Prefabricated foundation ring beam prefabrication method and construction method of storage tank using prefabricated foundation ring beam

A foundation construction and foundation ring technology, applied in infrastructure engineering, construction, etc., can solve problems such as difficulty in quality control, discontinuous operation process, and heavy workload, so as to facilitate quality control, save costs, and save resource effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following is attached figure 1 - attached Figure 6 And embodiment technical scheme of the present invention is described in detail:

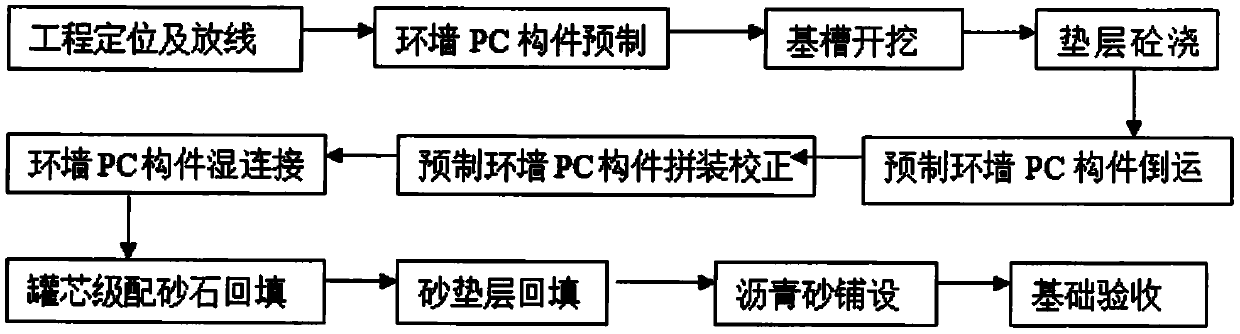

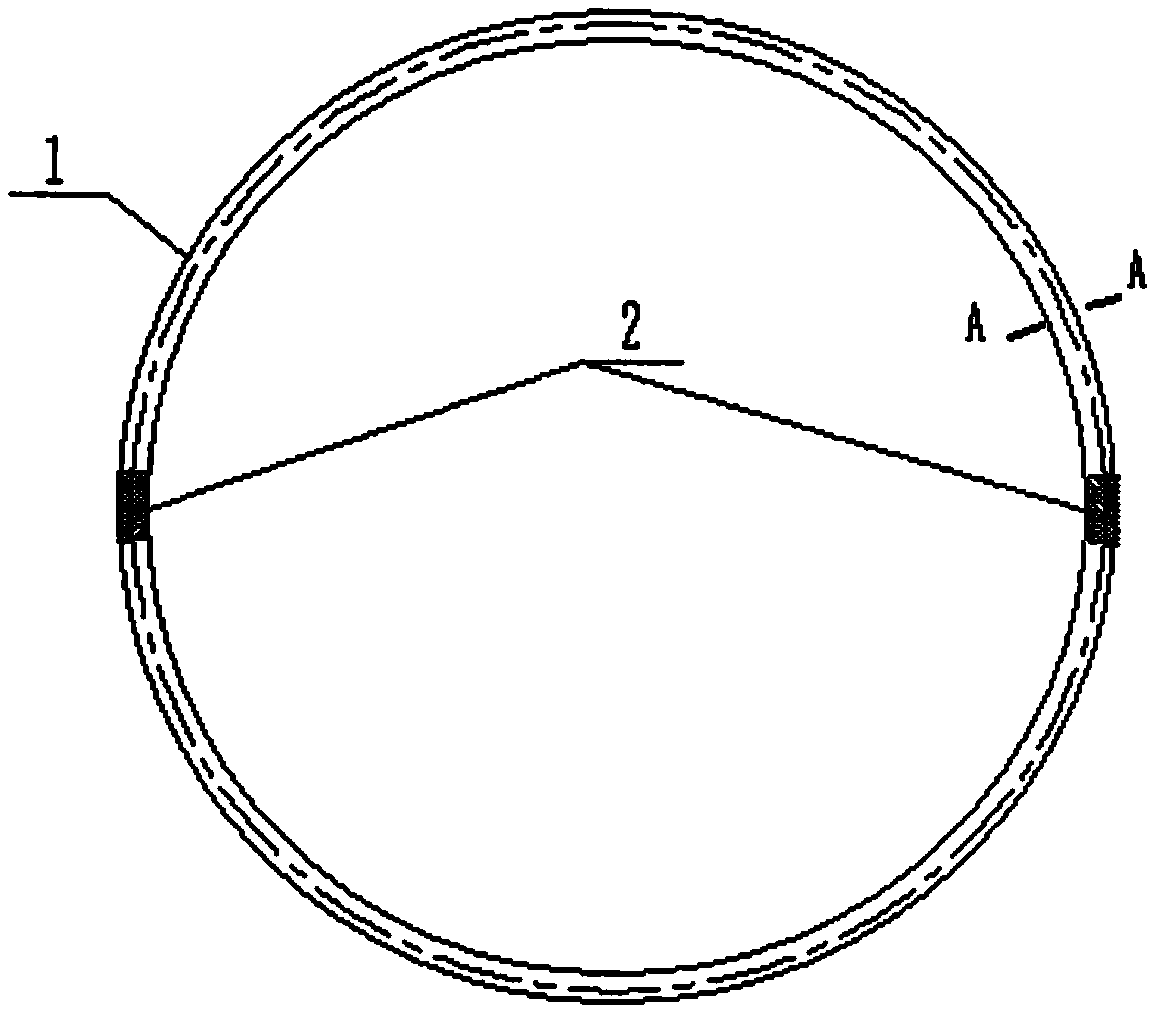

