Construction method for cleaning mud blocks on blades of spiral drilling machine

An auger drilling machine and auger-cleaning technology are applied in drilling tools, drilling equipment, earthwork drilling and mining, etc. It can solve the problems of safe and civilized construction, increase the labor intensity of workers, and the cleaning speed can not keep up. It is easy to popularize and apply, and equipment Low composition cost and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

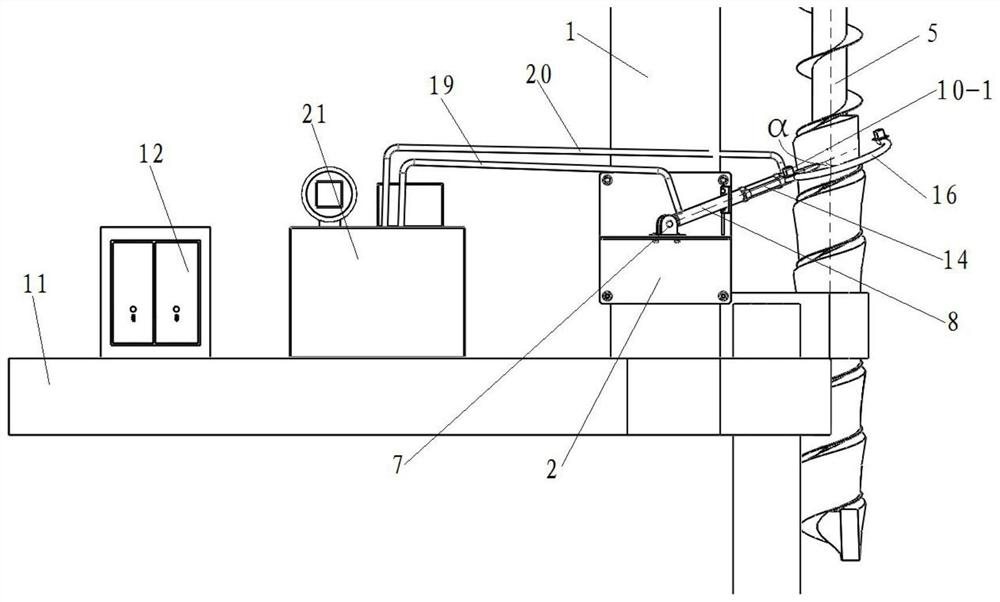

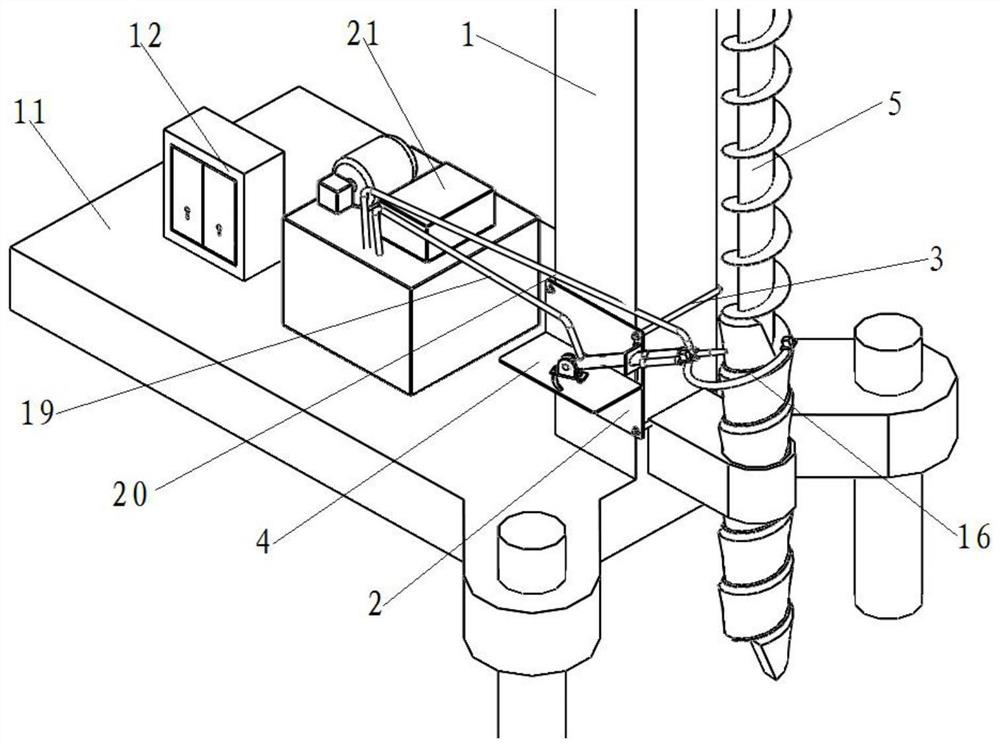

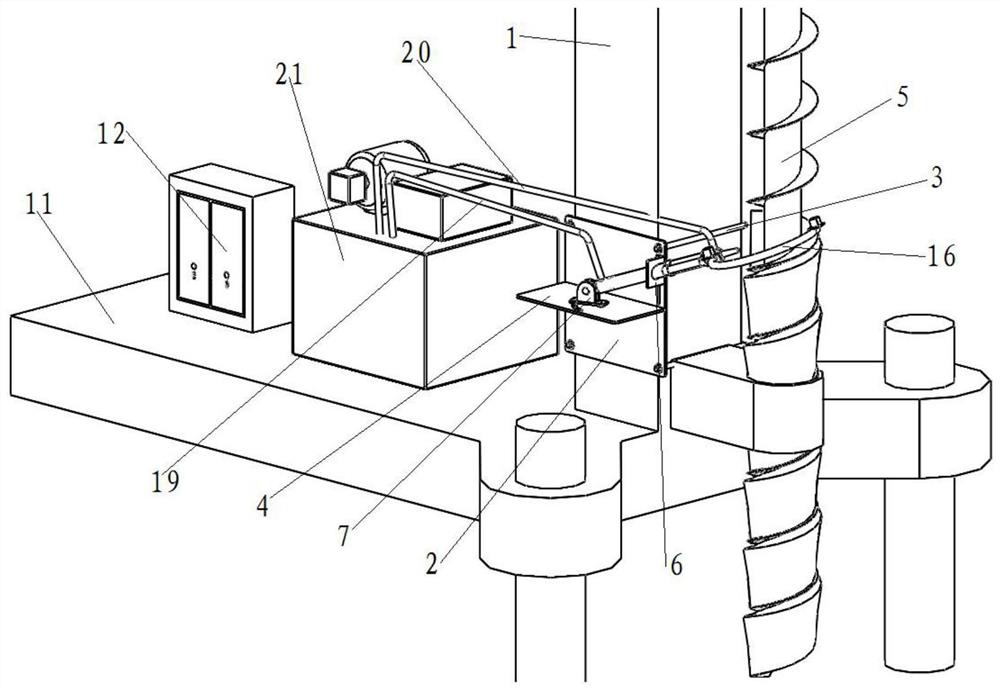

[0047] Such as Figure 1 to Figure 7 Shown is a construction method for cleaning mud on the blade of the auger drill, comprising the following steps:

[0048] Step 1. Install the auger drilling rig blade mud cleaning equipment, the process is as follows:

[0049] Step 101, install the fixed support: install the fixed support on the main rod 1 of the auger; wherein, the fixed support is a T-shaped support, and the fixed support includes vertically arranged on the main rod 1 The vertical fixed plate 2 and the horizontal fixed plate 4 horizontally arranged on the vertical fixed plate 2, the vertical fixed plate 2 and the horizontal fixed plate 4 are perpendicular, and the vertical fixed plate 2 is close to On the main pole 1, the vertical fixing plate 2 is vertically fixed on one side of the main pole 1 through a plurality of horizontally arranged snap rings 3, and the horizontal fixing plate 4 is horizontally fixed on the vertical The middle part of the fixed plate 2, the vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com