A hot spot stress estimation method for offshore floating platform based on response surface model

A technology of response surface model and hot spot stress, which is applied in the field of shipbuilding and ocean engineering, can solve the problems of few influencing factors, strict requirements on the location of measuring points, and no consideration of wave load characteristics, etc., so as to make up for the gaps in existing technologies and evaluate safety , The effect of small hot spot stress error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention, and provides a detailed implementation manner and a specific operation process, but the protection scope of the present invention is not limited to the following embodiments.

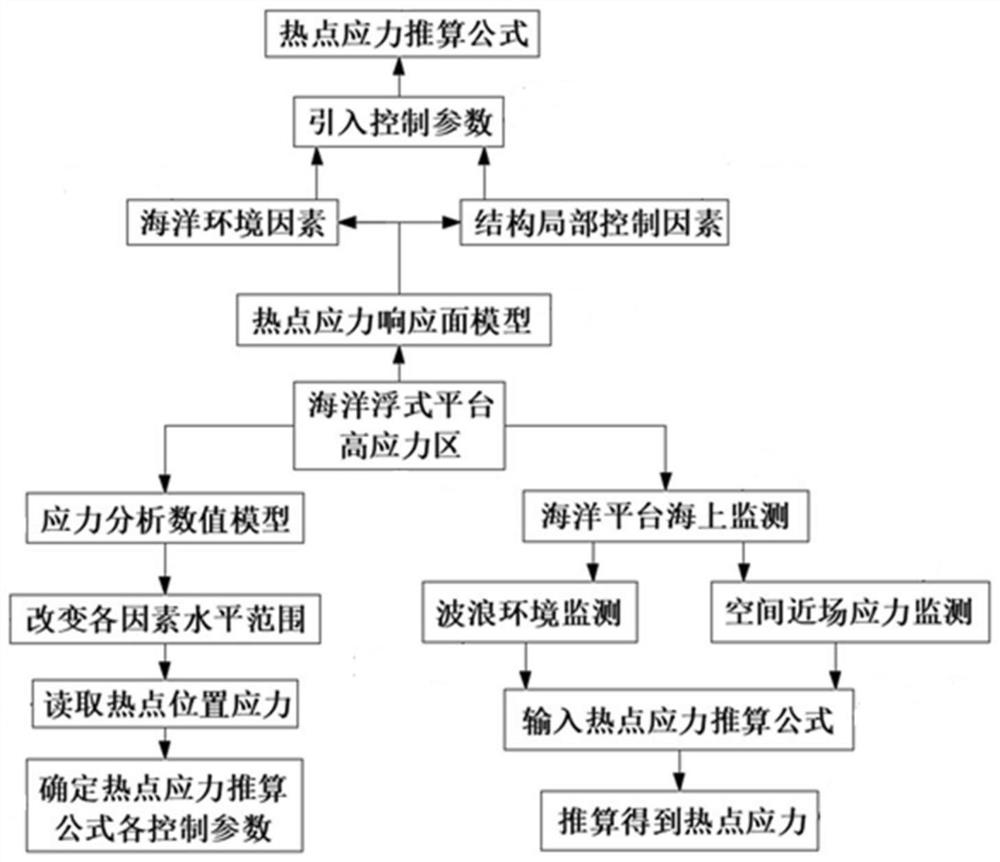

[0031] like figure 1 As shown, a method for calculating the hot spot stress of an ocean floating platform based on a response surface model includes:

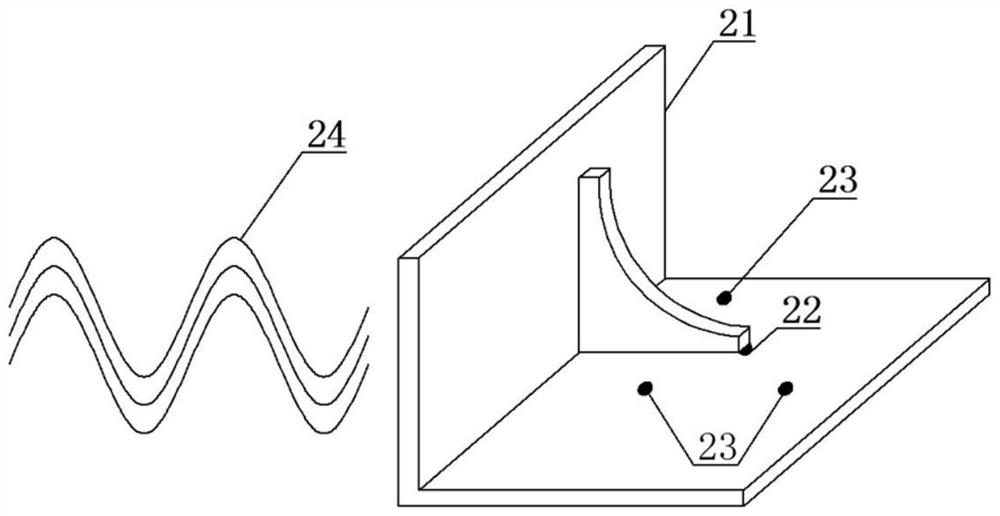

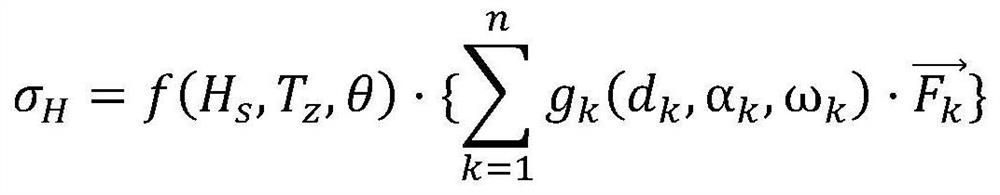

[0032] Step S1: take the high stress area of the target marine floating platform as the research object, first establish the hot spot stress response surface model of the complex structure position of the platform, and take the marine environmental factors and local structural control factors as the main influencing factors;

[0033] Among them, the marine environmental factors include the significant wave height H under eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com