Arch bridge skewback excavation construction method applicable to steep mountain massif

A construction method and mountain technology, applied in excavation, infrastructure engineering, construction, etc., can solve problems such as over-excavation, irregular abutment excavation, and damage to the stability of mountain slopes, so as to ensure the excavation size and avoid disturbance , The effect of construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

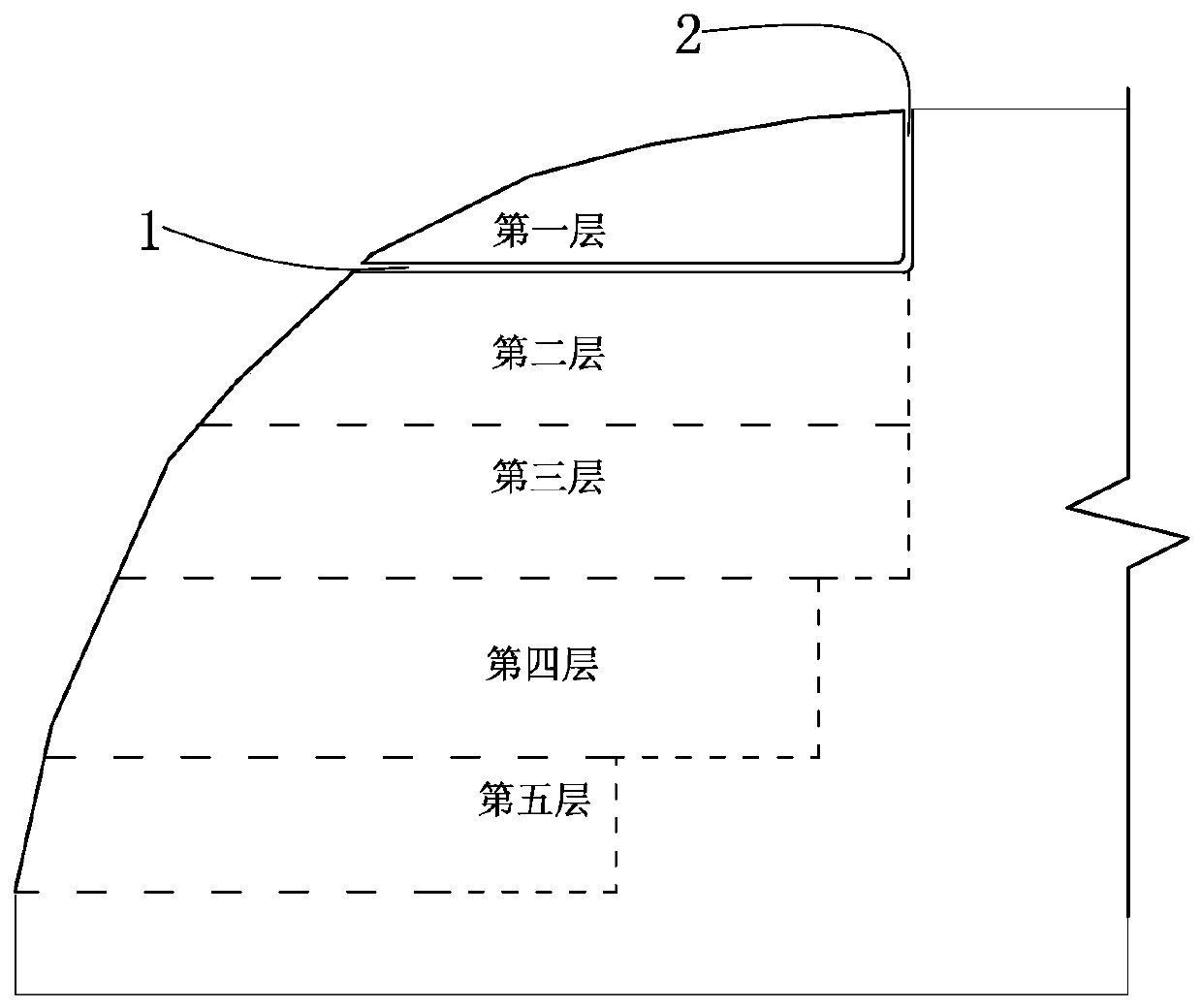

[0019] Wire saw is a tool for circular cutting, which is often used in mining, block shaping, bridge cutting, underwater cutting and other fields. The present invention utilizes the characteristics of the wire saw to cut the large rock mass at the excavation site of the abutment into multiple flakes with smaller volume and thinner thickness by using the wire saw for the rock mass that is not suitable for blasting construction, and then breaks the rock flakes and clear.

