Single-circulation ball nut body capable of being spliced

A nut body, single-cycle technology, applied in belts/chains/gears, mechanical equipment, transmissions, etc., can solve the problem of difficulty in changing the length of the nut, and achieve the effects of low processing difficulty, reduced processing costs, and internal space savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

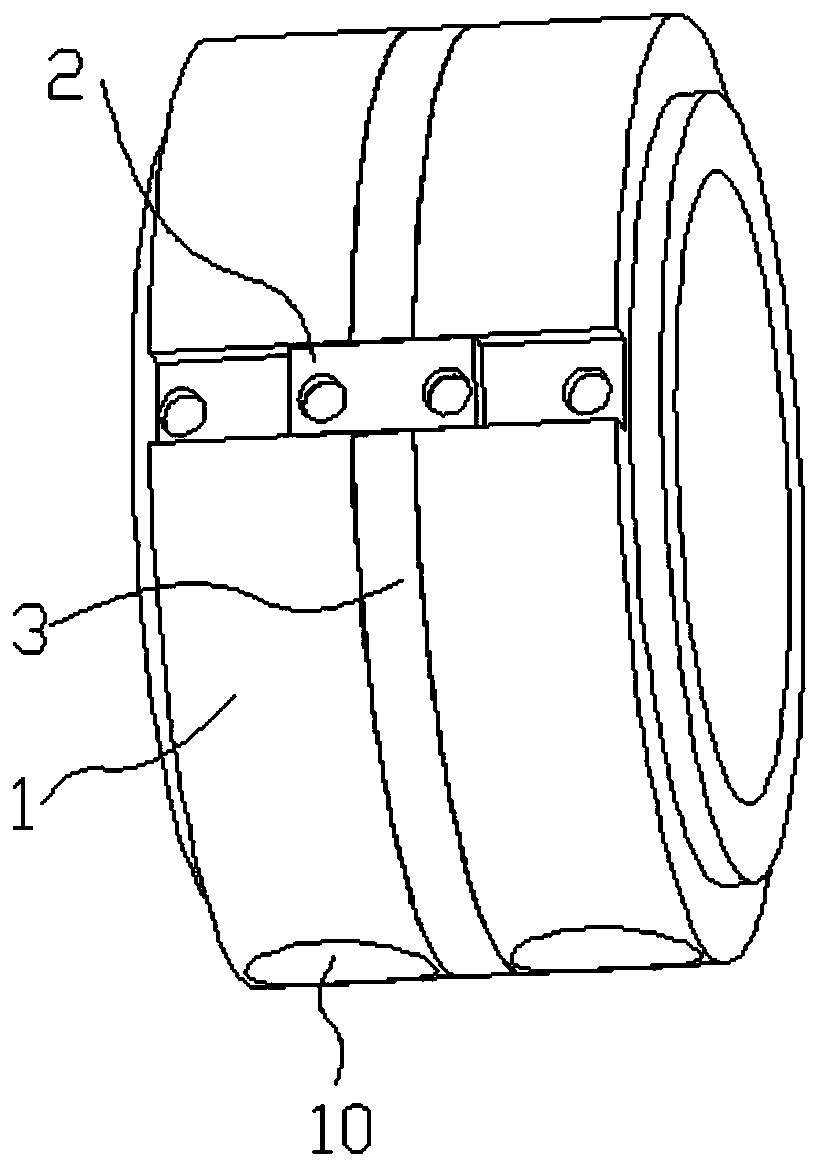

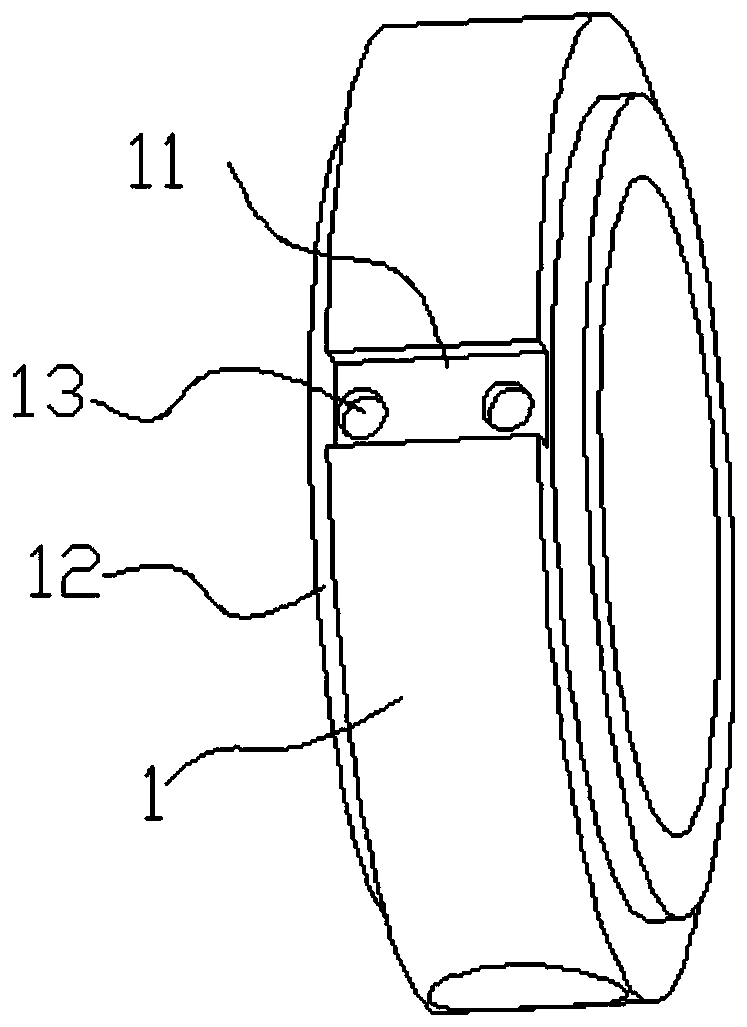

[0016] Such as Figure 1 to Figure 3 , The present invention is a splicable single circulation ball nut body, including a nut body 1, a connecting block 2 and a washer 3, and a reverser installation hole 10 is provided in the radial direction of the circumferential wall of the nut body 1.

