Patents

Literature

36 results about "Occlusal appliance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An occlusal appliance is a noninvasive, removable, hard acrylic device that fits on the incisal and occlusal surfaces of the teeth.1 The appliance may be referred to as a nightguard, biteguard, splint, or other similar term.

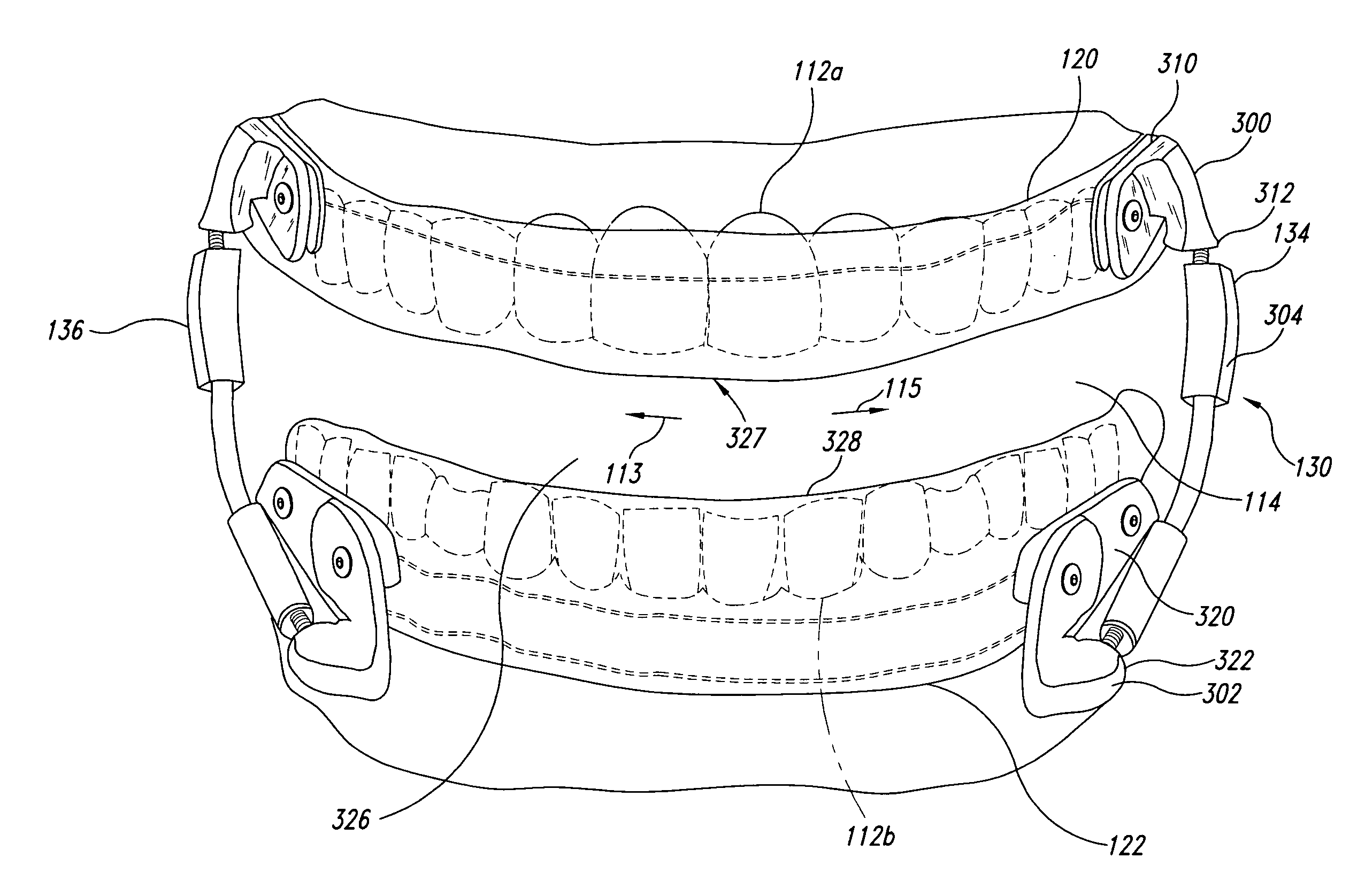

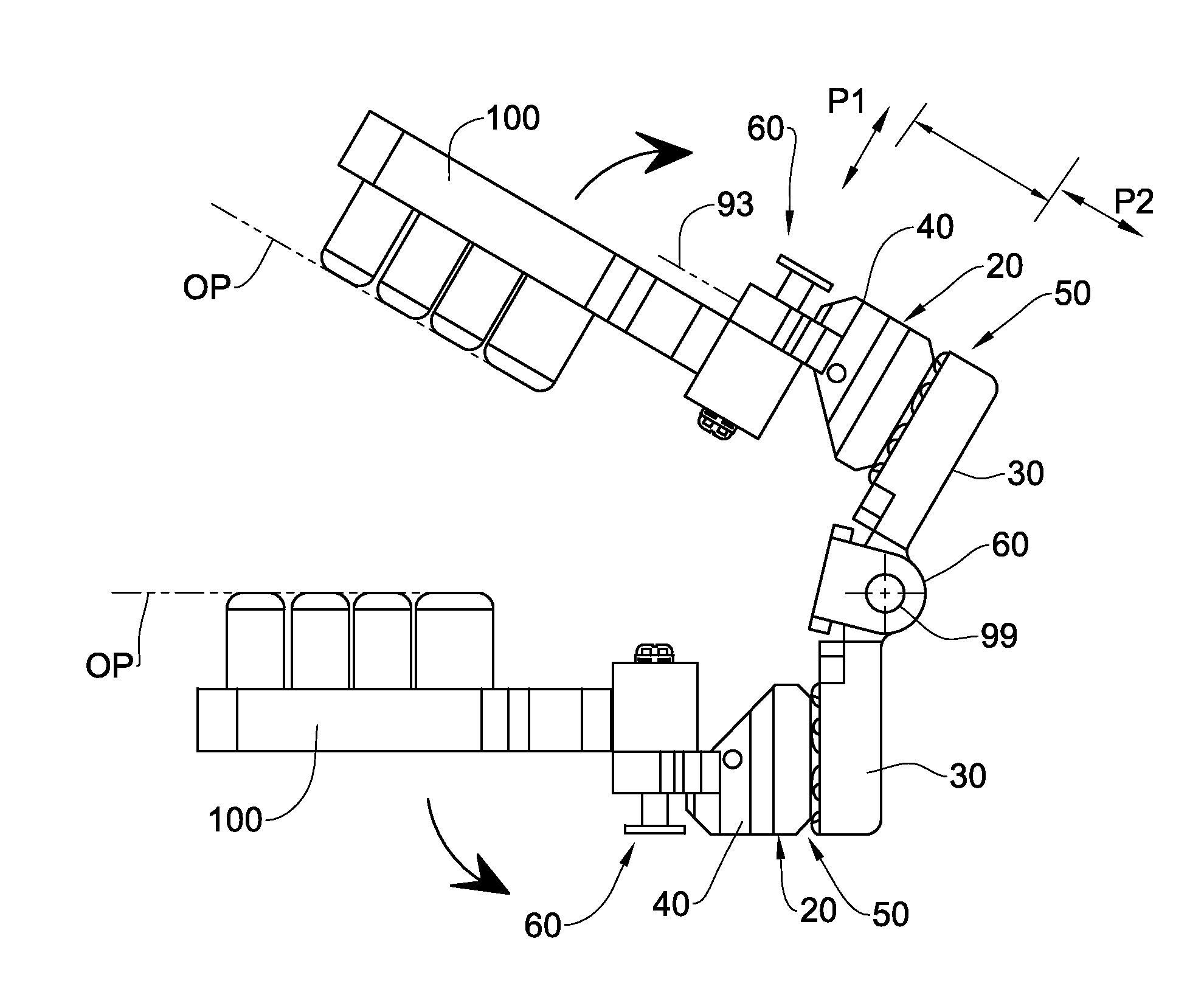

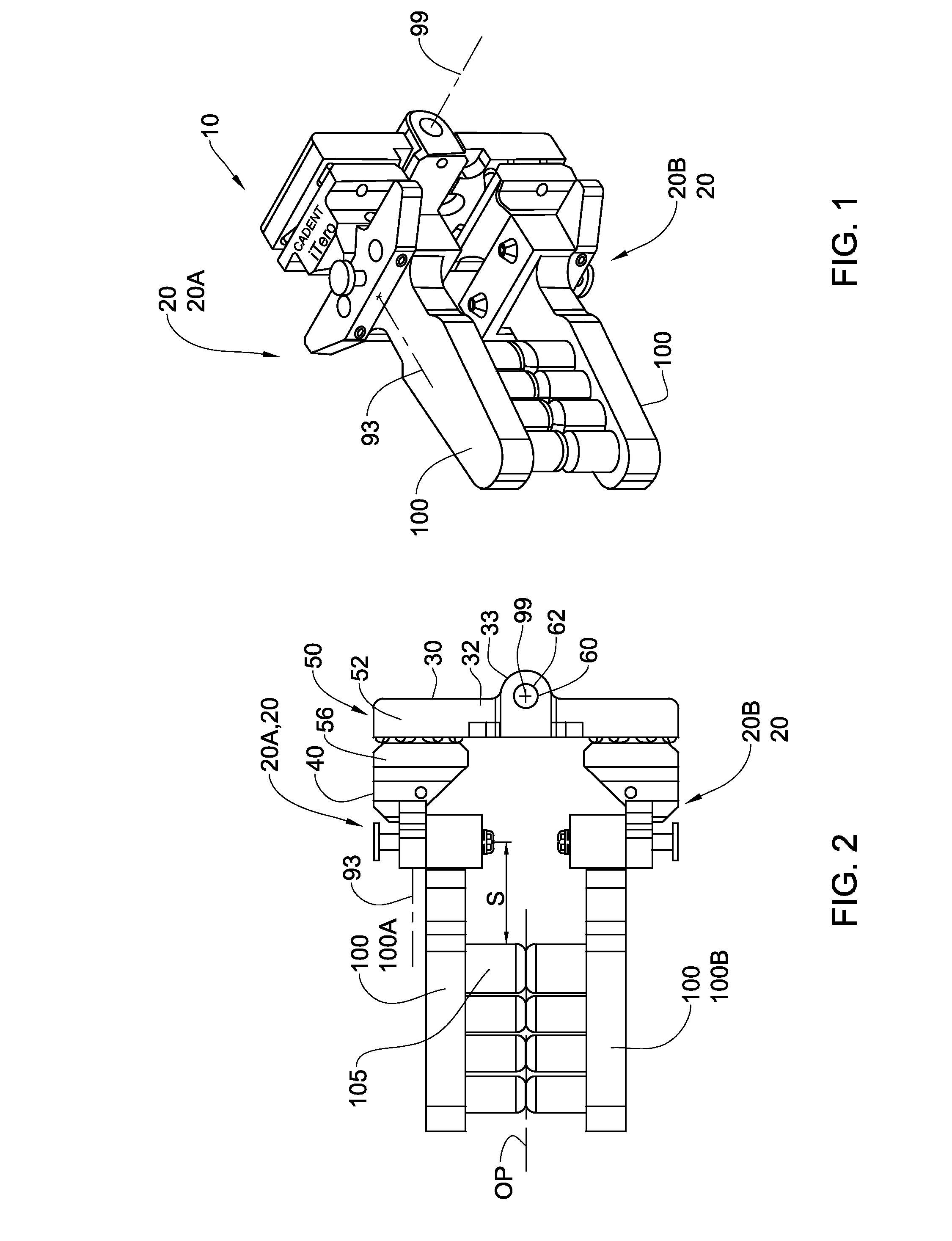

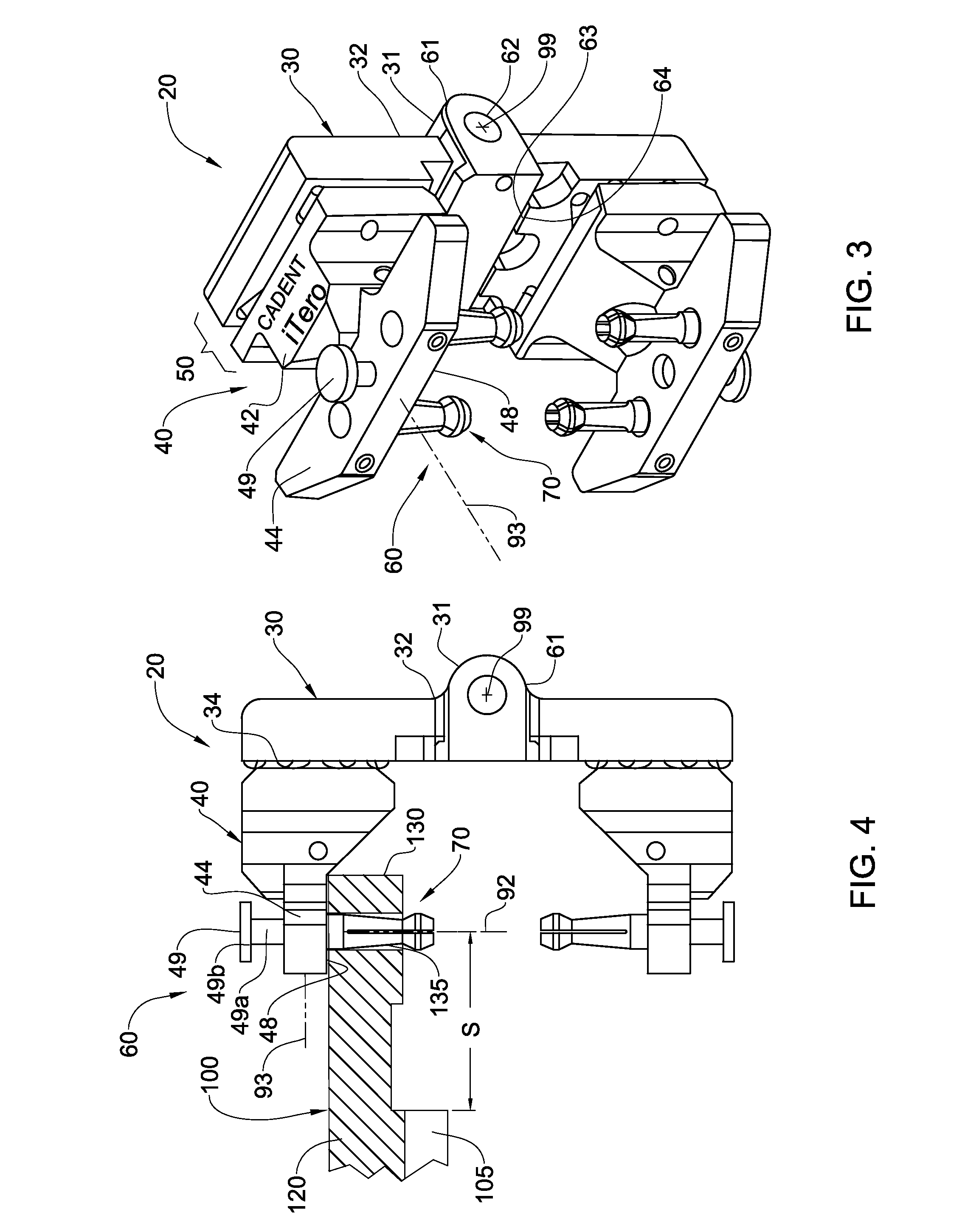

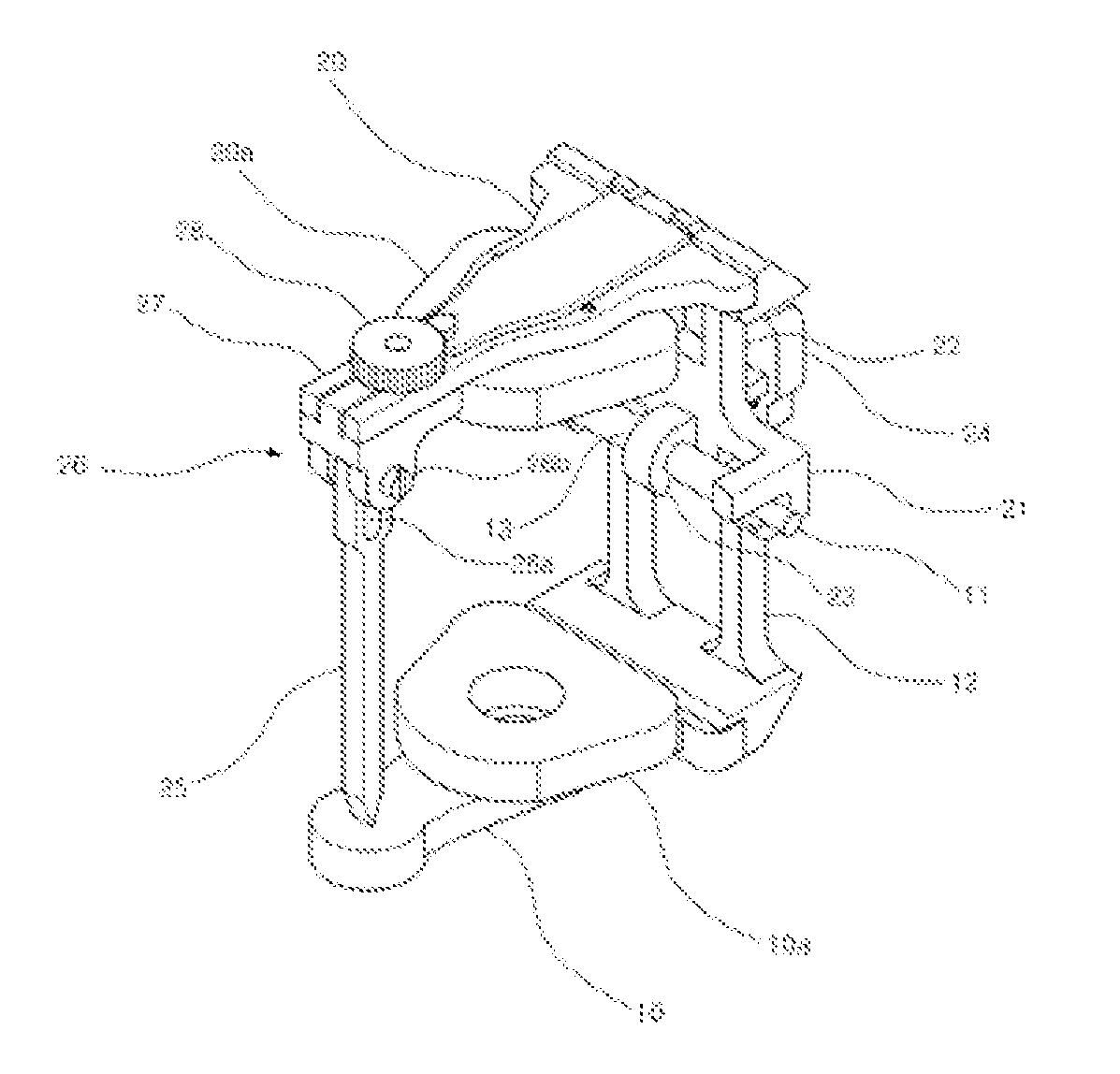

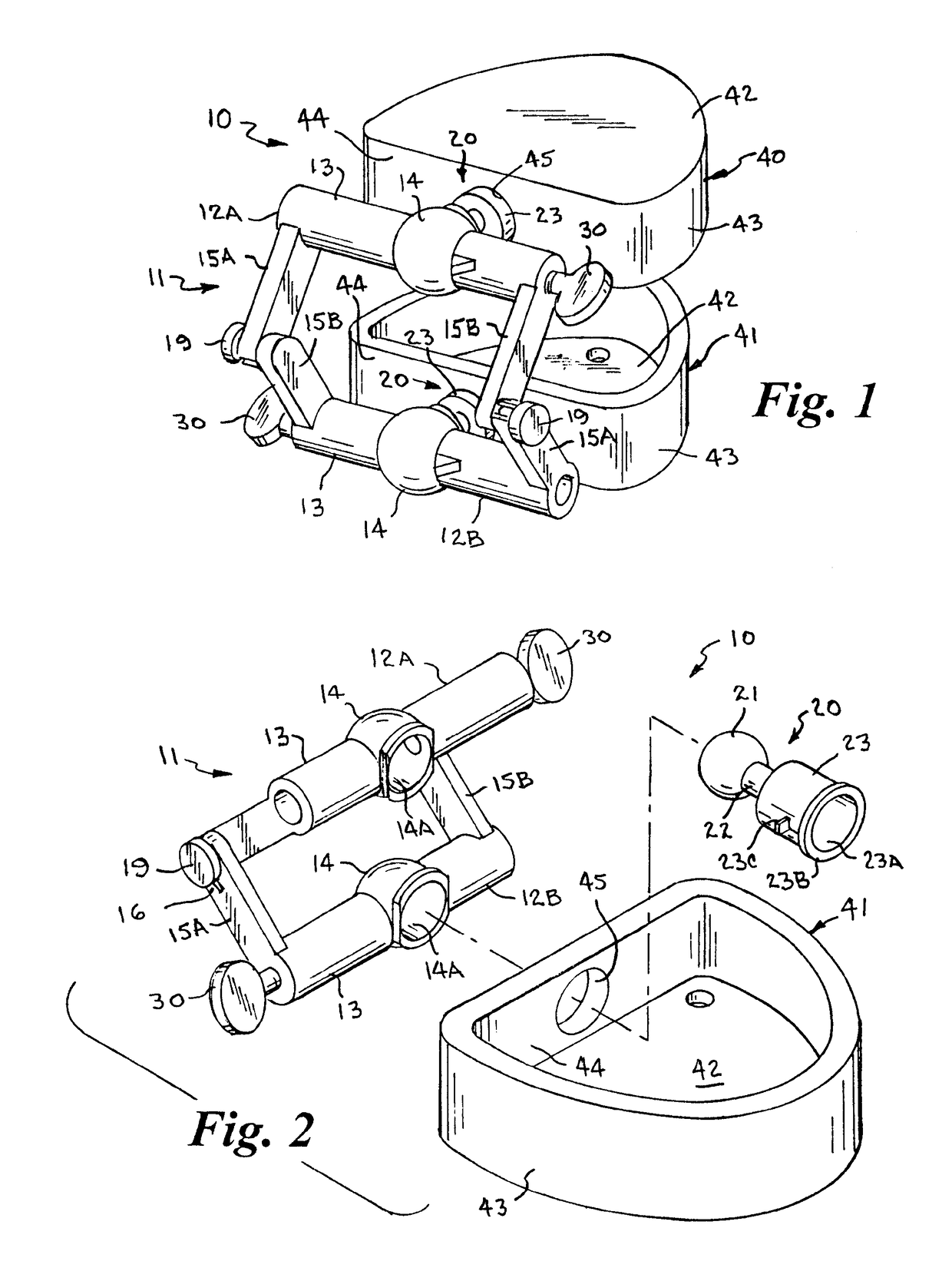

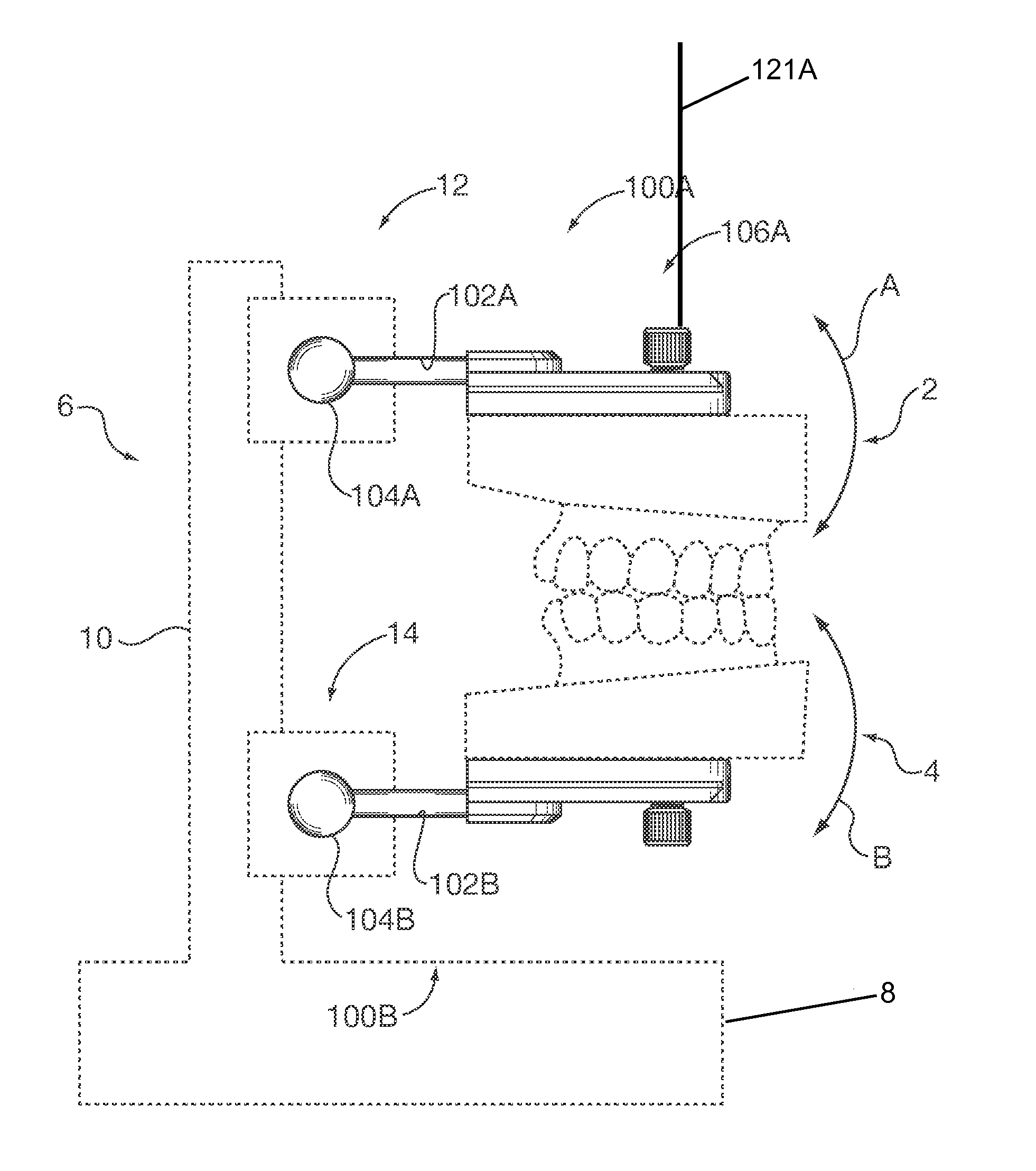

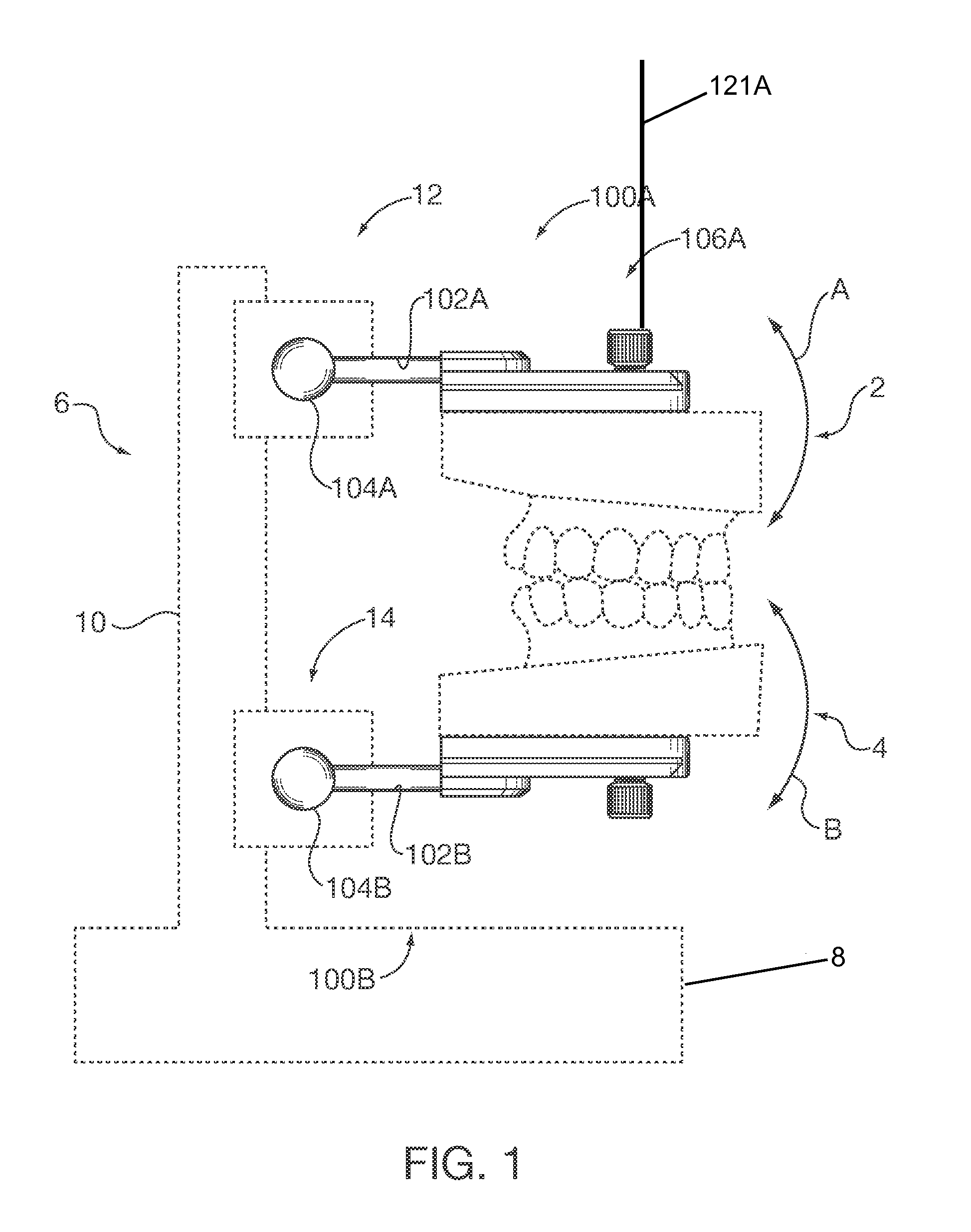

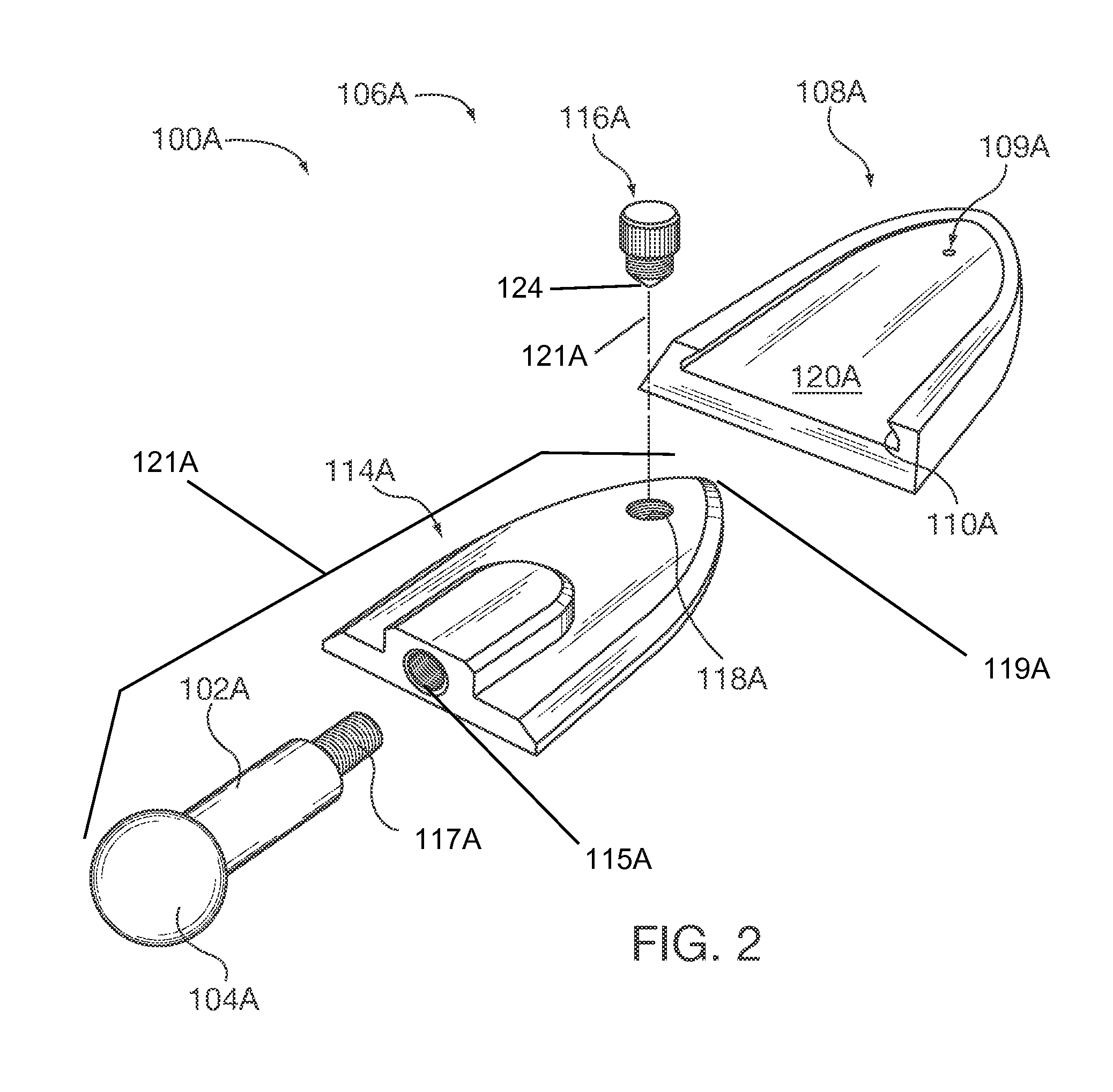

Dental orthotic and methods of using the same

Apparatuses, systems, and methods for treating oral functions are shown and described. An orthotic dental system for treating oral functions includes an upper dentition orthotic, a lower dentition orthotic, and an articulator system. The articulator system extends between the upper and lower dentition orthotics and can have at least one rigid connector pivotally coupled to the upper dentition orthotic and the lower dentition orthotic. A spacer can be positioned and configured to spatially separate the upper dentition orthotic and the lower dentition orthotic a desired minimum distance. The orthotic dental system can improve various types of oral functions.

