Low-yield-ratio seamless steel tube and manufacturing method thereof

A technology of seamless steel pipe and low yield ratio, which is applied in the field of low yield ratio seamless steel pipe and its manufacturing, and can solve the problems of inability to adapt to the use requirements of low yield ratio seamless steel pipe, low safety of use, and limited application range etc. to achieve excellent comprehensive mechanical properties, low manufacturing cost, and low composition cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

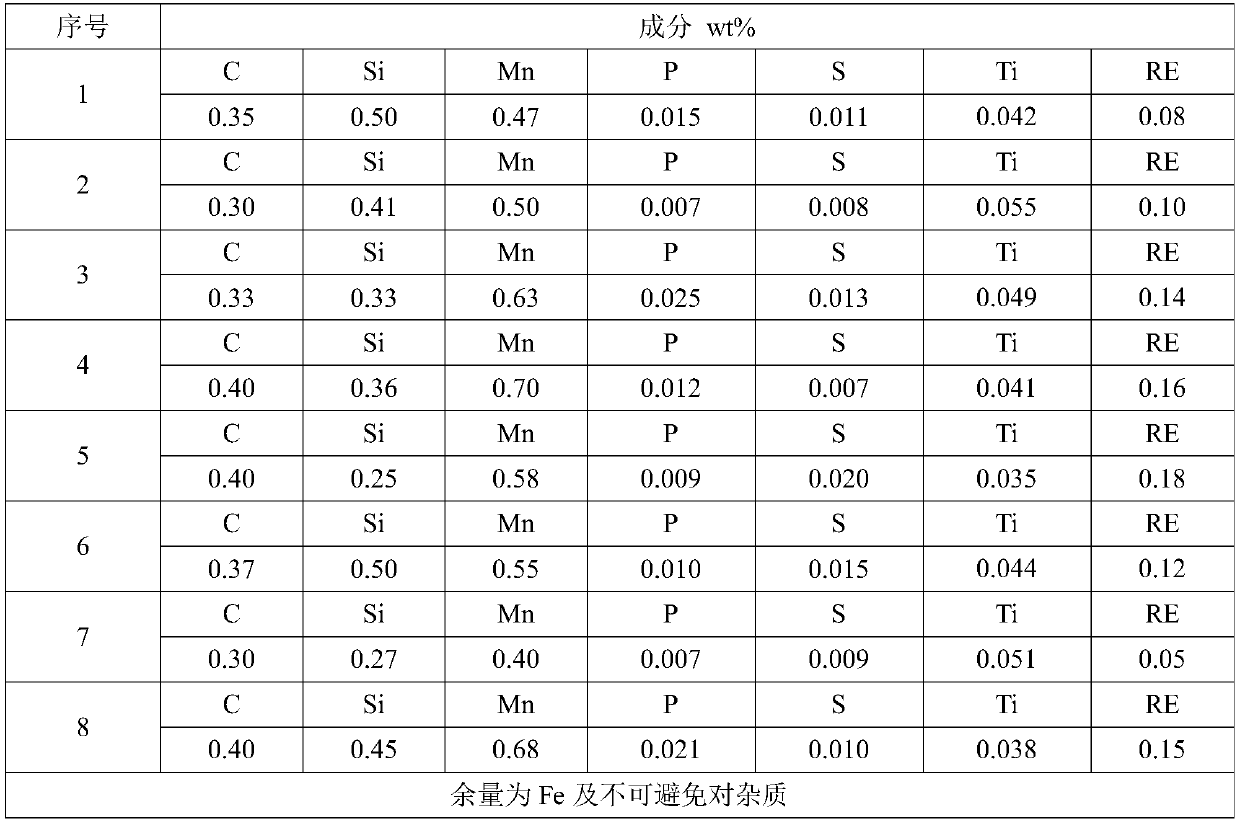

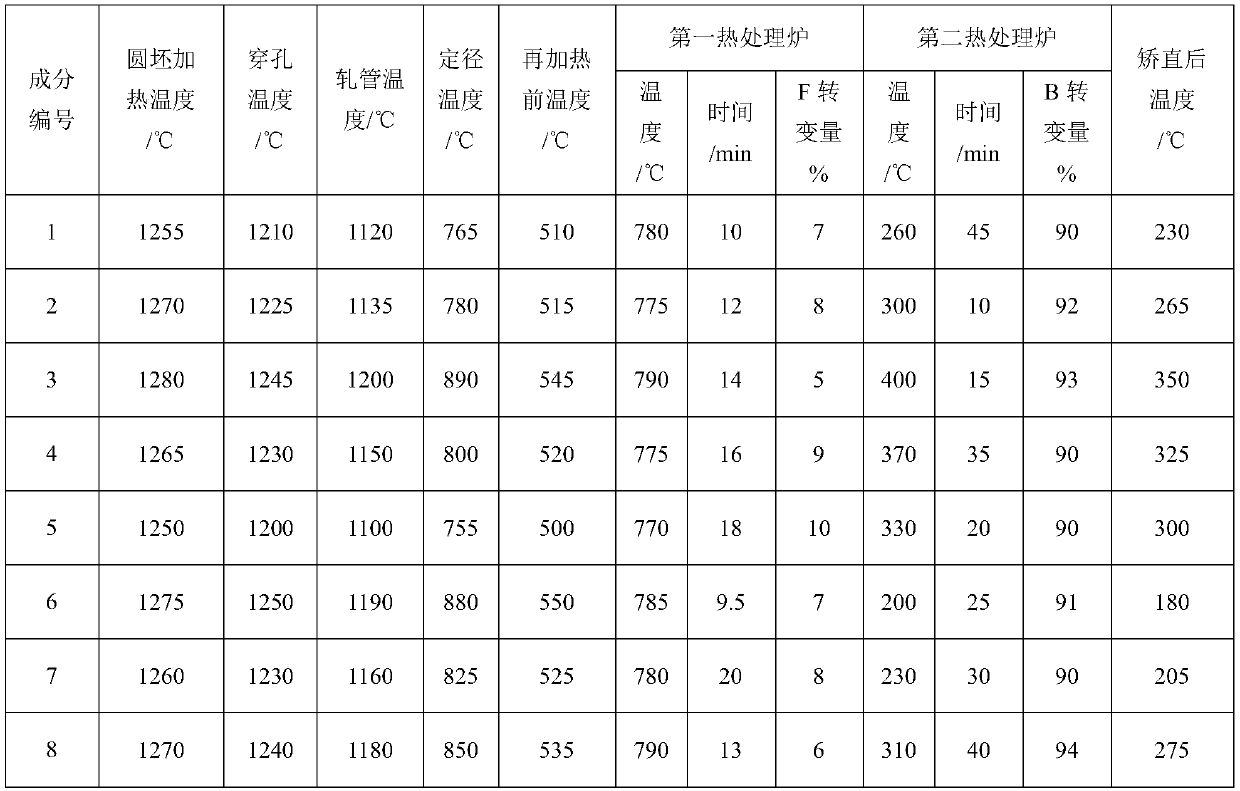

[0027] A low yield ratio seamless steel pipe according to the present invention, the chemical composition of the seamless steel pipe is calculated by mass percentage: C 0.30%-0.40%, Si 0.25%-0.5%, Mn 0.4%-0.7%, P ≤0.025%, S≤0.020%, Ti0.035%~0.055%, RE: 0.05%~0.18%, the balance is Fe and unavoidable impurities.

