Construction method of light steel roof for assembly building

A construction method and technology of light steel, applied in the direction of building structure, building, building components, etc., can solve the problems affecting the overall structural stability of light steel roof, the distance between steel beams and slabs cannot be accurately controlled, and the processing of roof panels is unfavorable. Achieve the effect of good installation effect, prevent safety problems, and not easy to shift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

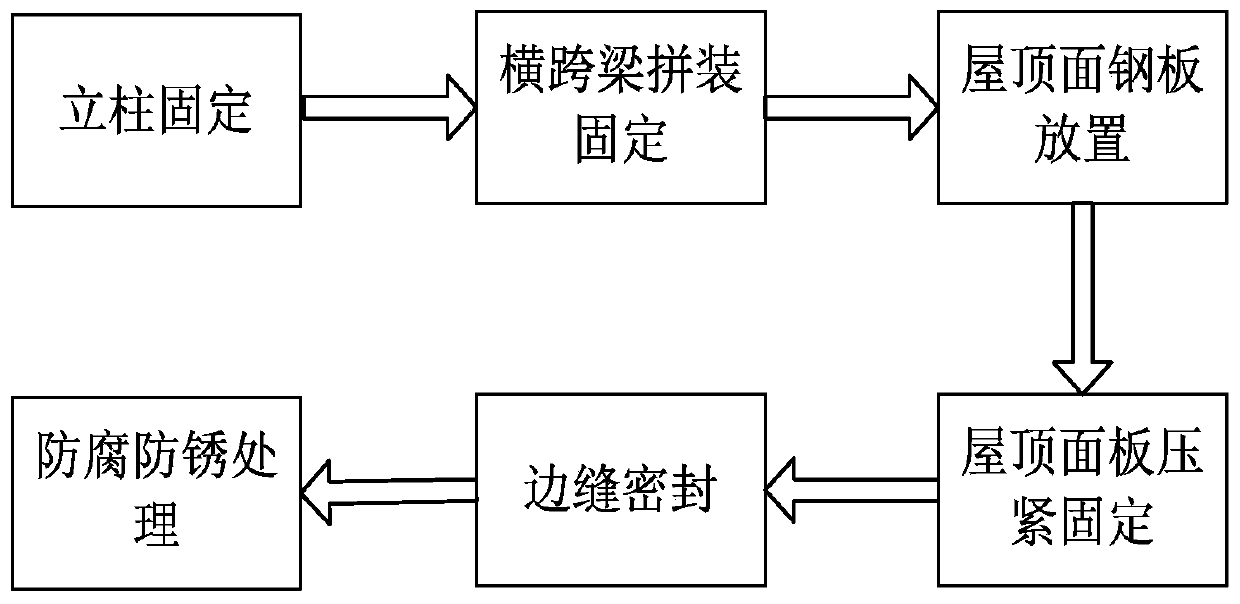

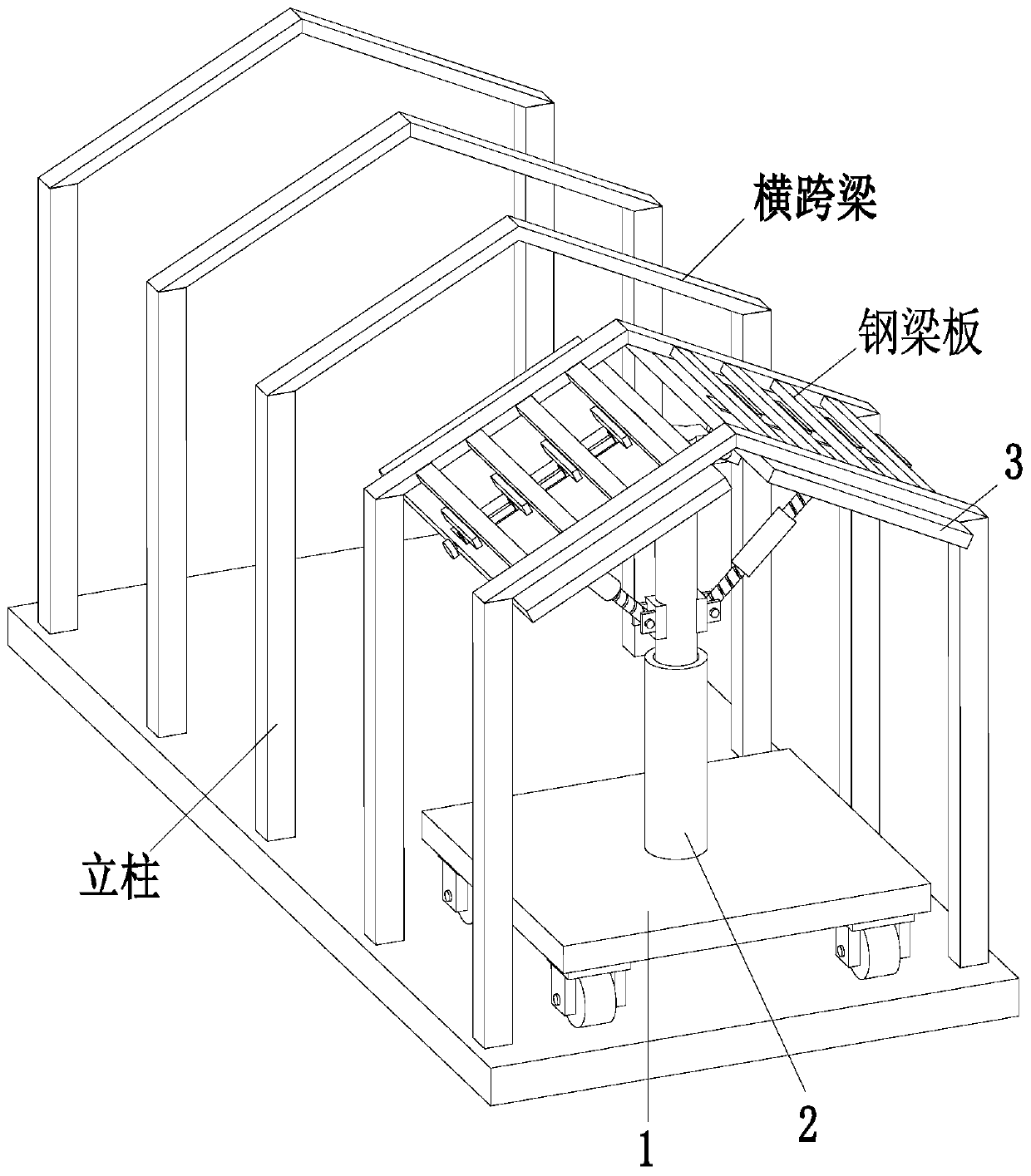

[0034] like Figure 1 to Figure 5 As shown, a light steel roof construction method for an assembled building comprises the following steps:

