Battery roll core and energy storage device

A battery roll and battery technology, which is applied in the field of energy storage, can solve problems such as damage, short circuit of positive and negative diaphragms, misalignment of positive and negative diaphragms, etc., and achieve the effect of reducing safety hazards and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment provides a lithium-ion battery, and the lithium-ion battery includes a casing and a battery winding core built in the casing. Lithium-ion battery electrolyte is also injected into the casing.

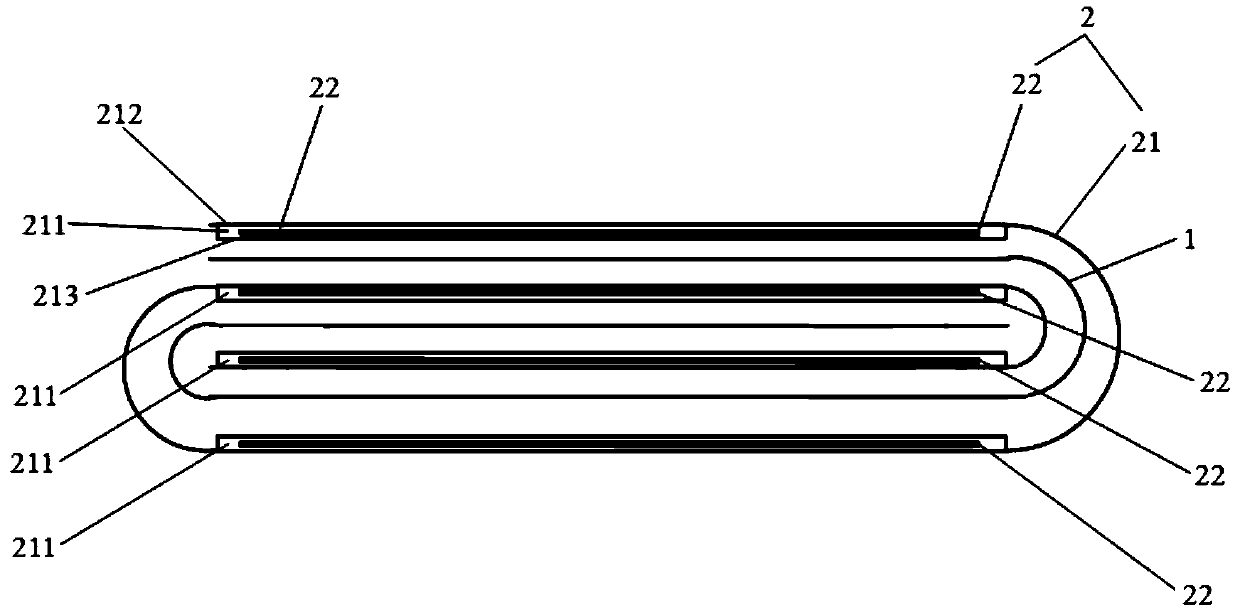

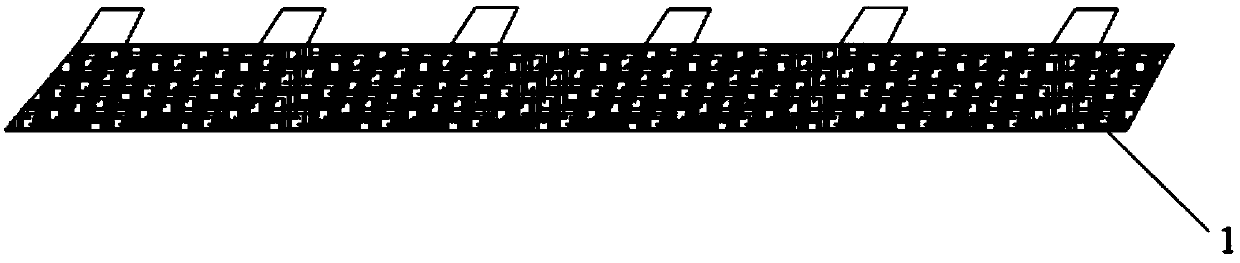

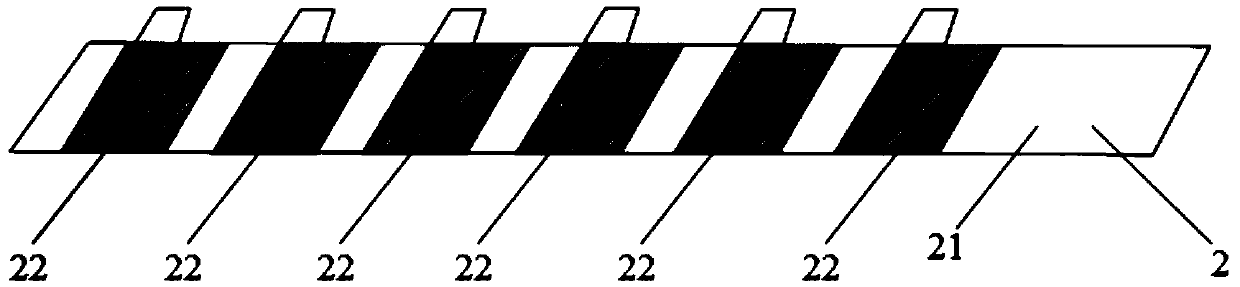

[0025] The battery core consists of a strip-shaped first pole piece 1 (see figure 2 ) and strip-shaped composite sheet 2 (see image 3 ) formed by winding, the combined sheet 2 includes a strip-shaped strip 21 and a plurality of second pole pieces 22 whose polarities are opposite to those of the first pole piece 1, the strip The body 21 has a plurality of independent and equally spaced packaging spaces 211, and a plurality of the second pole pieces 22 are packaged in a plurality of the packaging spaces 211 in one-to-one correspondence (see figure 1 ). Specifically, the strip body 21 includes a strip-shaped first diaphragm 212 and a plurality of spaced linear second diaphragms 213 that are stacked and fixed on the first diaphragm 212, and the number of the seco...

Embodiment 2

[0031] This embodiment provides a supercapacitor, and the supercapacitor includes a casing and a battery winding core built in the casing. The casing is also injected with supercapacitor electrolyte.