Owner:ROBSON FARRAND C

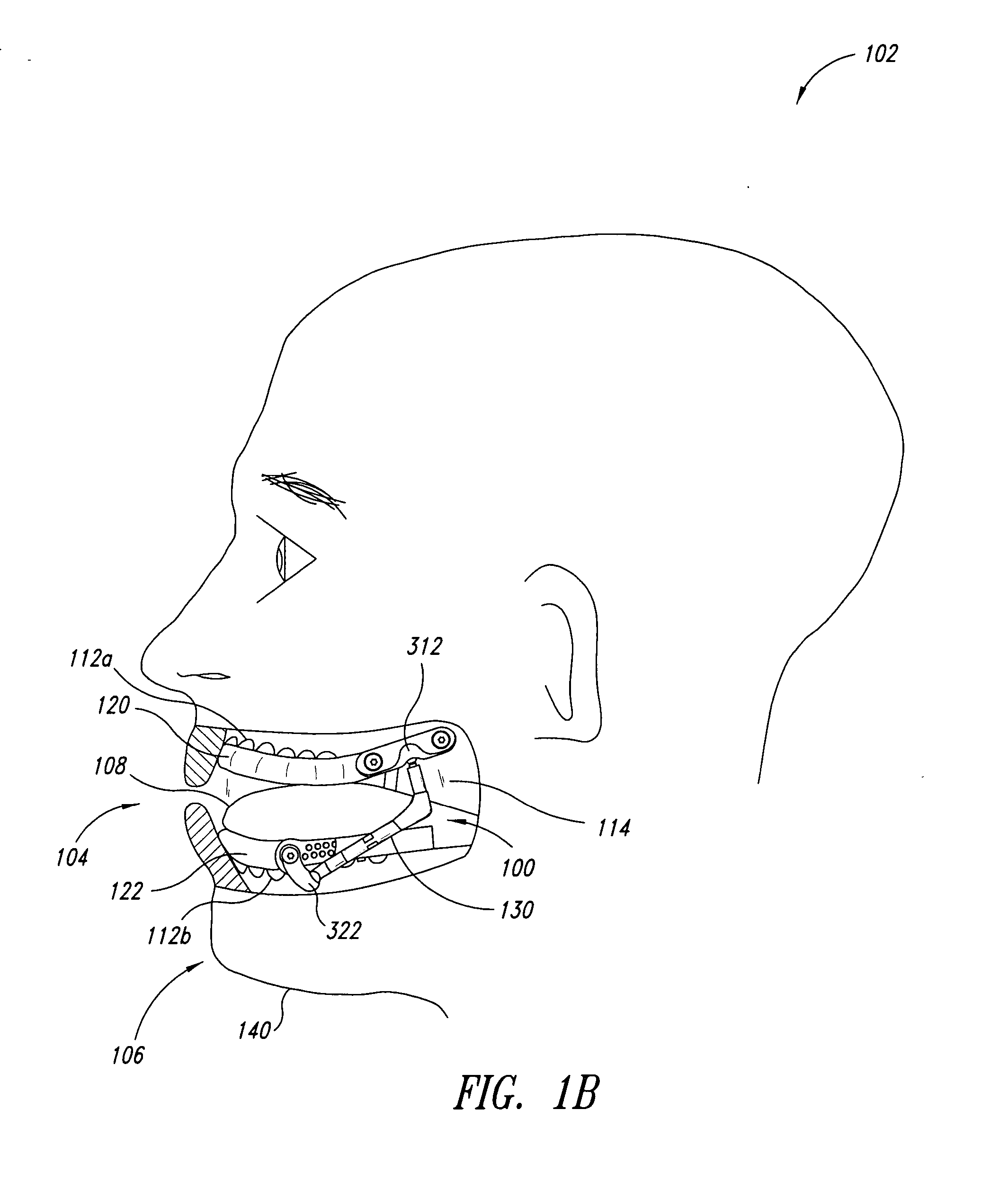

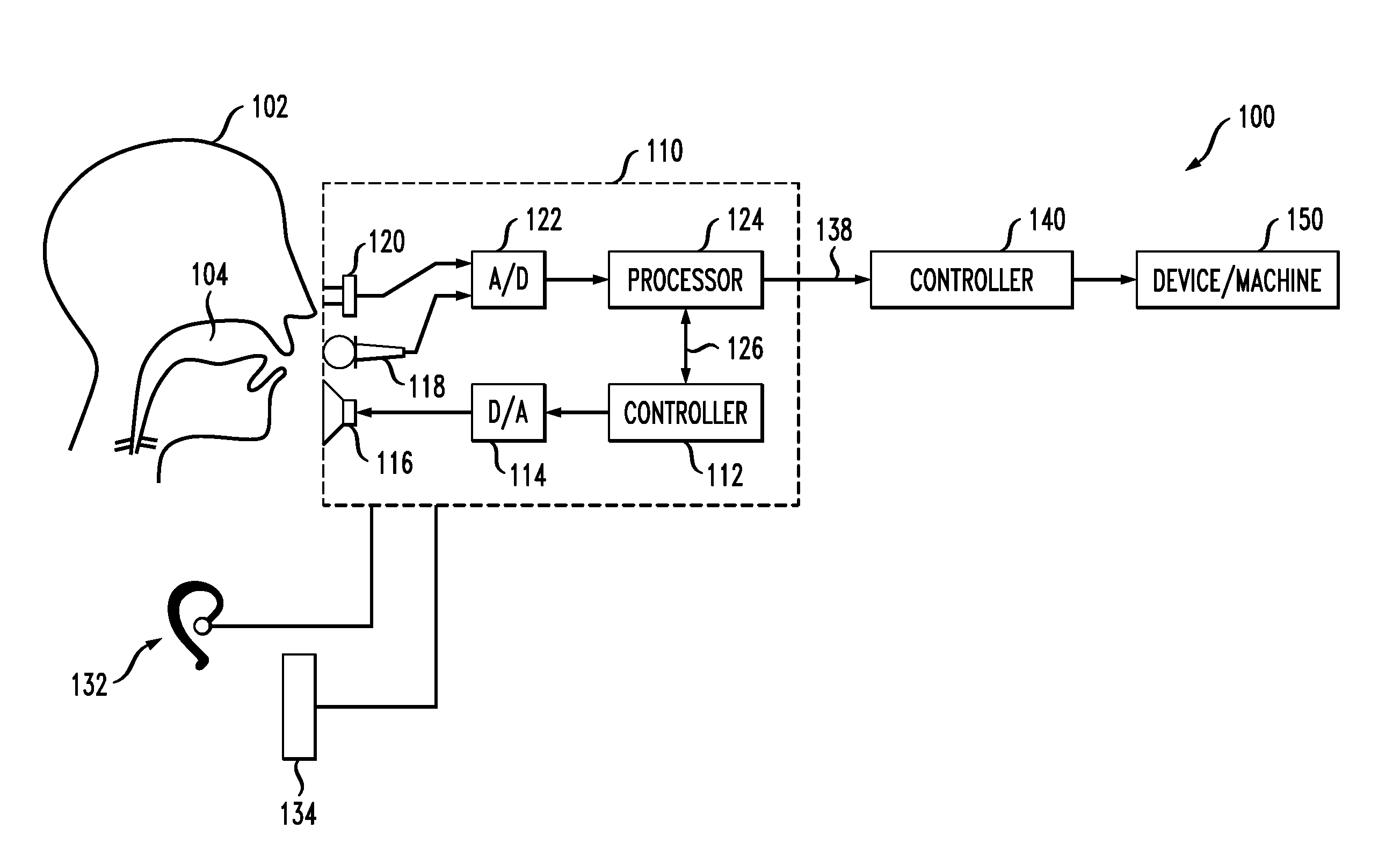

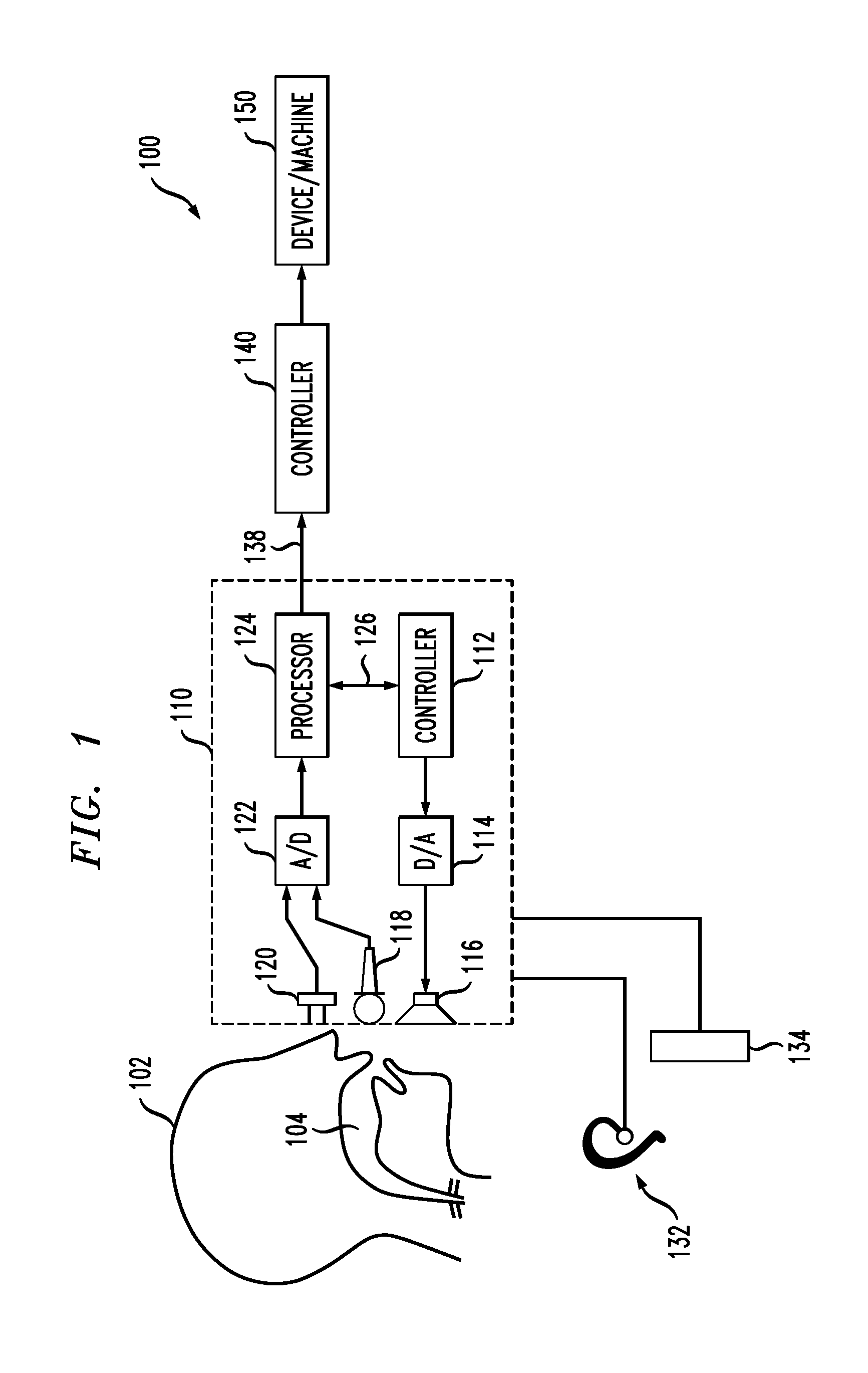

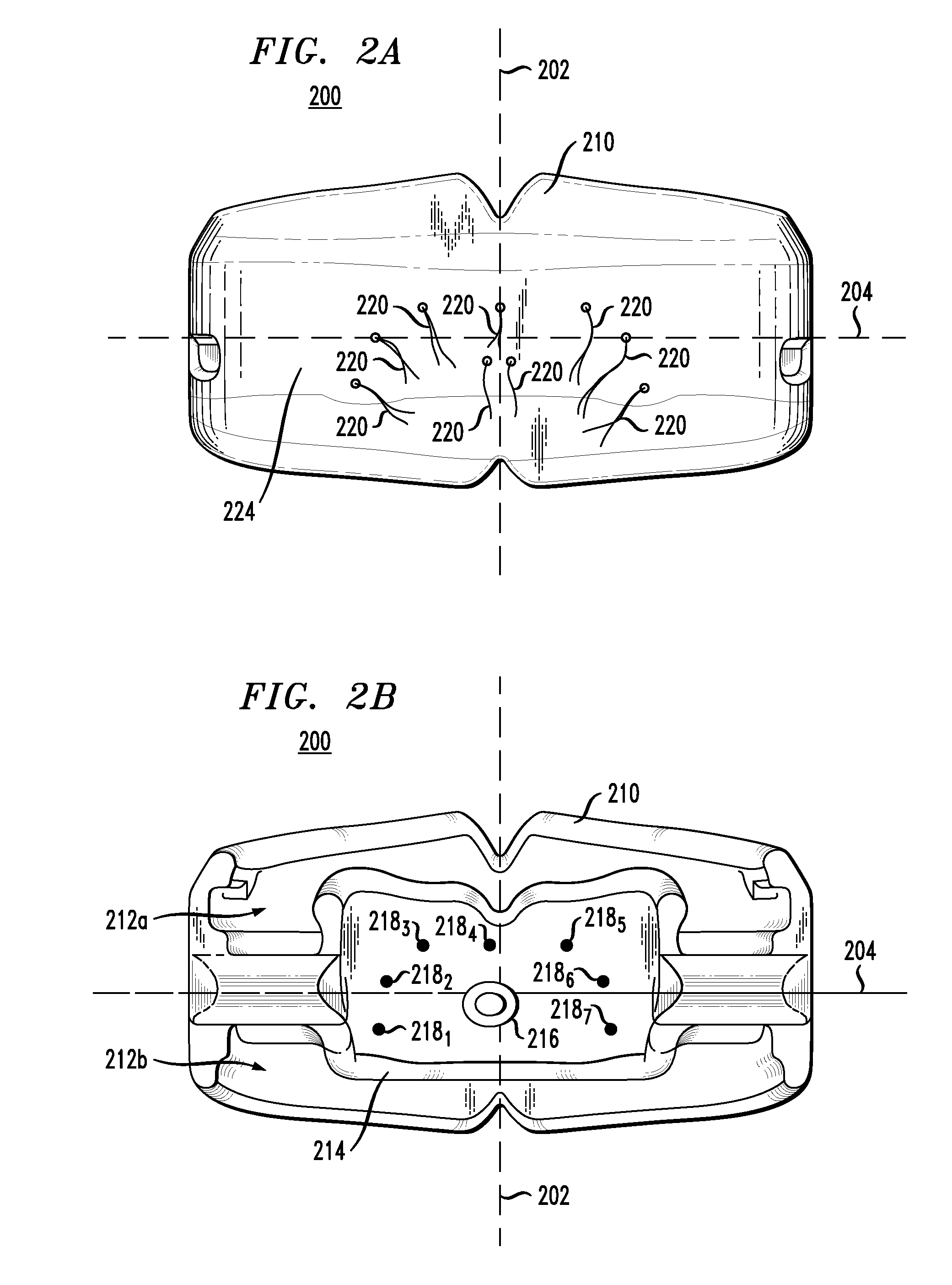

Biometric-Sensor Assembly, Such as for Acoustic Reflectometry of the Vocal Tract

A biometric-sensor assembly, e.g., for acoustic reflectometry of the vocal tract. In one embodiment, the sensor assembly includes a dental appliance for in-mouth mounting, an acoustic sensor attached to the dental appliance, and an optional headset. The dental appliance enables secure placement of the acoustic sensor in the mouth of the user, e.g., for tracking movements of the tongue and / or other internal articulators of the vocal tract. A boom arm of the headset can be used for holding an additional acoustic sensor and / or a miniature video camera, e.g., for tracking movements of the lips.

Owner:ALCATEL LUCENT SAS

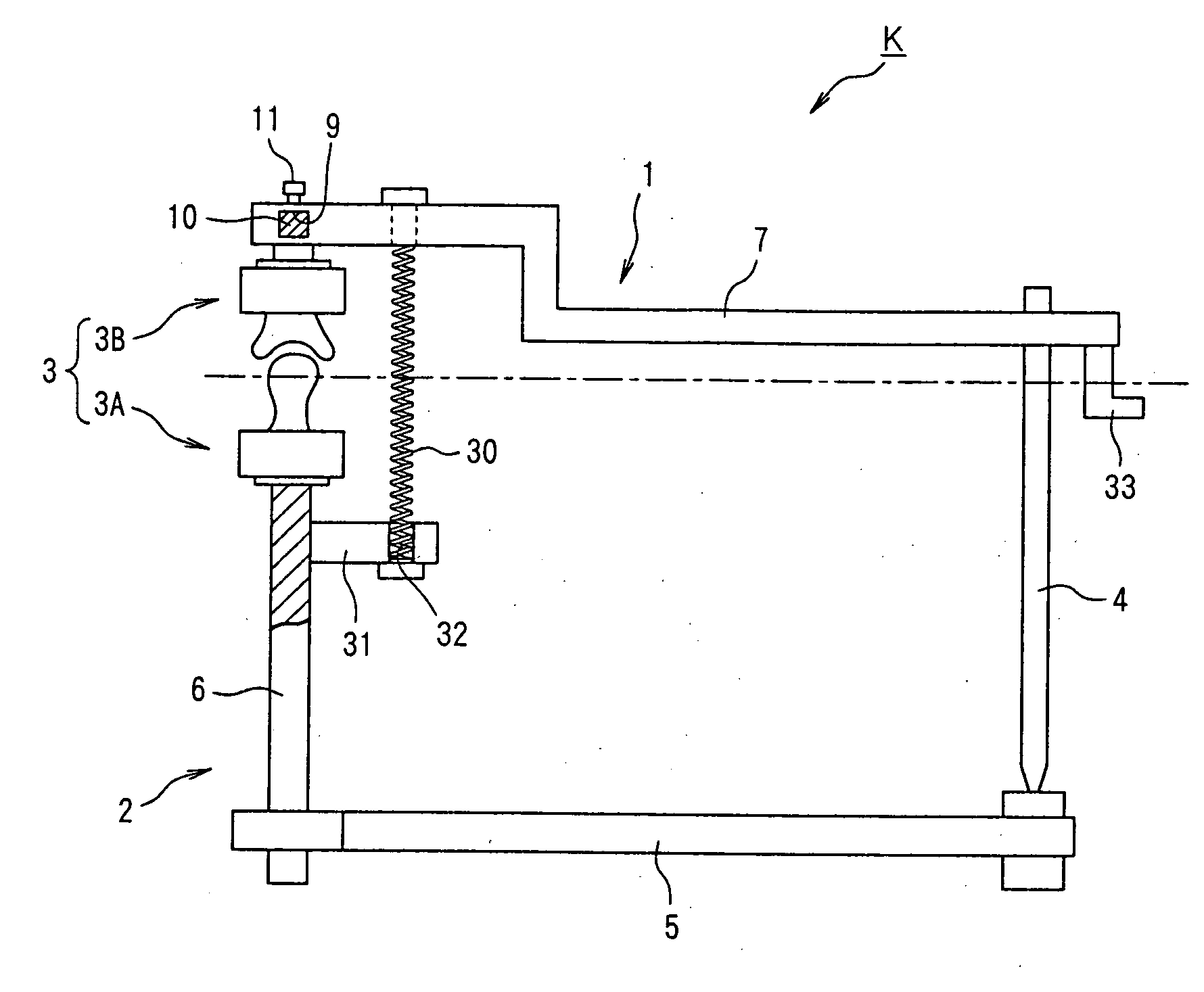

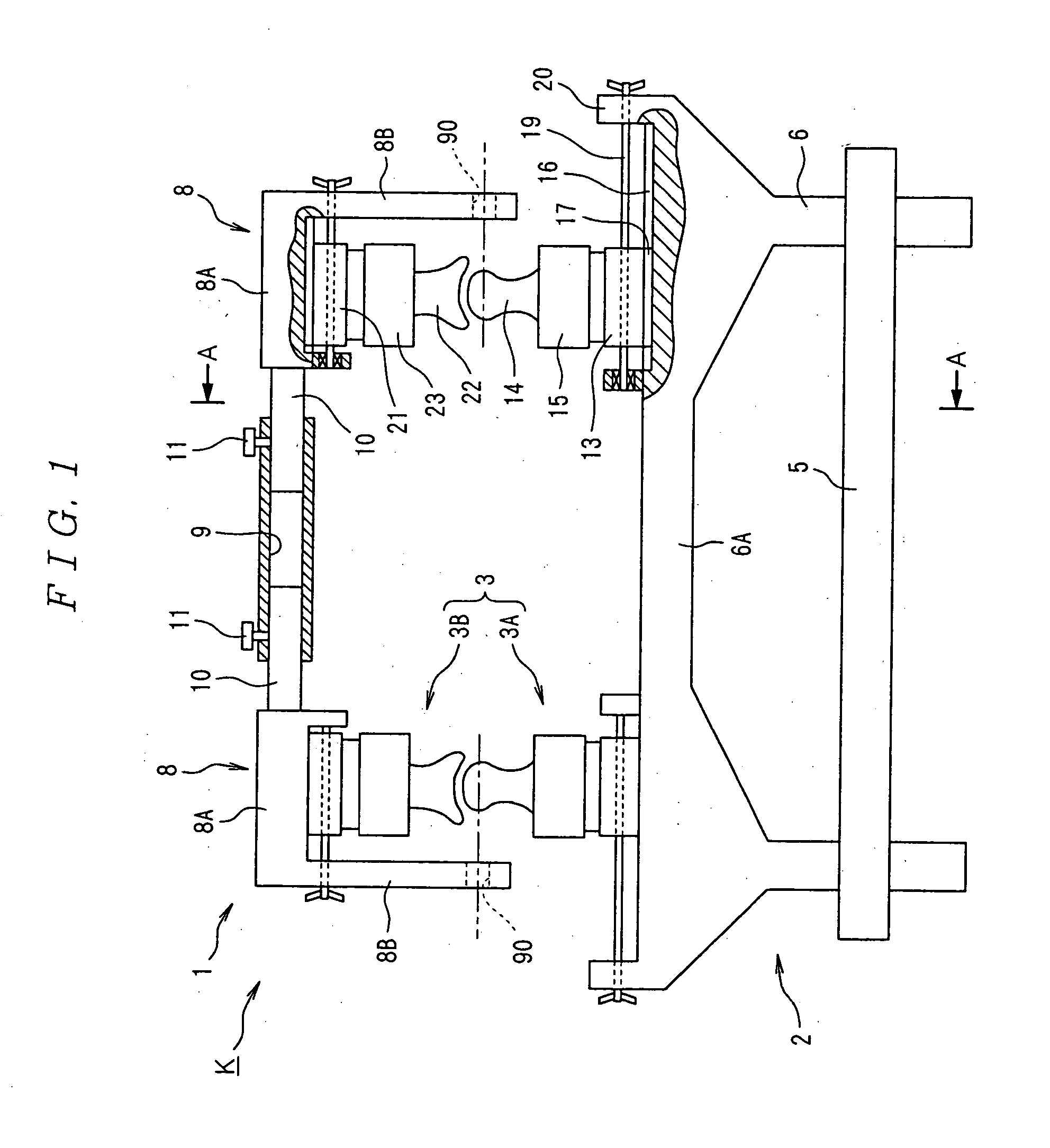

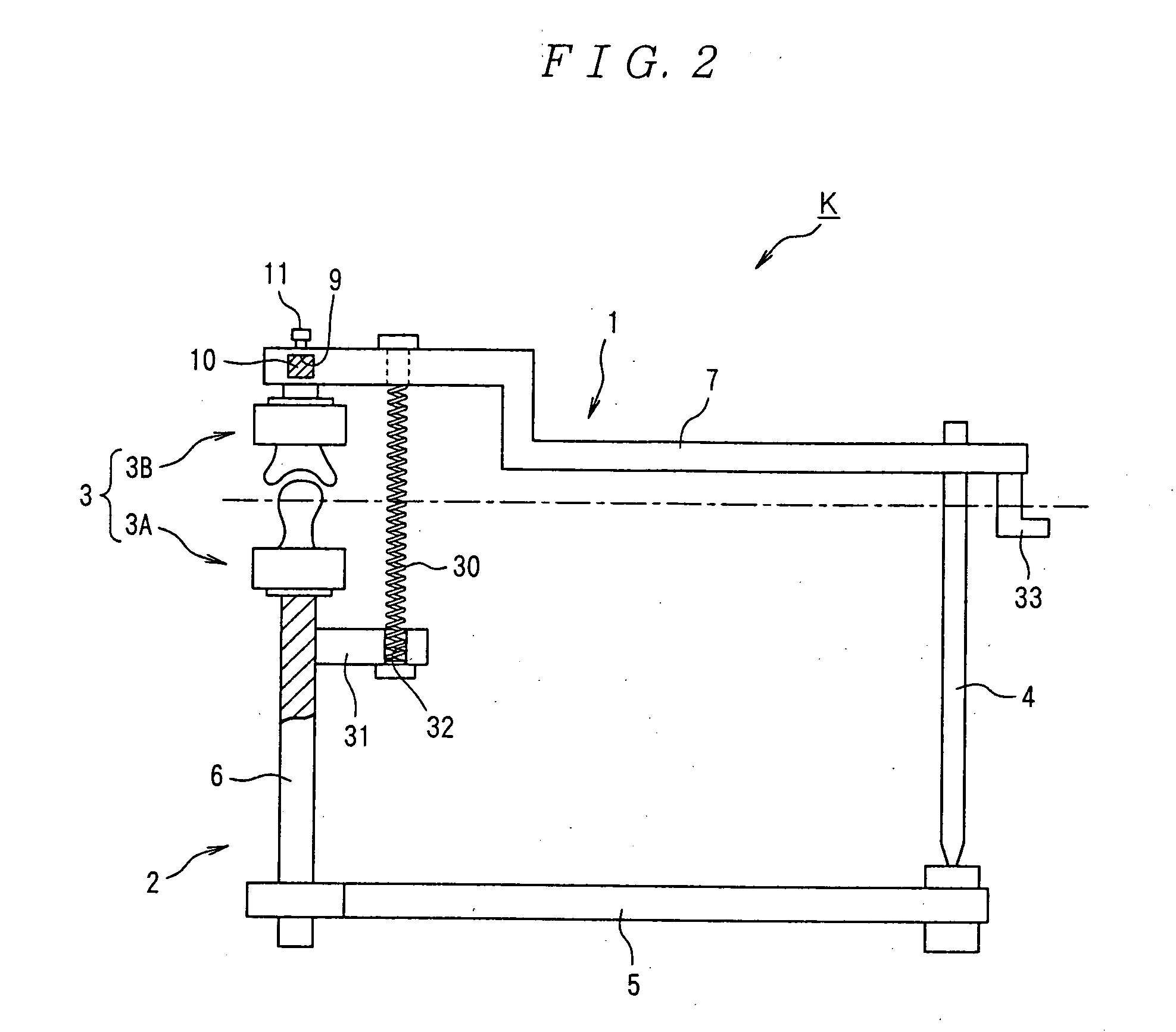

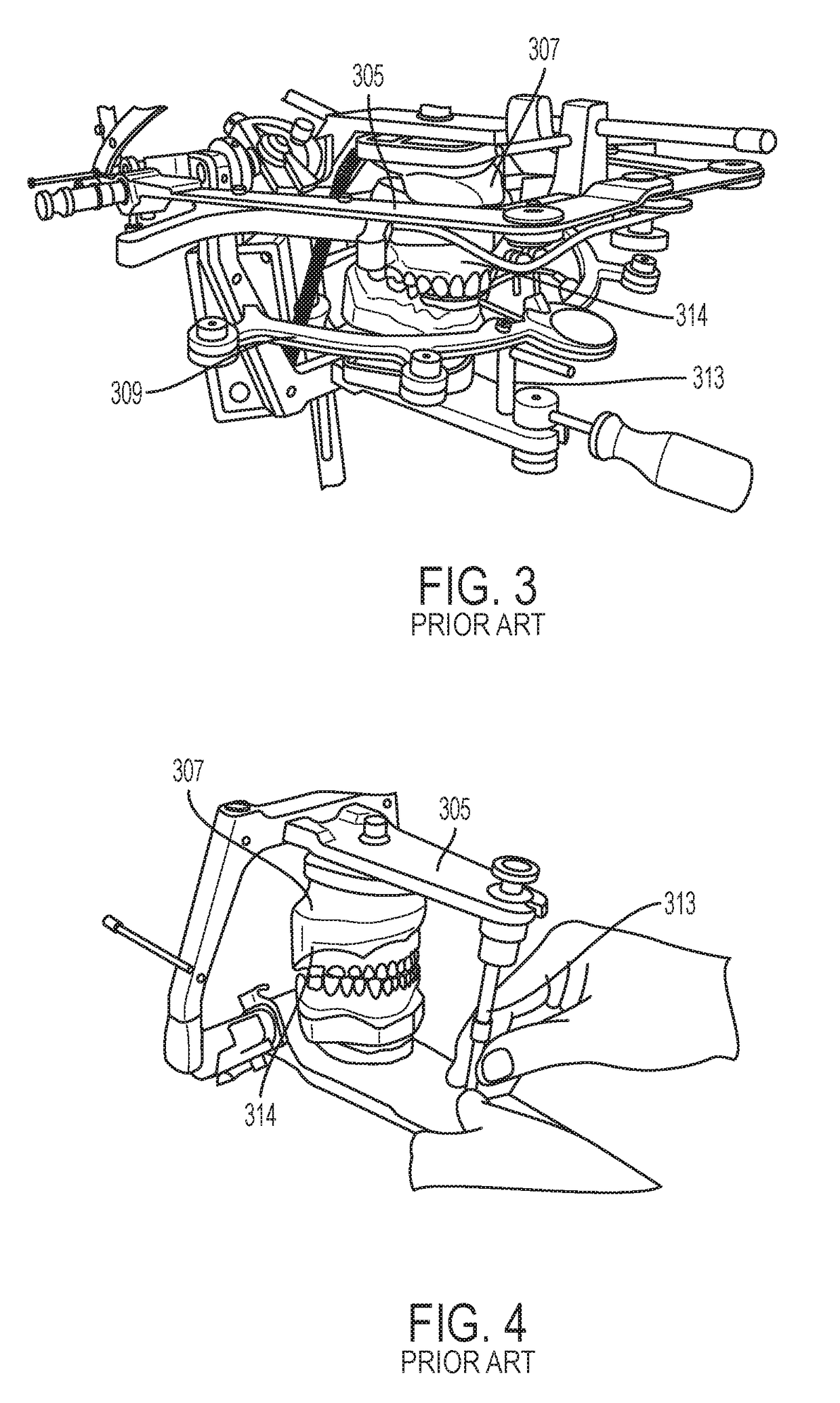

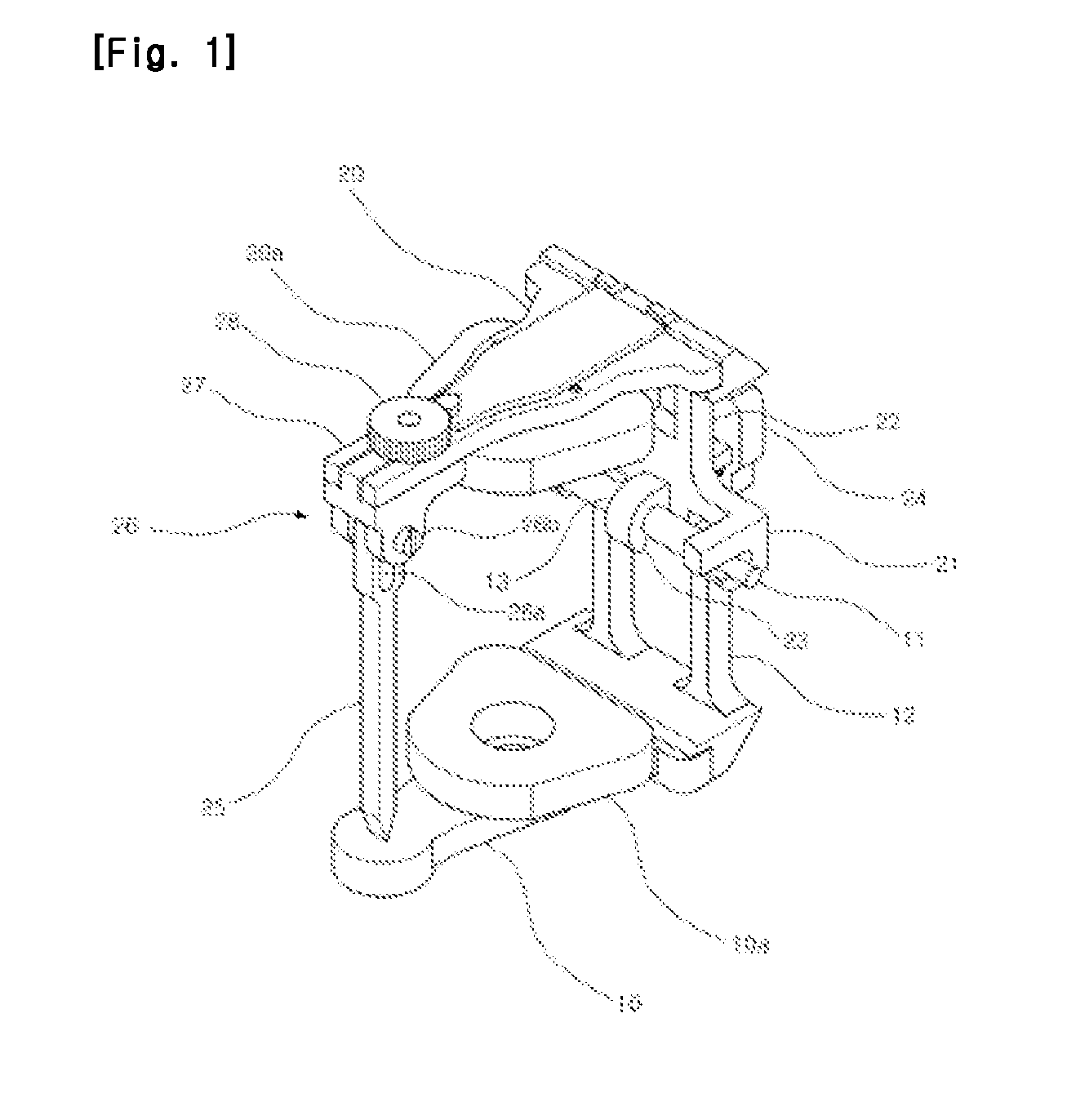

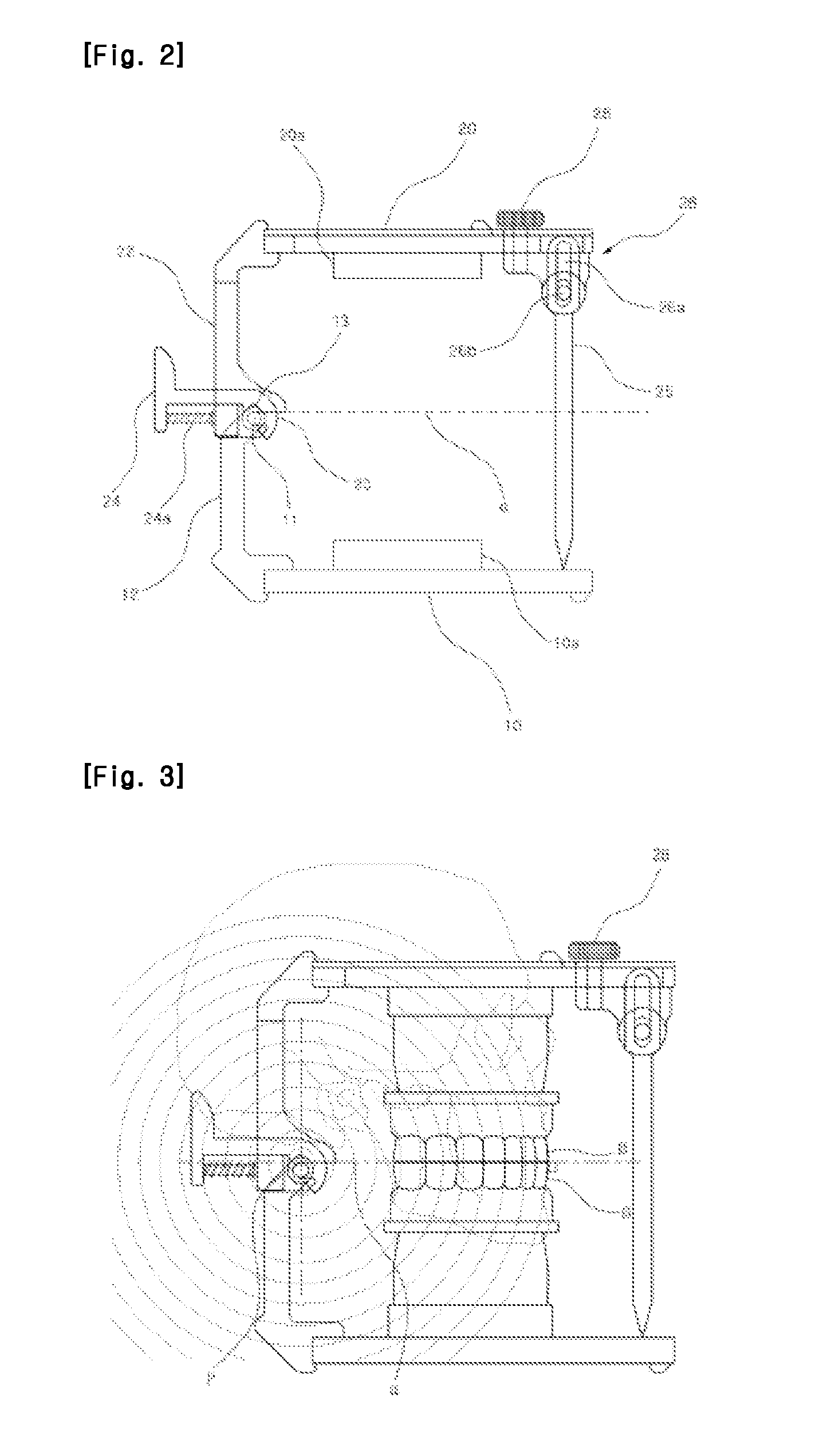

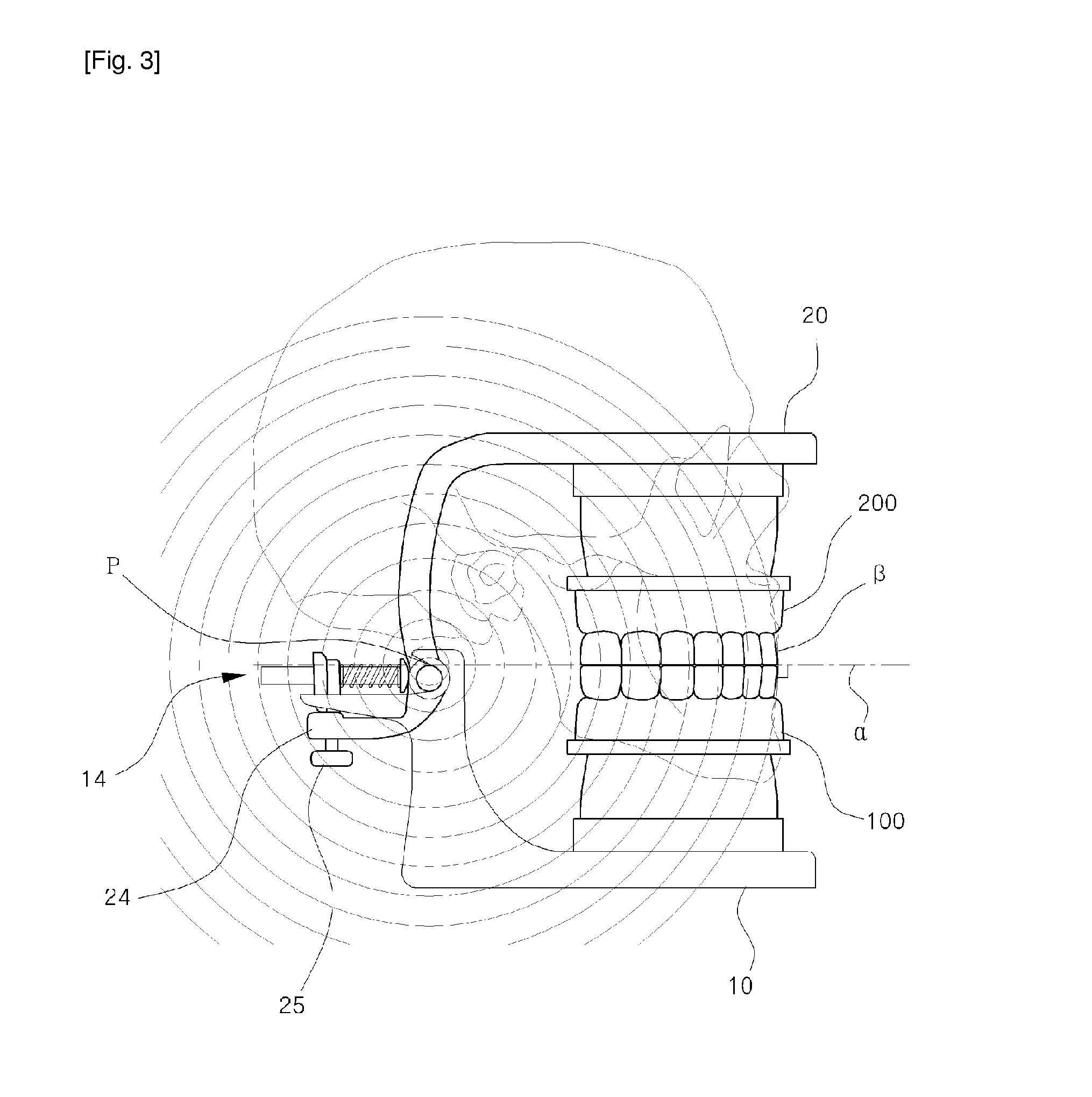

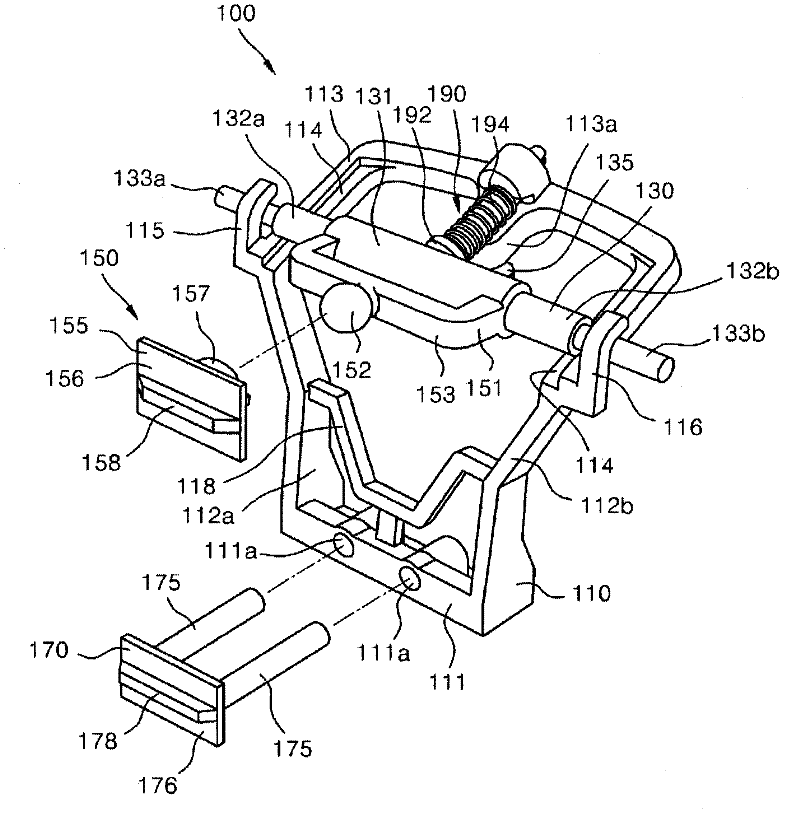

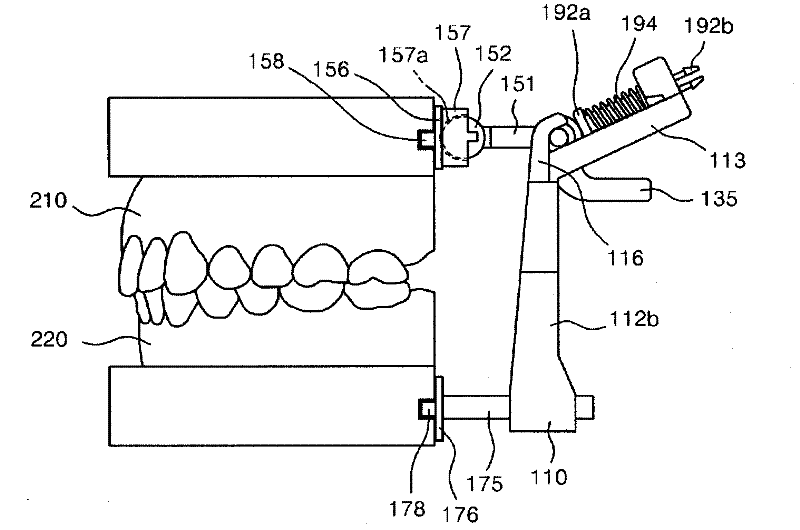

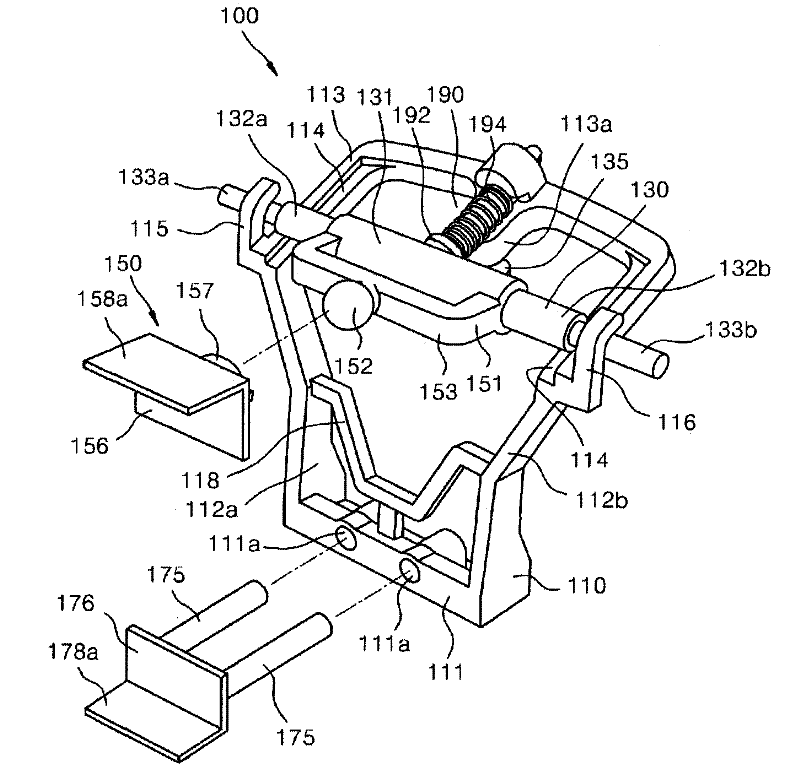

Occludator, face bow, occlusion-confirming system and temporomandibular joint-reproducing system

