Repair construction method of hardened road surface and house roof crack

A construction method and crack technology, applied in the field of construction, can solve the problems of time-consuming and laborious maintenance costs, secondary damage to roadbed and road surface, and high repair costs, and achieve the effects of reducing energy consumption, saving maintenance costs, and low composition costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

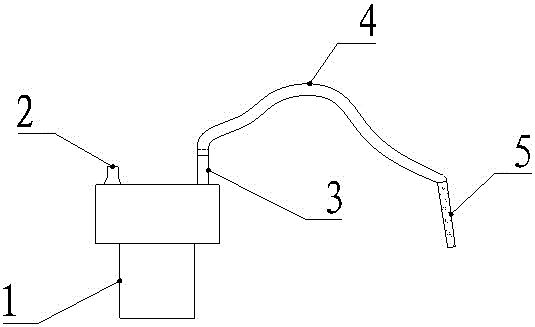

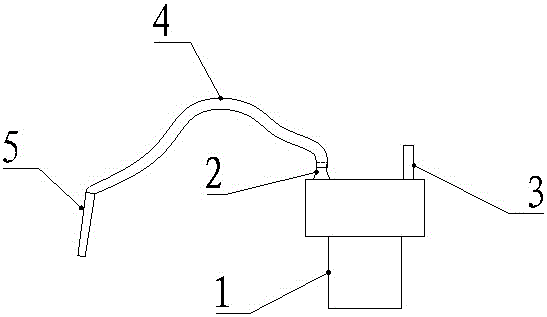

[0026] Such as figure 1 As shown in or 2, a repairing device for hardened road surfaces and roof cracks, it includes a vacuum pump 1, the air inlet 3 of the vacuum pump 1 is provided with an air guide tube 4 or the air outlet 2 is provided with an air guide tube 4, and the air guide tube 4 The end is provided with air guiding nozzle 5.

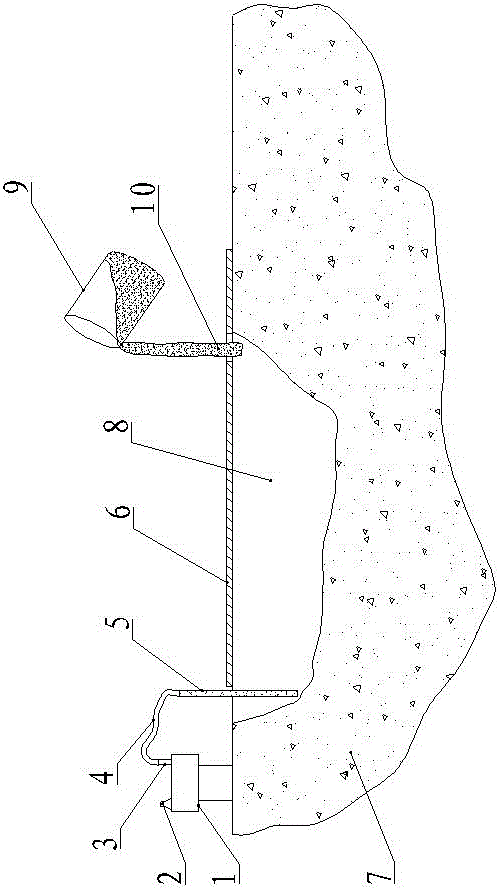

[0027] Such as image 3 Shown, the construction method of the repairing device of described hardened road surface and house roof crack, this construction method comprises the following steps:

[0028] Step 1: If figure 2 As shown, install the air guide tube 4 on the air outlet 2 of the vacuum pump 1, insert the air guide nozzle 5 at the end of the air guide tube 4 into the crack 8 to be cleaned, start the vacuum pump 1, and the compressed gas discharged by the vacuum pump 1 will blow the crack 8 clean up the dust;

[0029] Step 2: cover the sealing film 6 on the crack 8 cleaned in step 1, so that the sealing film 6 completely covers th...

Embodiment 2

[0033] Such as figure 1 As shown in or 2, a repairing device for hardened road surfaces and roof cracks, it includes a vacuum pump 1, the air inlet 3 of the vacuum pump 1 is provided with an air guide tube 4 or the air outlet 2 is provided with an air guide tube 4, and the air guide tube 4 The end is provided with air guiding nozzle 5.

[0034] The vacuum pump 1 is a vacuum pump.

[0035] The air guide nozzle 5 is conical or cylindrical or a combination of conical and cylindrical.

[0036] Such as image 3 Shown, the construction method of the repairing device of described hardened road surface and house roof crack, this construction method comprises the following steps:

[0037] Step 1: If figure 2 As shown, install the air guide tube 4 on the air outlet 2 of the vacuum pump 1, insert the air guide nozzle 5 at the end of the air guide tube 4 into the crack 8 to be cleaned, start the vacuum pump 1, and the compressed gas discharged by the vacuum pump 1 will blow the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com