[0035] S1. Column fixing: Fix the column evenly on the concrete floor with screws, and the interval between adjacent columns is the same;

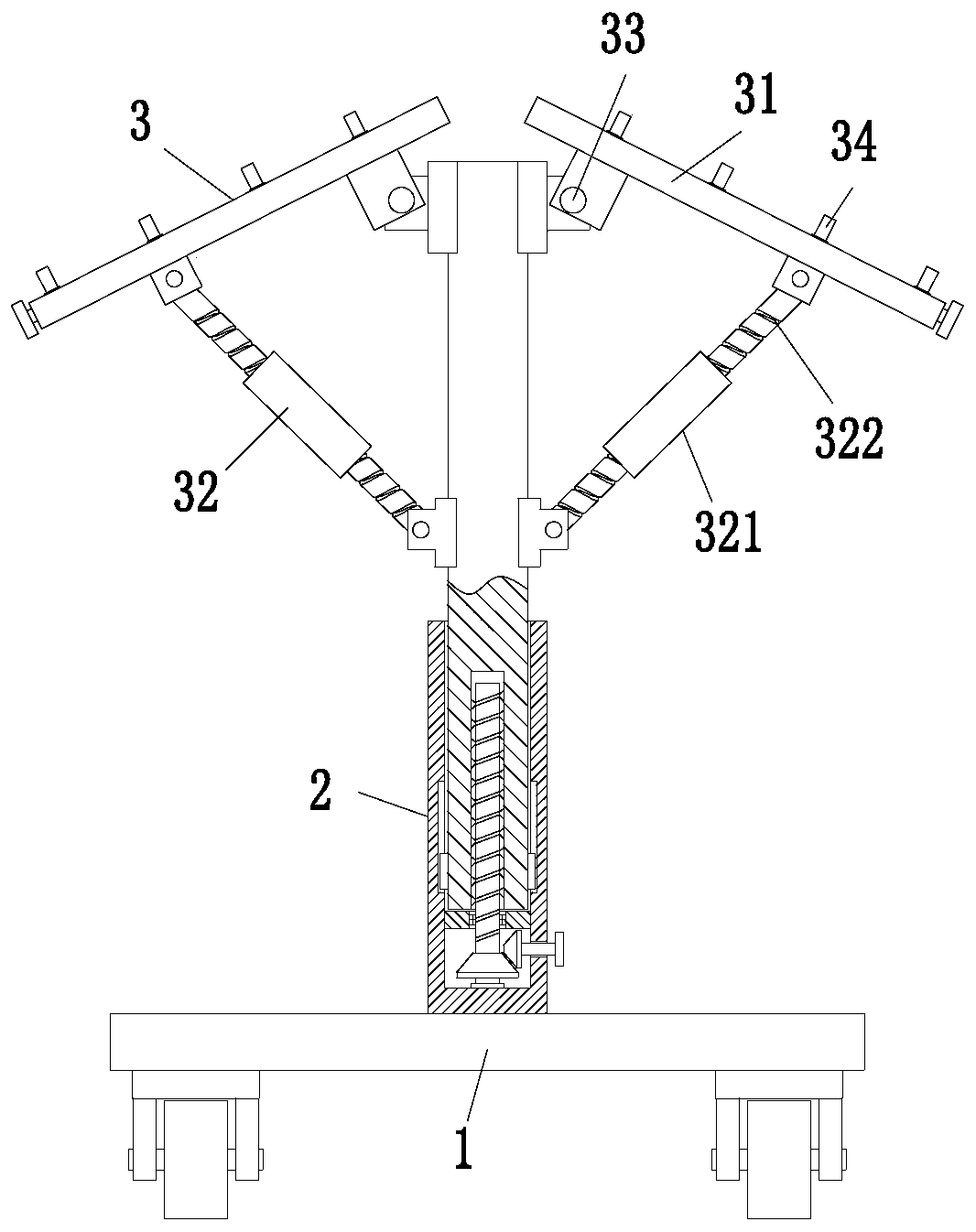

[0036] S2. Assembling and fixing the cross-span beam: manually adjust the angle of the jacking device 3, place the cross-span beam on the upper end of the jack-up device 3, and install the cross-span beam between the two opposite columns by means of welding and fixing;

[0037] S3. Place the steel plate on the roof surface: evenly place the steel beam plate on the upper end of the jacking device 3, and the steel beam plate and the cross beam are perpendicular to each othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com