InactiveUS20050277086A1Easy to moveAdditive manufacturing apparatusDental articulators3d imageStandard plane

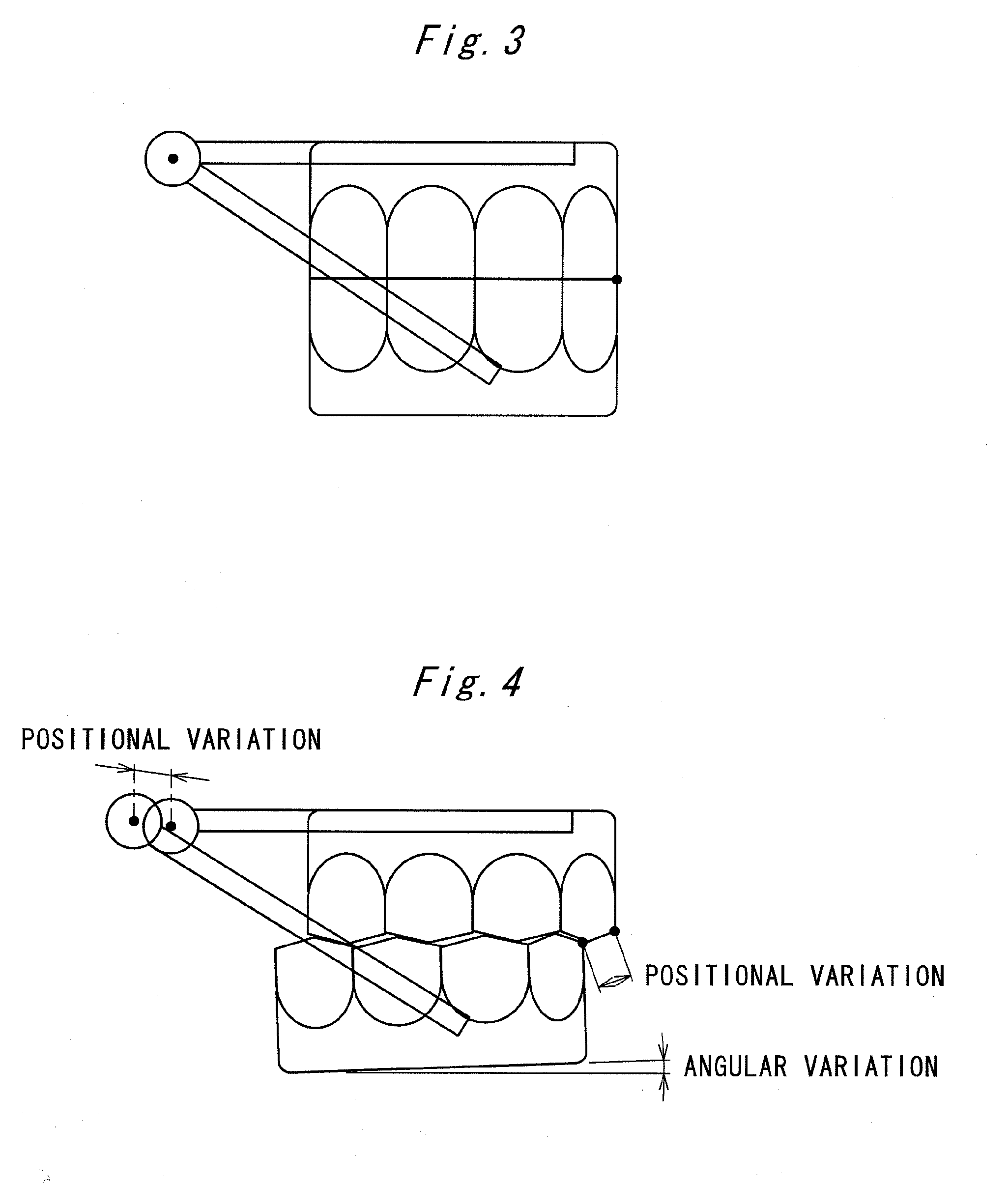

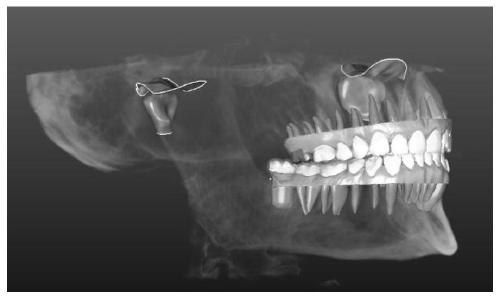

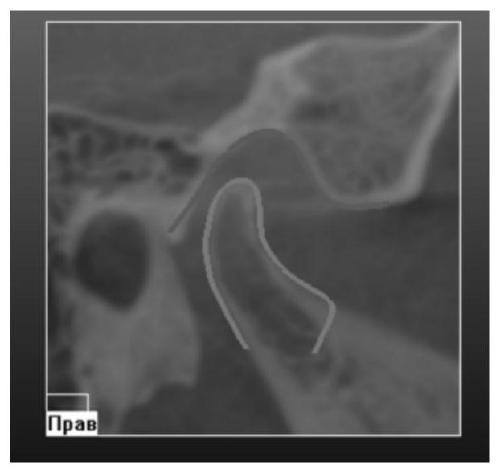

It is intended to provide an occludator whereby joint movements at occlusion being similar to the actual tempromandibular joint movements of an individual patient or ideal movements can be reproduced, and a face bow to be used for the occludator. To achieve this object, an occlusion plane against a standard plane is accurately drawn by using the above face bow F whereby the occlusion plane can be drawn at a high accuracy. A solid model of the tempromandibular joint similar to the tempromandibular joint form of an actual patient is used as the joint unit of the occludator K, while the positional relationship in the body at occlusion is three-dimensionally reproduced in the occludator I with the use of the above-described face bow F. It is also intended to provide an occlusion-confirming system and a tempromandibular joint-reproducing system with the use of an occludator whereby joint movements at occlusion being similar to the actual tempromandibular joint movements of an individual patient or ideal movements can be reproduced. To achieve this object, the tempromandibular joint of the body is photographed with a local X-ray CT device to give three-dimensional image data and then a solid model of the tempromandibular joint is constructed based on the three-dimensional image data. This solid model is employed as the joint unit of the occludator K and the positional relationship in the body at occlusion is three-dimensionally reproduced.

Owner:NIHON UNIVERSITY

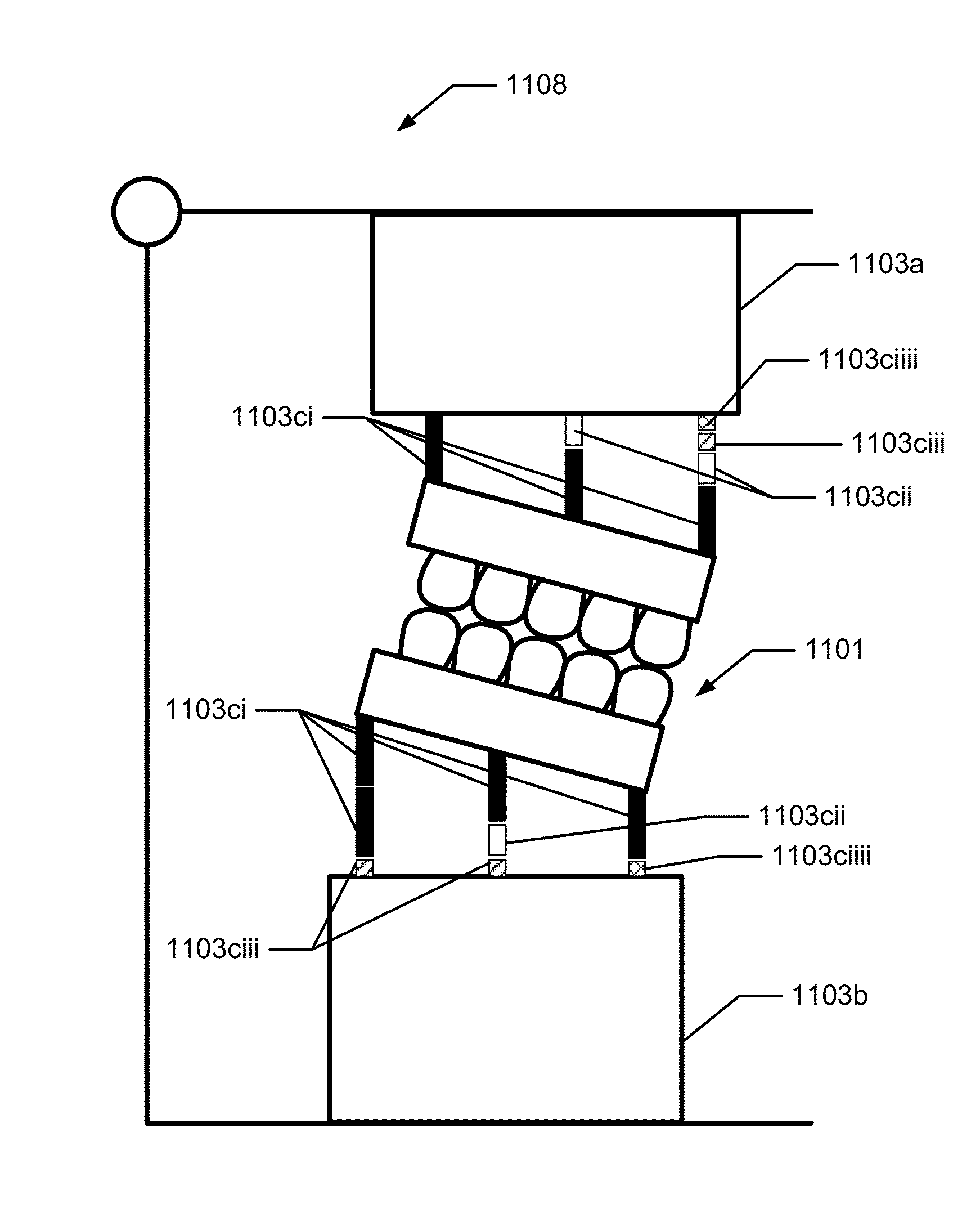

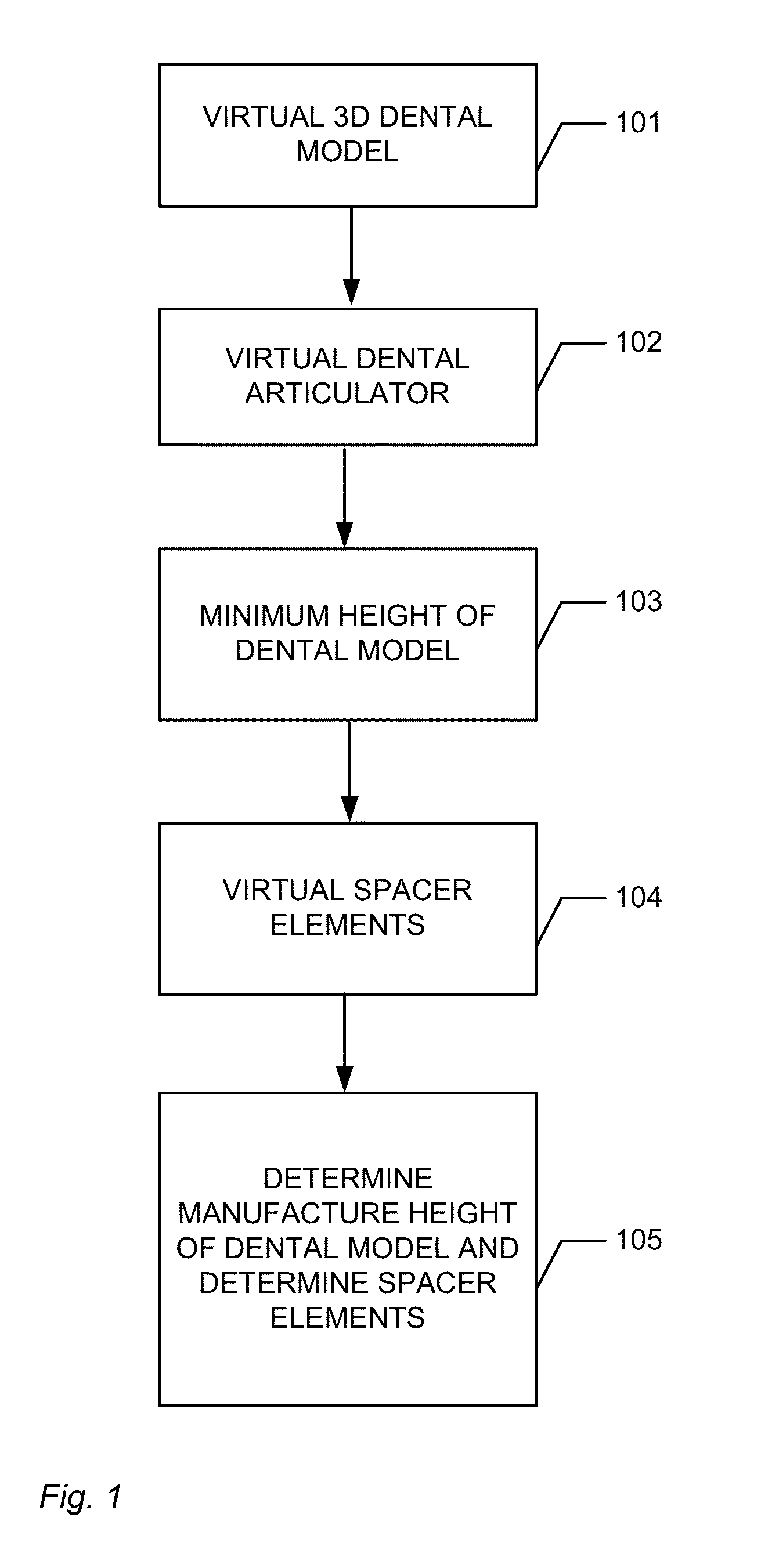

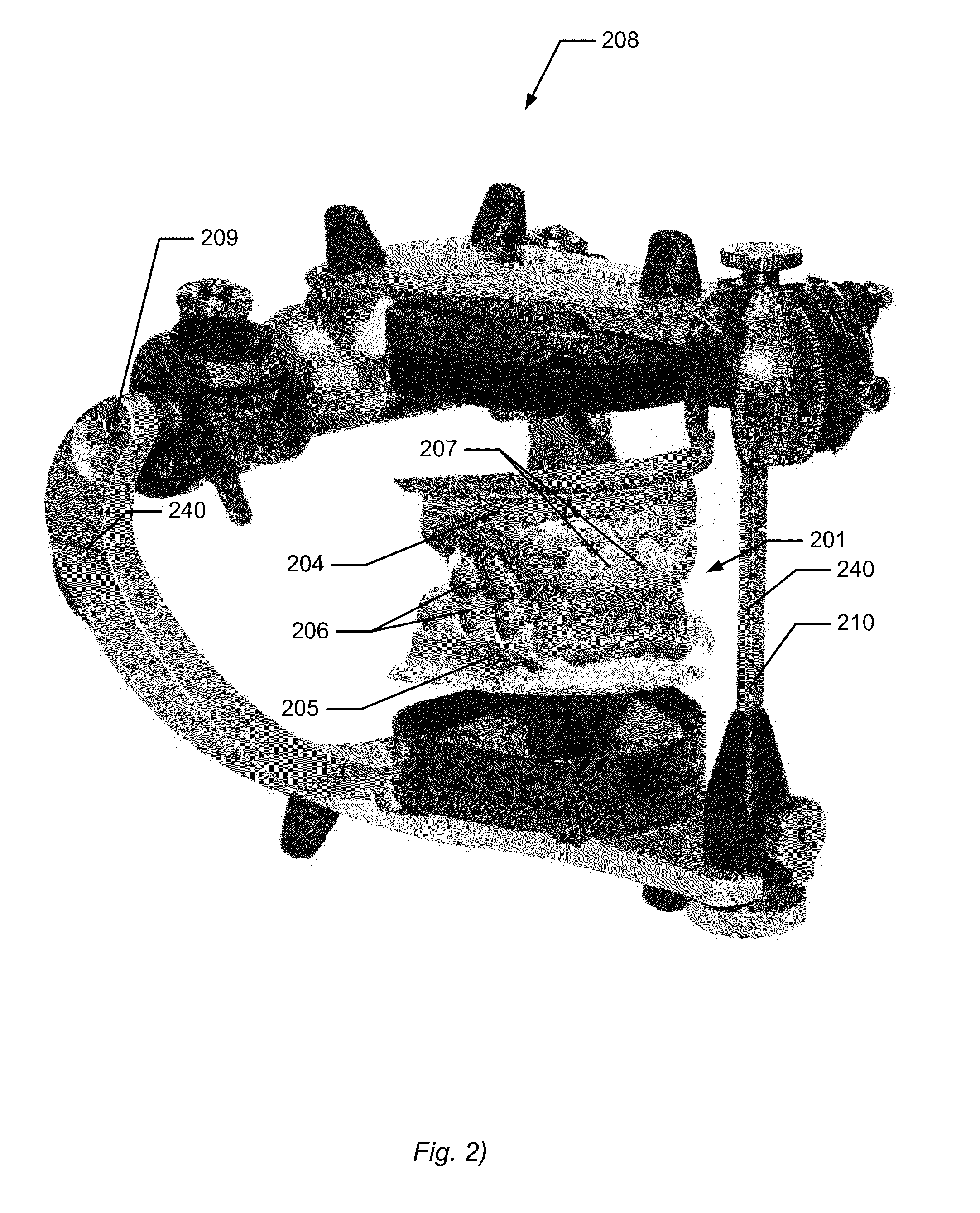

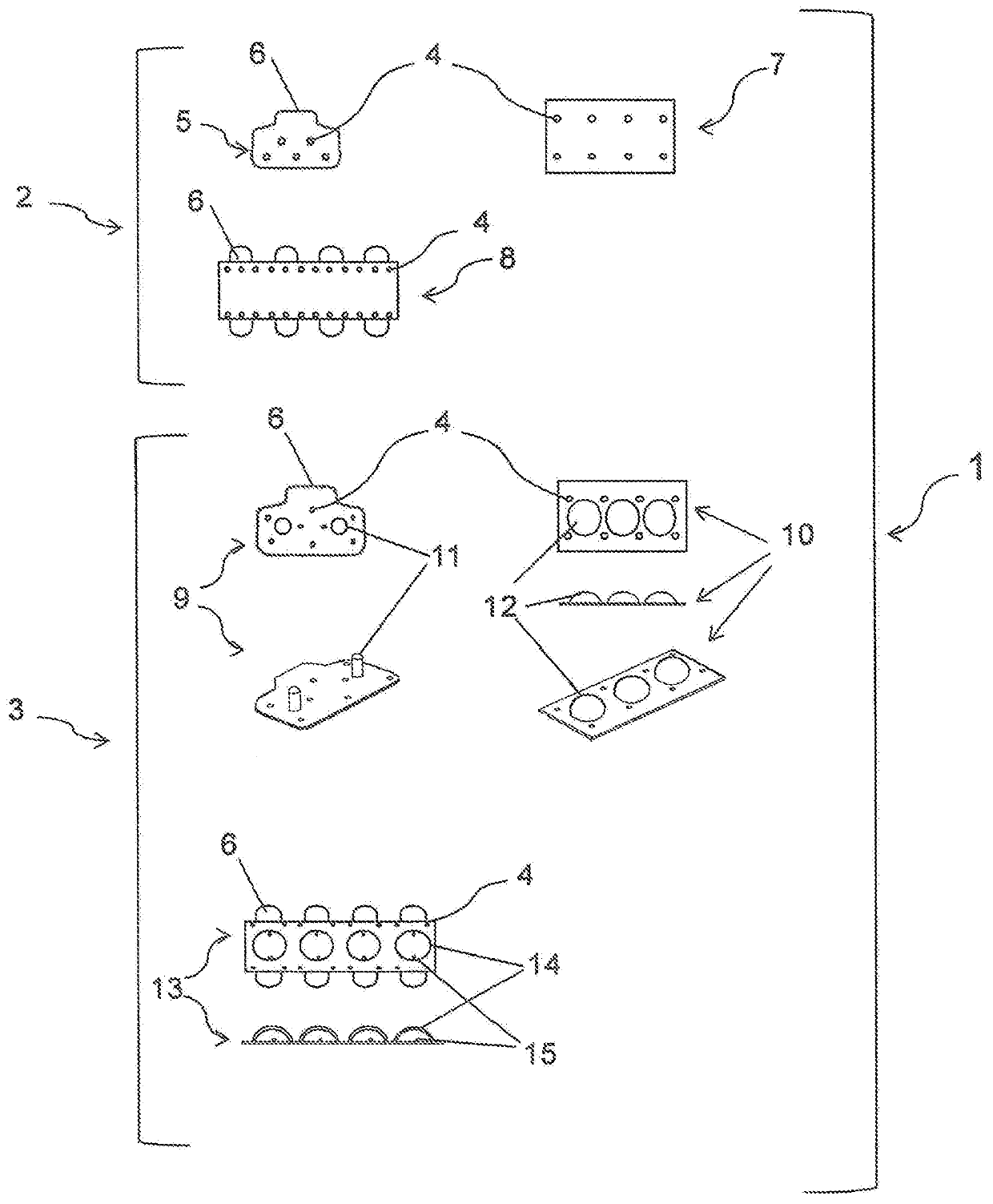

Virtual design of attachment of dental model in articulator

ActiveUS20140242539A1Effective expansionImpression capsMechanical/radiation/invasive therapiesDental ArticulatorsOcclusal appliance

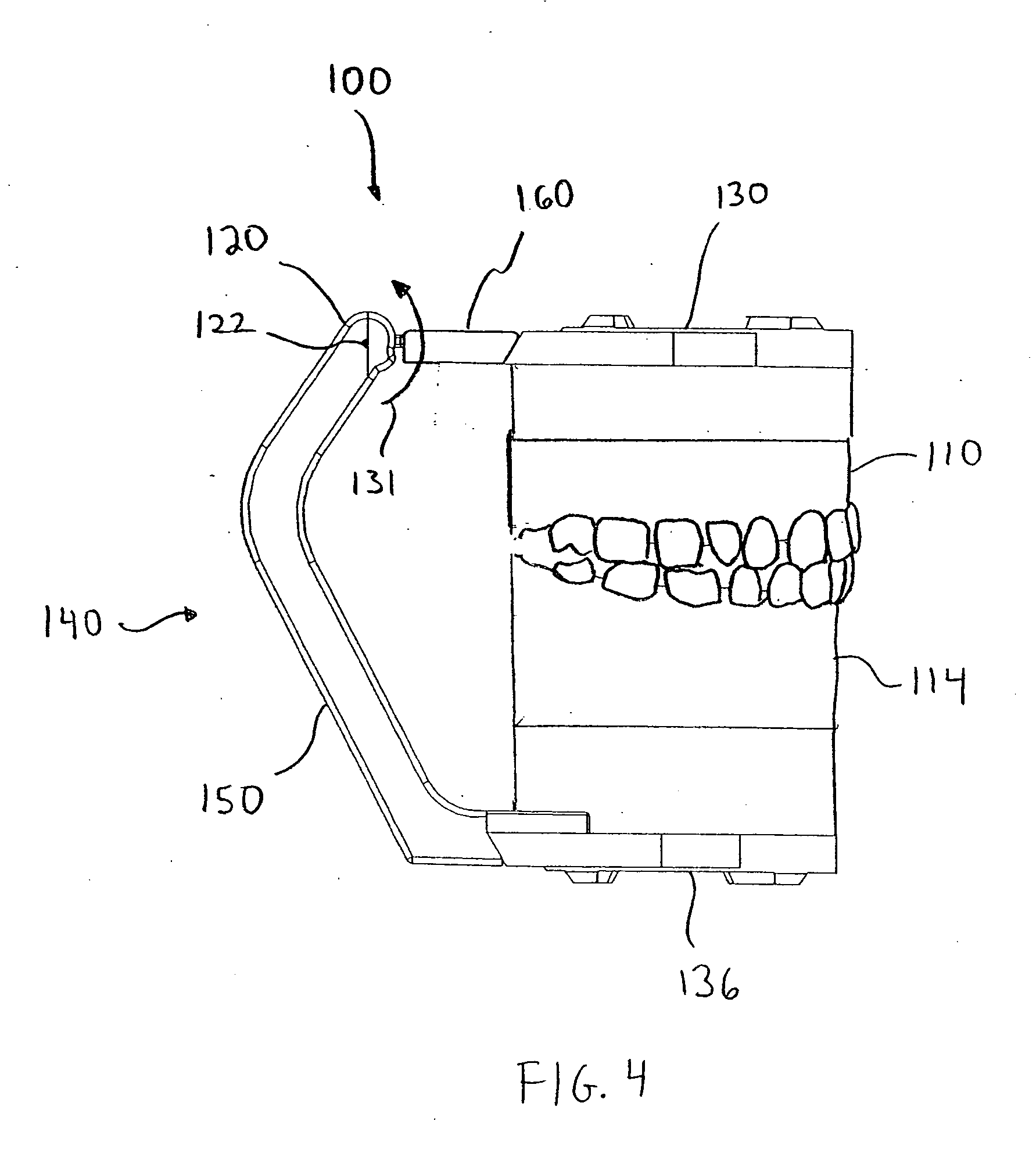

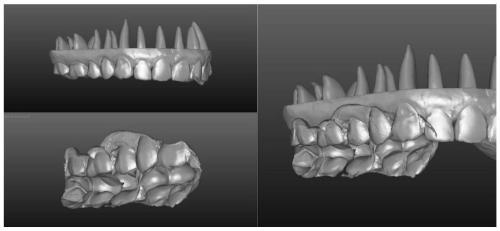

Disclosed is a method for virtually designing the attachment of a manufactured dental model of a patient's set of teeth in a physical dental articulator by means of one or more kinds of spacer elements, where the method comprises:obtaining a virtual 3D dental model of the patient's set of teeth, where the virtual 3D dental model is provided by means of 3D scanning;providing a virtual dental articulator type corresponding to a physical dental articulator, where the dental articulator comprises an upper arm and a lower arm and has a known articulator height, which is the distance between the upper arm and the lower arm in the static position of the dental articulator;providing a minimum height of the dental model, where the height of the dental model is the height of an upper part and the height of a lower part of the dental model;providing one or more kinds of virtual spacer elements with predetermined heights, where each kind of virtual spacer element corresponds to a physical spacer element;determining a manufacture height of the dental model and determining the number of each of the kinds of spacer elements to be used for the attachment of the manufactured dental model in the physical articulator,such that the manufacture height of the dental model and the total effective spacer element height, which is the added height of the determined spacer elements, equal the articulator height, and where the manufacture height of the dental model is not less than the minimum height of the dental model.

Owner:3SHAPE AS

Dental Articulator

A dental articulator is provided in which at least one of the two arms thereof has a base member that is articulated with respect to a bracket element onto which a dental model may be mounted, allowing independent movement of the dental model with respect to the pivot axis hingedly linking the arms.

Owner:ALIGN TECH

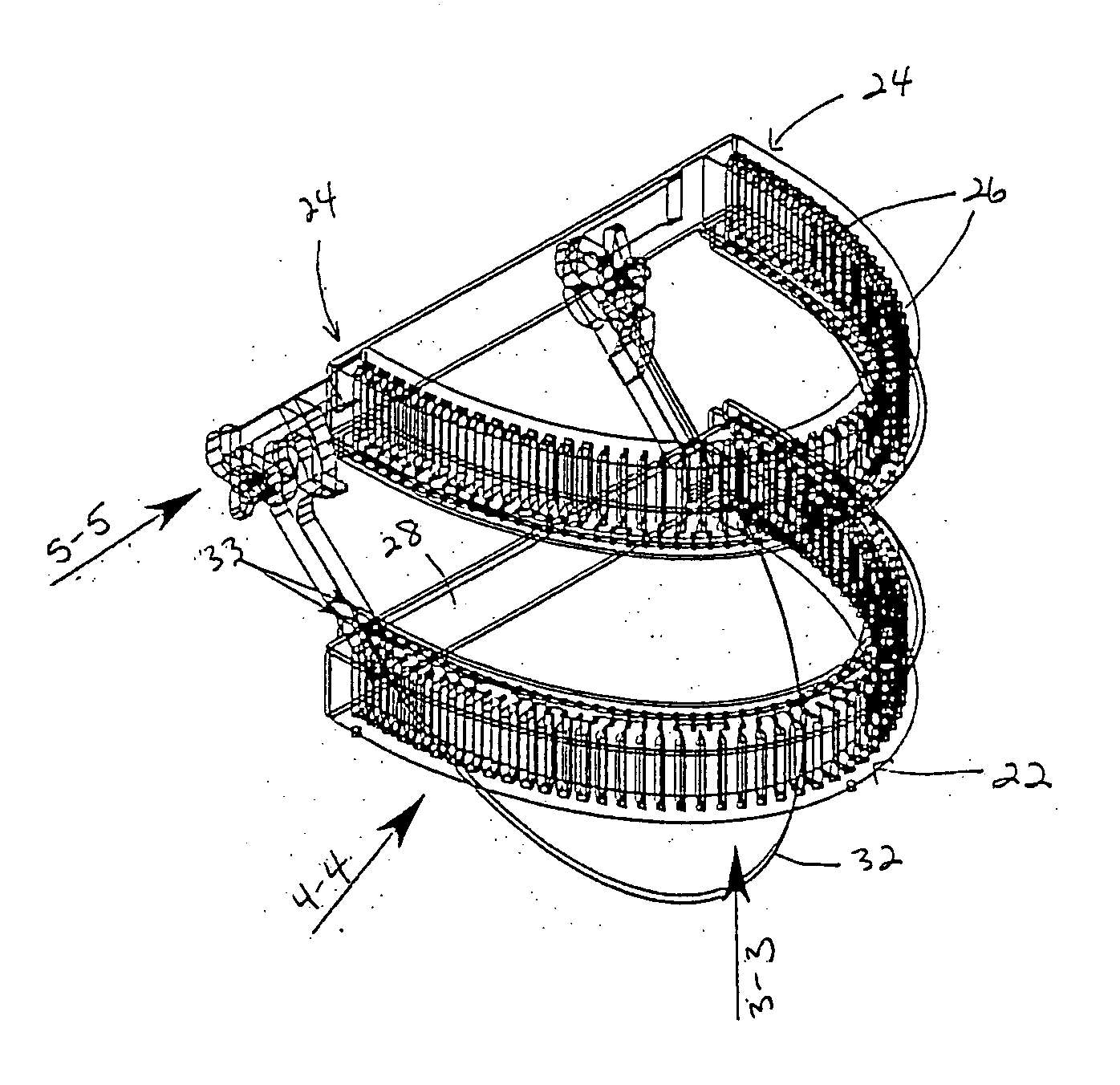

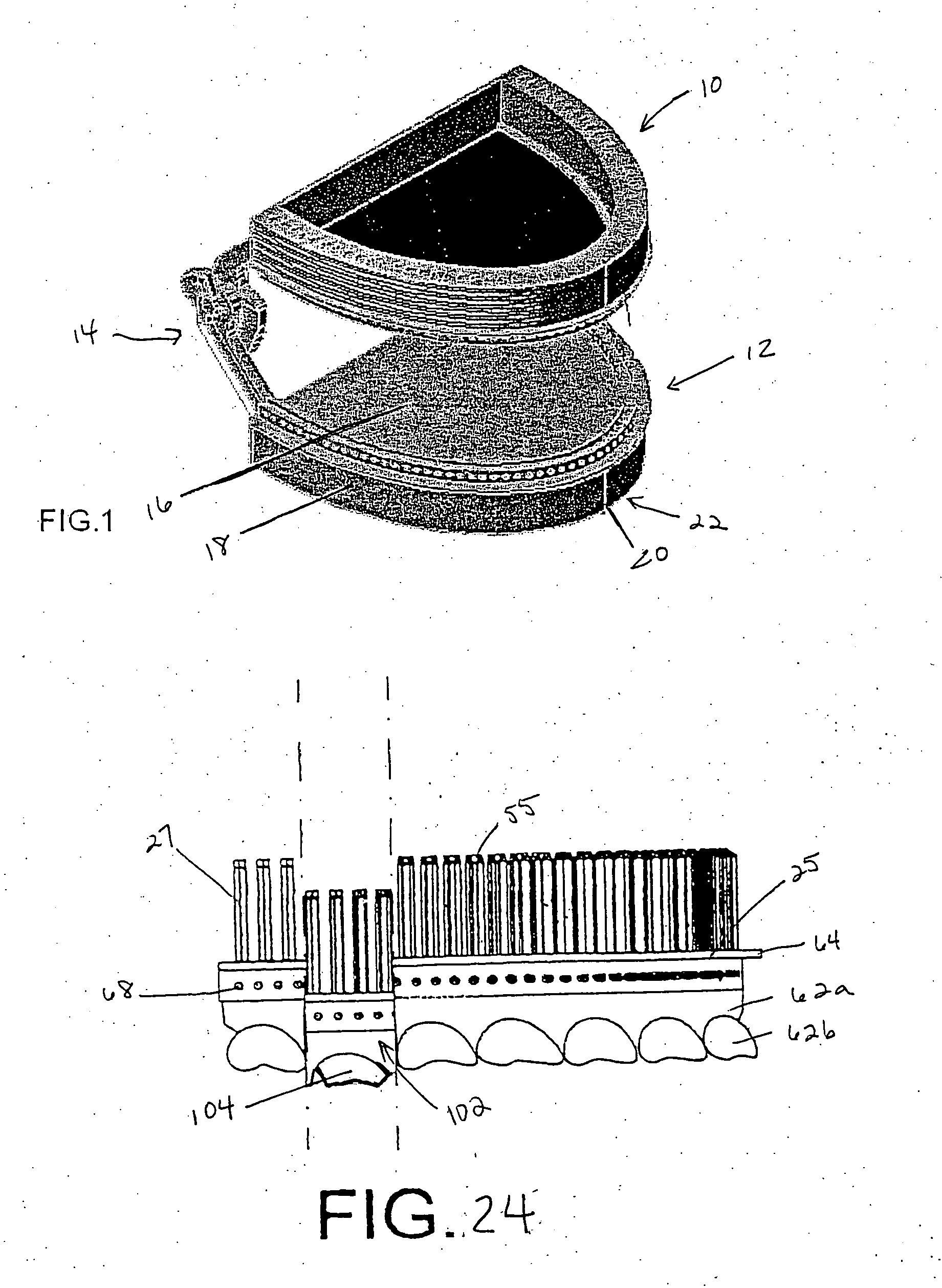

Dental device for modeling system with articulator, adjustable articulator stand, classified label and protective cover

InactiveUS20050089815A1Simple and convenient procedureMinimize timeImpression capsDental articulatorsDental ArticulatorsModel system

A three-dimensional articulator model having upper and lower base members movable in relation to each other through the action of a hinged articulator joint mechanism, and also having a built-in work stand and label assembly that is adjustable with the articulator mechanism. Each of the arch-shaped base members has a plurality of channels extending therethrough to receive a corresponding dowel pin tray having plurality of outwardly extending dowel pins with grooved end surfaces to facilitate insertion and removal of the pins from the base members. Dental casts are formed upon the dowel pin trays and the movement of the articulator provides for full jaw movement simulation through the design of the articulator joint mechanism. The workstand and label assembly provides a convenient and organized means for working on the model as well as for tracking the information associated with the particular model upon completion thereof, and the model is easily and safely transported in a specially designed carrying cover that protects the model while also providing identifying information in conjunction with the classification panel of the label assembly.