[0028] The seamless steel pipe has the following performance characteristics:

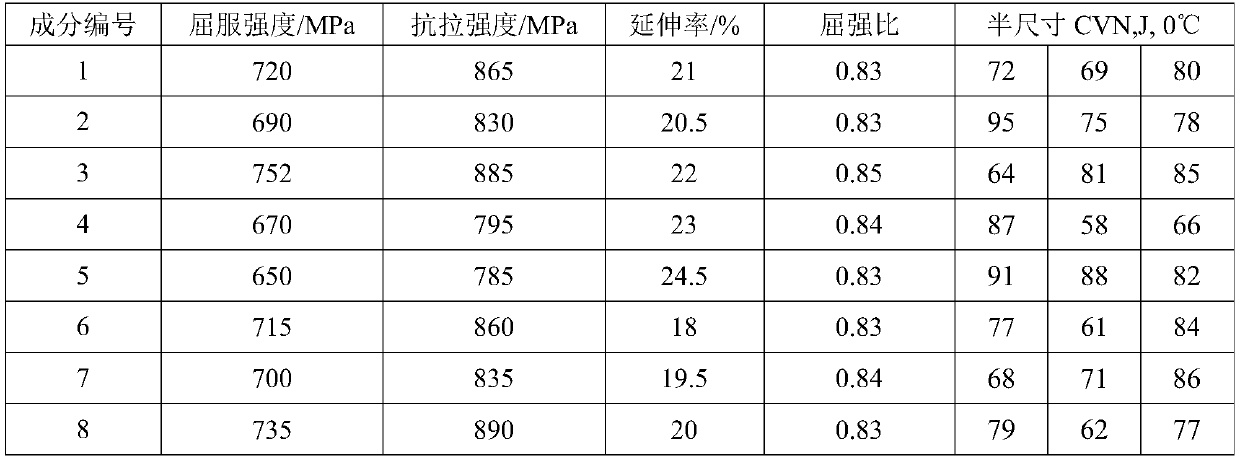

[0029] 1) The minimum yield strength Rt0.5 reaches above 650Mpa;

[0030] 2) The minimum tensile strength Rm is above 785MPa;

[0031] 3) The maximum yield ratio is not greater than 0.85;

[0032] 4) The minimum elongation A after fracture is not less than 18%;

[0033] 5) The minimum value of V-notch impact energy at 0°C is not less than 58J.

[0034] The structural characteristics of the seamless steel pipe are: the structure is B+F or B+F+M composite structure; wherein, B is bundled bainite, and F is massive, granular or bundled ferrite , M is martensite, and the proportion of B in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com