[0032] The structure of the battery core can refer to the structure of the battery core in Embodiment 1, that is, refer to Figure 1-Figure 3, which is formed by winding a laminate composed of a strip-shaped first pole piece 1 and a strip-shaped composite sheet 2, and the composite sheet 2 includes a strip-shaped strip body 21 and a plurality of polarities connected with the The second pole piece 22 with the opposite polarity of the first pole piece 1, the strip body 21 has a plurality of independent and equally spaced packaging spaces 211, and a plurality of the second pole pieces 22 are packaged in multiple one-to-one correspondence. the encapsulation space 211. Specifically, the strip body 21 includes a strip-shaped first diaphragm 212 and a plurality of spaced linear secon...

Embodiment 3

[0037] This embodiment provides a lithium-ion hybrid capacitor, which includes a case and a battery winding core built in the case. The casing is also injected with lithium-ion hybrid capacitor electrolyte.

[0038] The structure of the battery core can refer to the structure of the battery core in Embodiment 1, that is, refer to Figure 1-Figure 3 , which is formed by winding a laminate composed of a strip-shaped first pole piece 1 and a strip-shaped composite sheet 2, and the composite sheet 2 includes a strip-shaped strip body 21 and a plurality of polarities connected with the The second pole piece 22 with the opposite polarity of the first pole piece 1, the strip body 21 has a plurality of independent and equally spaced packaging spaces 211, and a plurality of the second pole pieces 22 are packaged in multiple one-to-one correspondence. the encapsulation space 211. Specifically, the strip body 21 includes a strip-shaped first diaphragm 212 and a plurality of spaced line...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com