Reference denturealignment jig, kit for preparing dentures, and method for preparing dentures using same

A technology of alignment fixture and production method, applied in fasteners, medical science, dentistry, etc., can solve problems such as difficulty in maintaining standard dentures, inability to bite hard objects, and pain in jaw joints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

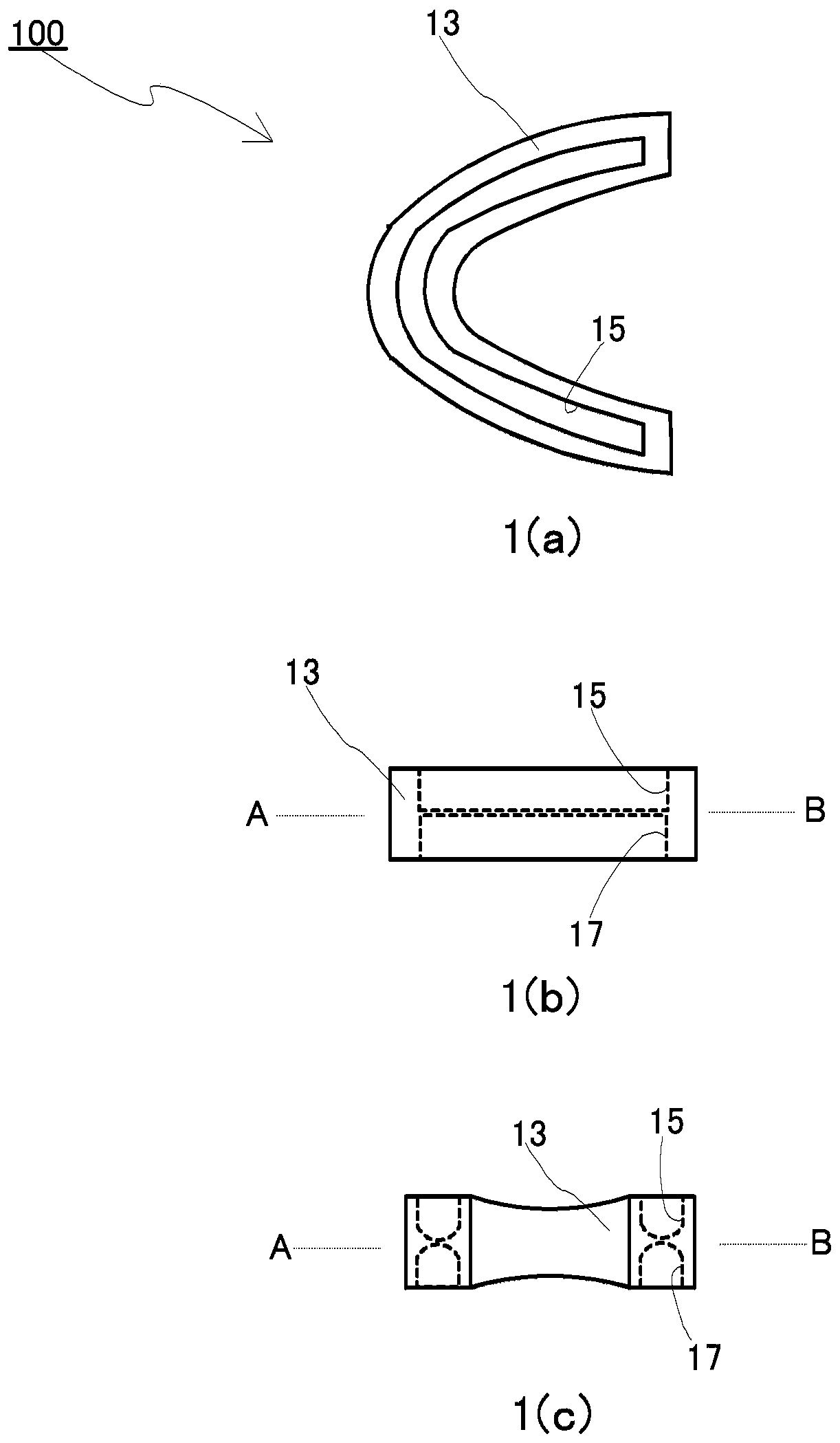

Image

Examples

reference example 1

[0135] The upper and lower edentulous jaw models were mounted on the mannequin (NISSIM type II, Nissim Co., Ltd.), and the upper and lower complete dentures were fabricated at the following set positions according to the general method.

[0136] (setting position of denture)

[0137] (1) Left and right incisors: Make the center of the edentulous jaw model coincide with the contact points of the left and right central incisors of the total denture (also for the upper and lower jaws).