[0028] Such as image 3 As shown, the foundation ring beam part of the tank body is formed by connecting the foundation ring wall 1 and the ring wall 2 at the post-casting zone. In the embodiment of the present invention, the foundation ring wall 1 and the ring wall 2 at the post-casting zone are divided into several arcs Shaped ring wall prefabricated components, the ring wall prefabricated components are prefabricated in advance, and then the prefabricated ring wall prefabricated components are transported to the site, and the prefabricated ring wall components are wet-connected by post-casting belts, and the prefabricated ring wall The prefabrication method of prefabricated components is described in detail as follows:

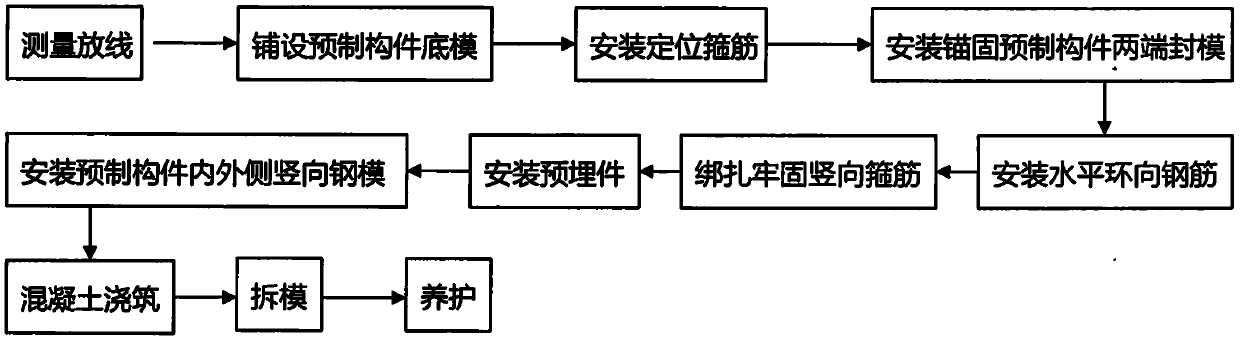

[0029] Before prefabricating the ring beam components, it is necessary to carry out the standardized design ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com