Fabricated bicycle lane and sidewalk isolation railing

A technology for non-motor vehicle lanes and sidewalks, applied in the field of prefabricated non-motor vehicle lanes and sidewalk isolation railings, can solve the problems of single structure of isolation railings, poor base stability, high maintenance costs, etc. beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

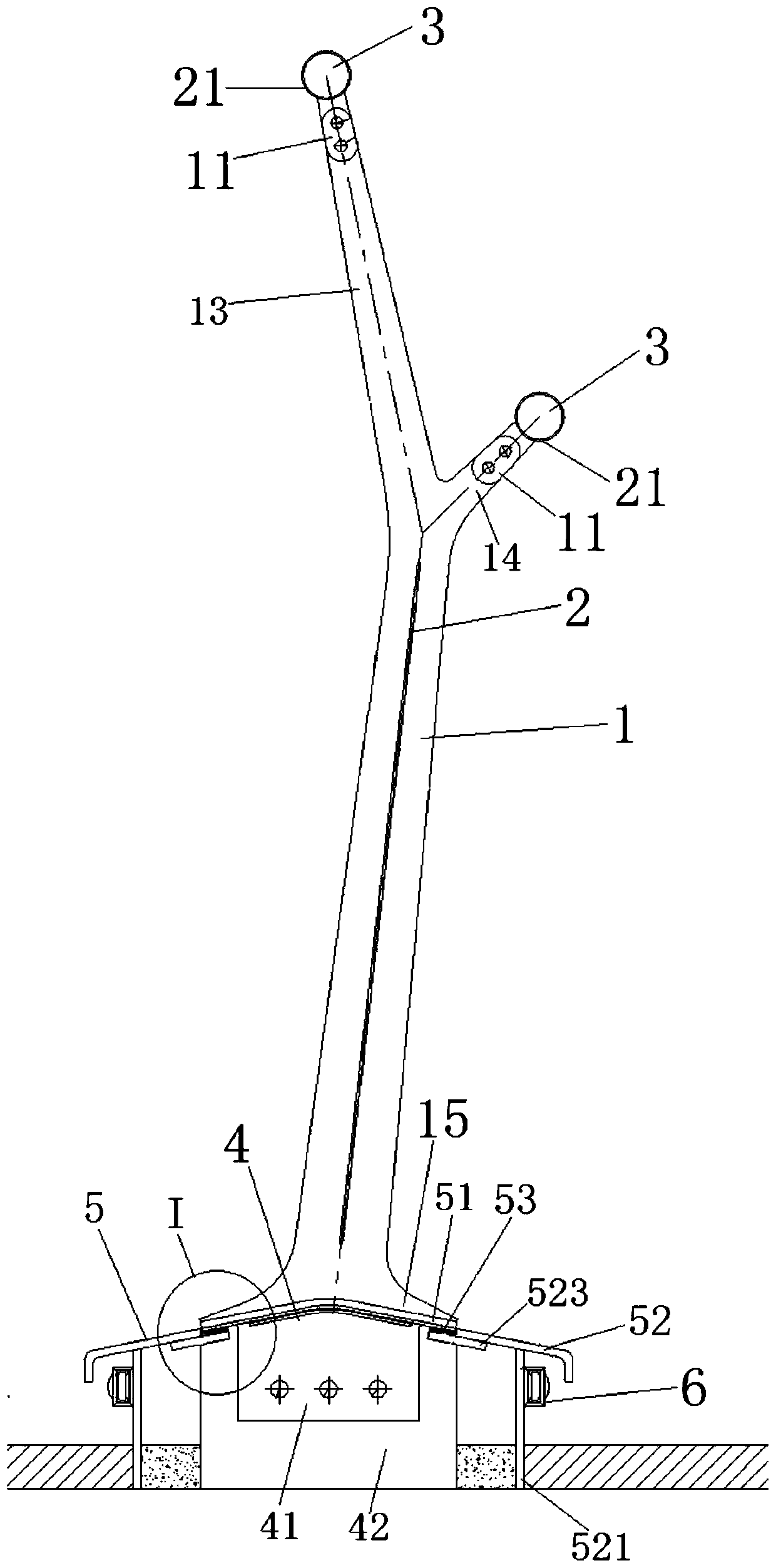

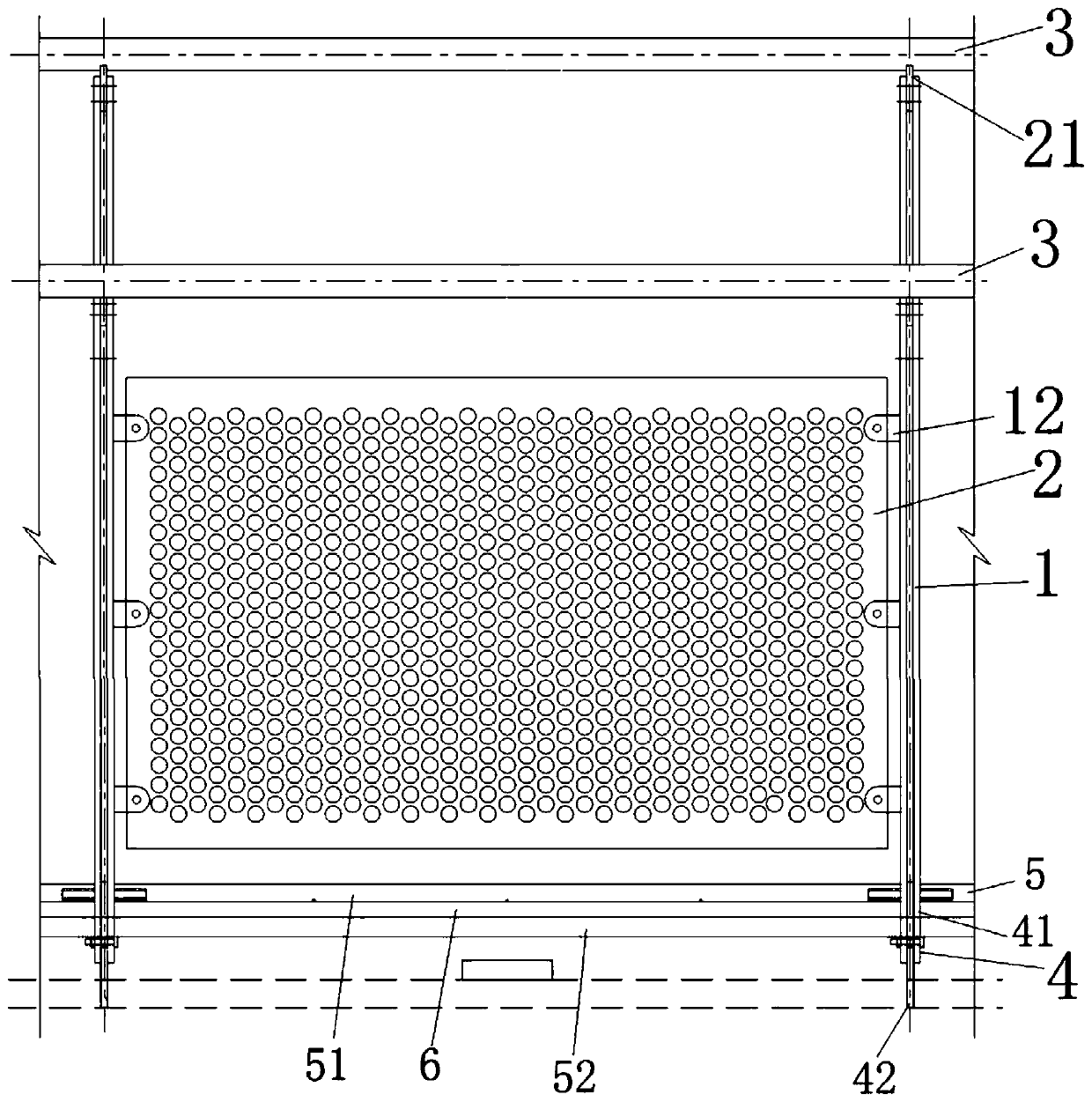