[0138] (2) Left and right molars: Make the center of the edentulous jaw model coincide with the midpoint of the line connecting the central fossa of the left and right first molars of the total denture (also for the upper and lower jaws).

[0139] (3) Upper and lower incisors: In the incisors of the maxillary total denture, the distance from the base edge to the incisal edge of the central incisor was 22 mm (measured with a caliper).

[0140] (4) Up and down incisors: In the incisors of the mand...

Embodiment 1

[0146] Total dentures were produced for 10 subjects using upper and lower reference dentures, hard interior materials (product name: Tokuyama Lining Material III) and alignment jigs. The position of the obtained total dentures (mentioned above Parameters). Each parameter is compared with the total denture made in Reference Example 1, and ○× (good or bad) is judged according to the following criteria. In each parameter, the number of people with ○ (good) is shown in Table 1.

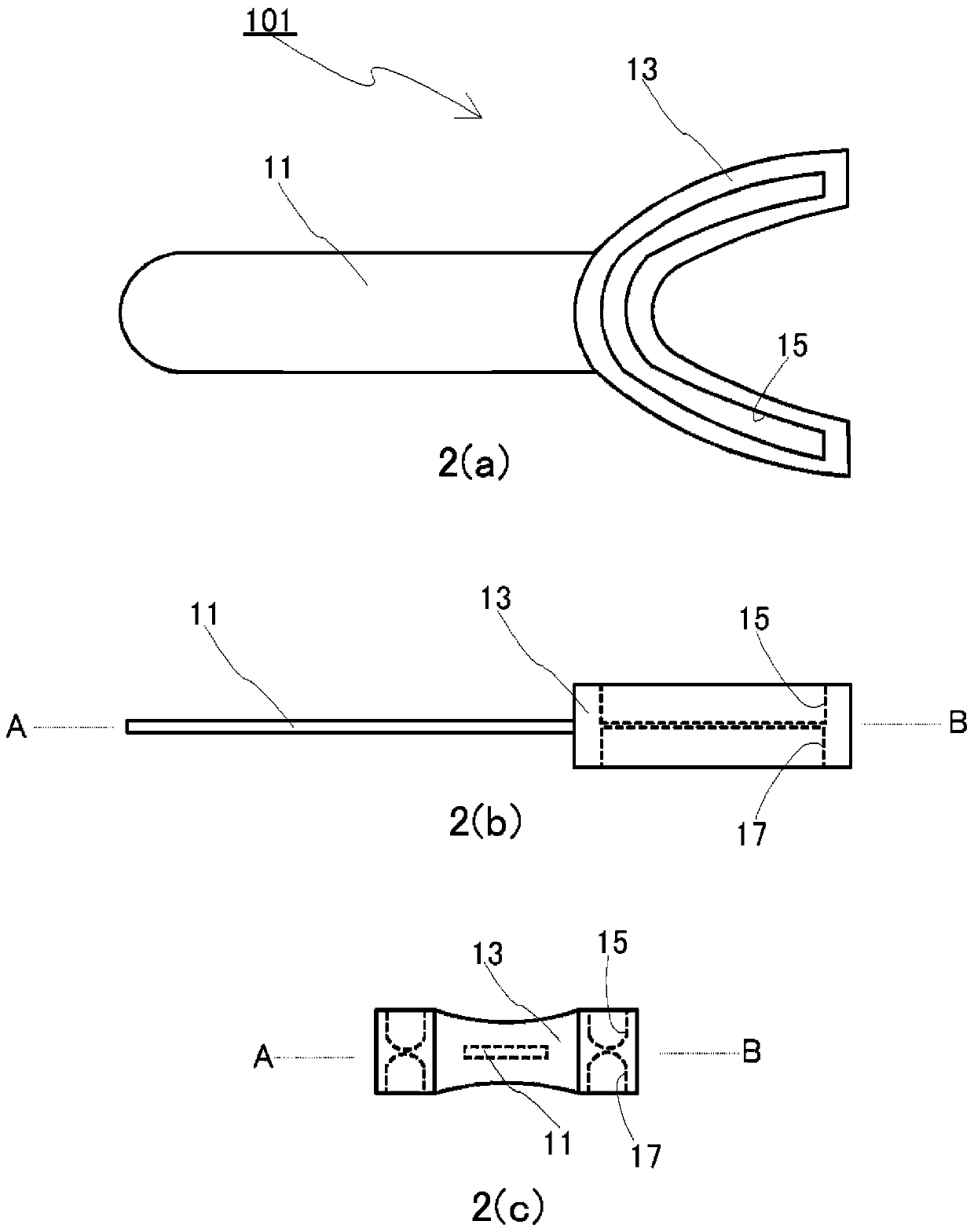

[0147] Alignment jigs used are figure 2 Alignment jig with the described structure. The reference denture is set in this reference denture holding part, and the hard interior material is mounted on the inner surface of the reference denture, and inserted into the oral cavity of the mannequin, and the shape of the mucosal surface is imprinted on the interior material and hardened, thereby producing Dentures.