[0020] Concrete construction method of the present invention is as follows:

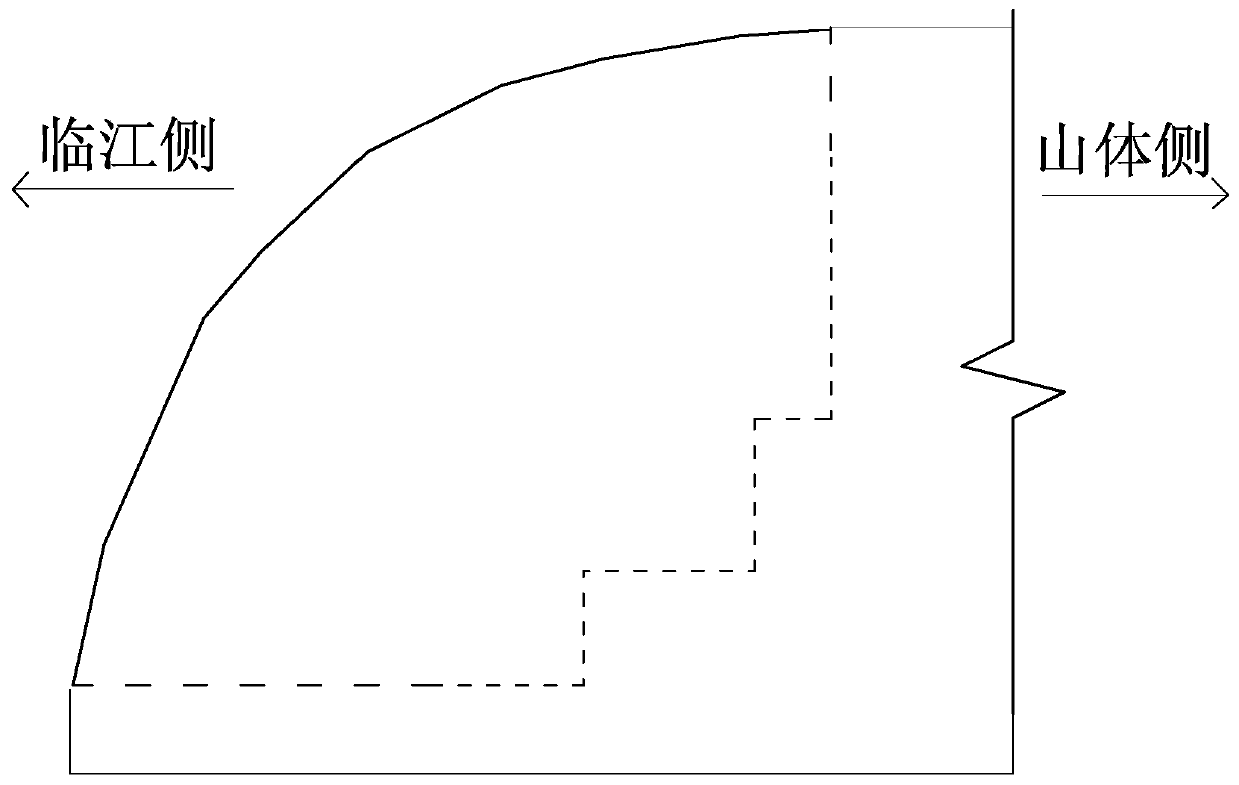

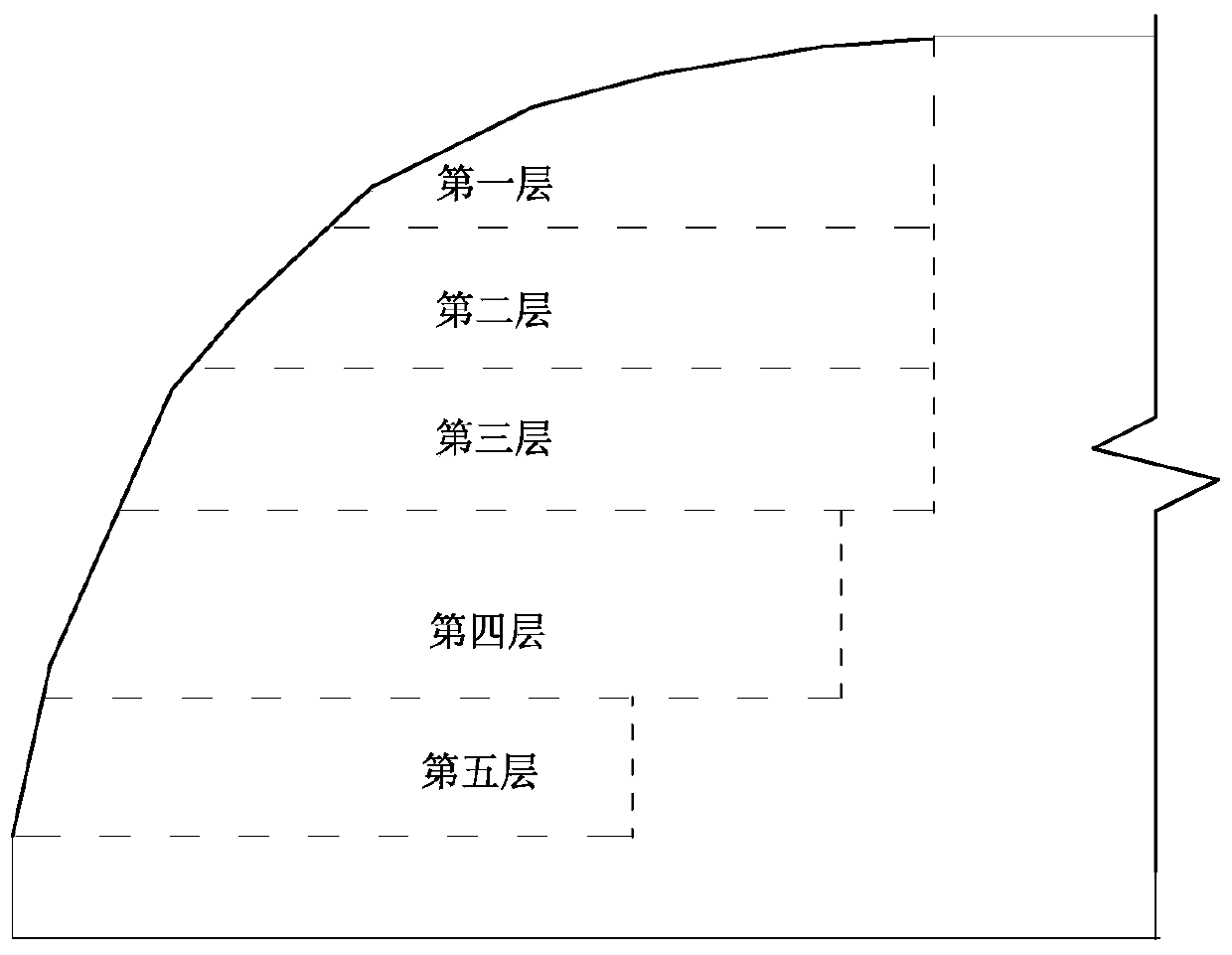

[0021] (1) if figure 2 As shown, the surveyors firstly measure and position the edge of the abutment, and then divide the excavation position of the abutment into multiple excavation layers from top to bottom, and the bottom surface of each excavation layer is parallel to the horizontal plane of the abutment steps. figure 2 In the shown embodiment, the rock mass at the excavation site of the abutment is divided into 5 excavation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com