Owner:LEE WAN KI

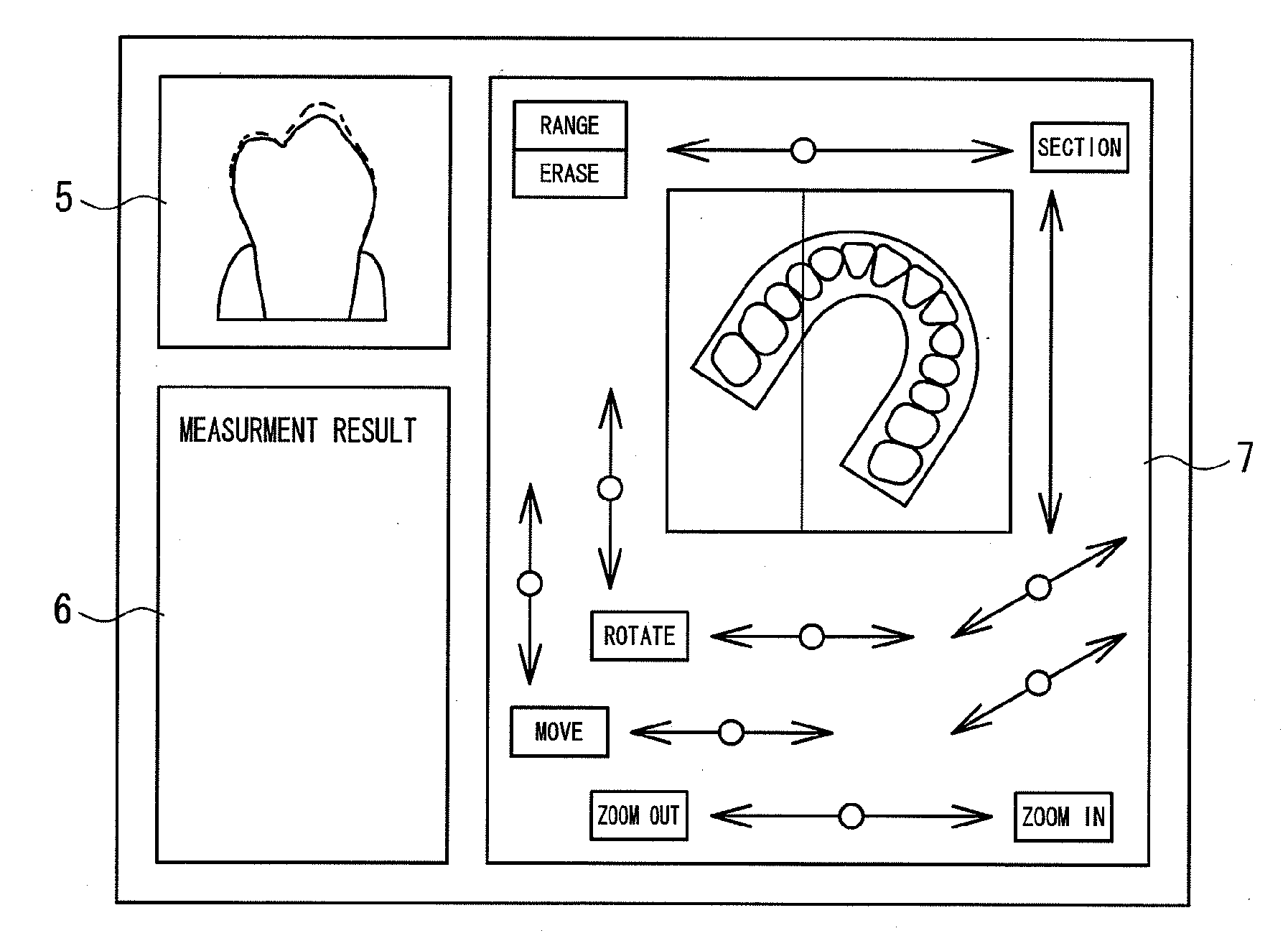

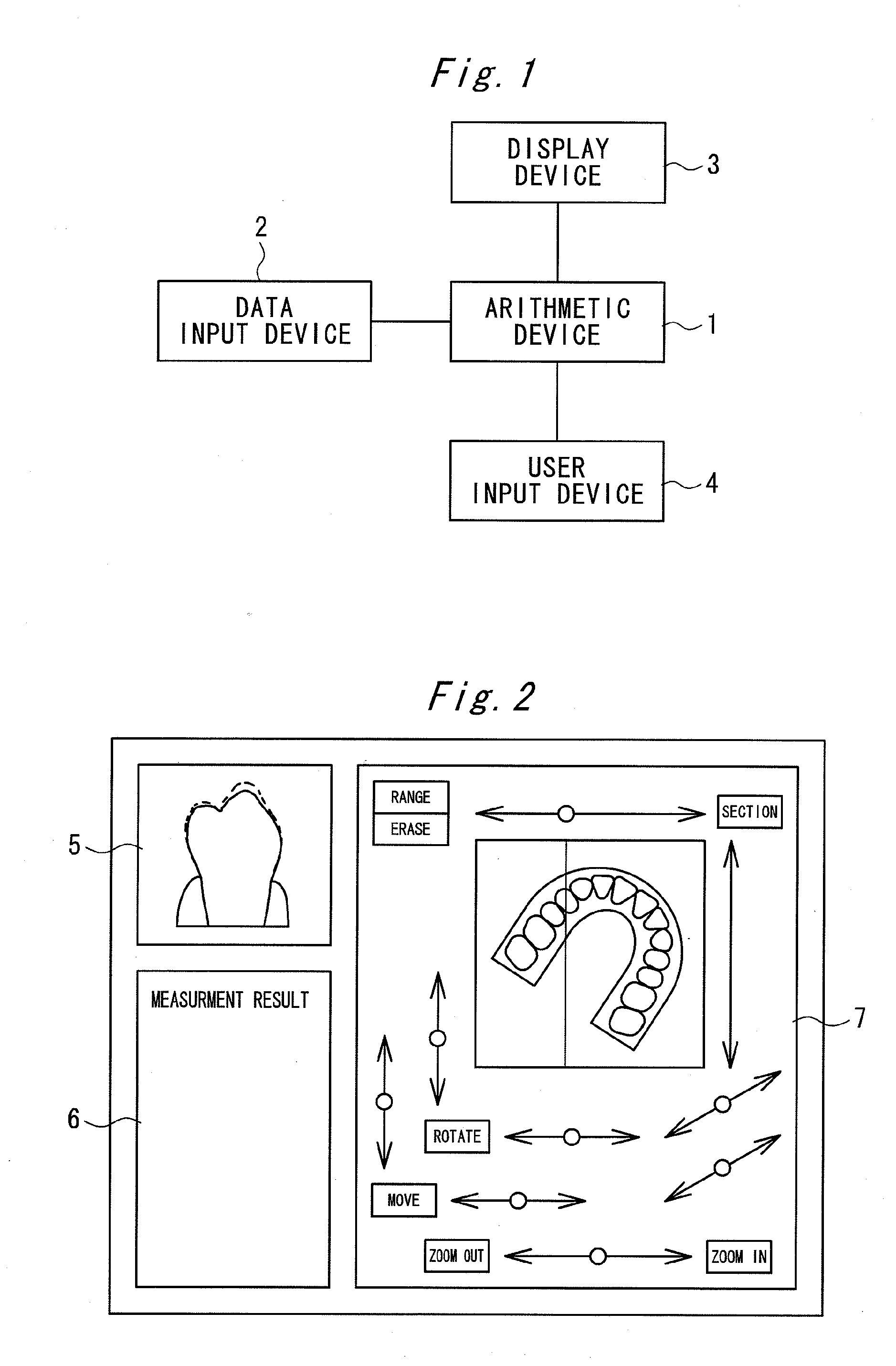

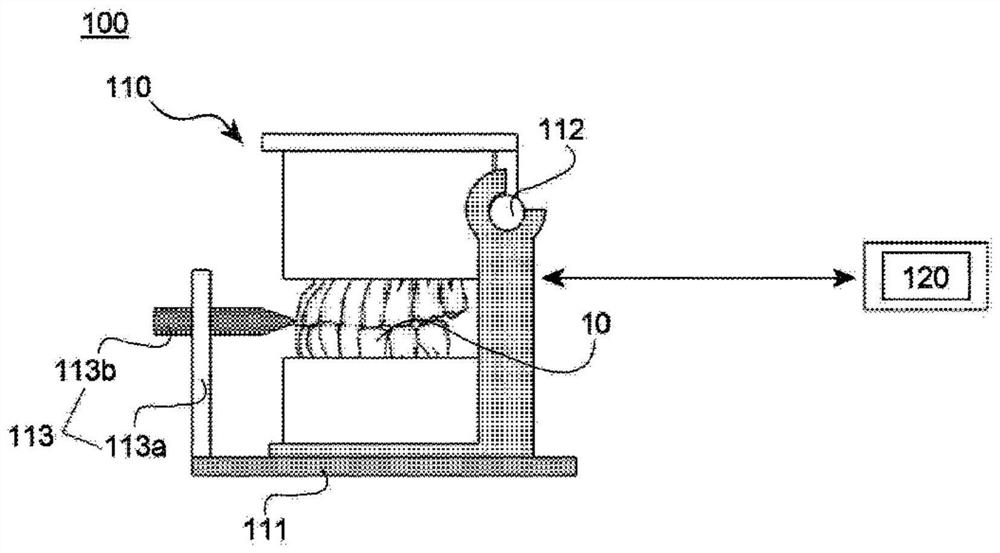

Occlusal wear evaluation apparatus and occlusal wear evaluation method

InactiveUS20130054190A1Accurate diagnosisReduce unevennessMedical simulationDigital computer detailsDental ArticulatorsDentures

An occlusal wear evaluation apparatus capable of evaluating quantitatively an occlusal wear of a used denture reads three dimensional data of a denture before use and three dimensional data of the denture after use, calculates a difference in a set value of an articulator allowing the maxillary dental arch and the mandibular dental arch of the denture to occlude between the denture before use and the denture after use, by way of simulating movements of a jaw in the articulator with the three dimensional data of the denture before use and the three dimensional data of the denture after use, and indicates the calculated difference.

Owner:SHOFU INC

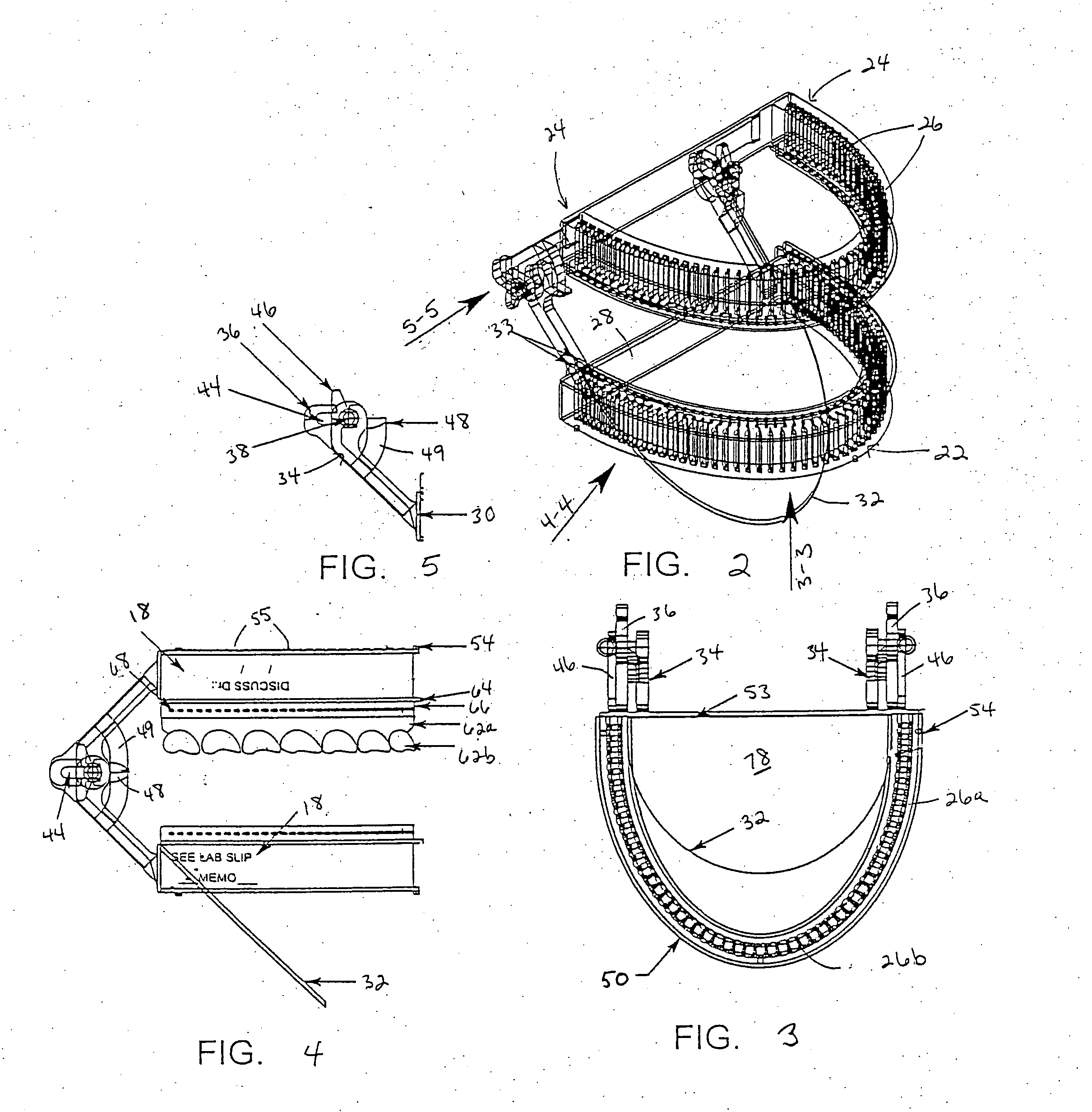

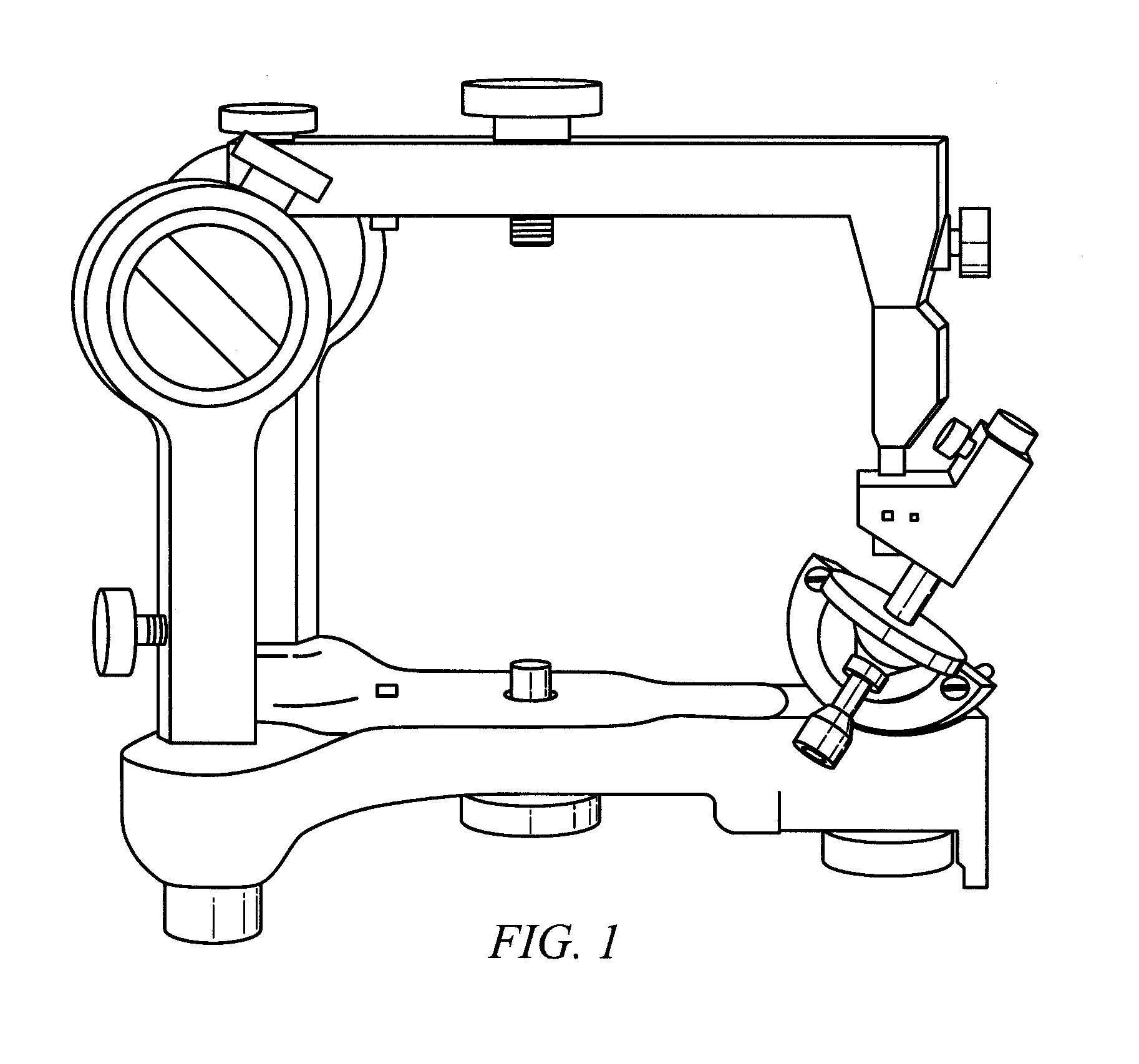

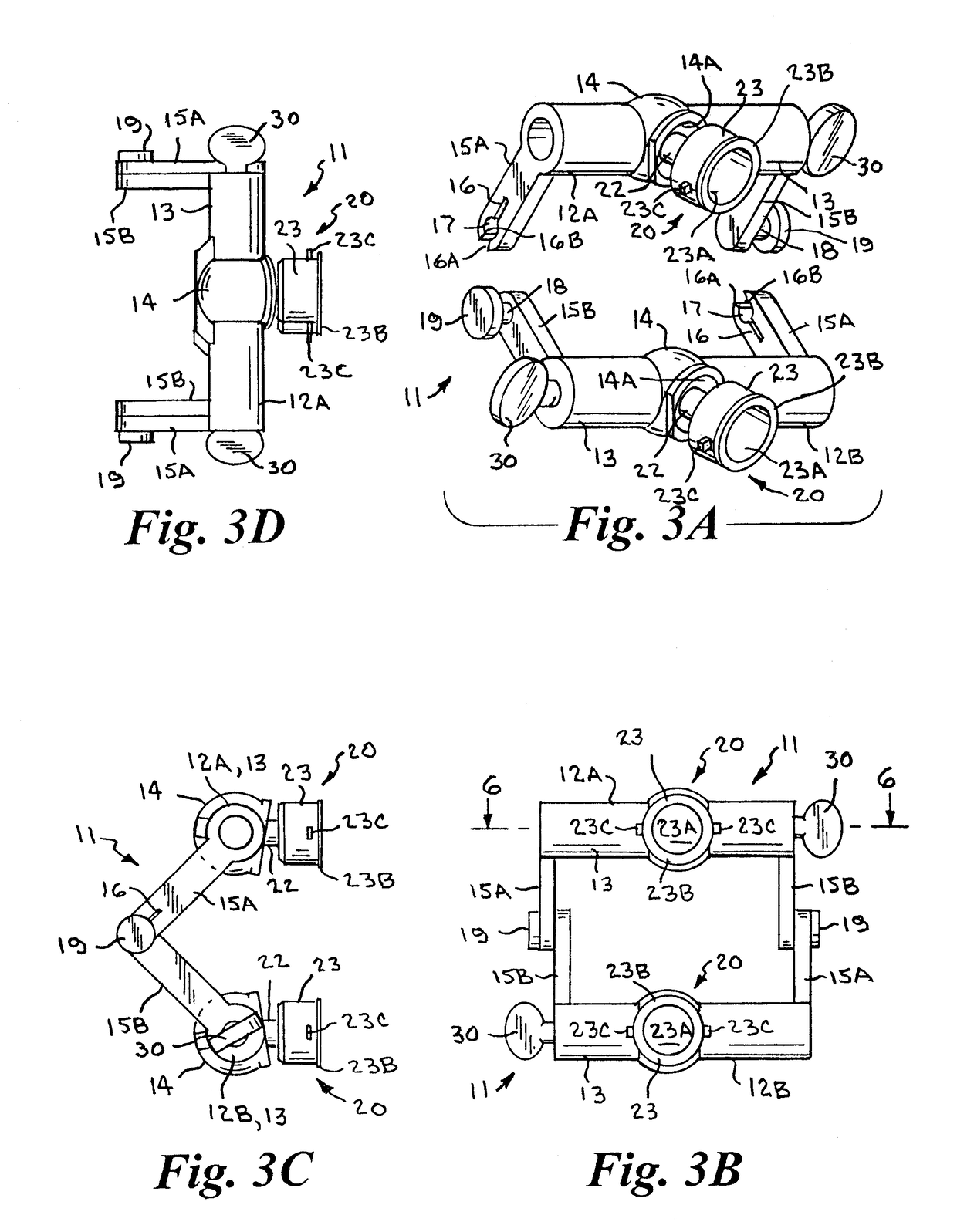

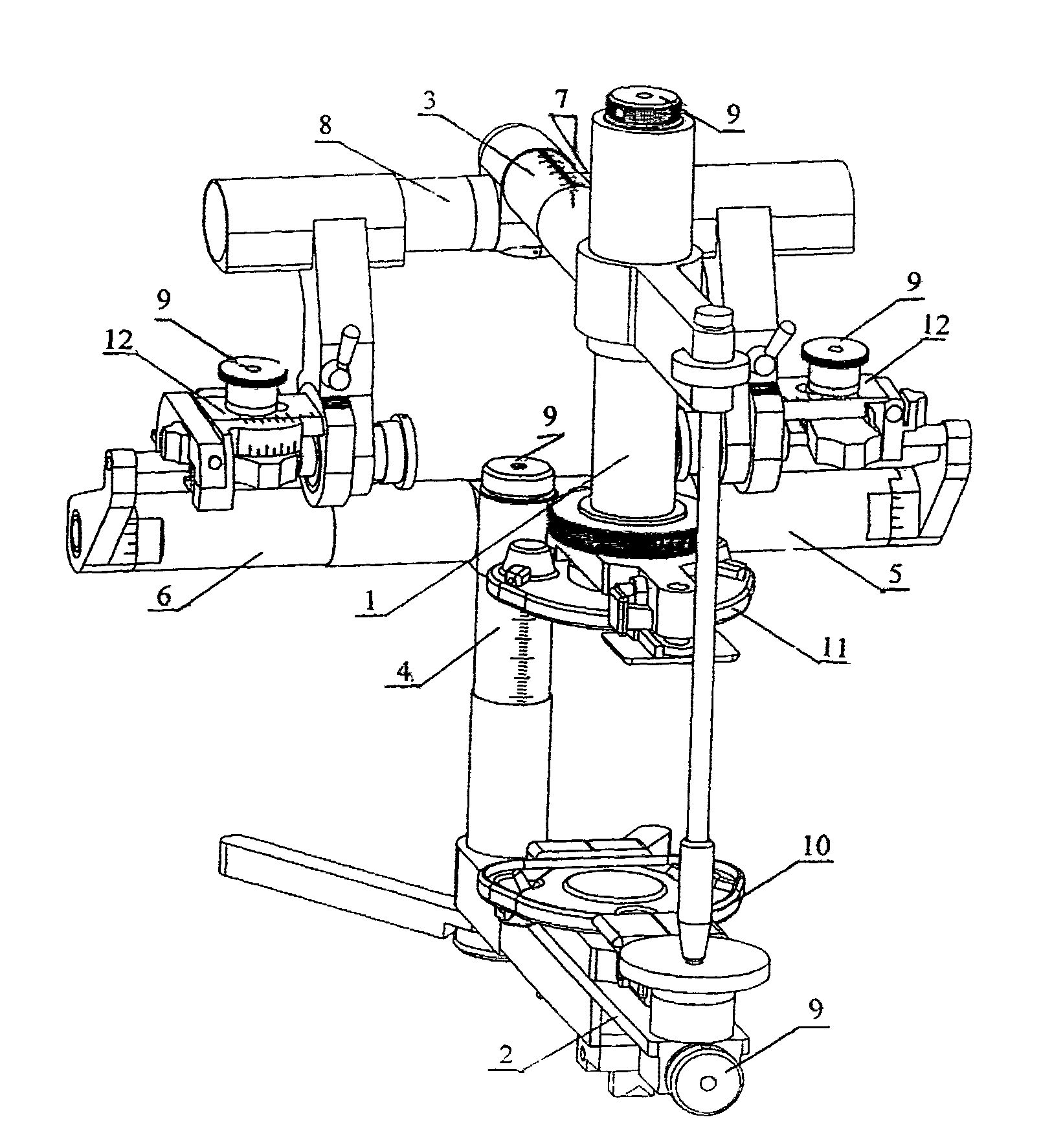

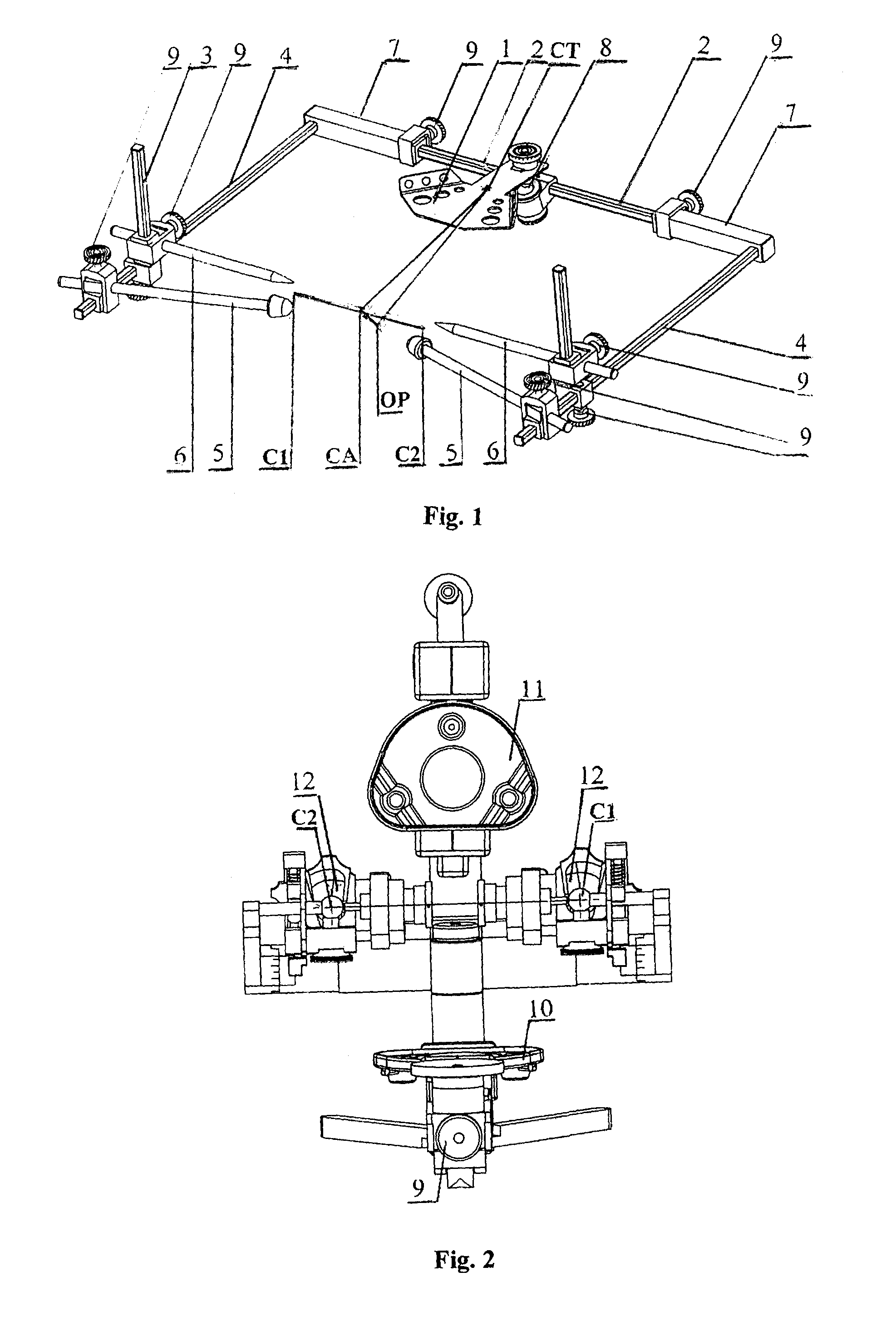

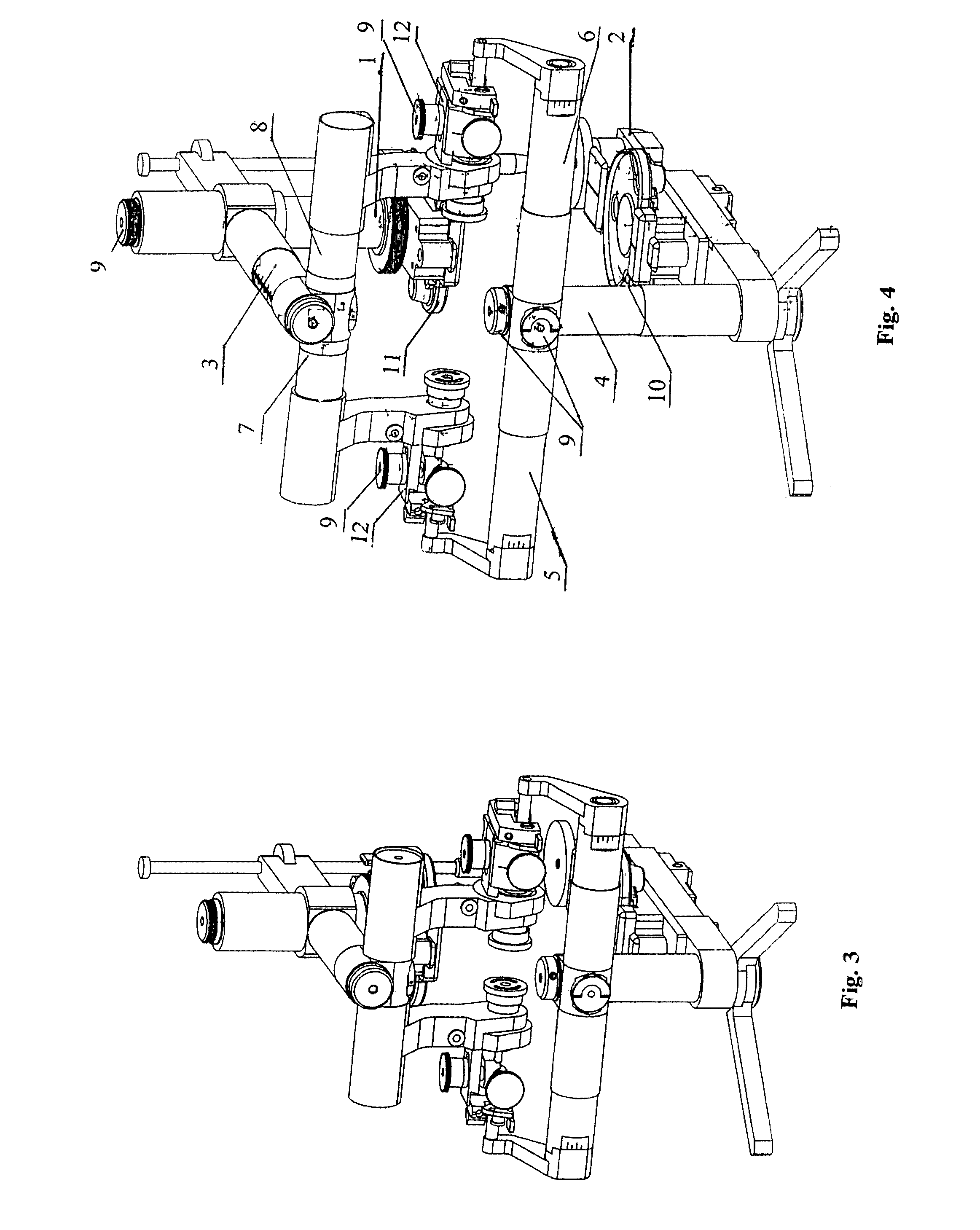

Method for articulator adjustment and gnathological instruments for work under this method

ActiveUS20150147726A1Improve accuracyImprove reliabilityImpression capsDental articulatorsOcclusal applianceOcclusal plane