Embodiment 2

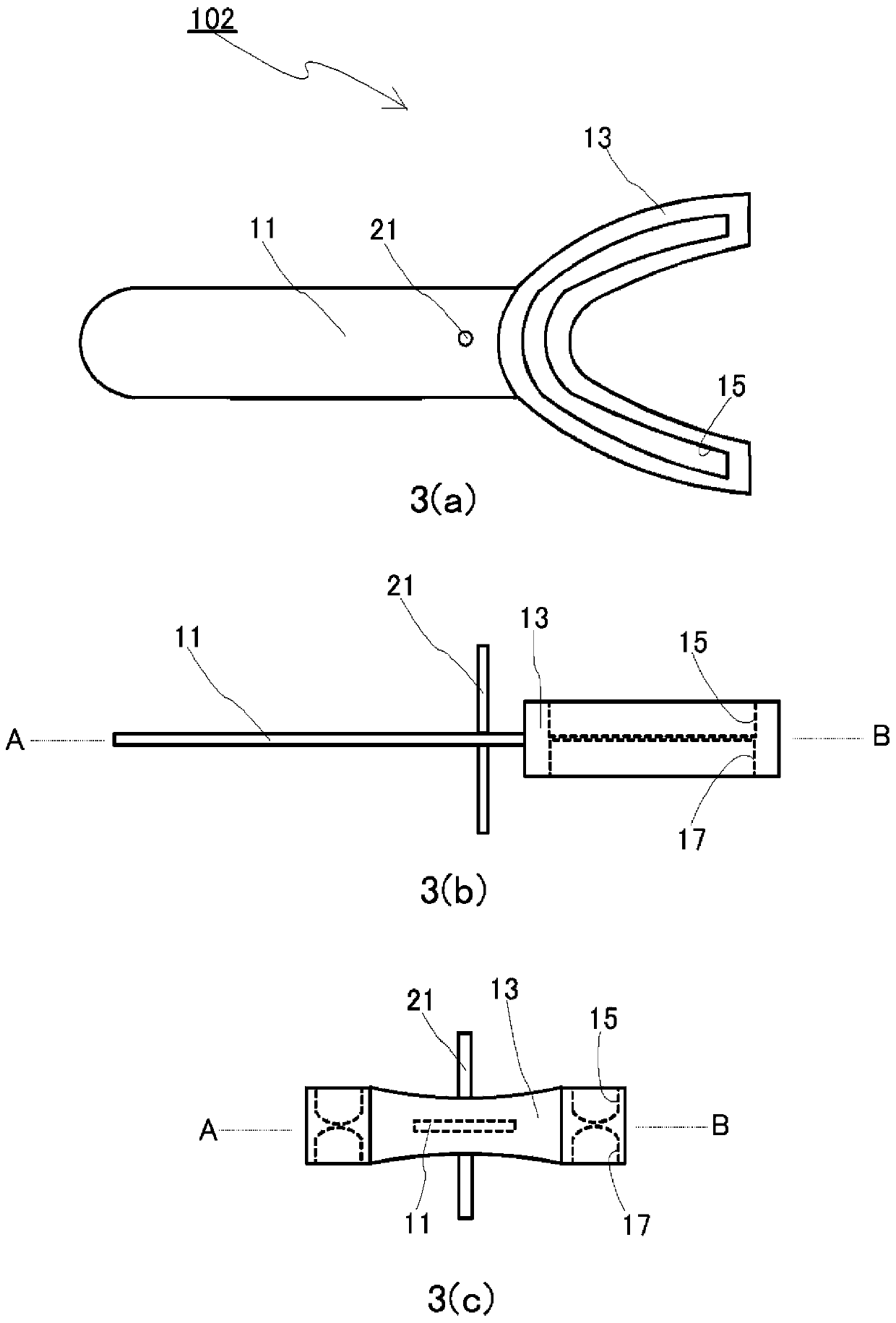

[0149] In addition to being used as an alignment jig in figure 2 Dentures were fabricated in the same manner as in Example 1, except that the handle of the alignment jig with the described structure indicated the alignment jig in the middle of the indicator line. In addition, at the time of production, instructions are made so that the median indicator line coincides with the median of the human body model.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com