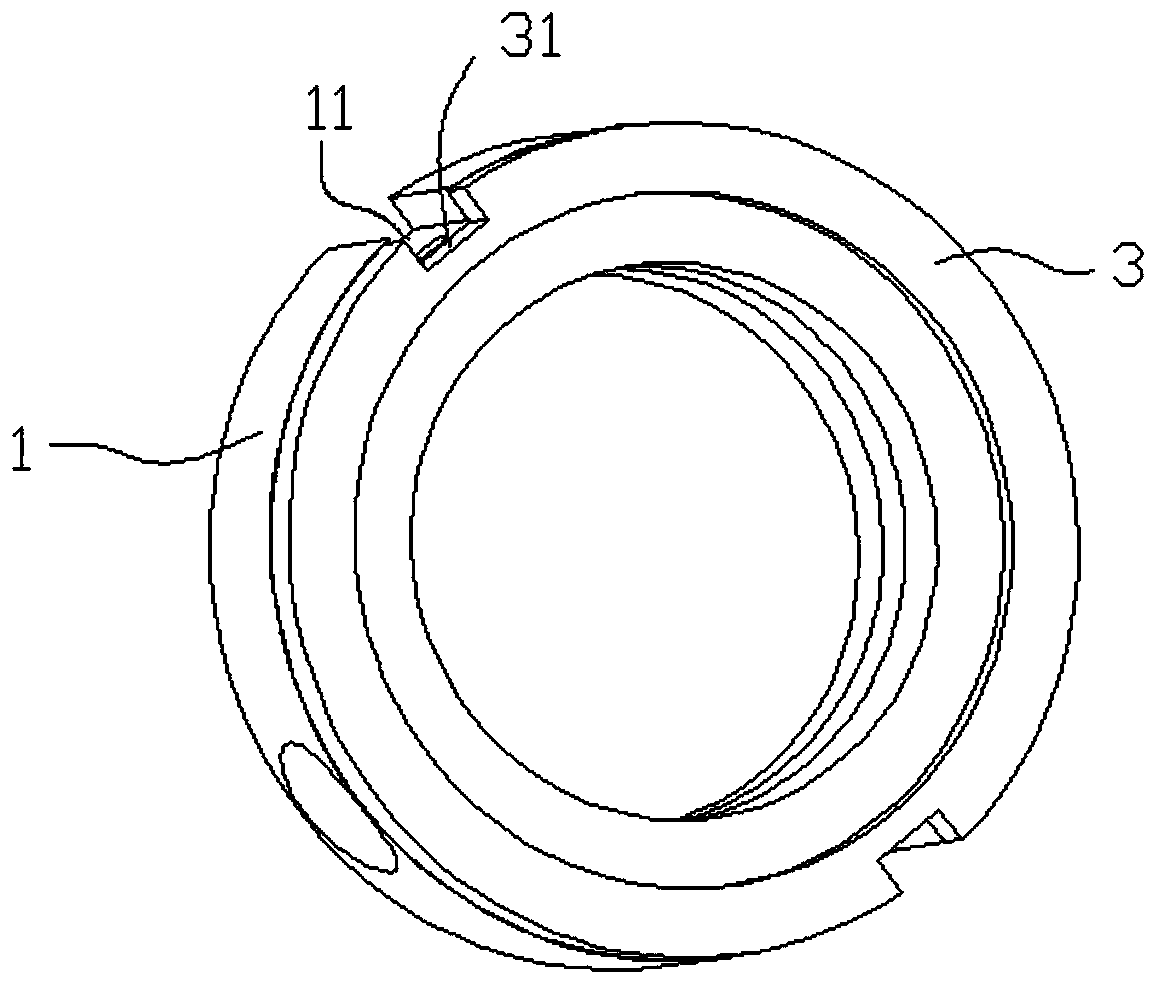

[0017] At least two first installation grooves 11 are provided on the outer peripheral wall of the nut body 1, and the first installation grooves 11 are arranged along the axial direction of the nut body 1, and at least two first installation grooves 11 are arranged on the outer peripheral wall of the washer 3. Two mounting slots 31. Several nut bodies 1 are arranged side by side and coaxially, a washer 3 is arranged between two adjacent nut bodies 1, the first installation groove 11 and the second installation groove 31 are connected, and the connecting block 2 is placed in the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com