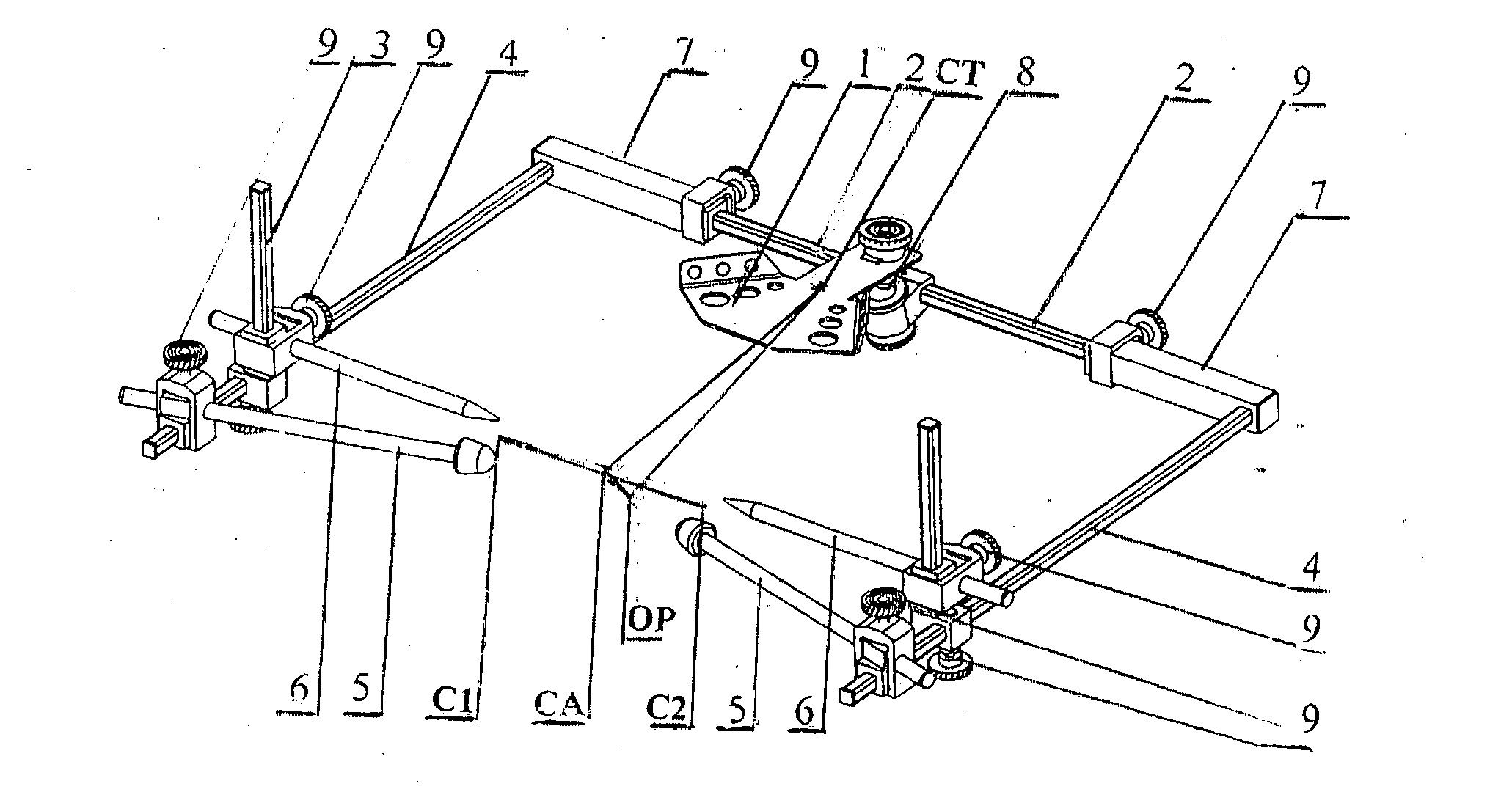

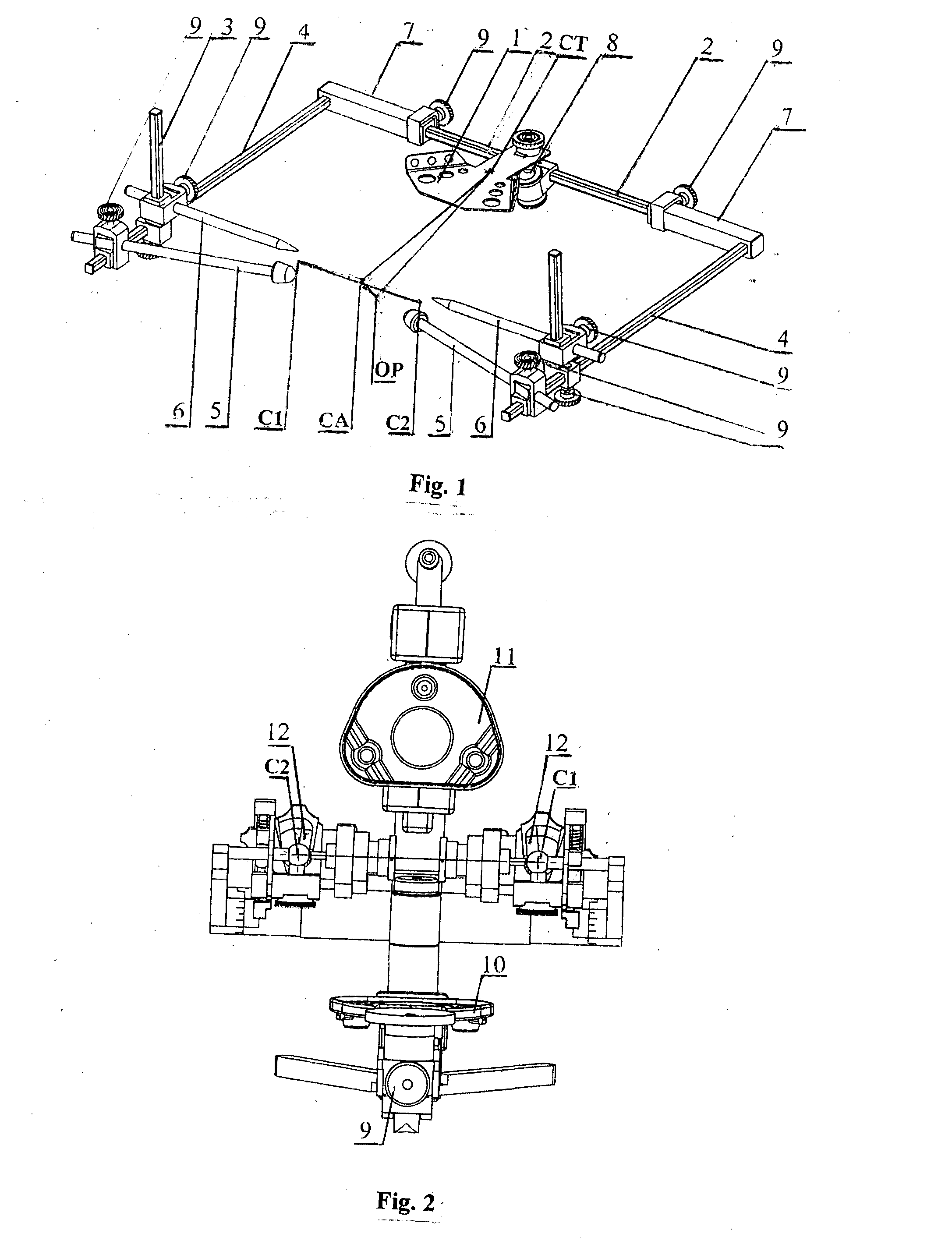

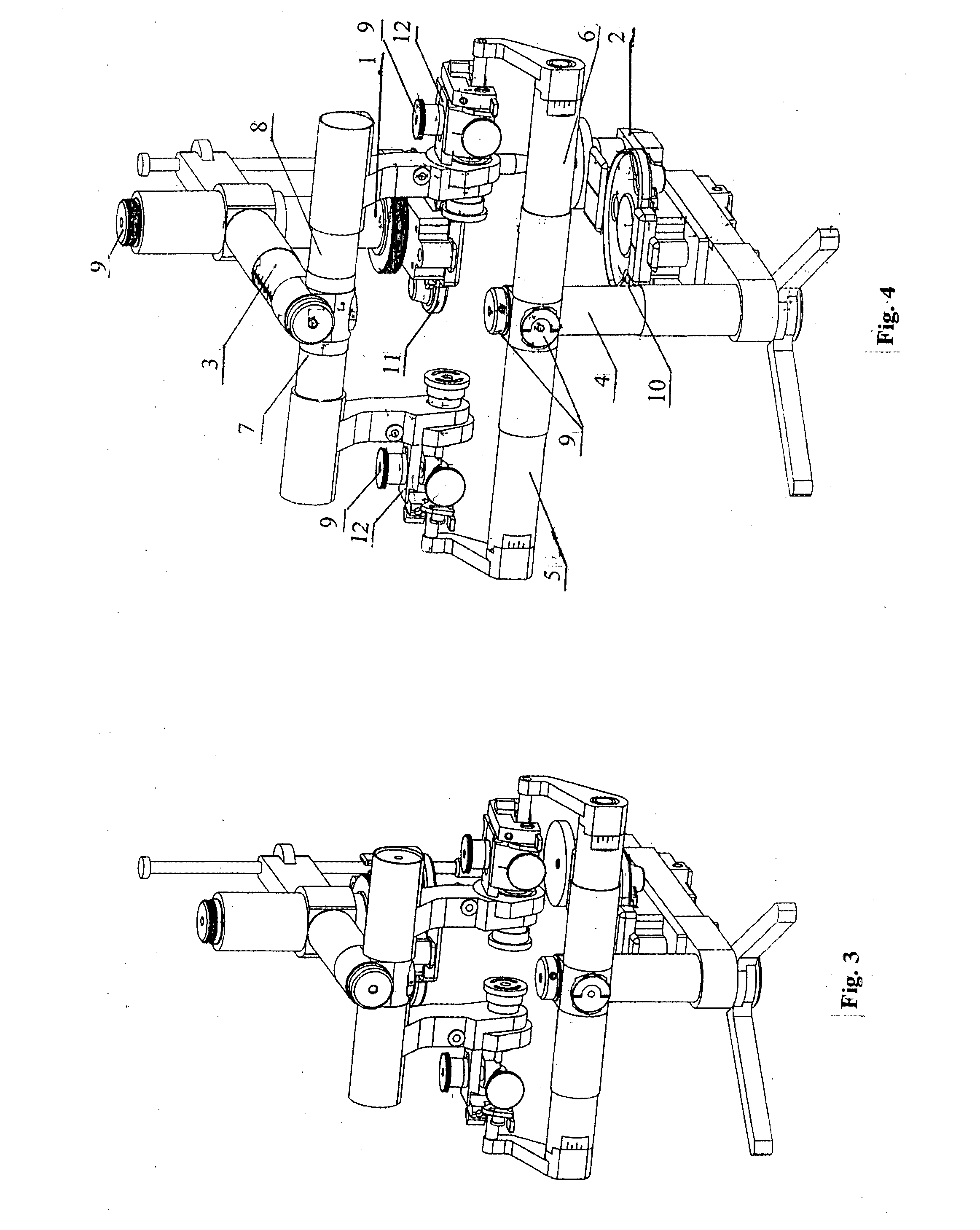

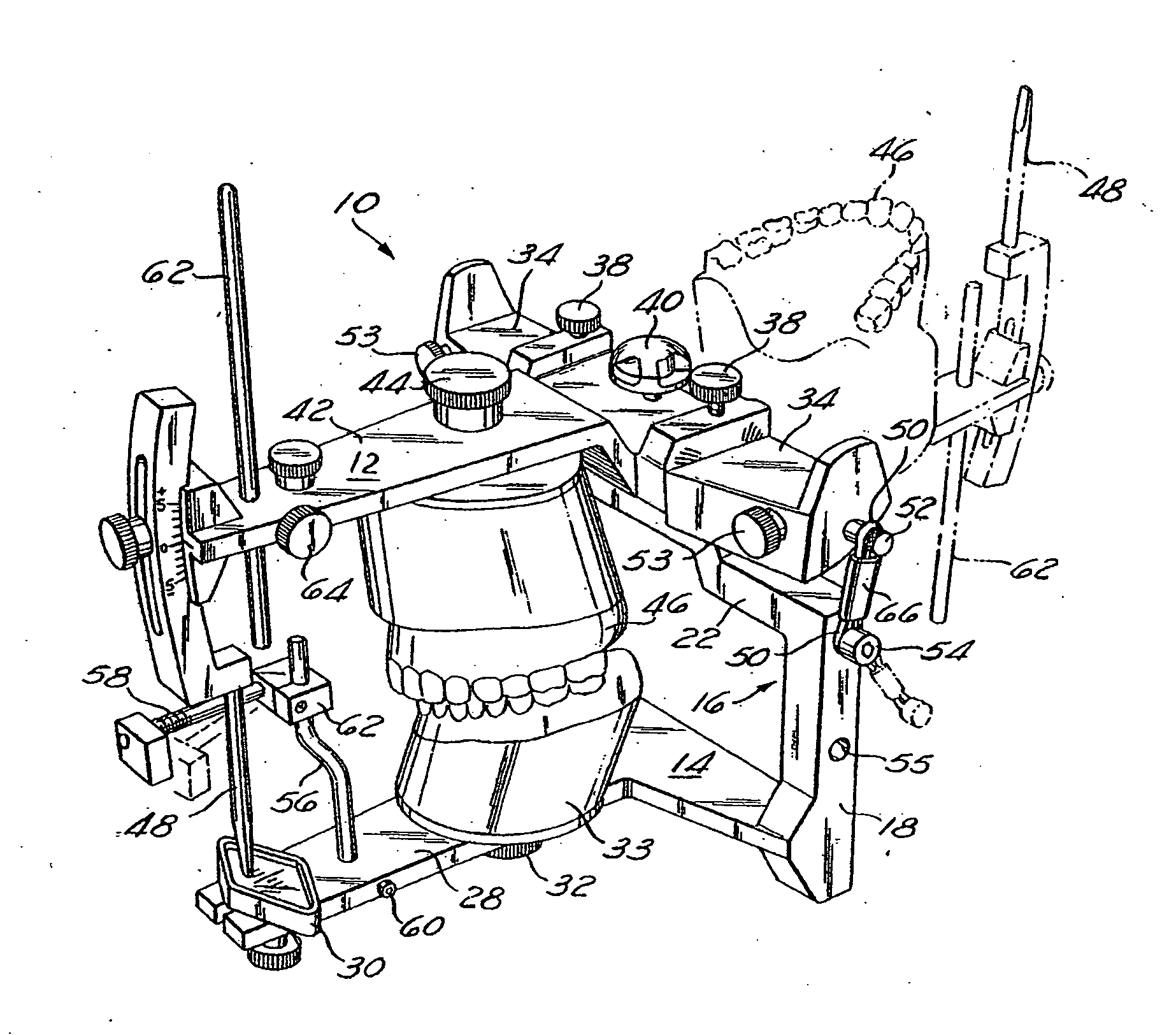

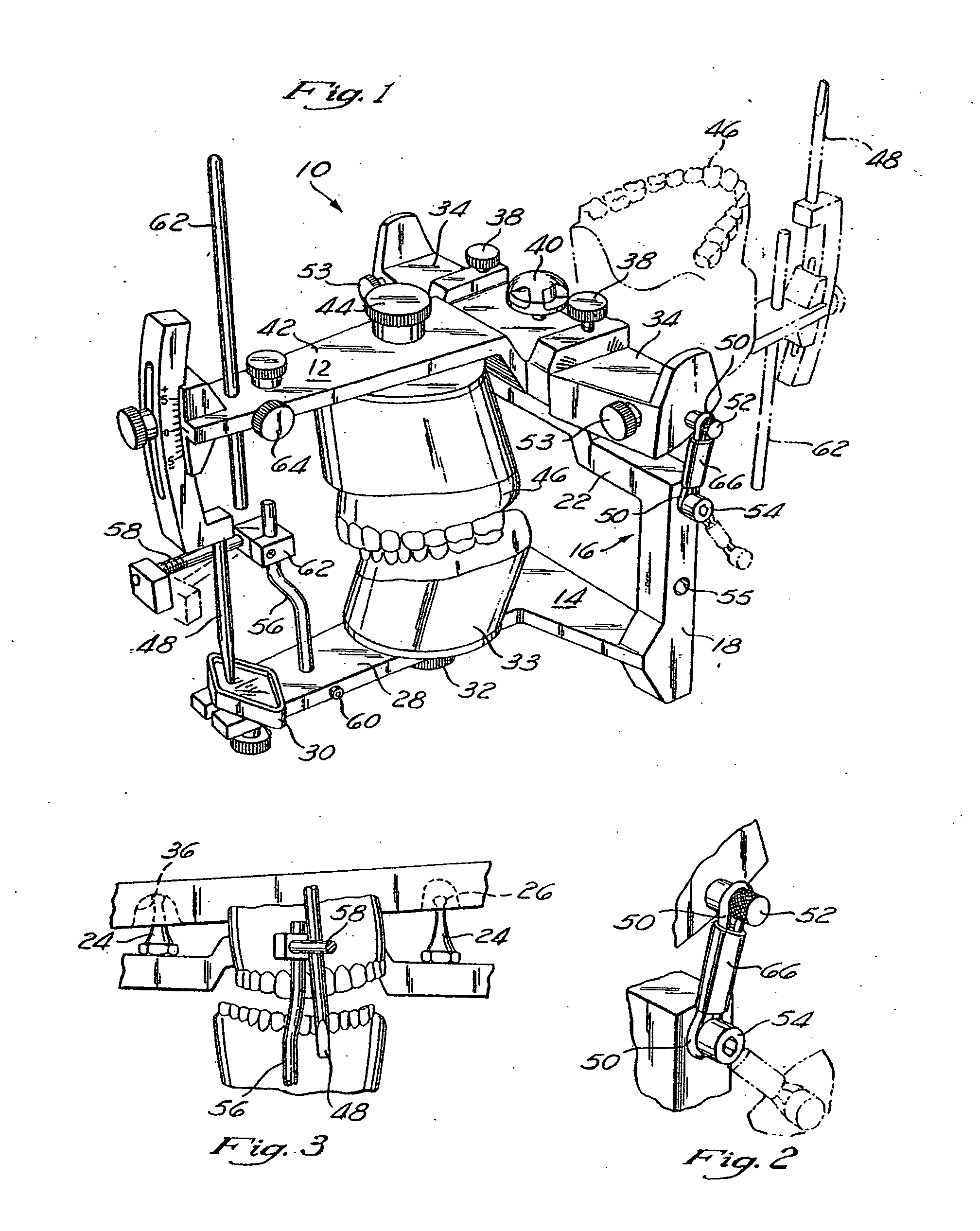

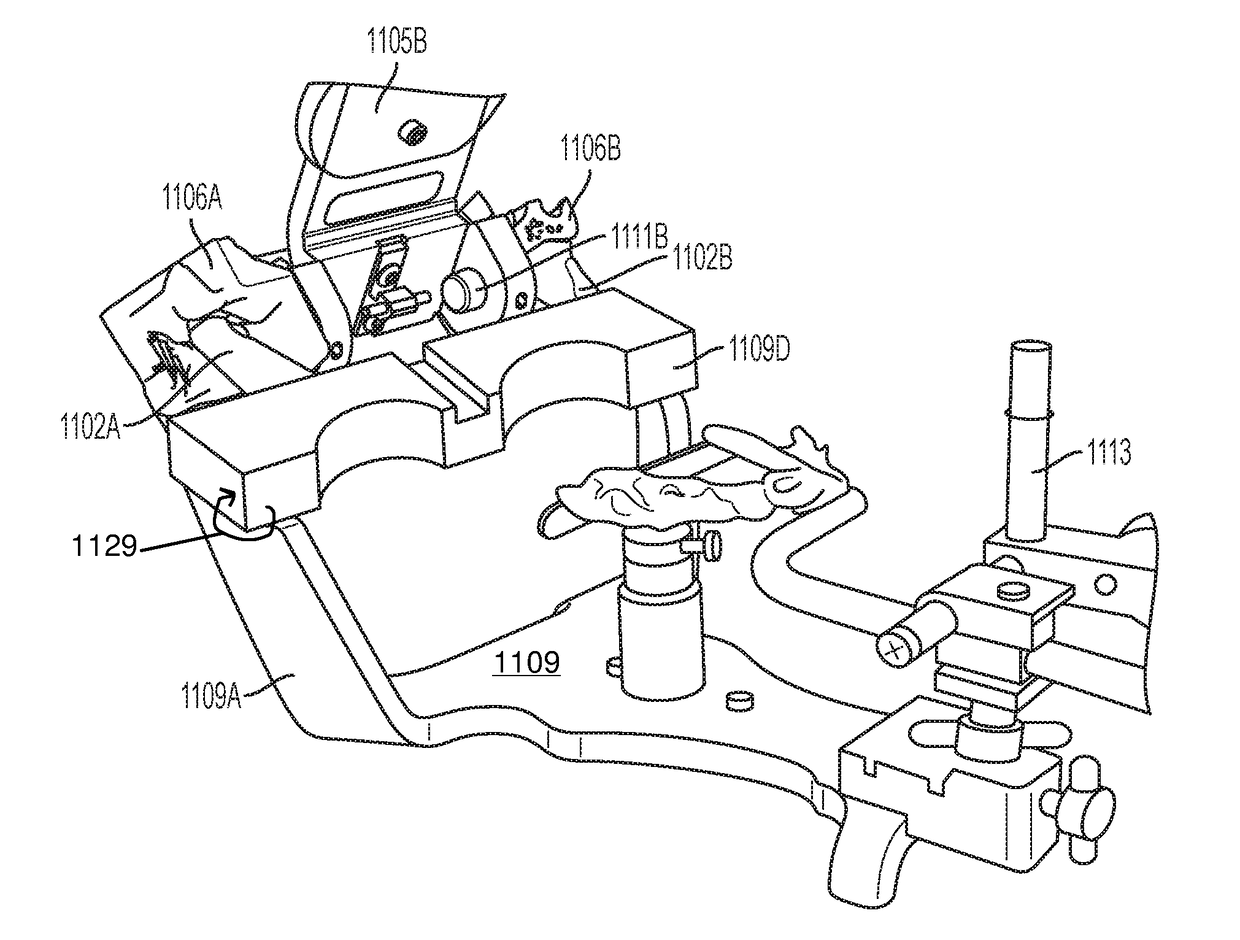

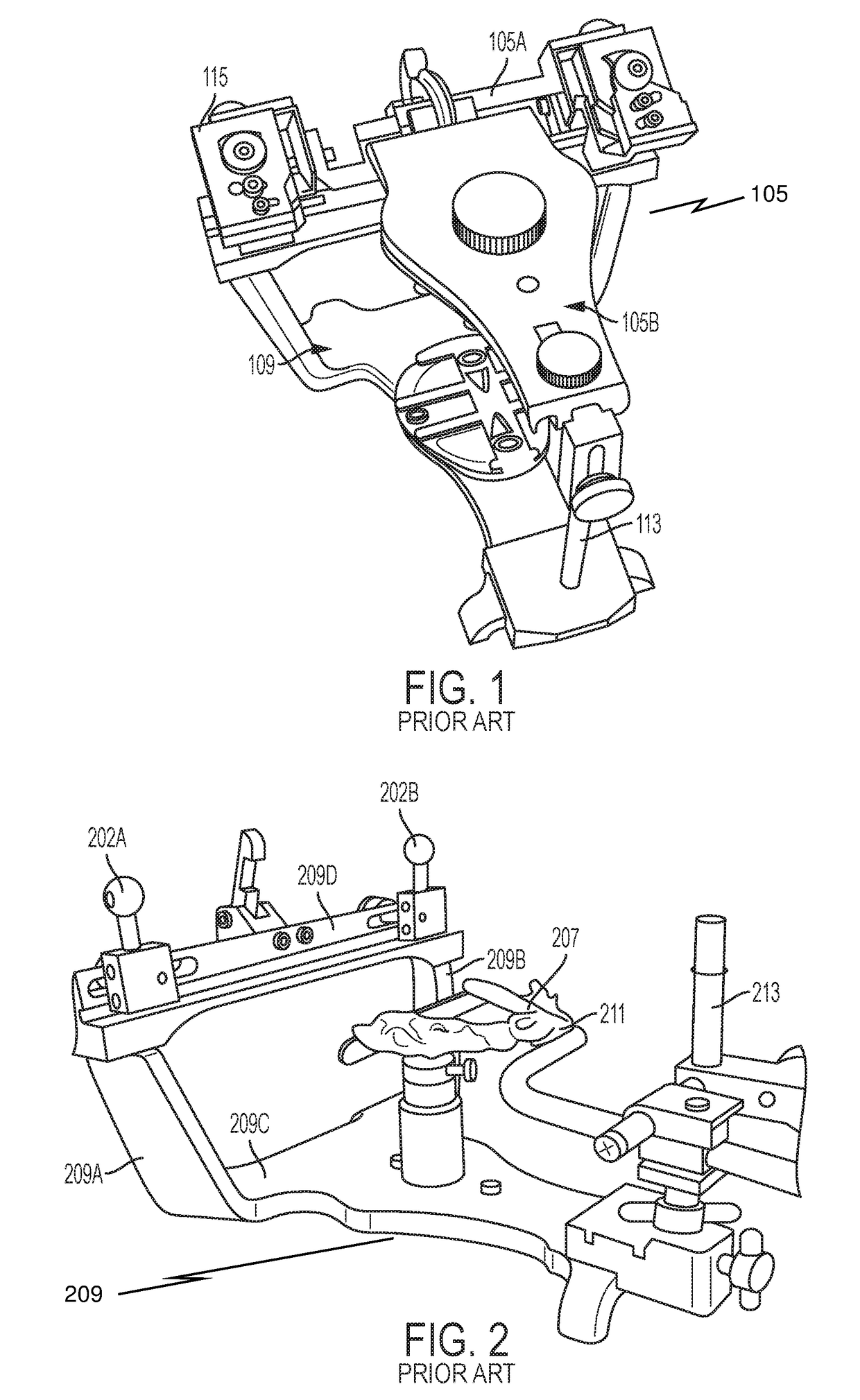

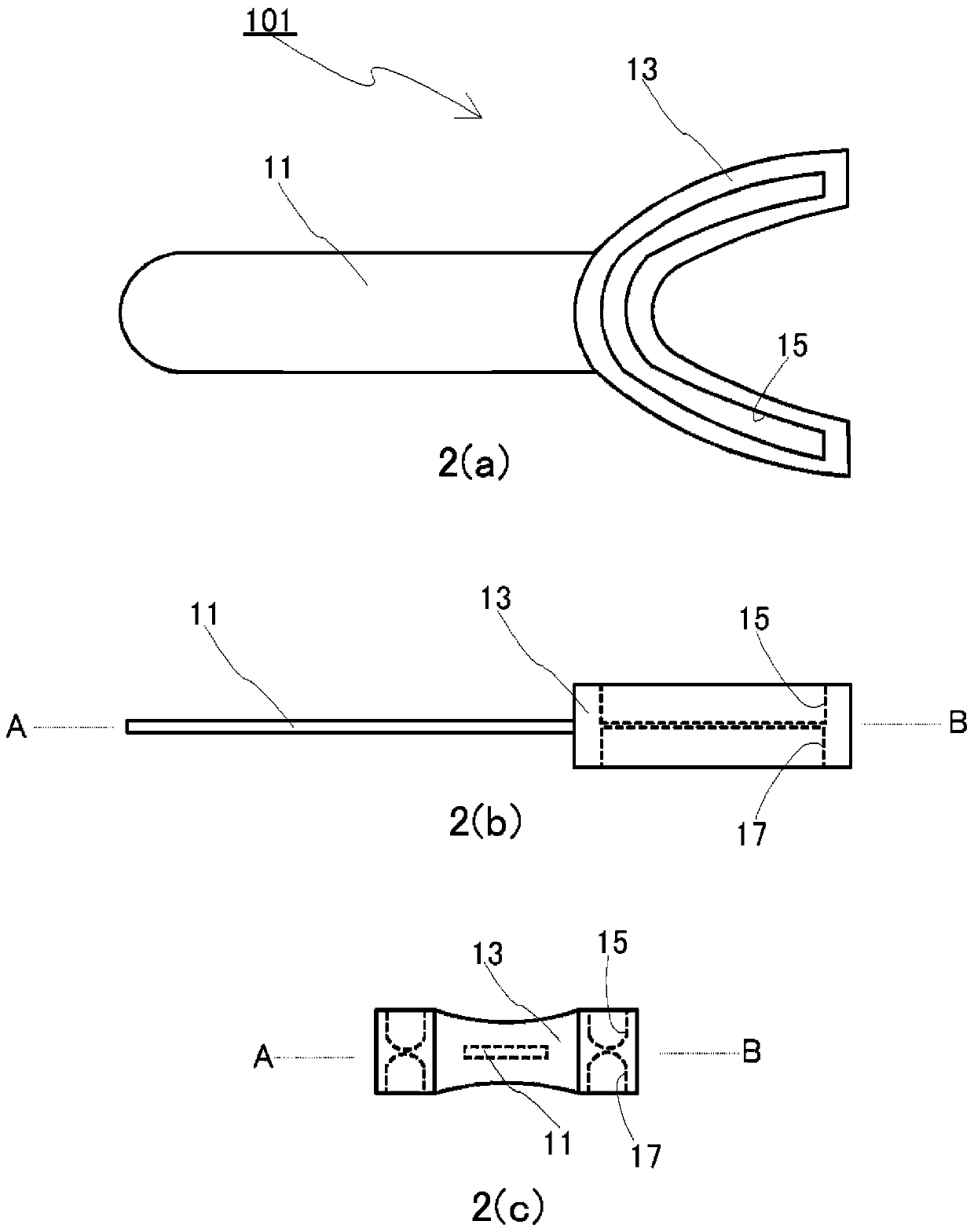

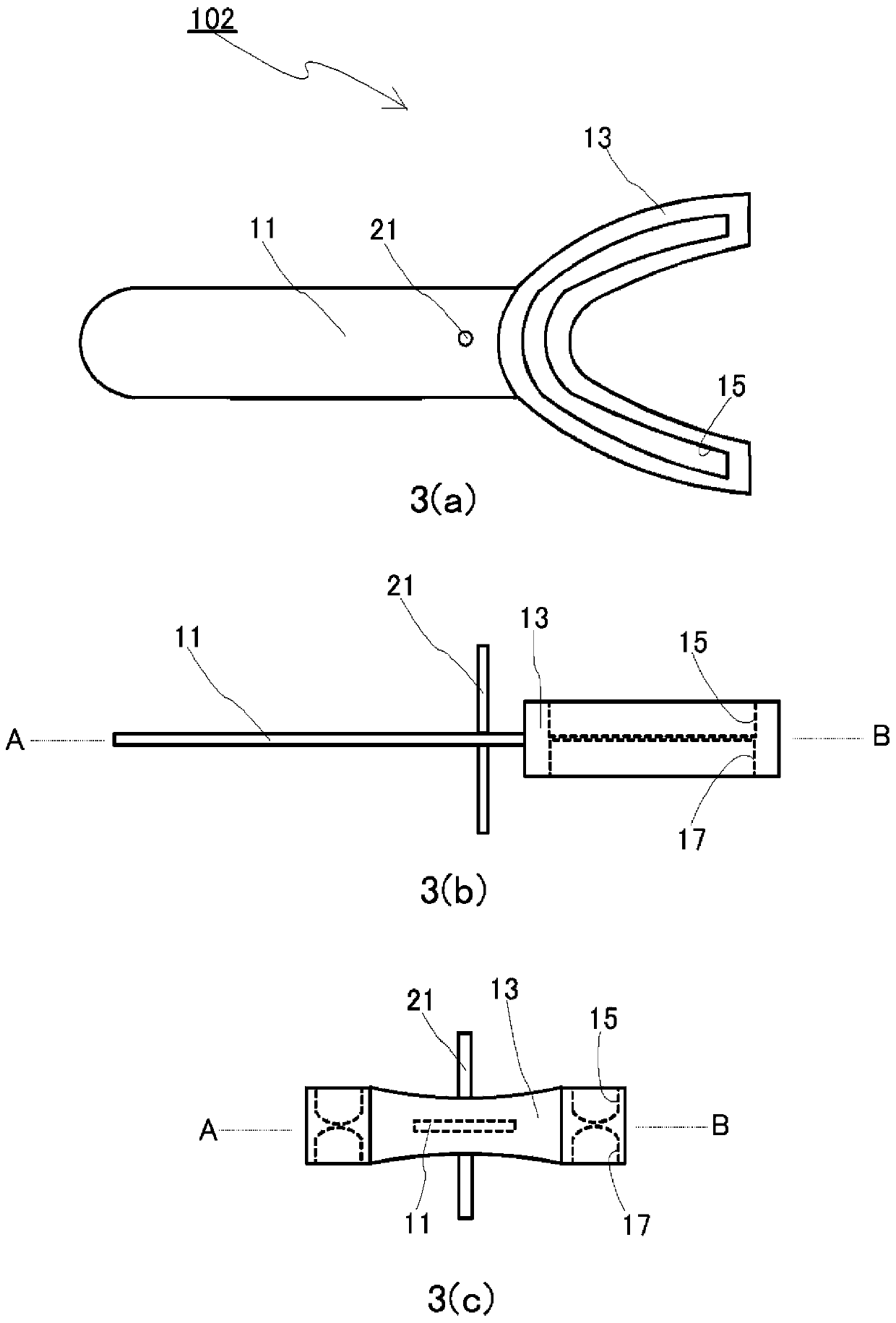

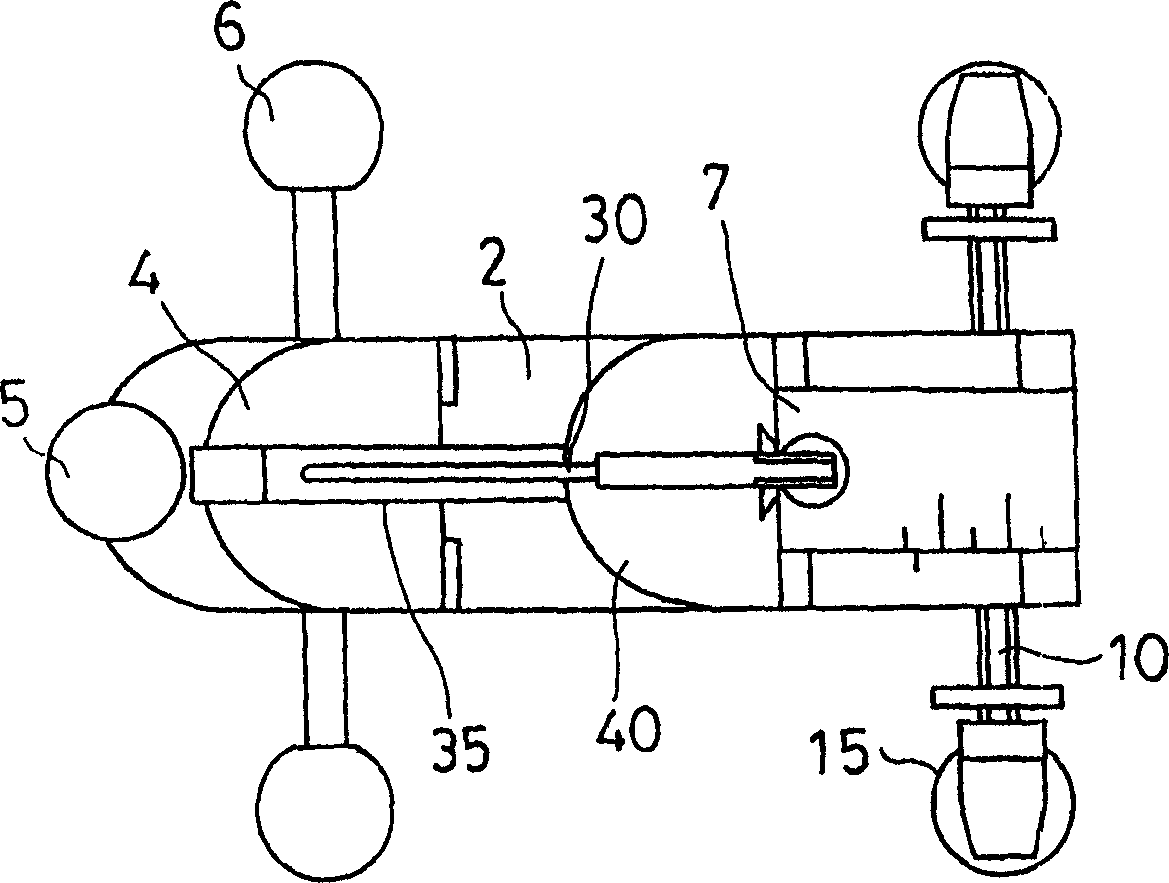

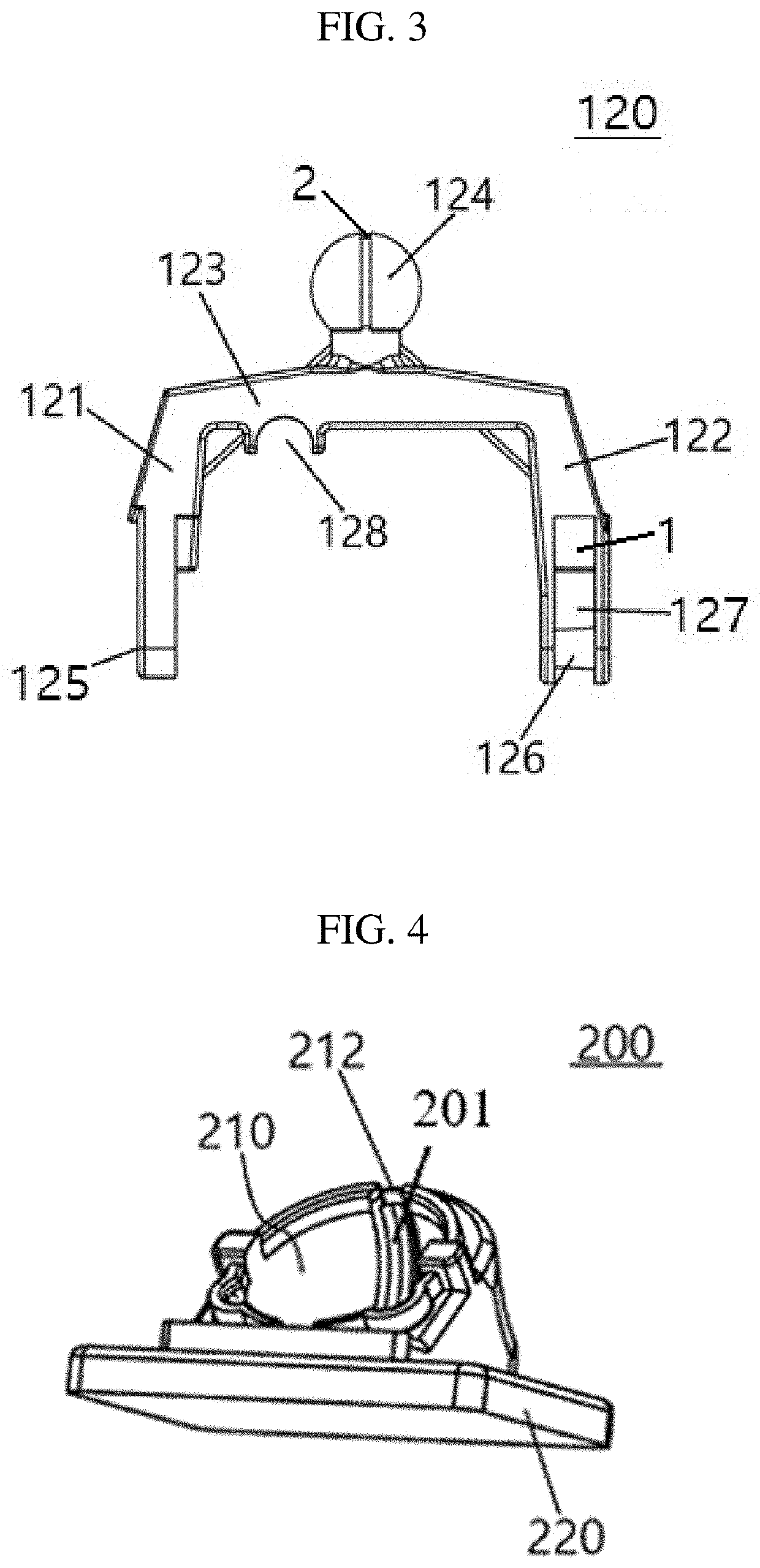

The method for articulator adjustment and gnathological instruments for work under this method find application in dental medicine and laboratory dental techniques. These and other goals of this invention are achieved with the measurement of the individual parameters of the patient's mandibular transversal hinge axis in the three planes: transversal, frontal and sagittal, including the following steps: measurement of inter-condylar distance; measurement of the distance between the condylar axis and the occlusal plane; measurement of the distance between the condylar axis and central incisors with a face-bow and bite-tray (FIGS. 1,10,11,12); recording of values; simultaneous fixation in the articulator in minimal gathered position of the manufactured in advance two primary working models juxtaposed in central position: a mandibular lower working model to the working plate of the lower articulator frame and a maxillary upper working model to the opposite working plate, which is connected in a telescopic way to the upper articulator frame (FIGS. 2,3,4,5,6,13); coincidence of the mandibular transversal hinge axis of a patient in terms of measured values of his individual parameters and the articulator transversal hinge axis (FIGS. 7,8,9,14); and closure of this articulator in an individual spread-out position.

Owner:F ARTICULATOR DENT

Dental articulator

ActiveUS20070134619A1ManipulatedSimple working processDental articulatorsEducational modelsDental ArticulatorsDental plaster

A dental articulator includes an articulator frame. The articulator frame has an upper member adapted to hold an upper mounting plate. The upper mounting plate holds an upper dental cast. An elongate lower member of the frame holds a lower mounting plate. The lower mounting plate holds a lower dental cast. The upper member is pivotally connected to the lower member so as to define an anatomically accurate hinge axis to simulate human jaw movement. The dental articulator can be used to form dental prostheses.

Owner:PANADENT CORP

Method for using dynamic virtual articulator for simulating occlusion when designing dental prosthesis for patient, and data carrier

The group of inventions relates to medical technology, and more particularly to means for dynamic virtual articulation. One of the inventions is a method for using a dynamic virtual articulator for simulating occlusion during a change in the initial position of the lower jaw or fragments thereof, and for modeling the position of the teeth in relation to one another and the position and shape of false teeth, said method being carried out with the aid of a computer. The method includes the following steps: providing a virtual articulator comprising a virtual three-dimensional model of the upperjaw and dental arch and a virtual three-dimensional model of the lower jaw and dental arch, resembling the upper jaw and upper teeth and the lower jaw and lower teeth, respectively, of the patient; and providing simulated movements of the virtual upper jaw and the virtual lower jaw in relation to one another for simulating dynamic occlusion, during which penetrating and non-penetrating contact mayoccur between teeth in the virtual upper and virtual lower jaw. Providing the virtual articulator further includes providing virtual three-dimensional models of the temporomandibular joints, resembling the heads of the lower jaw, the mandibular fossae, and the articular tubercles of the temporal bones, and carrying out simulated movements of the jaws in relation to one another is preceded by clinically or virtually setting initial and final positions. Furthermore, the virtual surfaces of the heads of the lower jaw and the virtual surfaces of the articular tubercles and the mandibular fossae of the temporal bones of the patient are disengaged. A second invention is a non-volatile machine-readable medium with a stored code containing instructions which, when executed, allow the proposed method to be carried out. The group of inventions makes it possible to provide a virtual articulator that simulates as closely as possible the actual processes occurring in the patient's mouth.

Owner:阿范提斯3D有限公司

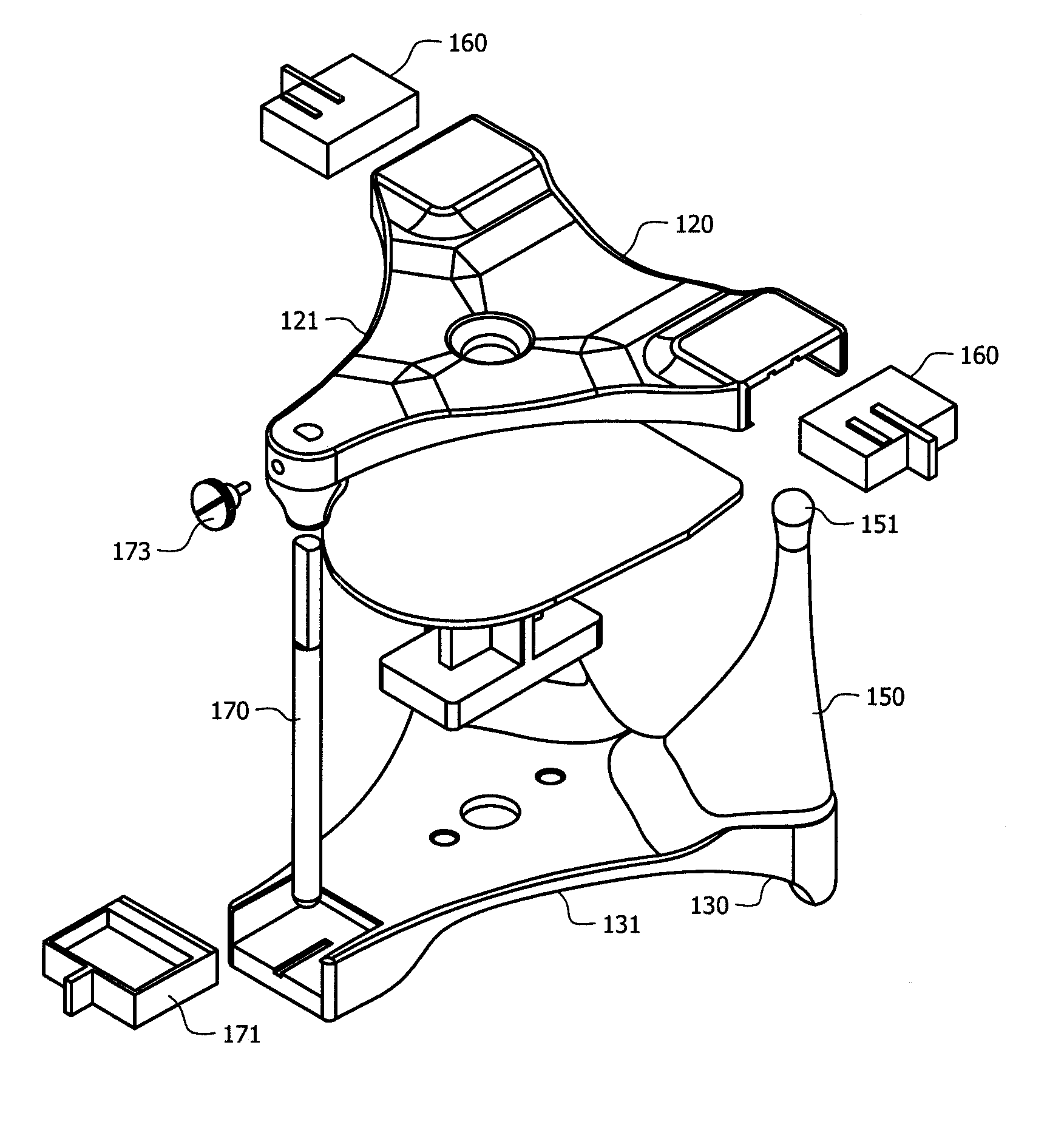

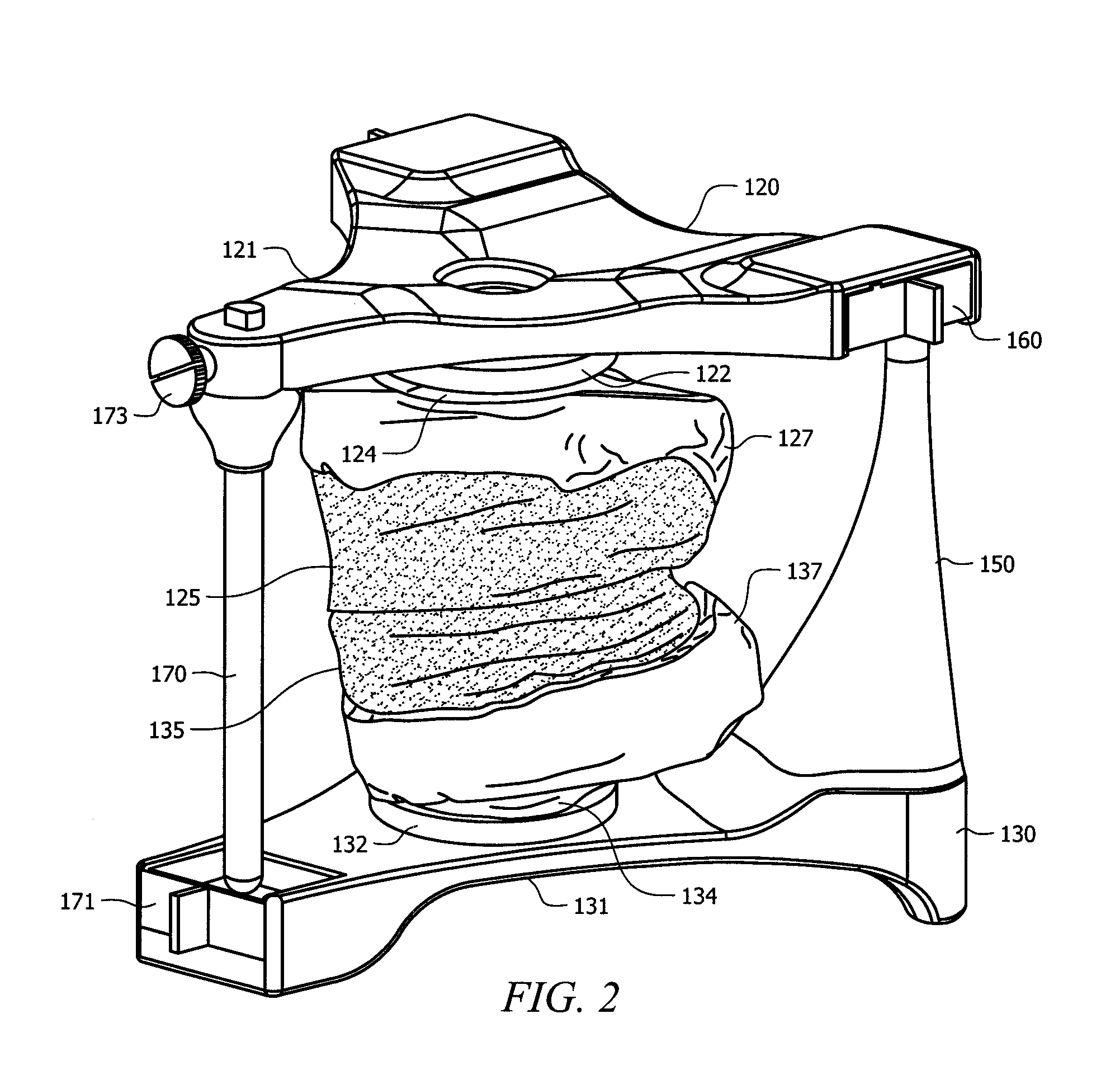

Anatomical articulator for dental diagonostic method and prosthetic reconstruction

InactiveUS20180153658A1Less cumbersome measurementLess cumbersome dialAdditive manufacturing apparatusDental articulatorsDigital dataDental Articulators

An anatomical articulator for modeling a temporomandibular joint includes a lower base portion comprising at least one upright support. A set of replica condyles produced from digital data representing a patient jaw structure is connected to the at least one upright support. An upper frame portion defines receptacles on either side. A set of replica mandibular fossae produced from the digital data representing a patient jaw structure is configured to connect to the upper frame portion via the receptacles. The replica condyles and the replica mandibular fossae meet to form a hinge of the articulator.

Owner:OHIO STATE INNOVATION FOUND

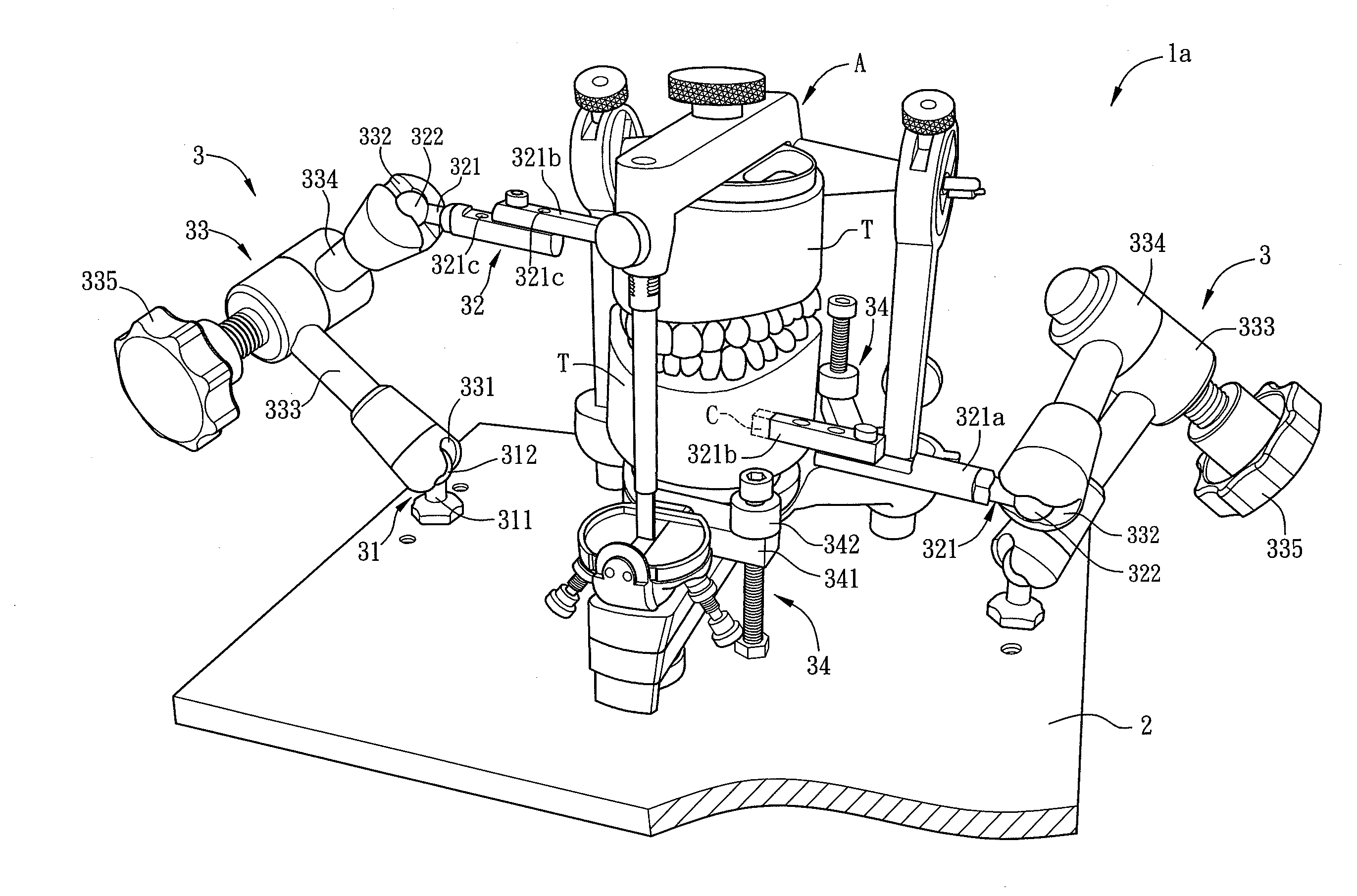

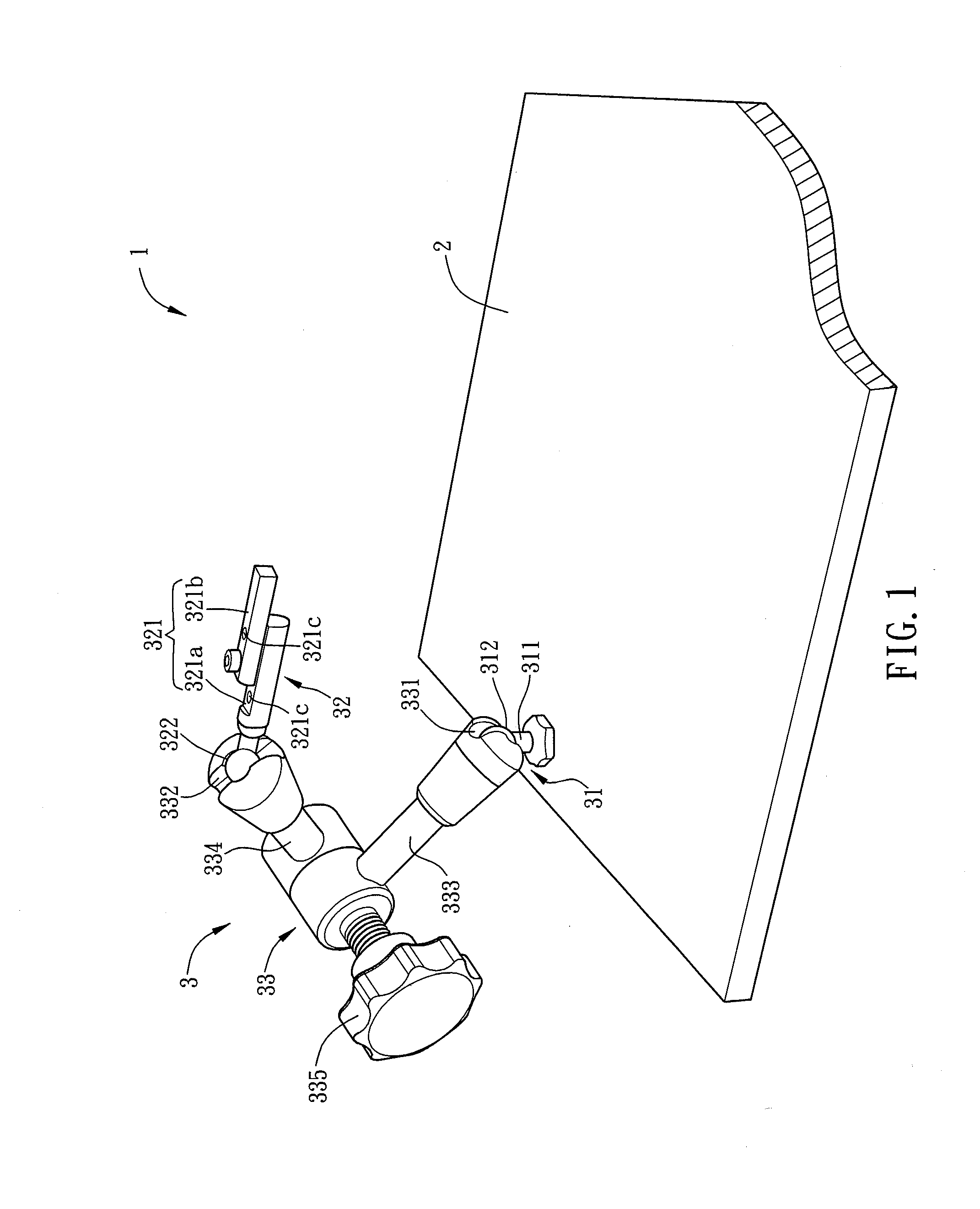

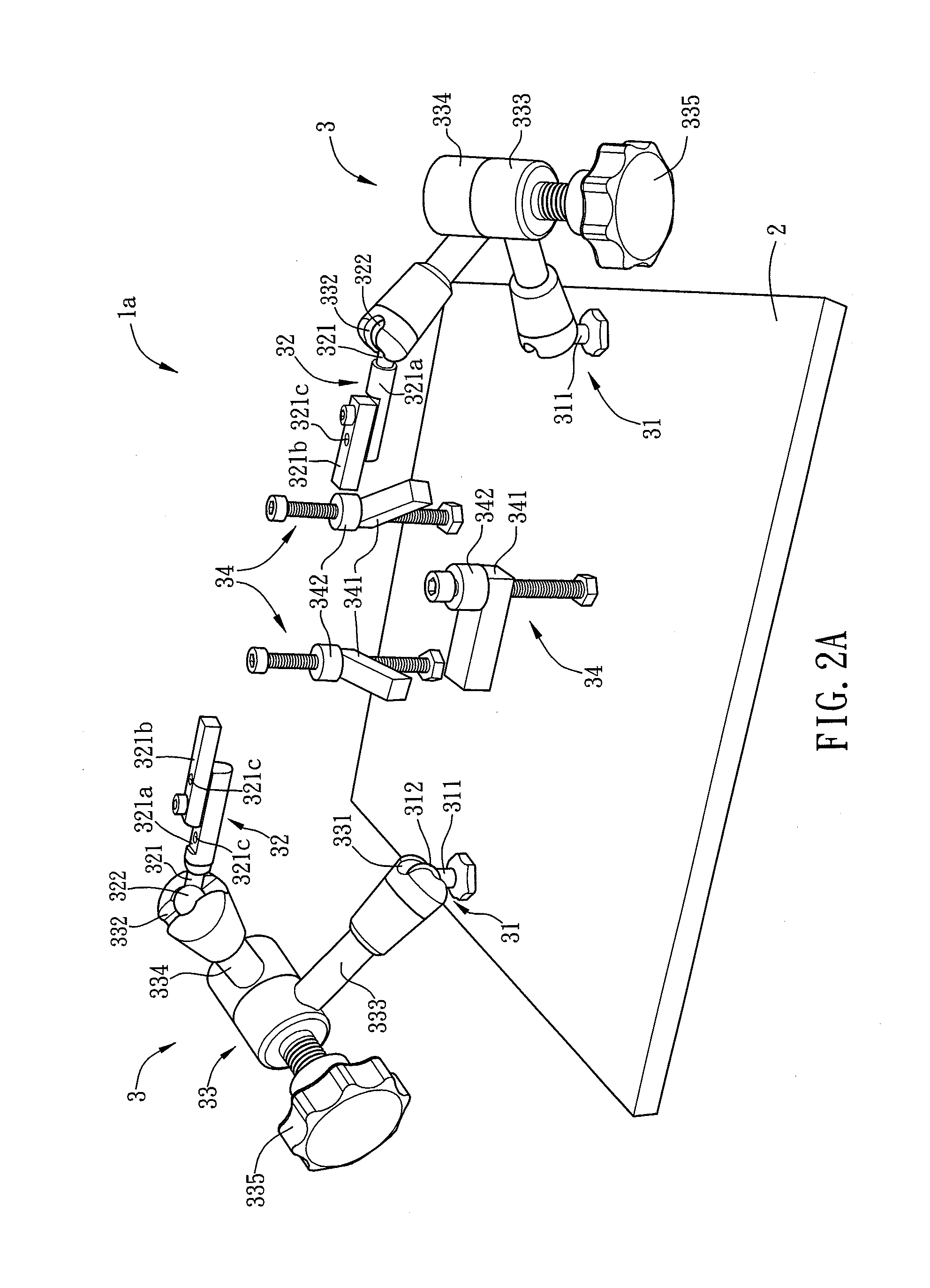

Auxiliary device for articulator

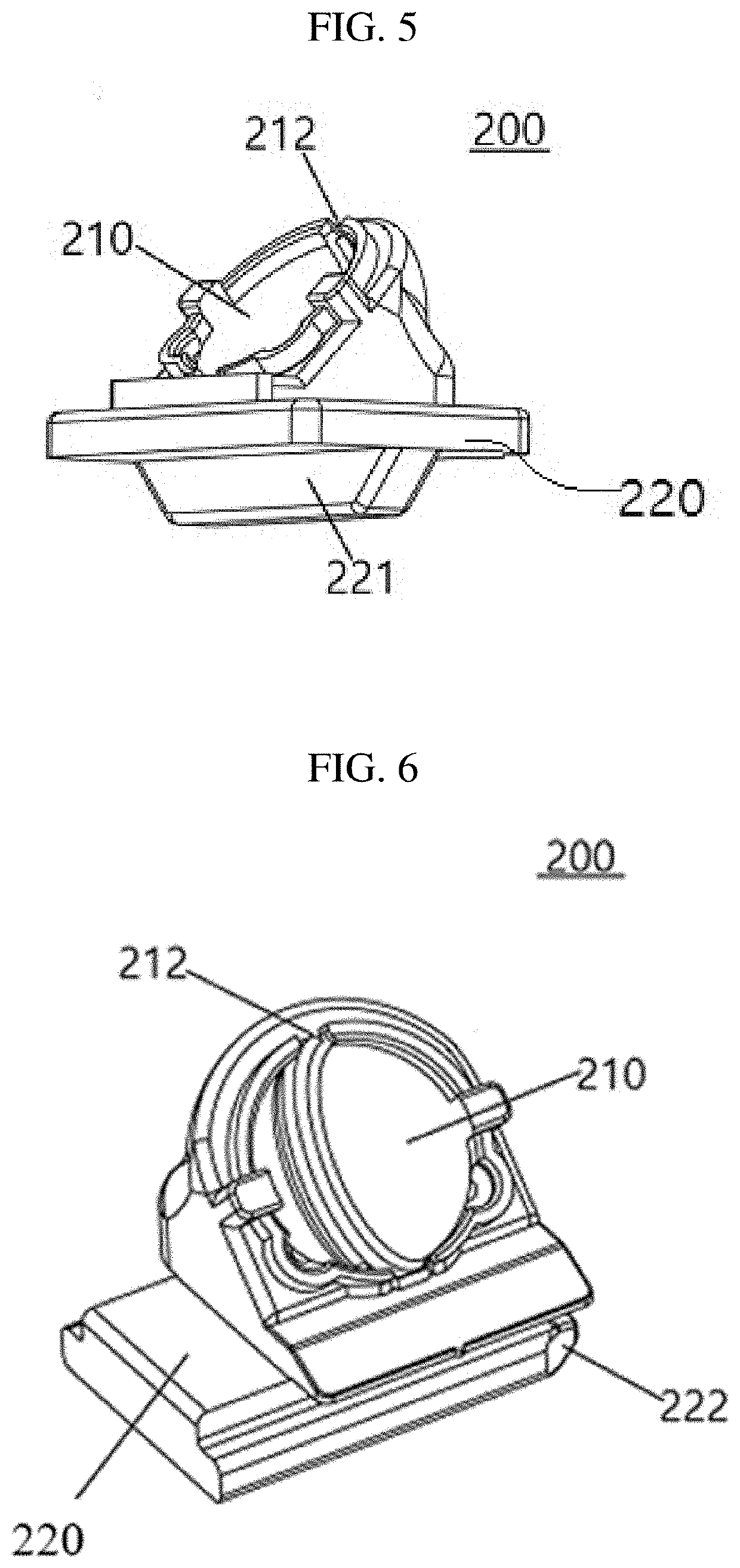

InactiveUS20140017627A1Increase freedomPromote repairDental articulatorsEducational modelsDental ArticulatorsOcclusal appliance

An auxiliary device for an articulator includes a base and at least an adjusting structure. The base is provided for positioning an articulator, and the adjusting structure is disposed on the base. The adjusting structure includes a first ball joint, a second ball joint and a connecting assembly. The first ball joint is connected to the base, and the two ends of the connecting assembly are connected to the first ball joint and the second ball joint, respectively. The adjusting structure is moved relatively to the articulator by the movement of at least one of the first ball joint and the second ball joint, thereby adjusting the position of a dental cast disposed on the articulator. The auxiliary device is advantageous for conveniently adjusting the dental cast disposed on the articulator and accelerating the process of the preoperative planning.

Owner:NAT CHENG KUNG UNIV

Articulator

InactiveUS20120329003A1Minimize error rangesAccurate toneDental articulatorsEducational modelsDental ArticulatorsDentures

The present invention relates to an articulator for the purpose of checking the alignment of dentures, by coupling together models of the upper and a lower jaws, in order to provide a simple movement of the upper and lower jaws, minimize occlusal errors, and accurately mount the upper and lower jaws onto the occlusion surface. Conventional articulators imitate the form of upper and lower jaw movements, wherein a reference axis is established and folded in accordance with a condyle, however, the process completely eliminates muscle movement, and inevitably leads to occlusal errors during upper and lower jaw movement. Consequently, the problem with conventional articulators is the need for post-processing, regardless of the extent of reduction of the occlusal errors through the use of diverse assisting means. In addition, while accurate occlusion cannot be achieved, conventional articulators have a structure that is too complicated and difficult to operate. Therefore, in the present invention, a reference axis is formed on a line extending from the central plane of an upper jaw mounting plate and a lower jaw mounting plate, so that the tangent of rotation creates a vertical motion on the occlusion surface, which allows upward and downward movements that are closer to physiological movements than conventional assisting means, which require making fine adjustments to occlusion, minimizes the margin of error of the articulator, and provides a simple operating structure for the upper and the lower jaw mounting plates and an easier usage thereof.

Owner:LEE CHAE BUNG +1

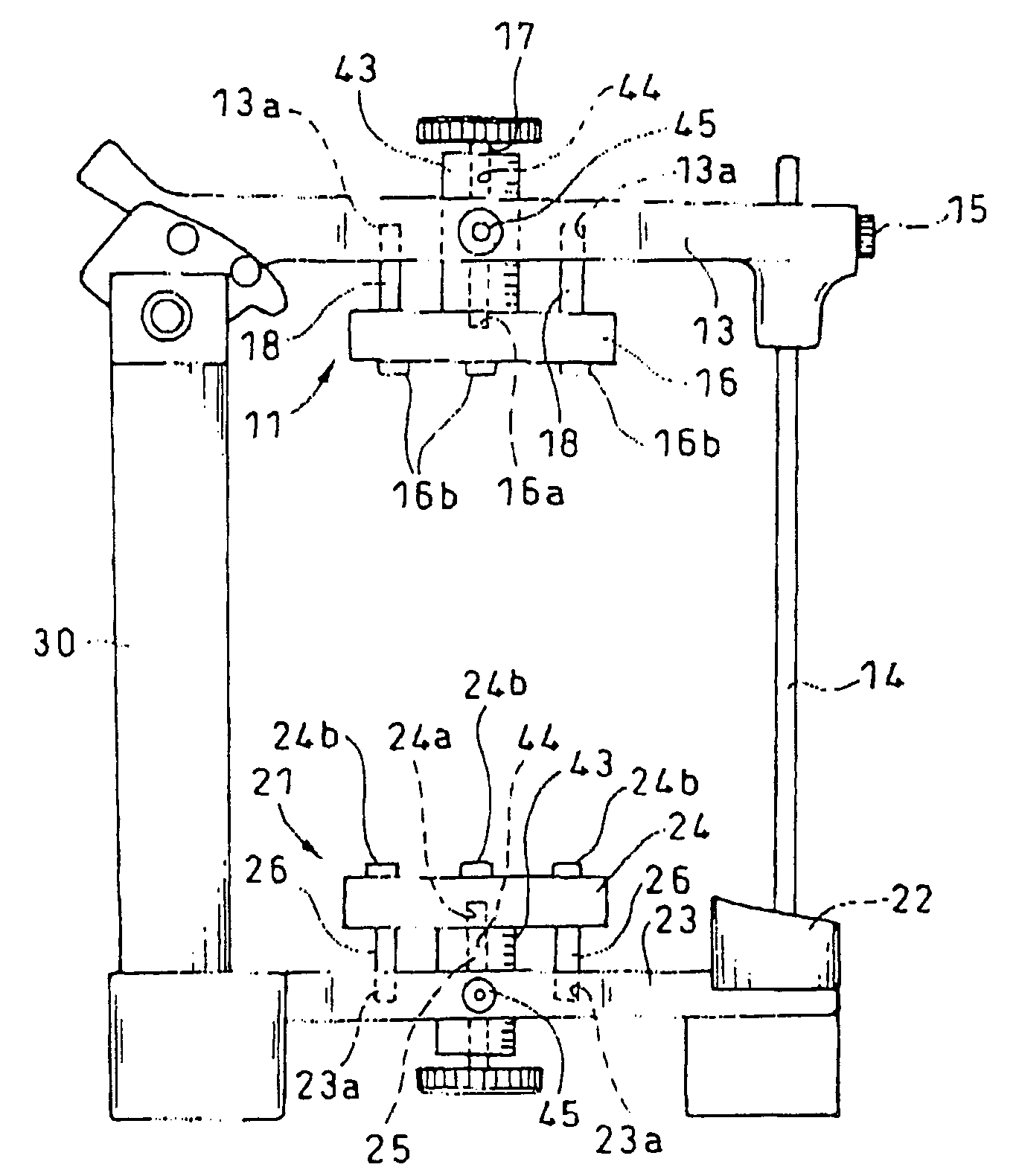

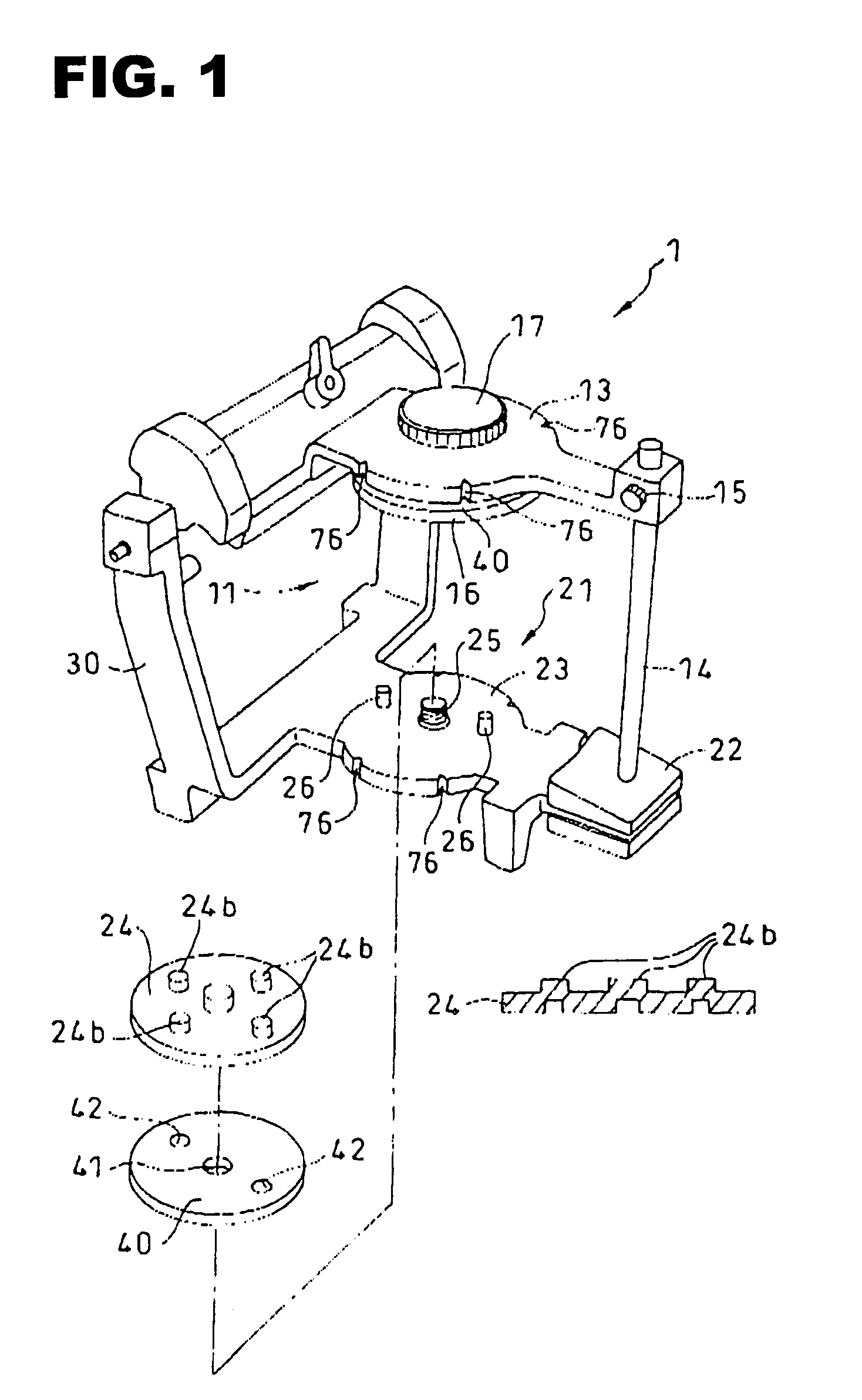

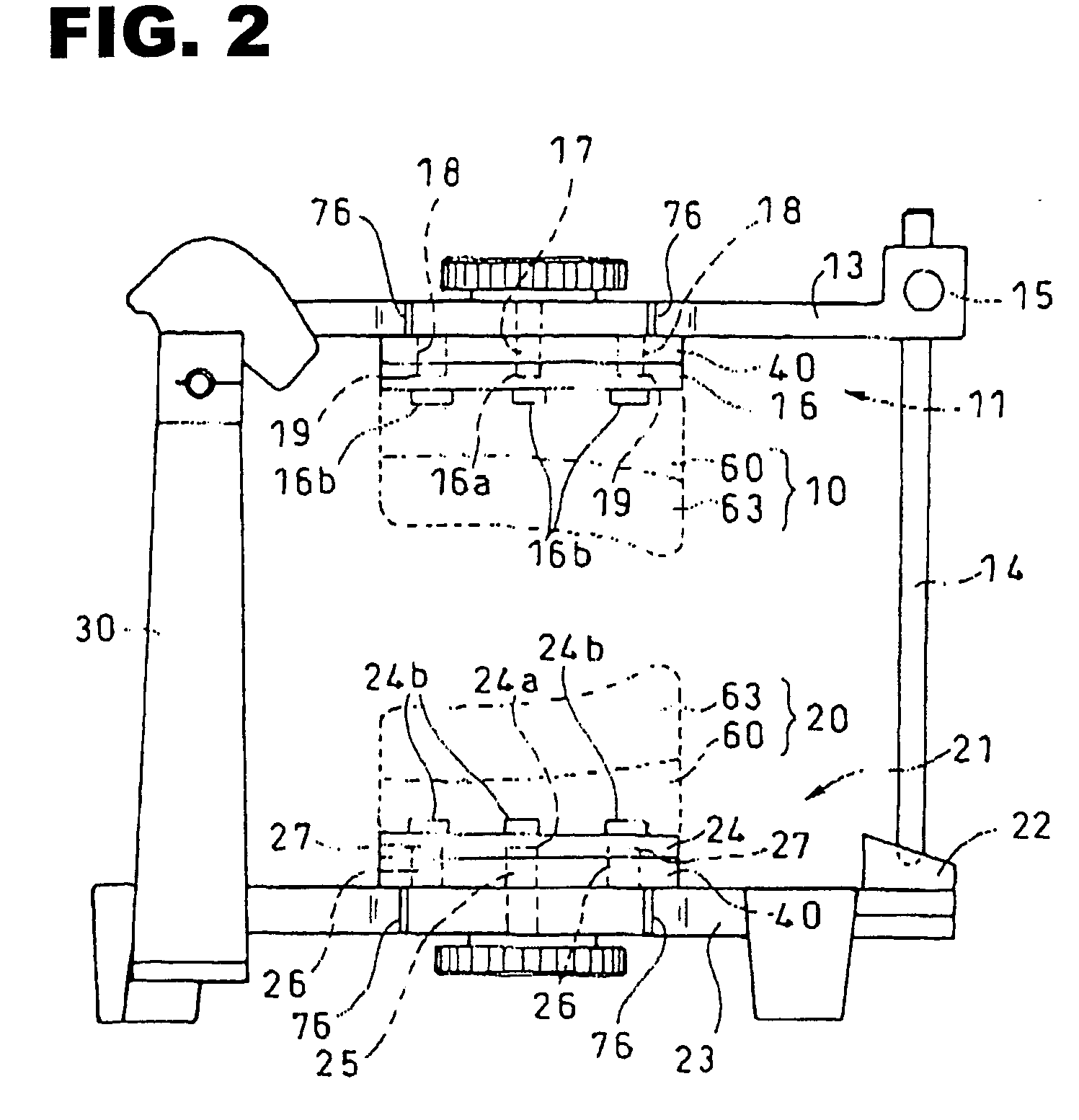

Dental articulator, method for producing dentures and method for adjusting the articulator in occlusion height in preparing the dentures

InactiveUS7156657B2Easy to adjustEnhance physical fitnessDental articulatorsArtificial teethDental ArticulatorsDentures

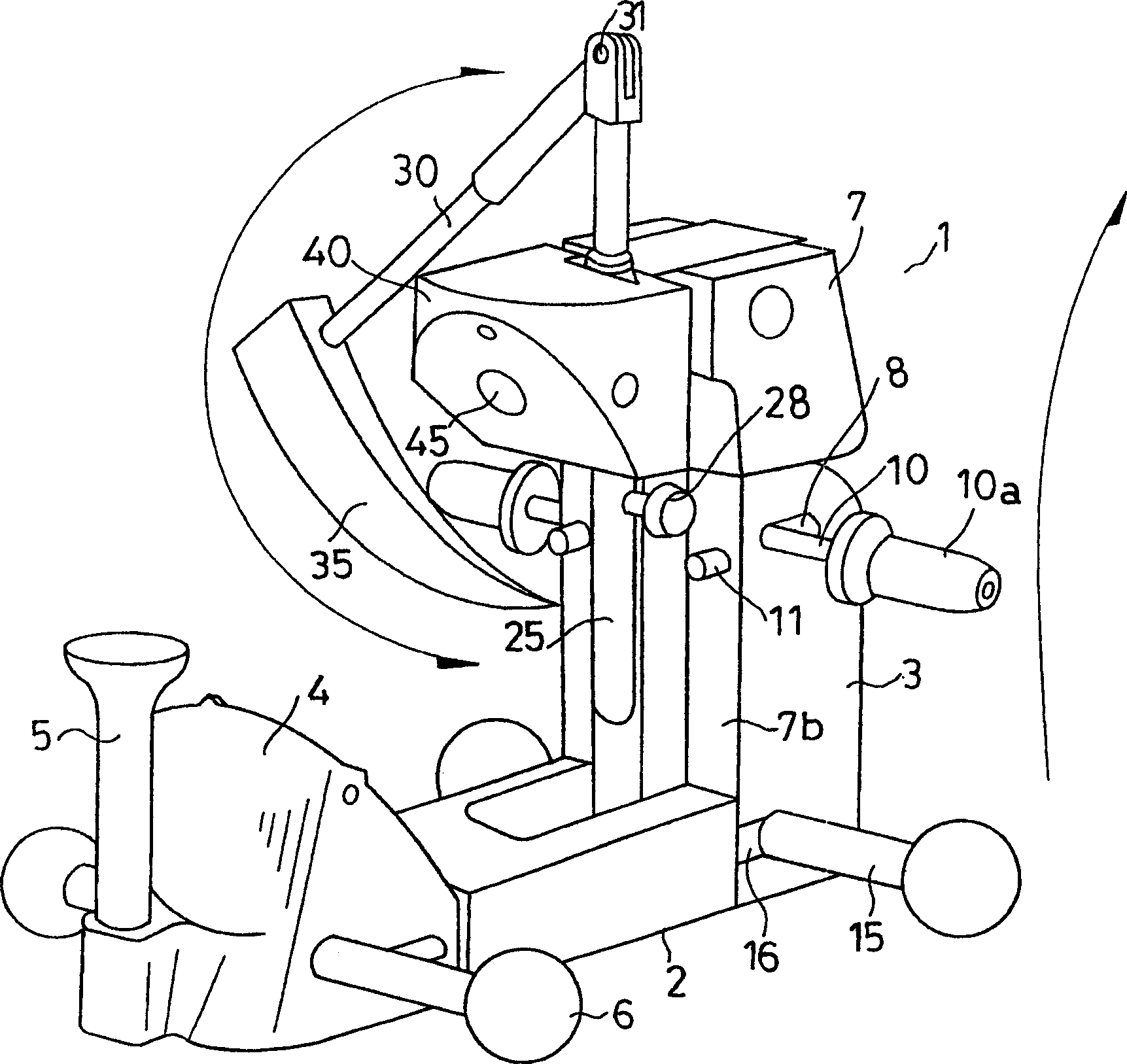

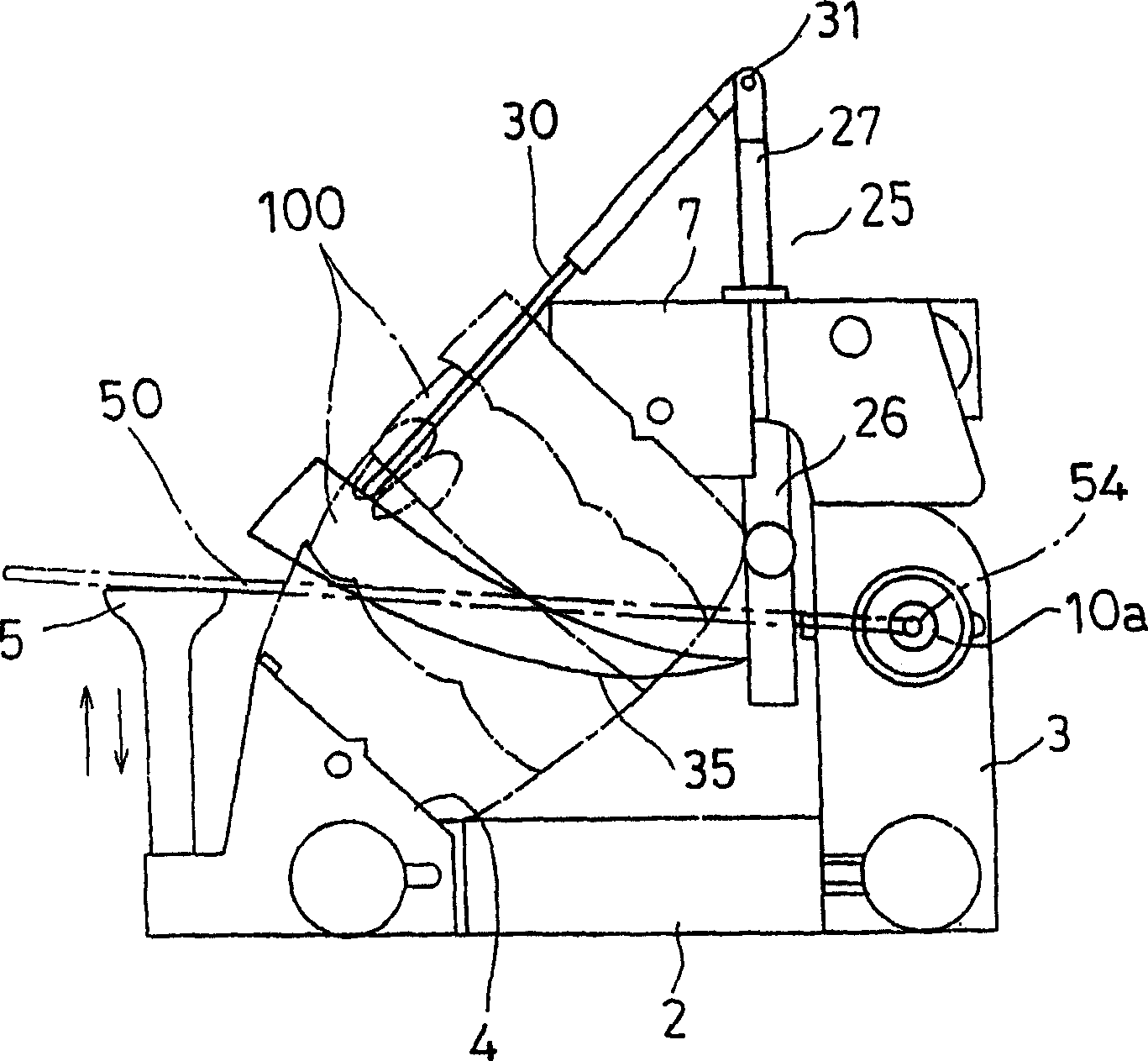

Articulator (1), which may precisely reproduce the occlusion height in the mouth in preparing a denture excellent in occlusion properties and favorable to a patient, comprises: lower frame (23) provided with lower jaw model support (21) in its upper surface, detachably mounted on which support (21) is a lower jaw model (20); stand (30) mounted in a rear portion of the lower frame (23) to extend upright; upper frame (13) provided with an upper jaw model support (11) in its lower surface, detachably mounted on which support (11) is an upper jaw model (10); circular plates (40) which vary in thickness and are provided in each of the supports (11, 21), the circular plates (40) being selected so as to enable a jaw model mounting surface of each of the supports (11, 21) to be movable in parallel with each of the frames (13, 23).

Owner:SASAGAWA OSAMU

Articulator

InactiveUS20120329004A1Minimize error rangesAccurate toneDental articulatorsEducational modelsPhysiological movementOcclusal appliance

The present invention relates to an articulator used for the purpose of checking the alignment of dentures, by coupling together models of the upper and lower jaws, in order to provide a simple movement of the upper and lower jaws, minimize occlusal errors, and accurately mount the upper and lower jaws on the occlusion surface. Conventional articulators imitate the form of upper and lower jaw movements, wherein a reference axis is established and folded in accordance with a condyle, however, the process completely eliminates muscle movement, and inevitably leads to occlusal errors of the upper and lower jaw movement. Consequently, the problem with conventional articulators is the need for post-processing, regardless of the extent of reduction of the occlusal errors through the use of diverse assisting means. In addition, while accurate occlusion cannot be achieved, conventional articulators have a structure that is too complicated and difficult to operate. Therefore, in a non-arcon type articulator, a reference axis is formed on a line extending from the central plane of an upper jaw mounting plate and a lower jaw mounting plate, so that the tangent of rotation creates a vertical motion on the occlusion surface, which allows upward and downward movements that are closer to physiological movements than conventional assisting means, which require making fine adjustments to occlusion, minimizes the margin of error of the articulator, and provides a simple operating structure for the upper and the lower jaw mounting plates and an easier usage thereof.

Owner:LEE CHAE BUNG +1

Dynamically Generated Dental Articulator Controls

ActiveUS20130034828A1Simulation is accurateAccurate interchangeabilityImpression capsDental articulatorsDental ArticulatorsDentures

This invention relates to improved methods and apparatus for recording and simulating the condylar movement of an individual. This invention also provides a dental articulator which is designed to simulate the jaw or condylar movements of a patient. This instrument enables a dentist to obtain the necessary diagnostic information for treatment of the occlusal irregularities, such as malocclusion, and the fabrication of dental cast or “dentures”.

Owner:PRESSWOOD RONALD G +1

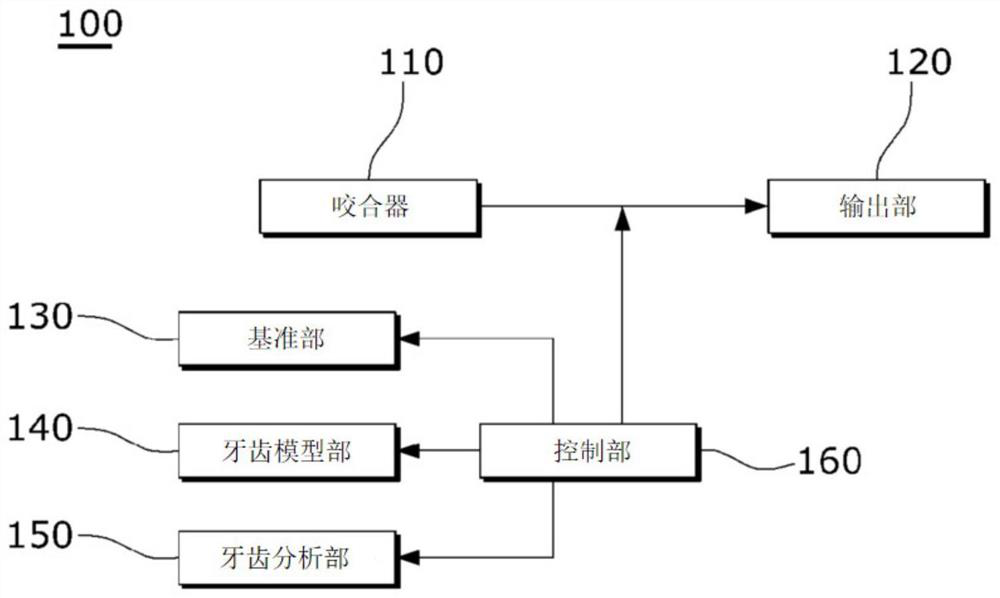

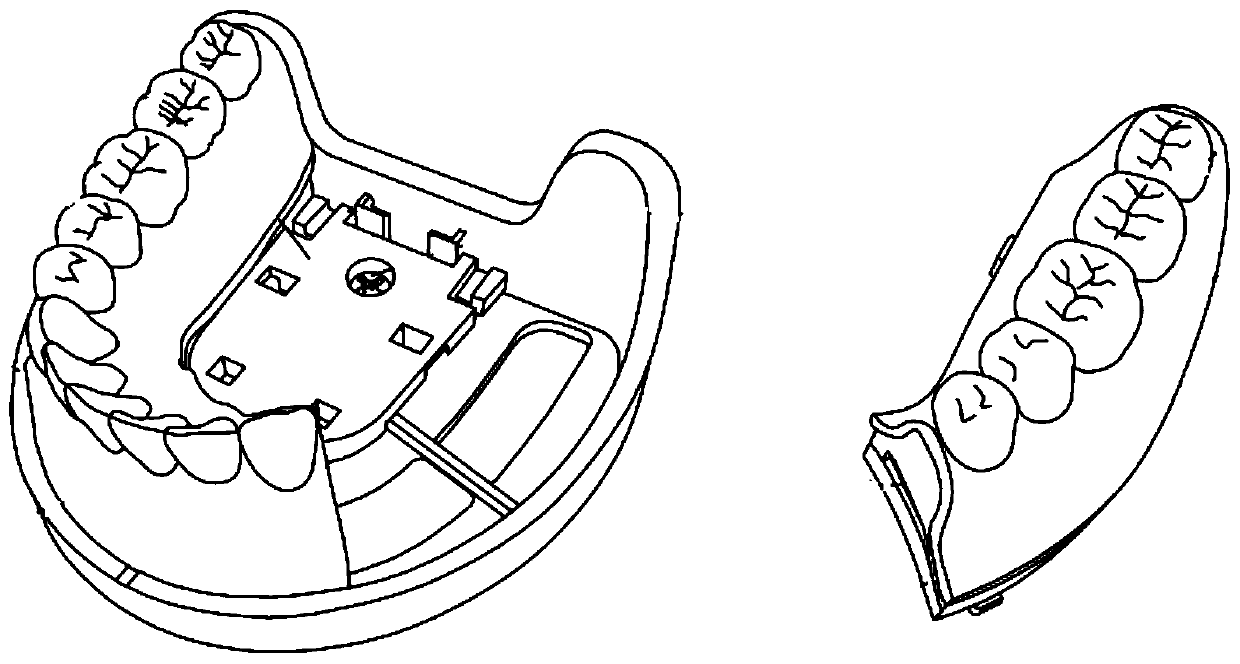

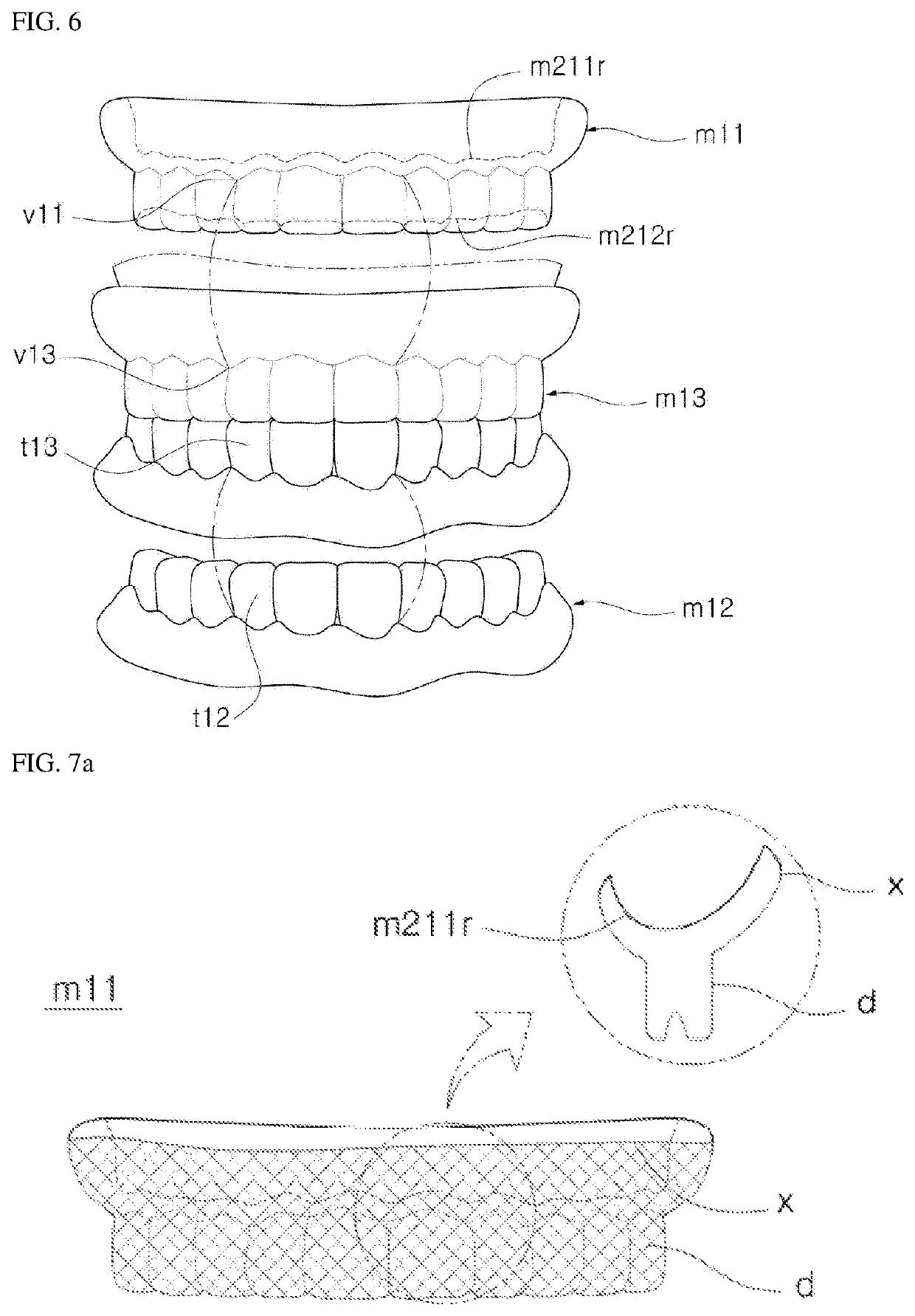

Digital three-dimensional tooth model system

ActiveCN113056241APrecise positioningCooperate accuratelyImpression capsDental articulatorsOcclusal applianceDental laboratory

The present invention relates to a digital three-dimensional tooth model system characterized by comprising: an occlusion unit on which a tooth model to be scanned is installed, the occlusion unit being mounted in a scan area of a tooth model scanner for scanning a tooth model and generating virtual 3D tooth model data; an output portion connected with the occlusion unit and configured to output an image obtained by matching position data of the tooth model scanned by the tooth model scanner and data regarding an anatomically ideal position stored therein; a reference portion comprising vertical and horizontal lines in analyzable types; a tooth model portion comprising a maxillary tooth model and a mandibular tooth model designed by a digital tooth design program, each of the maxillary tooth model and the mandibular tooth model constituting a module with the reference portion; and a tooth analysis portion interposed between the maxillary tooth model and the mandibular tooth model. When a digital three-dimensional tooth model is fabricated at a dental clinic or a dental laboratory, the tooth model is accurately positioned in a unique scan area by using a necessary tooth model scanner, thereby improving the accuracy, and the digital three-dimensional tooth model and a reference line that enables ideal anatomical positioning are modularized such that the tooth model engages in the ideal position quickly and accurately, thereby ensuring good occlusion and pronunciation.

Owner:李宇炯

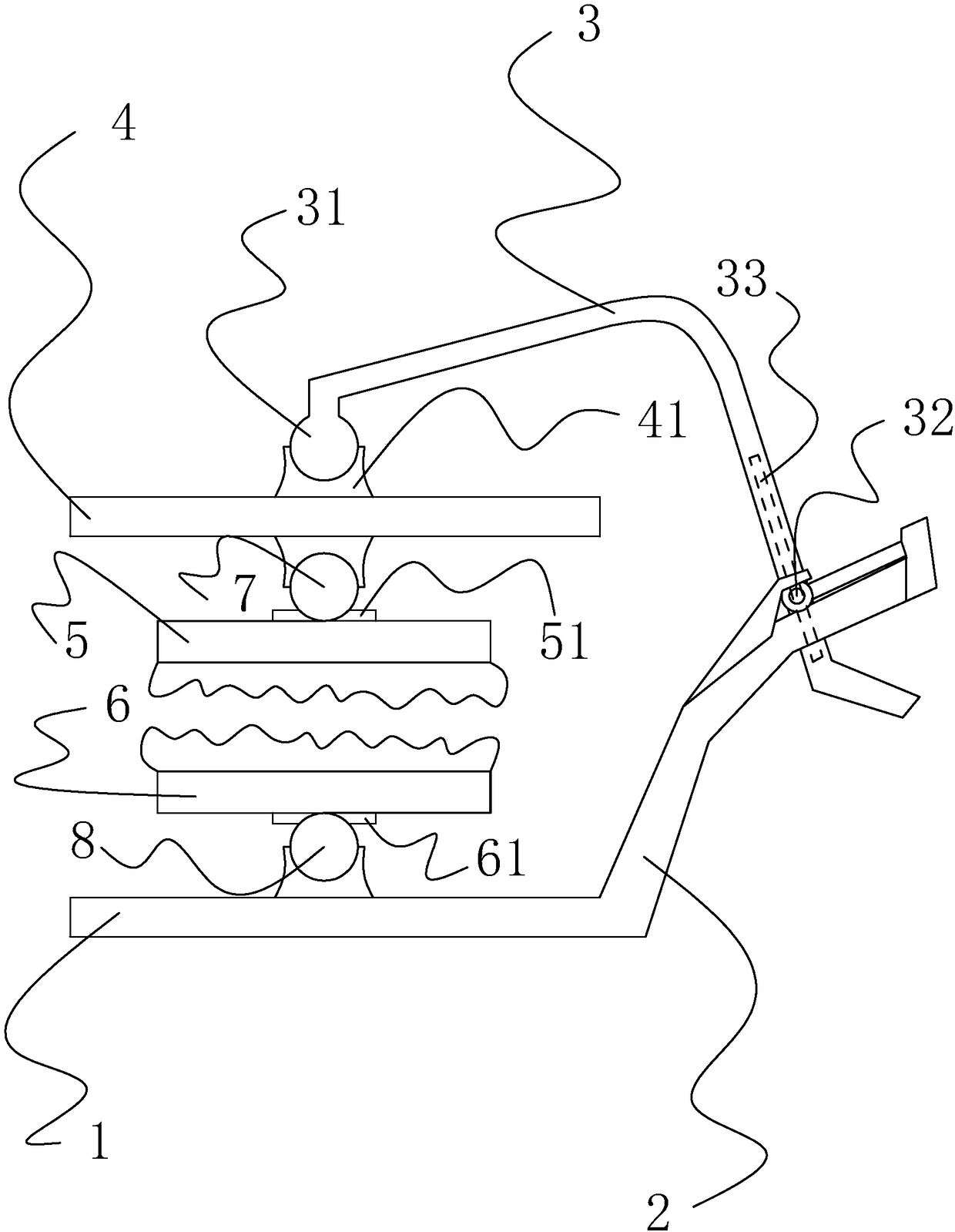

Tooth occluder

PendingCN108125726AImprove applicabilityMake up for occlusal defectsDental articulatorsEducational modelsOcclusal applianceEngineering

The invention discloses a tooth occluder, which comprises a bottom plate, a cylinder, a clamping arm, a top plate, a tooth model gingiva support upper plate, a tooth model gingiva support lower plate,an upper plate magnetic steering connection part and a lower plate magnetic steering connection part. The clamping arm comprises a clamping arm body, a magnetic steering ball, a fastening connectingpiece and a height adjusting part. According to the tooth occluder provided by the invention, by utilizing a magnetic attracting principle, the connecting piece for adjusting positions of the tooth model gingiva support upper plate and the tooth model gingiva support lower plate in the occluder can be replaced by the magnetic steering ball, and meanwhile, the height adjusting part is additionallyarranged on the clamping arm, so that an occlusion angle and the height of the tooth model gingiva support upper plate relative to the tooth model gingiva support lower plate can be adjusted, the applicability of the occluder is greatly improved, and an occlusion defect caused by long-time use of the clamping arm and the cylinder is overcome.

Owner:佛山市佛冠义齿有限公司

Dental model articulator

The present invention relates to a dental model articulator designed to allow the articulation of upper jaw dental model casts and lower jaw dental model casts respectively, comprising: an arm member supported so as to be able to rotate and to advance and retreat on a frame; a resilient biasing part for resiliently pressing the arm member forwards relative to the frame; a first joining piece formed so as to be able to join with an upper jaw dental model cast on the arm member; and a second joining piece which is joined so as to be able to advance and retreat through at least one through-hole formed in the frame, and is formed so as to allow a lower jaw dental model cast to be joined on. The dental model articulator of this type provides advantages in that dental model casts can be joined to the frame via attachable and detachable joining pieces, and securing onto the lower jaw dental model cast can be effected while adjusting the securing position by means of the advance and retreat of a rod such that articulation position securing and alignment is easy, albeit that if the securing position is wrong the cast can easily be taken out and corrected.

Owner:HOGEN DENTEL CO LTD

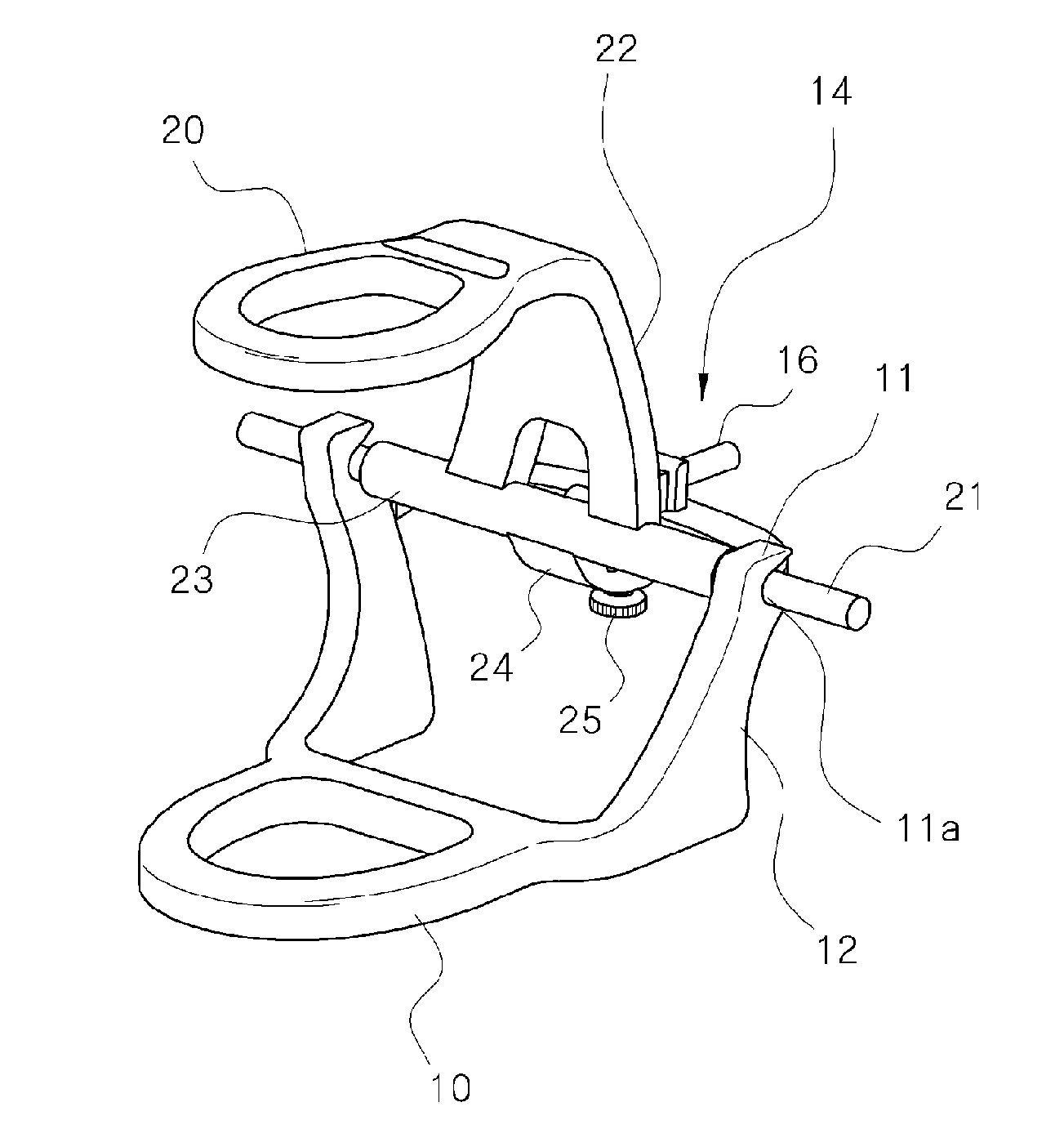

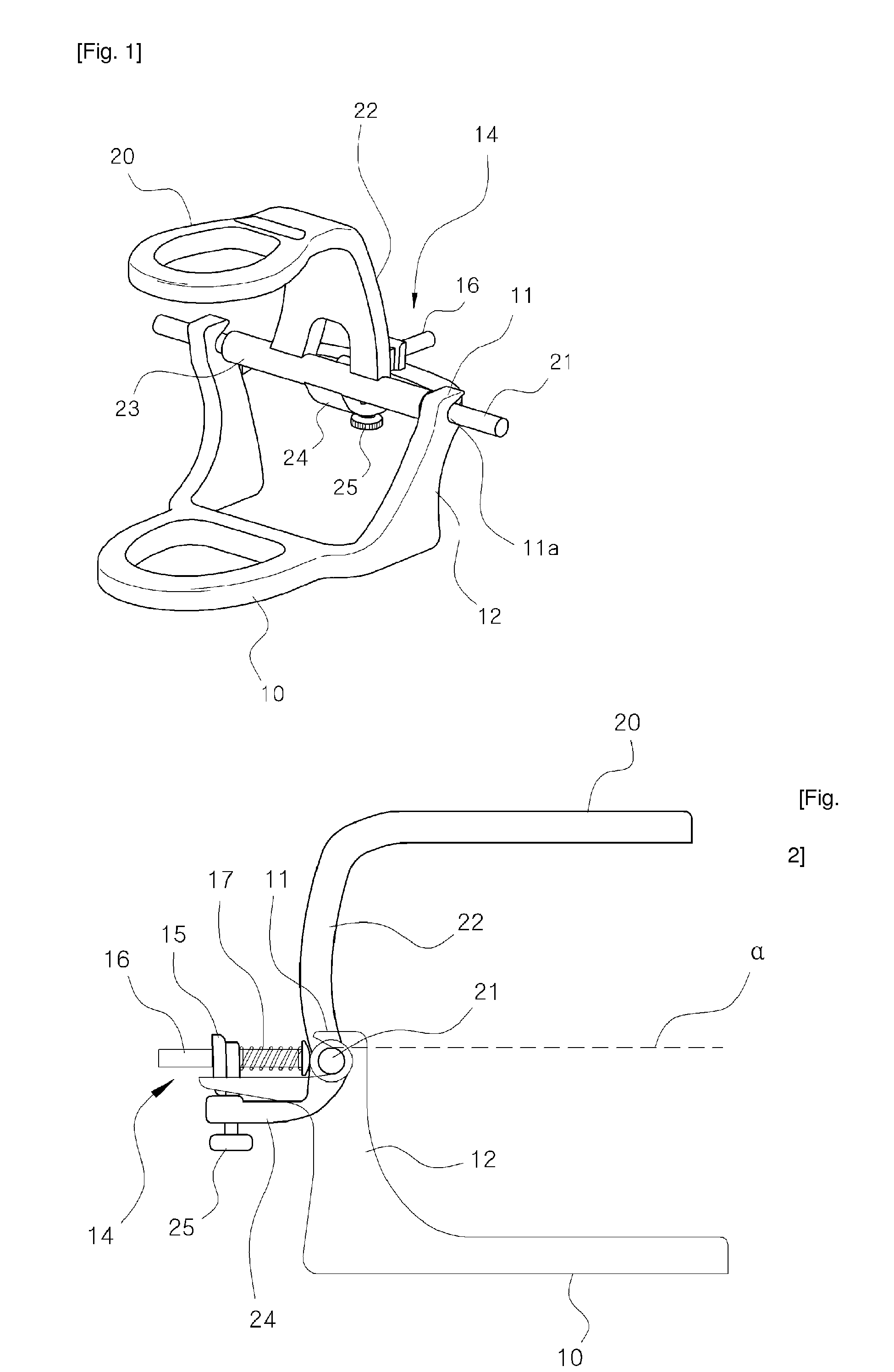

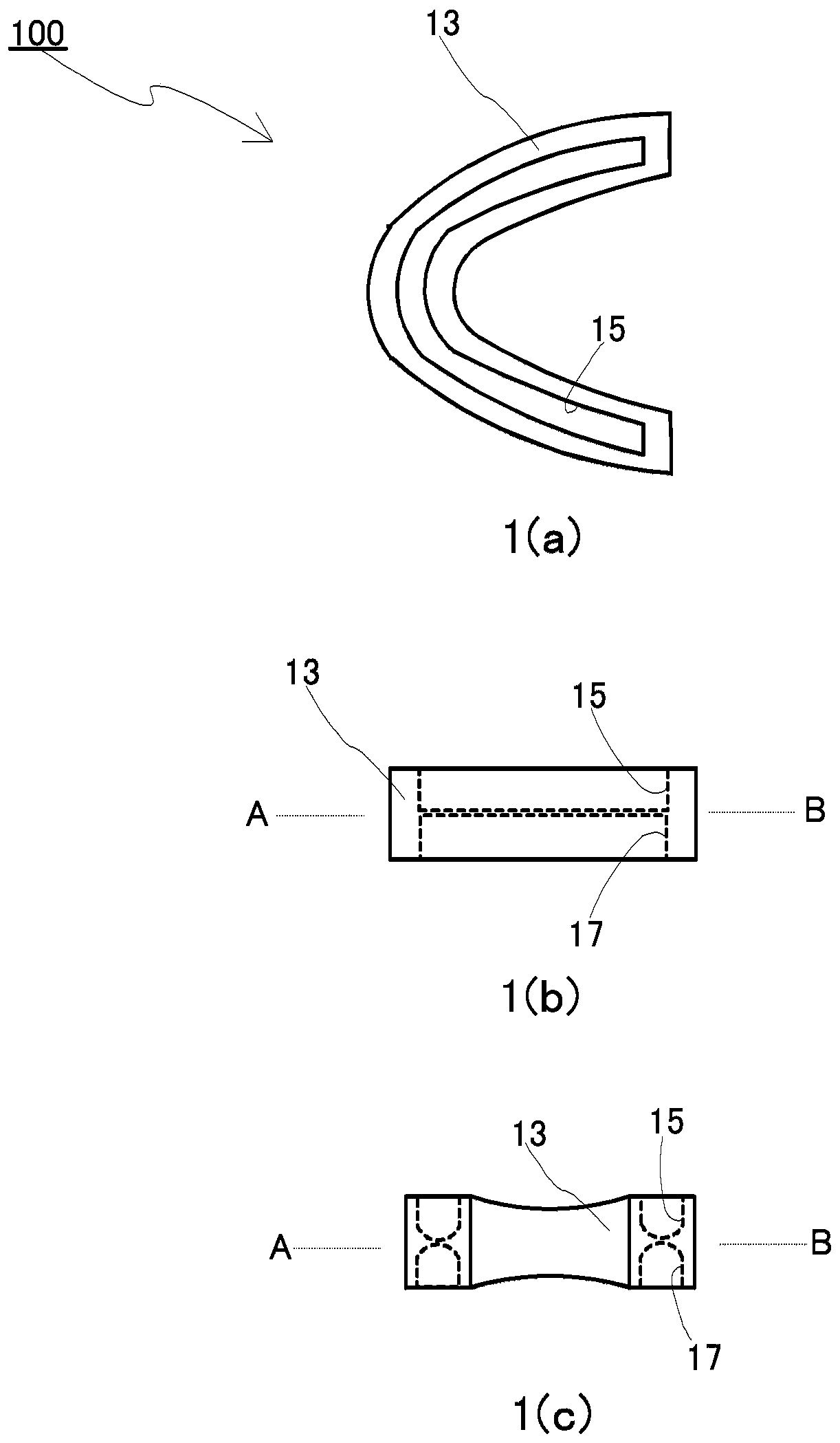

Reference denturealignment jig, kit for preparing dentures, and method for preparing dentures using same

ActiveCN110769778AEasy to manufactureImprove suitabilityImpression capsFastening prosthesisDenturesOcclusal appliance

Provided is a reference denture alignment jig which guides reference dentures into an oral cavity or to an articulator in which upper and lower edentulous jaw models are fixed, and aligns the reference dentures in the oral cavity or in the articulator in which upper and lower edentulous jaw models are fixed, the jig having a reference denture holding portion for holding reference dentures.

Owner:TOKUYAMA DENTAL CORP

Denture base and method of preparing it and instrument used therefor

A denture base which is used in a dental therapy field and capable of providing an occlusion suitable for each patient, wherein a denture is arranged along an occlusion curve represented based on the radius of curvature R of an optimal dentition determined from an X-ray photograph of a patient's temporal region and the center point set on a resultant force line representing the direction of a standard resultant force of forces produced at occluding. As the standard resultant force line, a line connecting a point at the front edge center of a frontal sinus on the X-ray photograph of the temporal region with an angle of lower jaw can be used. This denture base uses an articulator provided with a length-adjustable pendulum-shaped arm having a protrusion at the tip end thereof and supported three-dimensionally pivotally to bring a model supported on an upper jaw supporter and a lower jaw supporter into contact with the claw of the arm with the arm pivoting to thereby three-dimensionally display an occlusion curve having a radius of curvature equal to the effective length of the arm and fix the denture along the occlusion line.

Owner:西浜直树

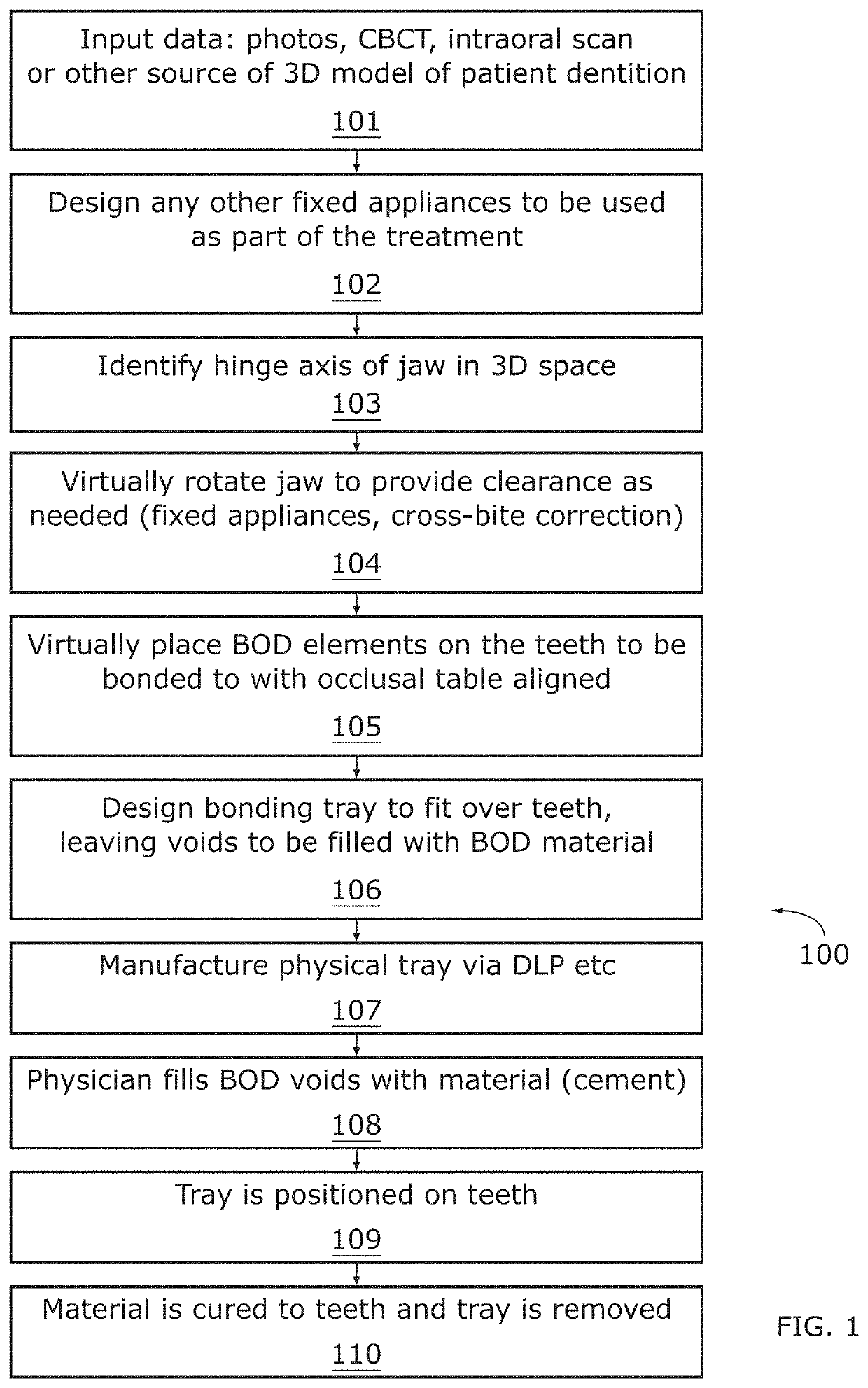

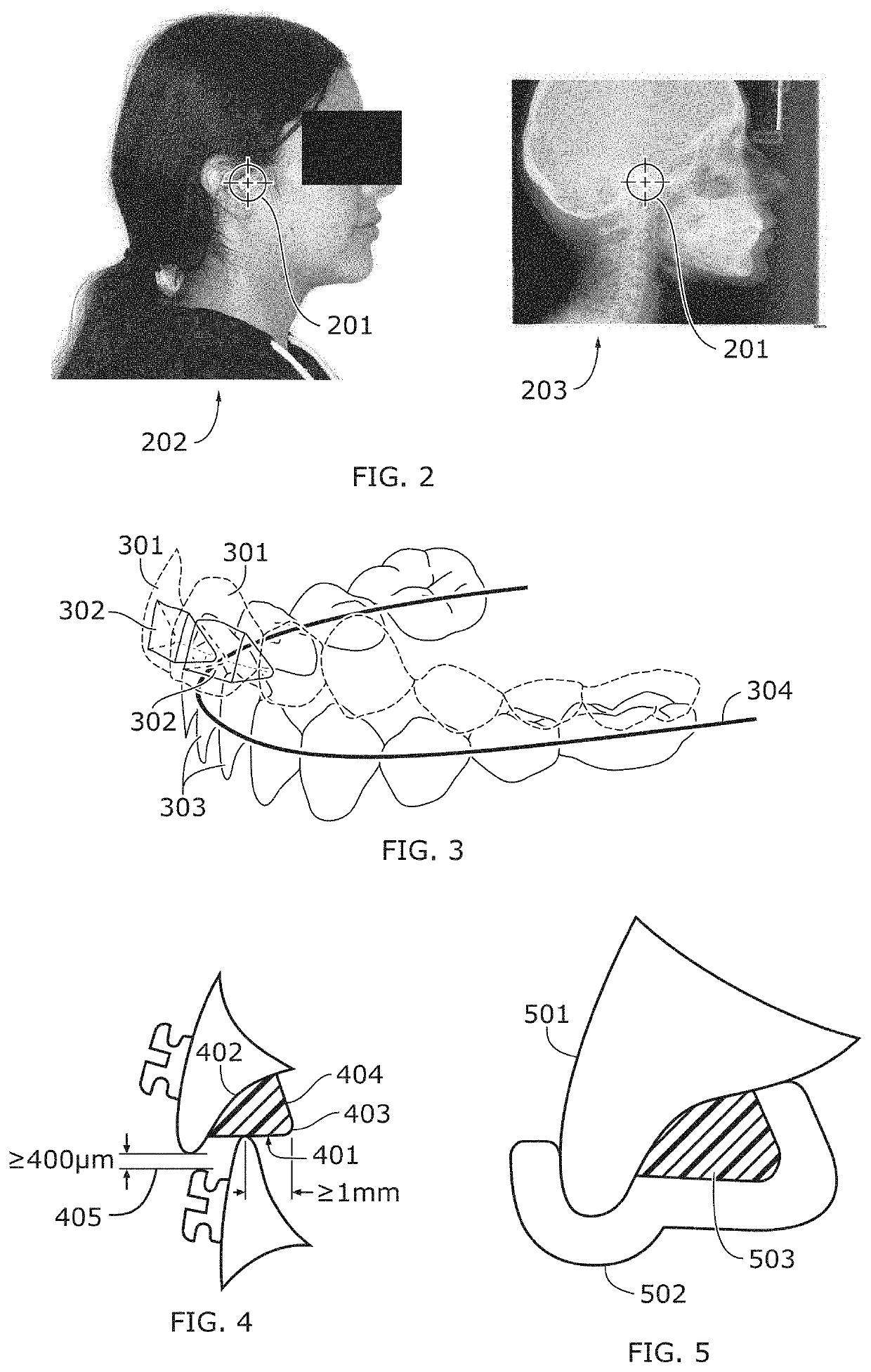

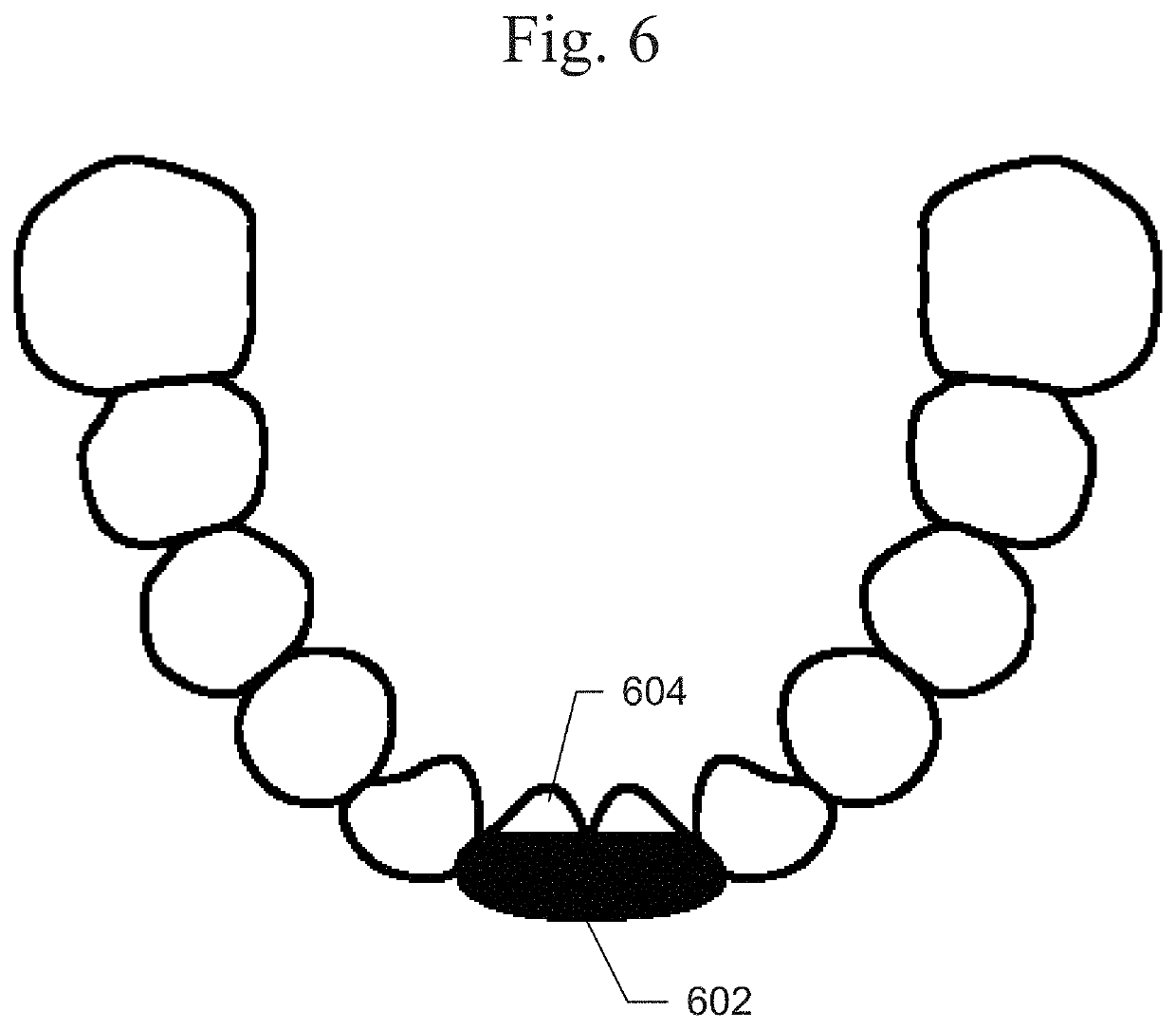

Process for fabricating a digital bite opening appliance during orthodontic treatment

PendingUS20210077227A1Quicker and easy to placeImprove accuracyGeometric CADImpression capsJaw boneThree-dimensional space

Embodiments may provide Bite Opening Devices (BODs) that are quicker and easier to place and provide improved accuracy. For example, a method may comprise using a computer system to perform: receiving data relating to teeth and jaws of a person, identifying a hinge axis of the jaw in three dimensional space using the data relating to teeth and jaws of a person, rotating the jaw to provide a desired clearance of the teeth, placing at least one Bite Opening Device on the teeth so as to provide the desired clearance of the teeth, and generating data defining a bonding tray to fit over the teeth, the bonding tray including a void corresponding to each Bite Opening Device, the generated data defining the bonding tray to be used for manufacturing the bonding tray using additive manufacturing.

