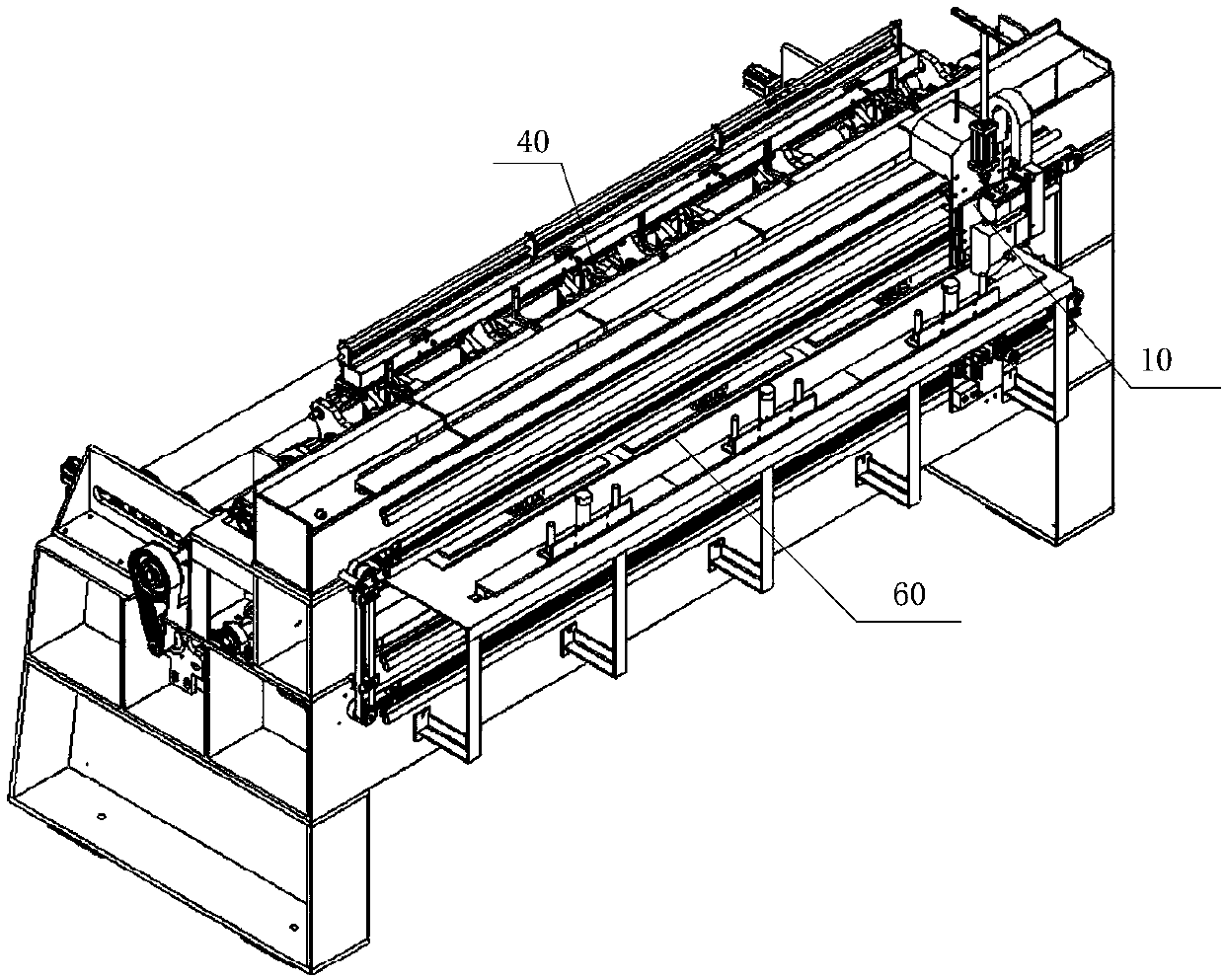

Spring mattress production equipment

A technology for production equipment and spring mattresses, applied in spring mattresses, mattresses, stuffed mattresses, etc., can solve the problems of high material costs, many manual operations, and many processes, and achieve the effects of improving environmental performance and simplifying production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