[0022] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

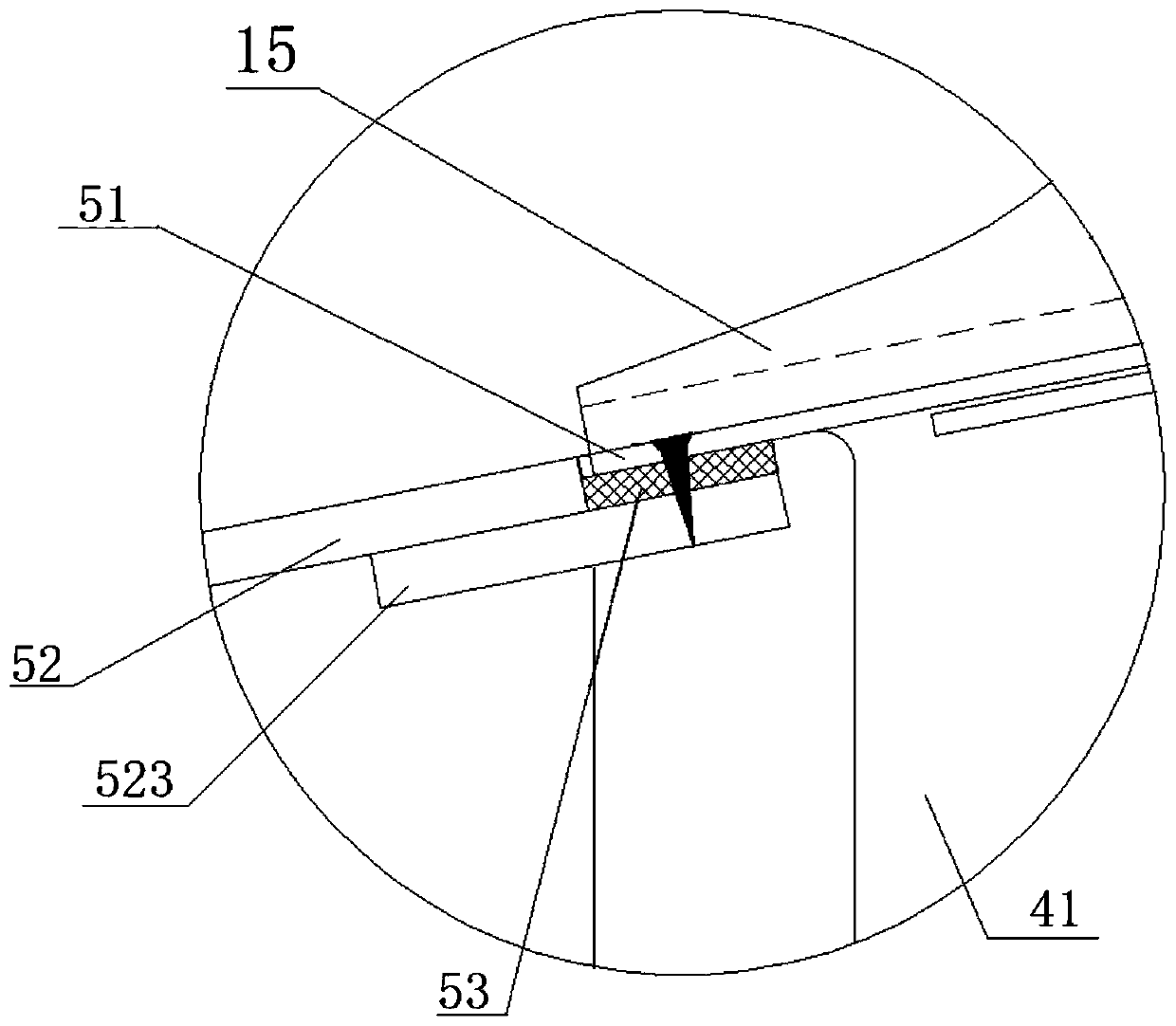

[0023] refer to figure 1 , 2 , an assembled non-motor vehicle lane and sidewalk isolation railing, the railing includes a plurality of special-shaped columns 1 parallel to each other and perforated aluminum plate railings 2 respectively arranged between two adjacent said special-shaped columns 1, the railing The upper end is provided with a stainless steel handrail 3, and the lower end is fixedly connected to the ground through a base 4, and a base protective shell 5 is provided outside the base 4.

[0024] The railings are arranged on both sides of the road surface, and the special-shaped column 1 is a double-layer metal plate clamping structure. The upper end of the plate surface is bifurcated, and the lower end of the plate surface gradually widens and extends symmetrically from the bottom to the front and rear directions to form claw-li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com