Owner:LIGHTFORCE ORTHODONTICS INC

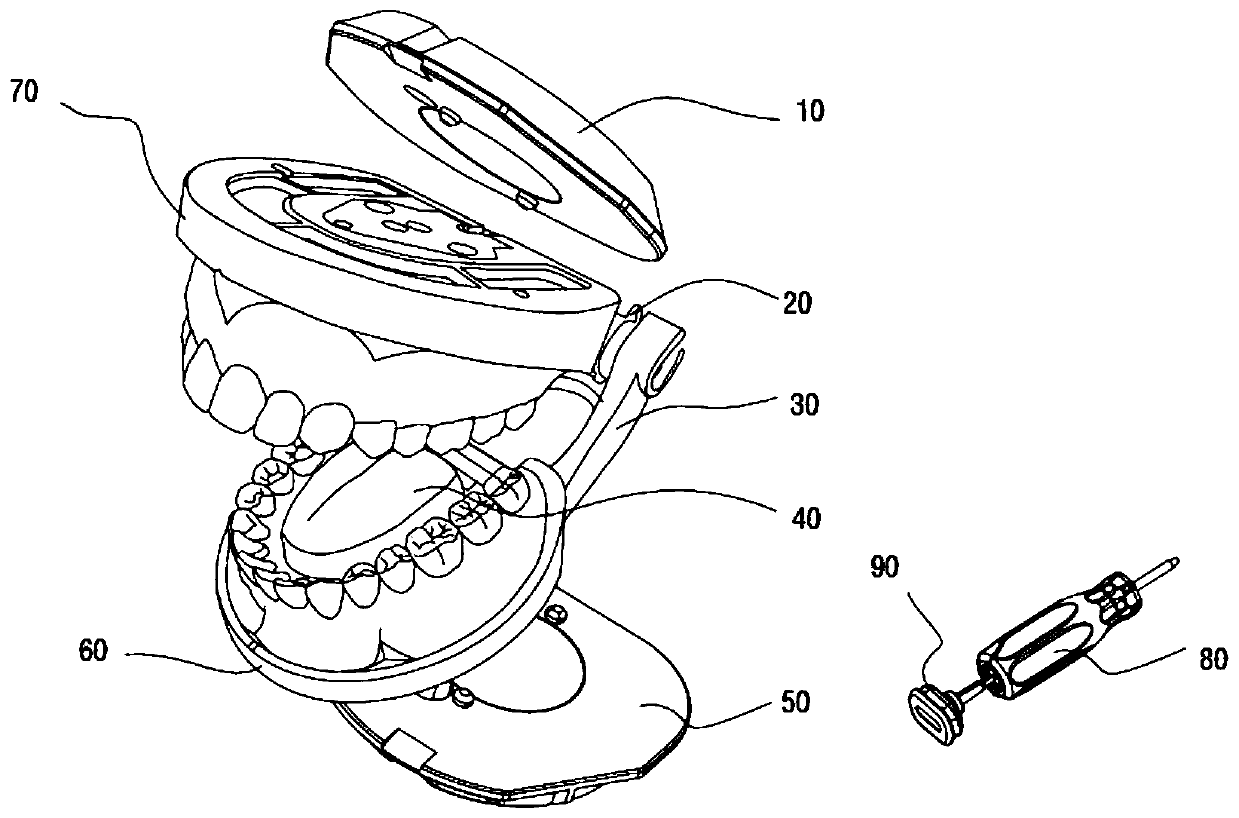

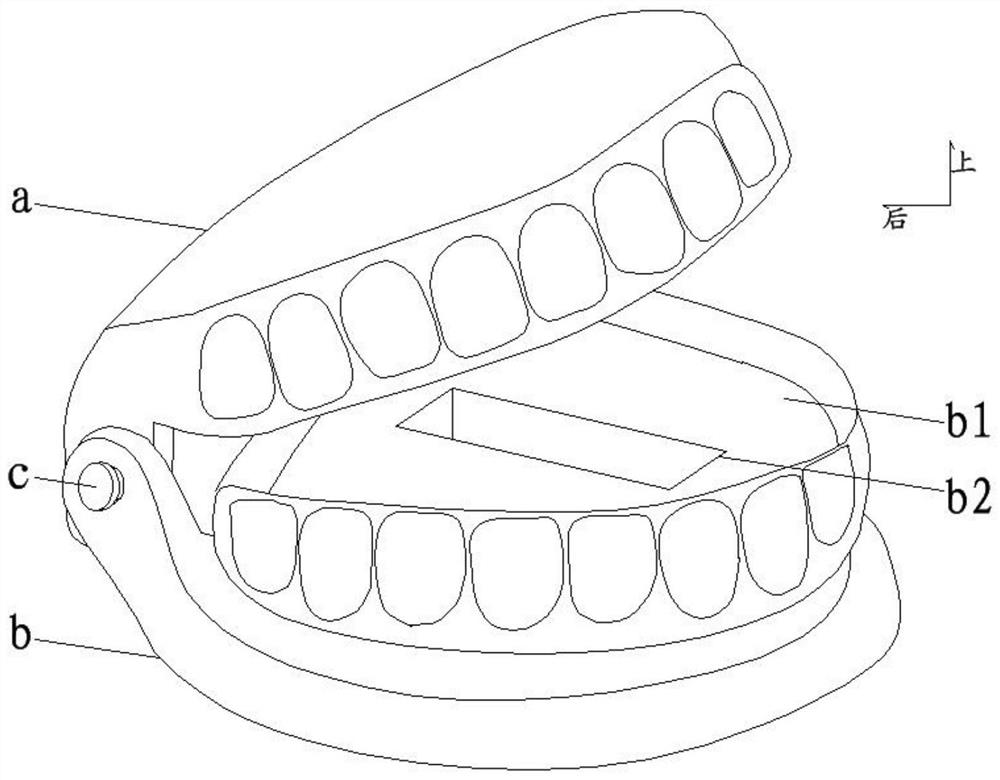

Oral cavity model for practice

PendingCN111192510AGuaranteed to be rightImprove operational skillsEducational modelsGonial angleOcclusal appliance

The invention discloses an oral cavity model for practice. The model comprises an upper jaw occluder, a lower jaw occluder, a model upper jaw, a model lower jaw and model teeth. The upper jaw occludercan be mounted on the lower jaw occluder in a manner of rotating and keeping a set angle, the model upper jaw is fixedly mounted on the upper jaw occluder, and the model lower jaw is fixedly arrangedon the lower jaw occluder. A plurality of tooth grooves are formed in the model upper jaw and the model lower jaw, the model teeth are inserted into the tooth grooves in a one-to-one correspondence manner, and the model teeth and the tooth grooves are detachably and fixedly connected through at least one of a buckle structure and a connecting piece. The oral cavity model is simple in structure, high in simulation degree and stable in structure, facilitates various operations in the practice process and is beneficial for students to improve the operation skills.

Owner:NISSIN EDUCATION PROD KUNSHAN CO LTD

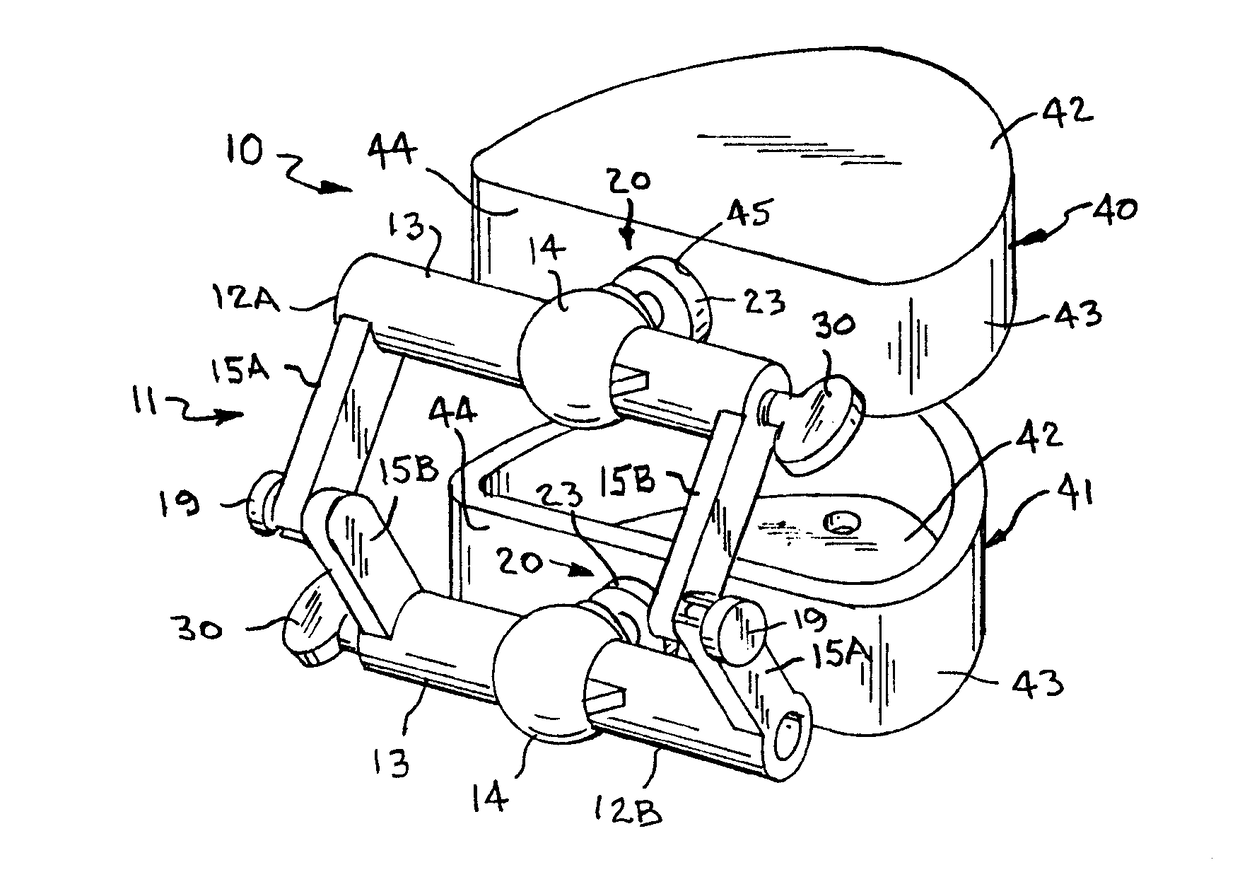

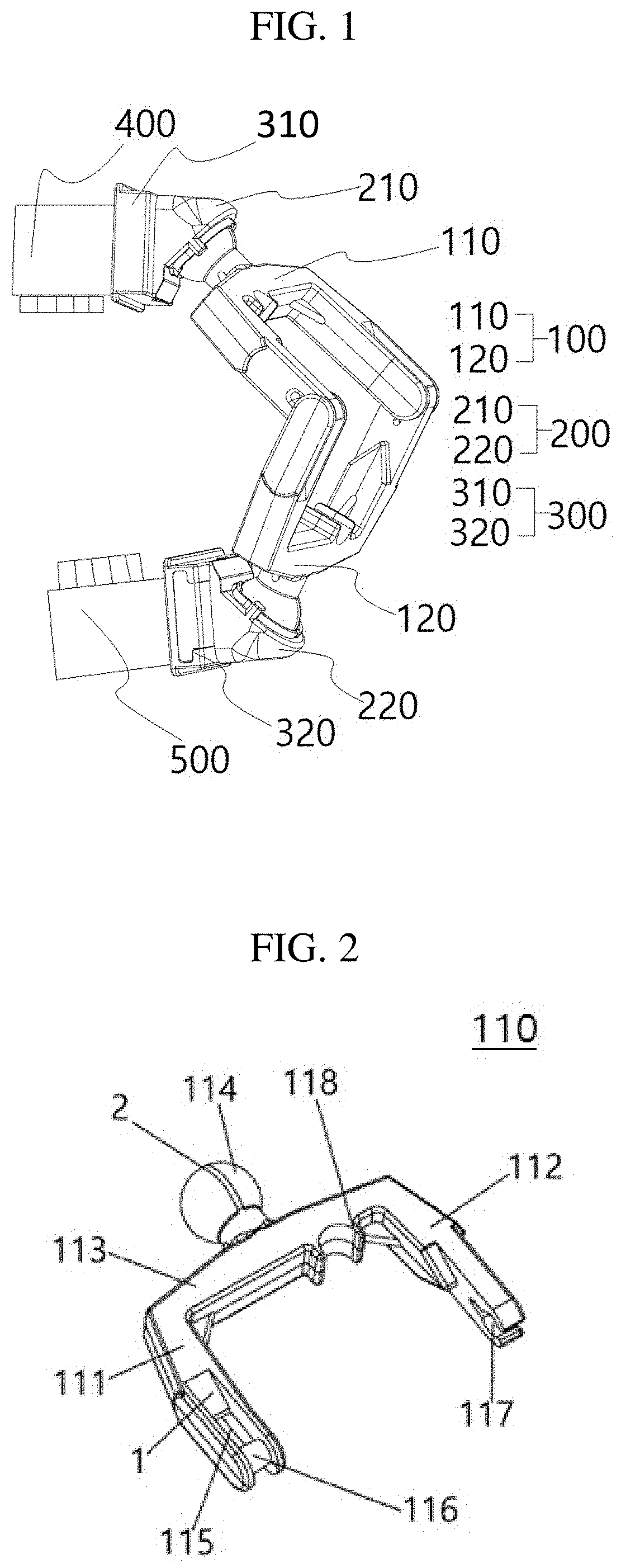

Dental articulator

ActiveUS9883928B2Easy to installEasy to removeDental articulatorsEducational modelsSet screwDental Articulators

A dental articulator apparatus and method of forming dental casts utilizing a dental articulator having pivotally connected upper and lower arms that each have a ball socket which receives a ball at the outer end of a respective model anchor, the opposed end of which is cast into a dental model. The model anchor ball is adjustably secured in the ball socket of the articulator arms by a set screw coupled with a rotatable magnetic extension rod that are installed, removed, advanced, and retracted as a unit and allow relative rotation between the set screw and the extension rod to facilitate fitting and positioning the ball in the socket when the set screw is loosened, and eliminate manually installing and positioning separate small shims and plungers that can be accidentally dropped and lost.

Owner:ELNAJJAR JEAN J

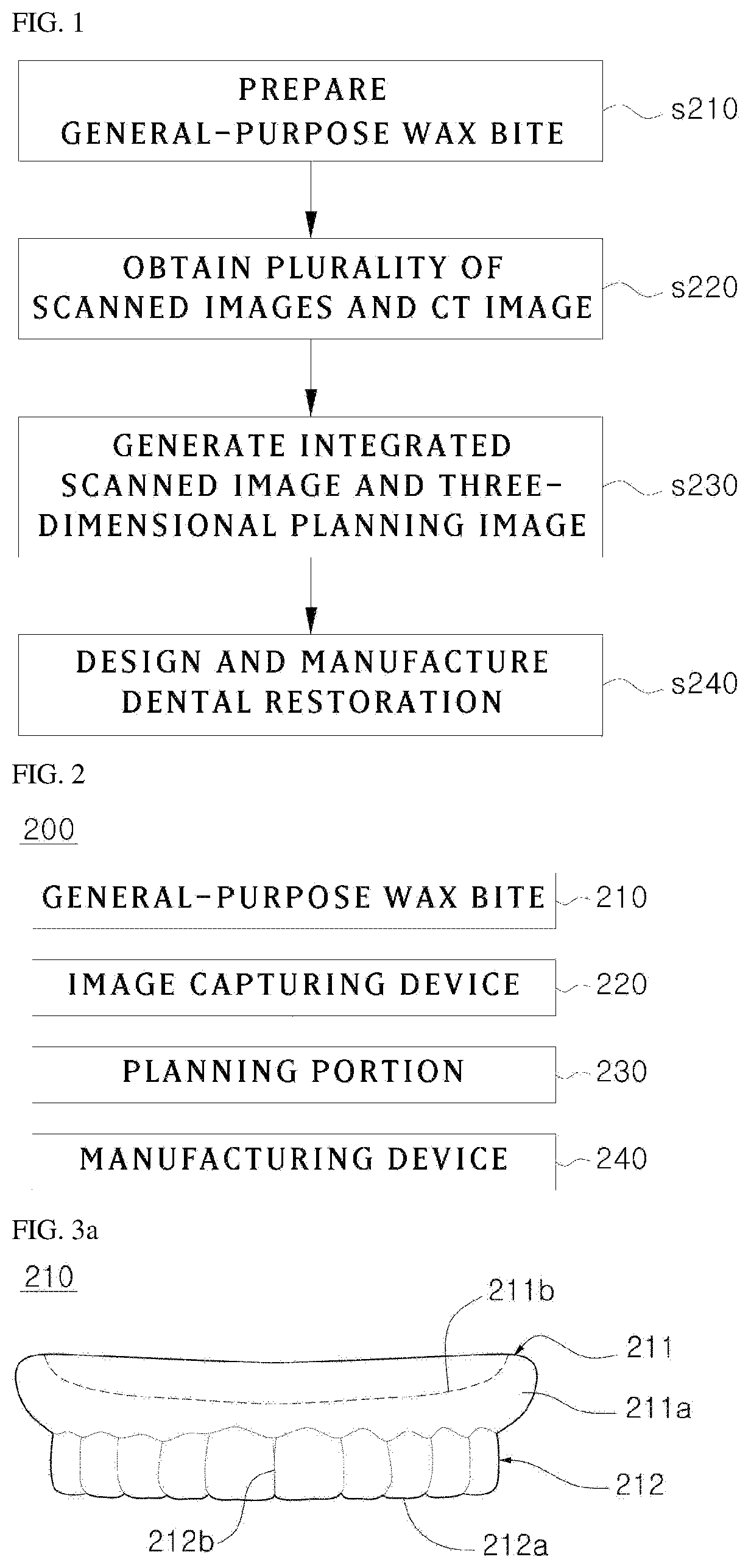

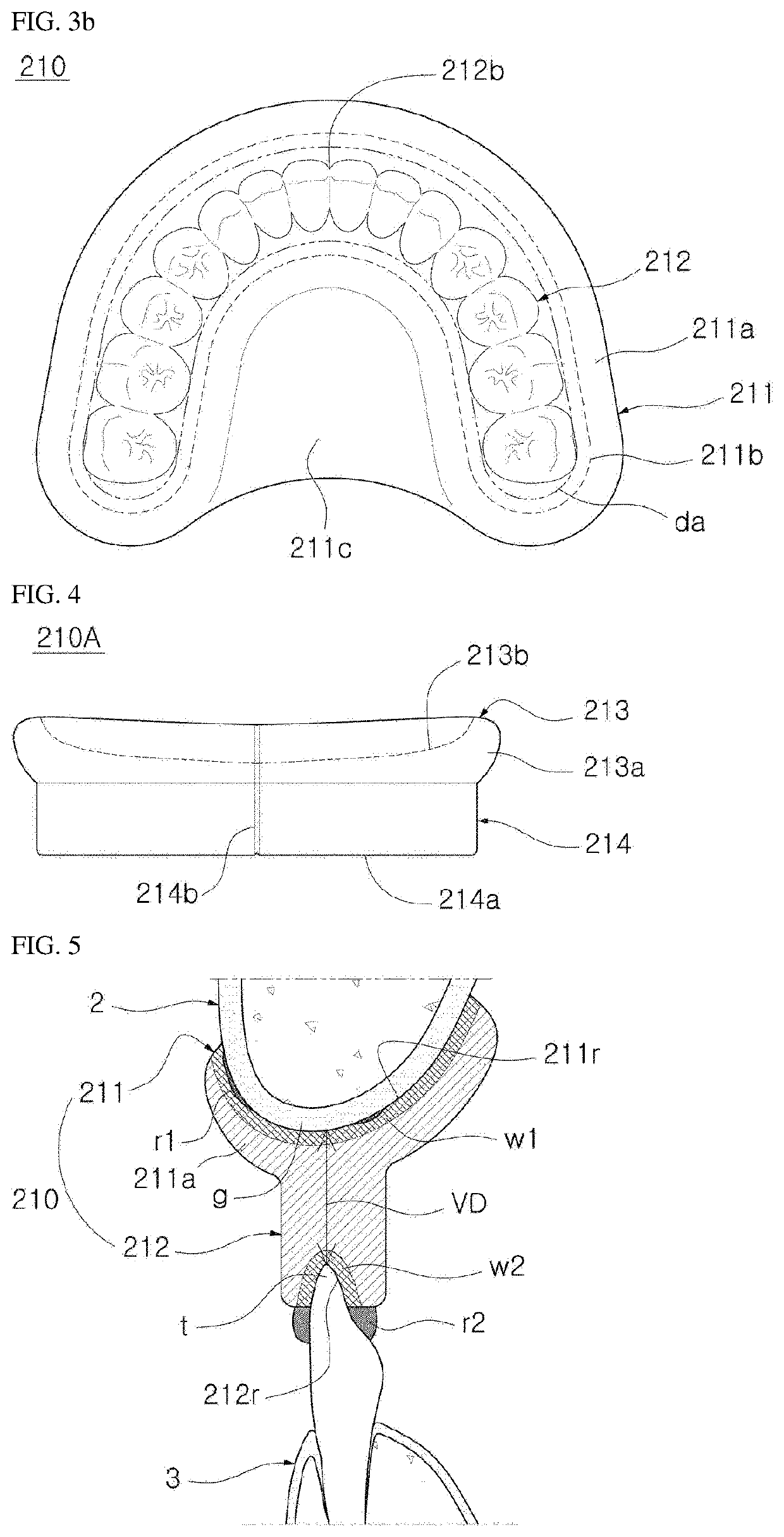

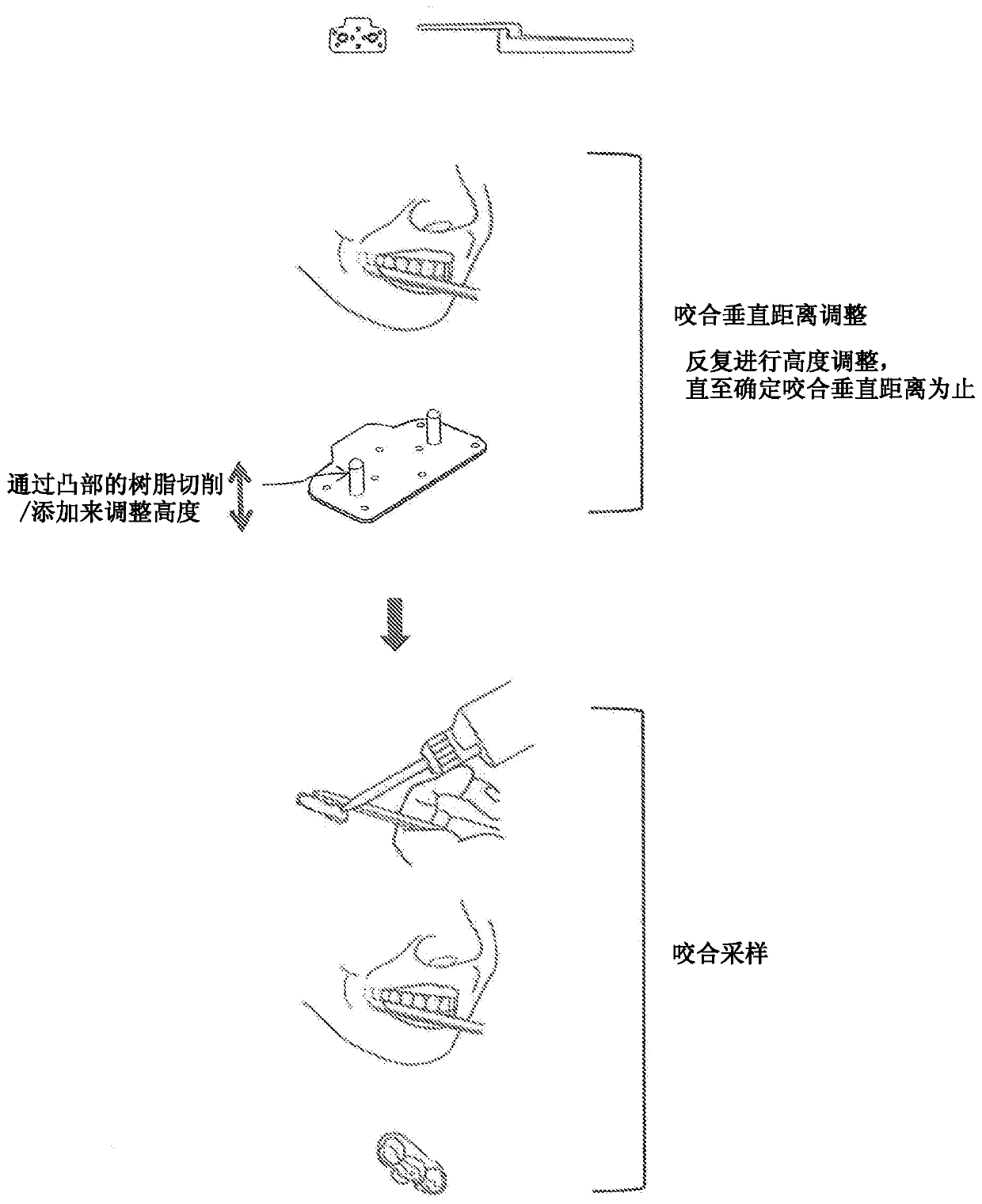

Dental restoration manufacturing method and manufacturing system, and general-purpose wax bite applied thereto

PendingUS20210386527A1Improve usabilityEasy to transformImage enhancementImpression capsParaffin waxOcclusal appliance

To improve the precision of a dental restoration, the present invention provides a dental restoration manufacturing method comprising: a first step of preparing a general-purpose wax bite which is formed of paraffin wax, and which is formed to be standardized in correspondence to a preset standard dental arch profile and is arranged between a part in which implantation is to be performed and an opposite corresponding part, and which comprises a variable matching part corresponding to the part in which implantation is to be performed and being softened when heated to the temperature greater than or equal to a preset temperature, and a press protrusion part that is formed integrally with the variable matching part and protrudes to correspond to the opposite corresponding part and that is softened when heated to the temperature greater than or equal to a preset temperature; a second step of respectively acquiring, through an image capture device, a plurality of scanning images of the part in which implantation is to be performed and of the opposite corresponding part, before the general-purpose wax bite is provided and after the general-purpose wax bite is provided in a state where inner and outer surface parts of the heated general-purpose wax bite are corrected by occlusal pressure in consideration of an occlusal vertical dimension of a patient, and a CT image of an oral cavity occluded through the general-purpose wax bite, and transmitting the acquired images to a planning unit; a third step of generating an integrated scanning image by arranging the plurality of scanning images so as to correspond to the occlusal vertical dimension, and generating a three-dimensional planning image by allowing the integrated scanning image to be overlapped and matched with respect to a common part with the CT image; and a fourth step of generating design information about the dental restoration in consideration of the occlusal vertical dimension, on the basis of the three-dimensional planning information, and transmitting the design information about the dental restoration to a manufacturing device, thereby manufacturing a dental restoration.

Owner:DIO

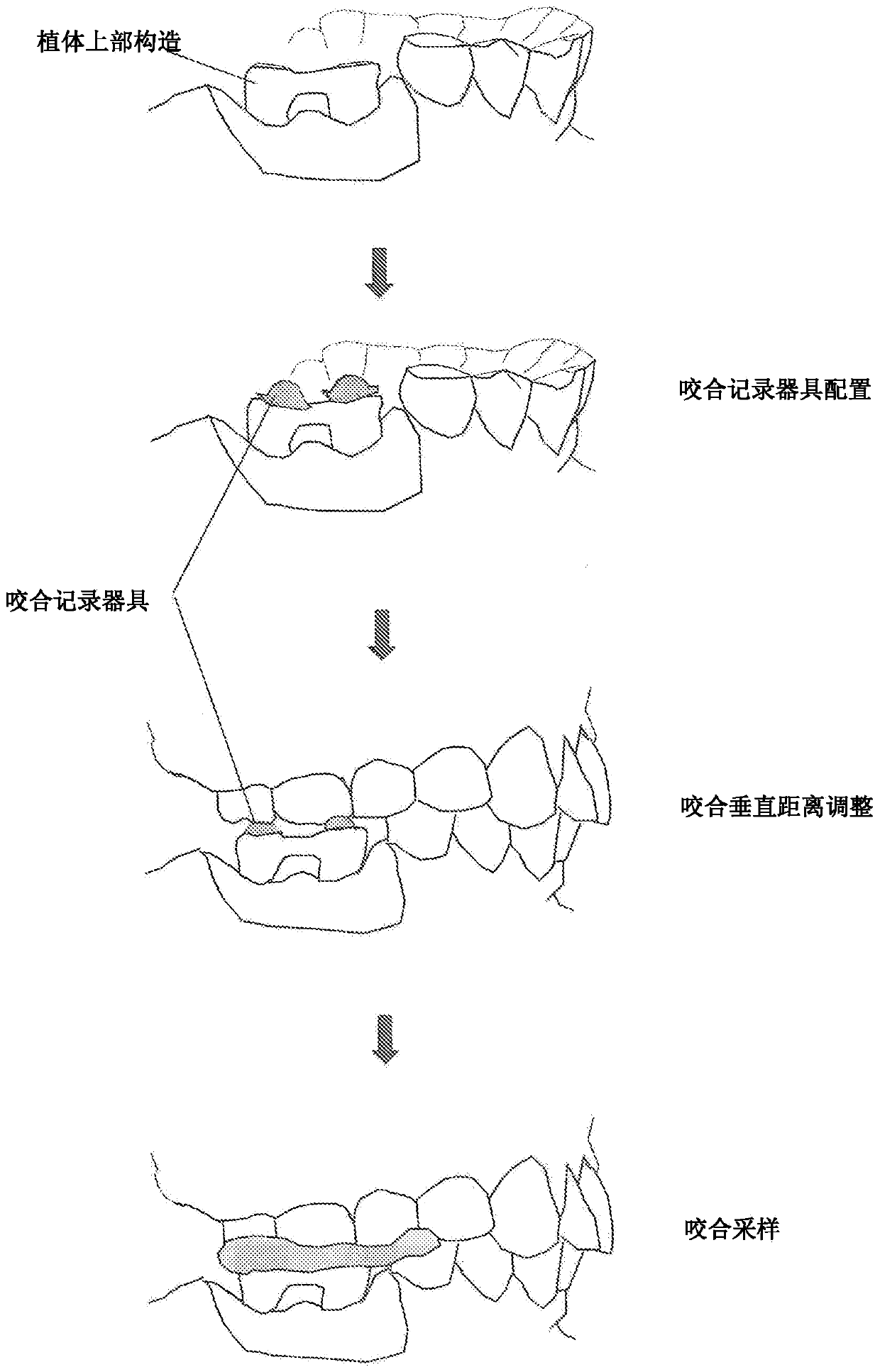

Occlusion recording instrument and articulator

InactiveCN110740706AHigh precisionReduce the burden onDental articulatorsEducational modelsProsthesisOcclusal appliance

Provided is an instrument capable of performing bite checking after accurately acquiring the occlusal vertical dimension within the oral cavity of a patient. Using these instruments in the oral cavitymakes it possible to perform bite checking in a state in which occlusion stability is reproduced by point contact, and to produce a prosthetic device. In addition, a prosthetic device can be producedirrespective of the experience of the operator by an articulator capable of reproducing the shape and movement of the mandible.

Owner:山口荣二

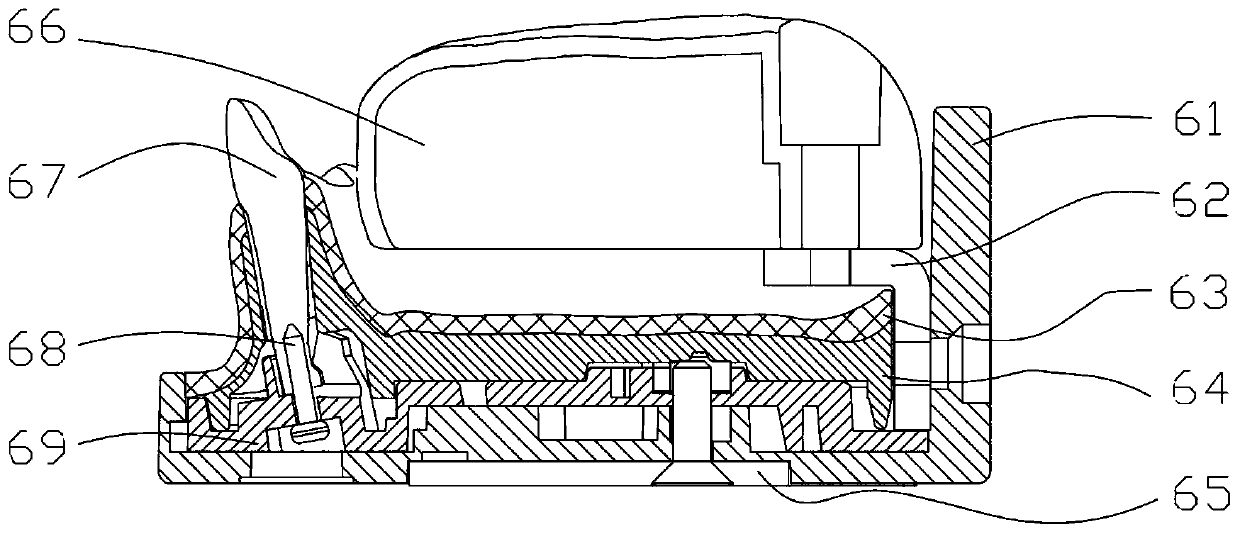

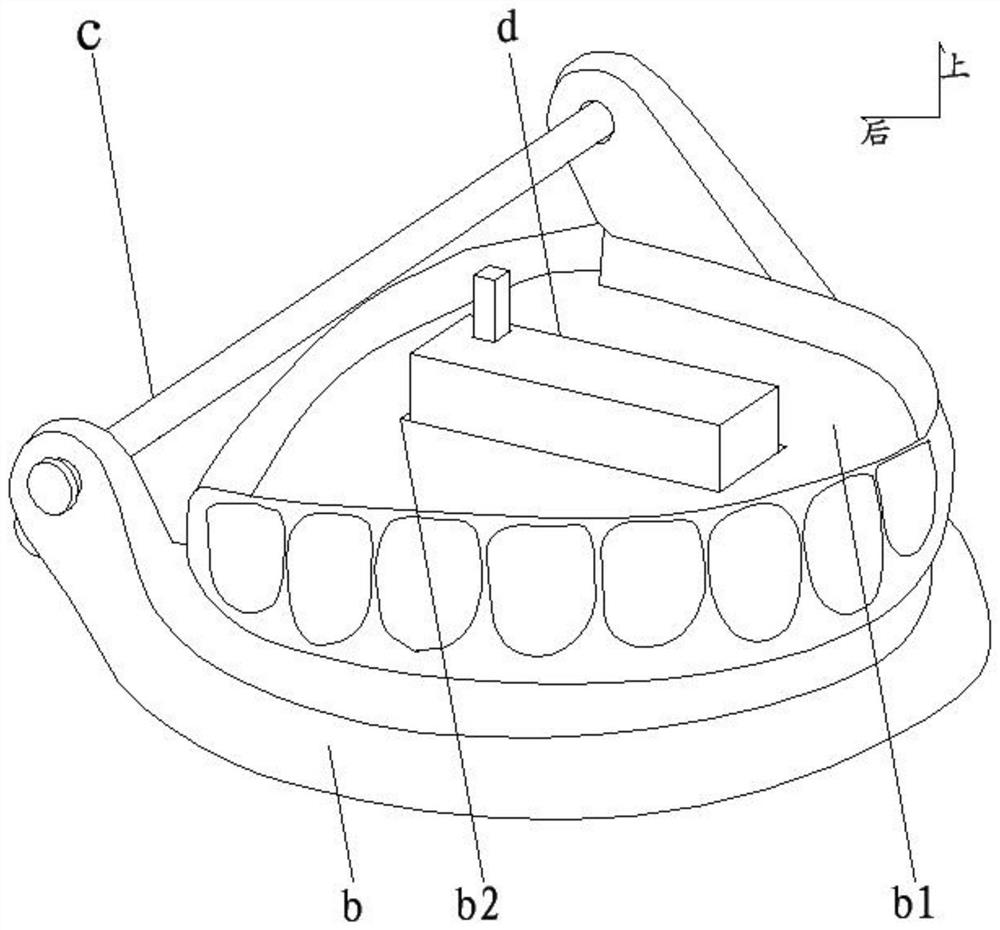

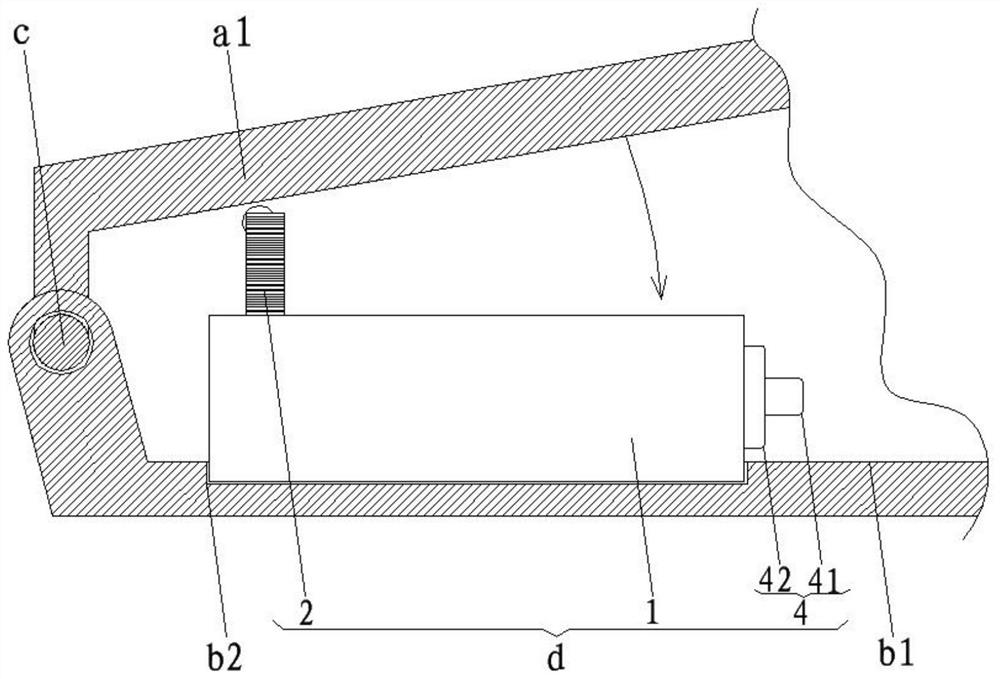

Damping assembly of occluder for oral training

InactiveCN113856149ACompact and reasonable structureAvoid damageMuscle exercising devicesUpper Jaw ToothOcclusal appliance

The invention discloses a damping assembly of an occluder for oral training. The occluder is at least provided with an upper jaw tooth sleeve and a lower jaw tooth sleeve which are connected through a hinge device. The damping assembly is used for providing damping when the occluder is closed. A damping base body comprises a rectangular base body arranged in a damping sinking groove, a small-diameter cavity arranged at the front end of the rectangular base body, a wide-diameter middle cavity formed in the middle of the small-diameter cavity, a transmission rear cavity formed in the upper end of the rear portion of the wide-diameter middle cavity and a gear rear cavity formed in the rear end of the transmission rear cavity. An abutting assembly comprises an abutting longitudinal rod, a transmission transverse shaft and a planet assembly. The number of damping core bodies is two, the damping core bodies are arranged in an axial symmetry mode, and each damping core body comprises a transfer assembly, a driving assembly and a compression assembly. Damping is achieved through the combined action of two damping assemblies in the occluder. When a single damping assembly is damaged and is to be replaced, the other damping assembly can multiply damping in a compensatory manner, so that the damping is kept constant.

Owner:韩艳菊

Disposable dental articulator

InactiveUS20220287806A1Precise alignmentMade preciselyDental articulatorsEducational modelsDental ArticulatorsOcclusal appliance

A disposable dental articulator is proposed. The disposable dental articulator includes a body, a socket coupled to the body and a fixing portion one side of which is slidably coupled to the first socket and the other side of which is configured to be coupled to one of a maxillary dental model and a mandibular dental model.

Owner:KIM YUNSOON +1

Cast mounting for articulator

InactiveUS20130143177A1Avoid damageDental articulatorsEducational modelsDental ArticulatorsOcclusal appliance

A mechanical interfitting connector for repeatably connecting dental models of teeth to articulators without damaging the former. The connector may include a socket mountable to a model and a male member mountable to the articulator, wherein the male member enters and engages the socket. The socket may be adhered to the model or alternatively partially embedded therein. A screw may be passed through the socket and male member so as to leave a small marking on the dental model, thereby indexing the socket and model for subsequent mountings, and also to prevent disengagement of the male member from the socket. A supplementary plate may be provided to secure anchoring of the male member to the socket, and to shield plaster which has not fully hardened against damage during hardening.

Owner:GAMBACORTA ENZO

Method for articulator adjustment and gnathological instruments for work under this method

ActiveUS9517116B2Improve accuracyImprove reliabilityImpression capsDental articulatorsDental ArticulatorsOcclusal plane

The method for articulator adjustment and gnathological instruments for work under this method find application in dental medicine and laboratory dental techniques. These and other goals of this invention are achieved with the measurement of the individual parameters of the patient's mandibular transversal hinge axis in the three planes: transversal, frontal and sagittal, including the following steps: measurement of inter-condylar distance; measurement of the distance between the condylar axis and the occlusal plane; measurement of the distance between the condylar axis and central incisors with a face-bow and bite-tray (FIGS. 1,10,11,12); recording of values; simultaneous fixation in the articulator in minimal gathered position of the manufactured in advance two primary working models juxtaposed in central position: a mandibular lower working model to the working plate of the lower articulator frame and a maxillary upper working model to the opposite working plate, which is connected in a telescopic way to the upper articulator frame (FIGS. 2,3,4,5,6,13); coincidence of the mandibular transversal hinge axis of a patient in terms of measured values of his individual parameters and the articulator transversal hinge axis (FIGS. 7,8,9,14); and closure of this articulator in an individual spread-out position.

Owner:F ARTICULATOR DENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com