Automatic tobacco stem bale opening mechanism for tobacco

An automatic and stalk-packing technology, applied in the field of tobacco processing machinery, can solve the problems of high labor intensity, large amount of environmental dust, and affecting the physical and mental health of workers, and achieve the goal of improving the level of automation, high degree of intelligence, and improving the working environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

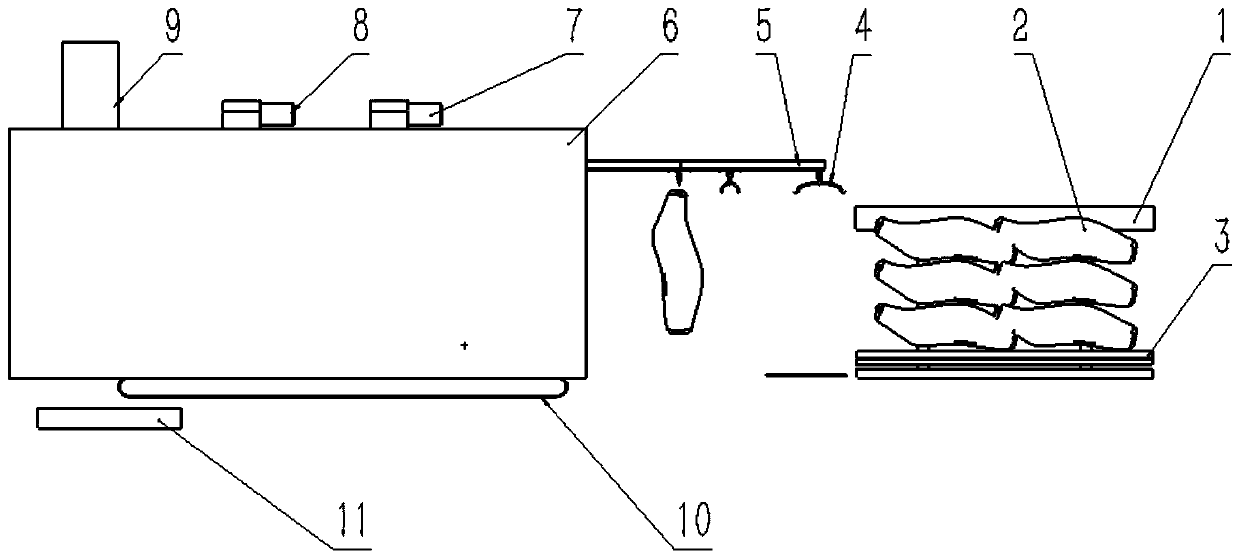

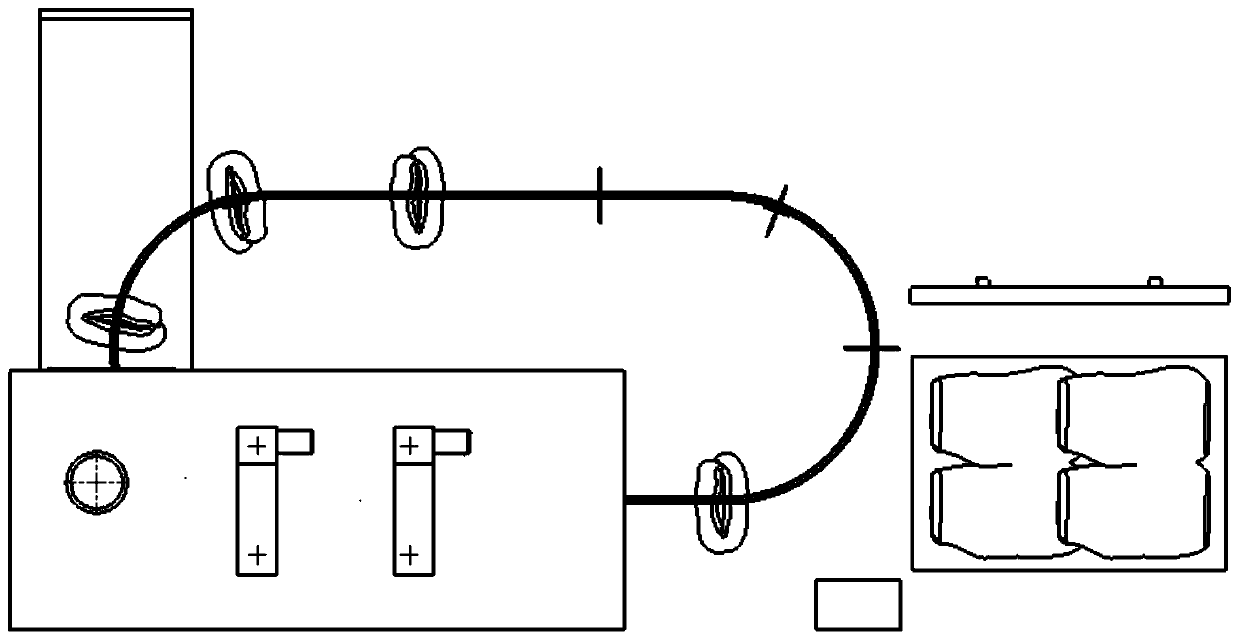

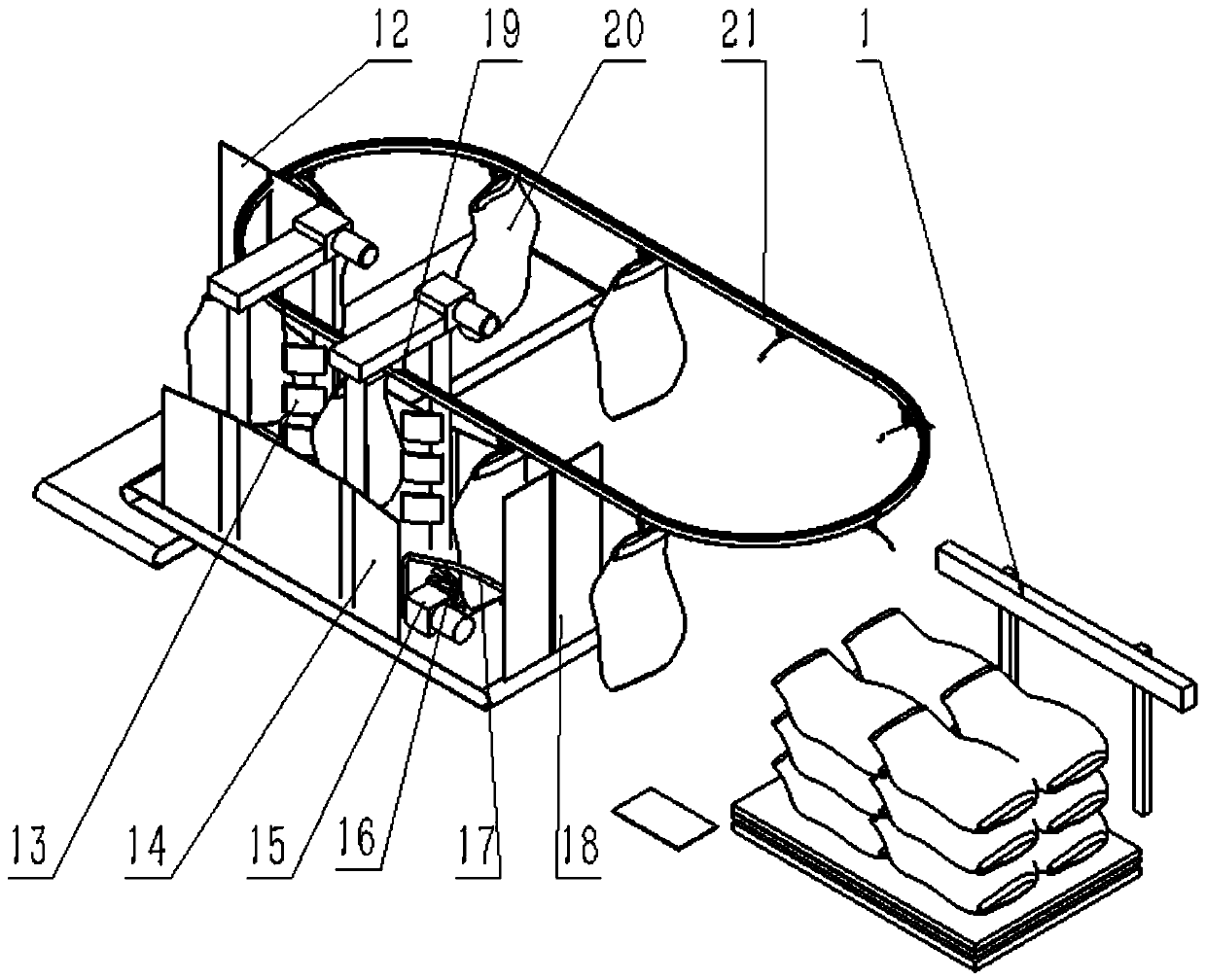

[0029] like Figures 1 to 3 As shown, a mechanism for automatically opening tobacco stem packs includes a lifting platform 3, a height sensor 1, a suspension system, an isolation chamber 6, a pack opening system, a conveying system, a dust removal system 9 and a control system.

[0030] The height sensor 1 is set on the side of the lifting platform 3; the height sensor is connected with the electrical signal of the control system; the lifting platform is used to lift the tobacco stem pack 2, and the height position of the tobacco stem pack is automatically controlled by the height sensor, so that the hanging tobacco stem pack is always ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com