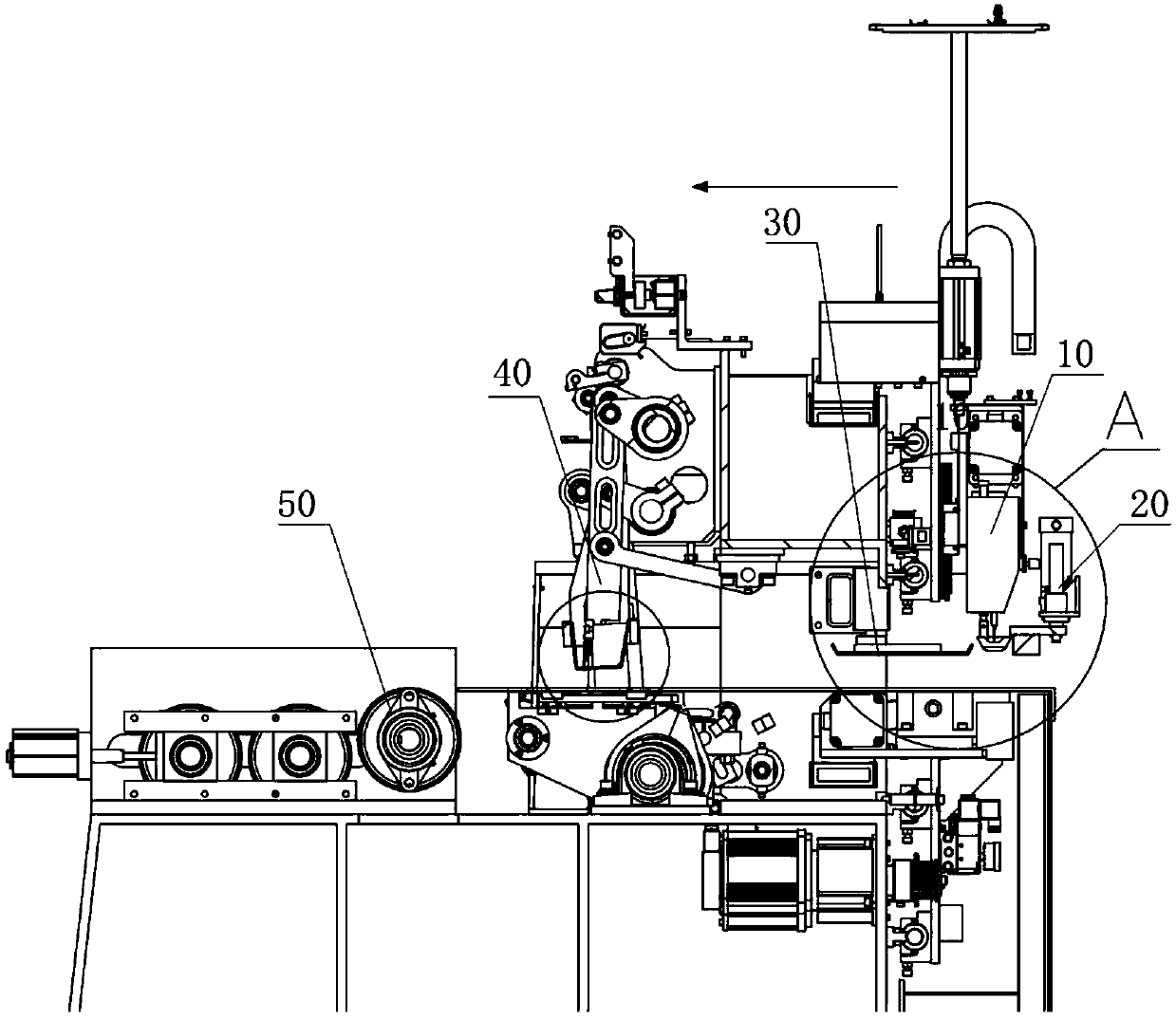

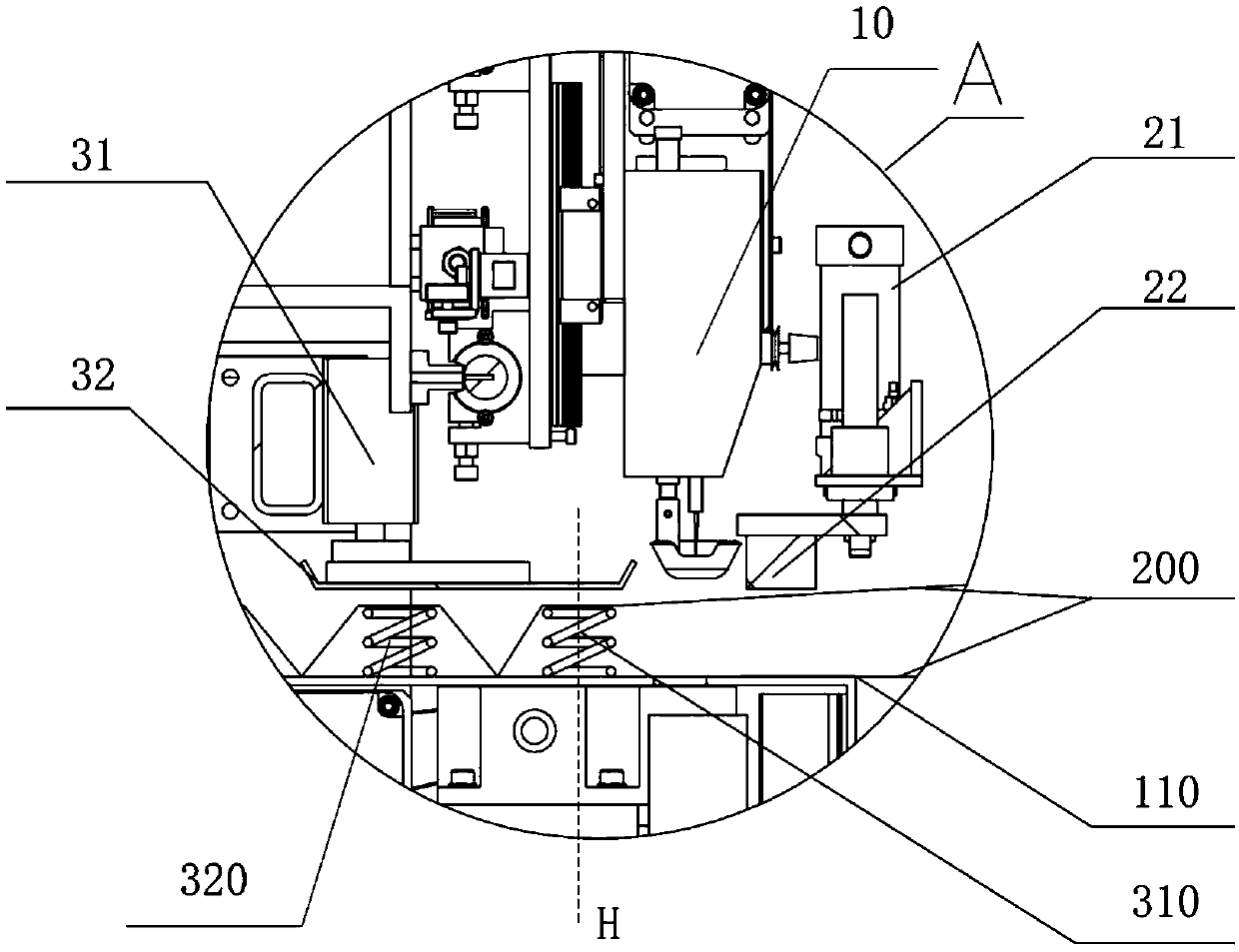

[0051] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0052] It should be noted that the "spring core" in the following description refers to a small piece of spring produced by spring production equipment such as a spring coiling machine. These small spring segments elastically support loads with a pre-set stiffness after being pre-compressed. These small springs are usually arranged in parallel to form various types of spring cushions, which are used in various end products, such as: mattresses, sofa cushions, chair cushions, chair backs, shoes, etc. Spring pads used in a specific end product can use spring cores of various specifications.

[0053] The spring pad production equipment according to one embodiment of the present invention includes: a material supply device, which is used to supply and tension the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap