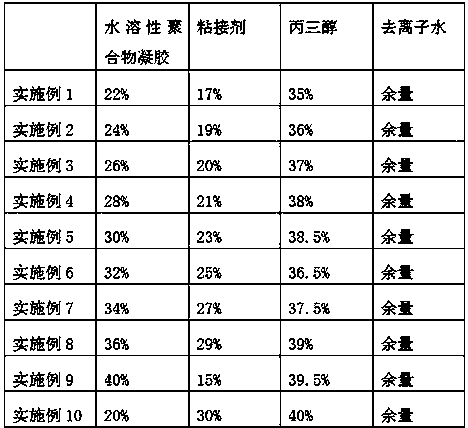

[0026] The following table is the remaining embodiments of the present invention, and the numerical values in the table are mass percentages:

[0027]

[0028] A method for preparing a solid-state coupling patch for ultrasonic flowmeter measurement, comprising the following steps:

[0029] Step 1. First adjust the temperature of the deionized water to 25-35°C, then add the water-soluble polymer gel into the deionized water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com