Preparation method of tandem solar cell capable of reducing cost and improving conversion efficiency

A stacked solar and stacked battery technology, applied in sustainable manufacturing/processing, circuits, photovoltaic power generation, etc., can solve the problems of limited scope of application, high production costs, and unsuitability for large-scale promotion and use, and achieve parity Going online, improving conversion efficiency, and benefiting large-scale industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

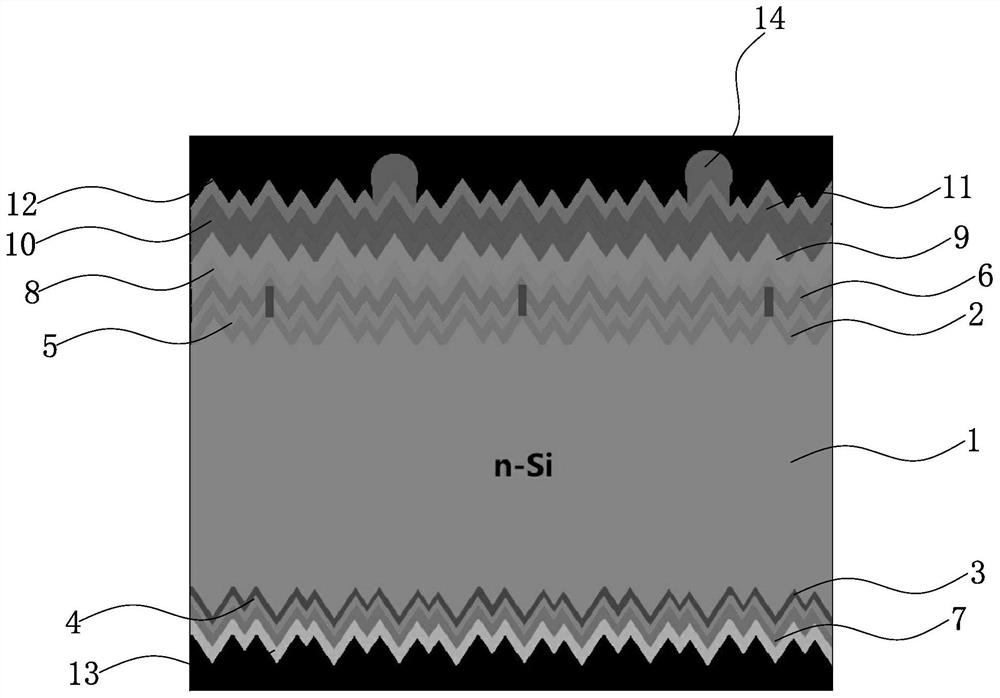

[0038] This embodiment provides a method for preparing a tandem solar cell that can reduce costs and improve conversion efficiency,

[0039] Such as figure 1 shown, including the following steps:

[0040] Step 1: Bottom battery preparation, texturing, using N-type monocrystalline silicon wafers as silicon substrates, placing them in texturing liquid for texturing treatment, wherein, the texturing solution can be according to the mass ratio KOH: texturing additive: H 2 The ratio of O=20:3:160 is prepared, the temperature of the texturing solution is 80°C, and then it is cleaned in hydrofluoric acid with a volume concentration of 2%, and the surface of the silicon wafer is cleaned to obtain a polysilicon layer 1. The texturing additive here It refers to the addition of chemical additives that are beneficial to the reaction results and product performance during the texturing process of monocrystalline silicon solar cells. It is generally composed of water, IPA, NaOH, weak acid ...

Embodiment 2

[0055] This embodiment provides a method for preparing a low-cost high-efficiency tandem solar cell, comprising the following steps:

[0056] Step 1: Bottom battery preparation, texturing, using N-type monocrystalline silicon wafers as silicon substrates, placing them in the texturing solution for texturing treatment, wherein the texturing solution is based on the mass ratio KOH: Texturing additive: H 2 The ratio of O=20:3:160 is prepared, the temperature of the texturing solution is 80°C, and then it is cleaned in hydrofluoric acid with a volume concentration of 4%, and the surface of the silicon wafer is cleaned to obtain a polysilicon layer 1;

[0057] Step 2: Form a pn junction. Print a layer of boron paste on one side of the polysilicon layer 1 by printing, inkjet or spin coating. The thickness of the boron paste is 10 μm, and then dry at a temperature of 300° C. The temperature is generally not as high as 600), and the pn junction layer 2 is obtained;

[0058] Step 3: T...

Embodiment 3

[0070] This embodiment provides a method for preparing a low-cost high-efficiency tandem solar cell, comprising the following steps:

[0071] Step 1: Bottom battery preparation, texturing, using N-type monocrystalline silicon wafers as silicon substrates, placing them in the texturing solution for texturing treatment, wherein the texturing solution is based on the mass ratio KOH: Texturing additive: H 2 The ratio of O=20:3:160 is prepared, the temperature of the texturing solution is 80° C., and then it is cleaned in hydrofluoric acid with a volume concentration of 5%, and the surface of the silicon wafer is cleaned to obtain a polysilicon layer 1;

[0072] Step 2: Form a pn junction. Print a layer of boron paste on one side of the polysilicon layer 1 by printing, inkjet or spin coating. The thickness of the boron paste is 20 μm, and then dry it at 200°C to obtain a pn junction. junction2;

[0073] Step 3: Tunneling silicon oxide deposition, using hot oxygen equipment, deposi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com