Steel smelting slag treatment method

A treatment method and technology for iron and steel smelting, applied in furnaces, furnace components, descaling devices, etc., can solve problems such as pollution, poor screening effect, and unsatisfactory washing effect, and achieve the effect of improving distribution uniformity and ensuring comprehensiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

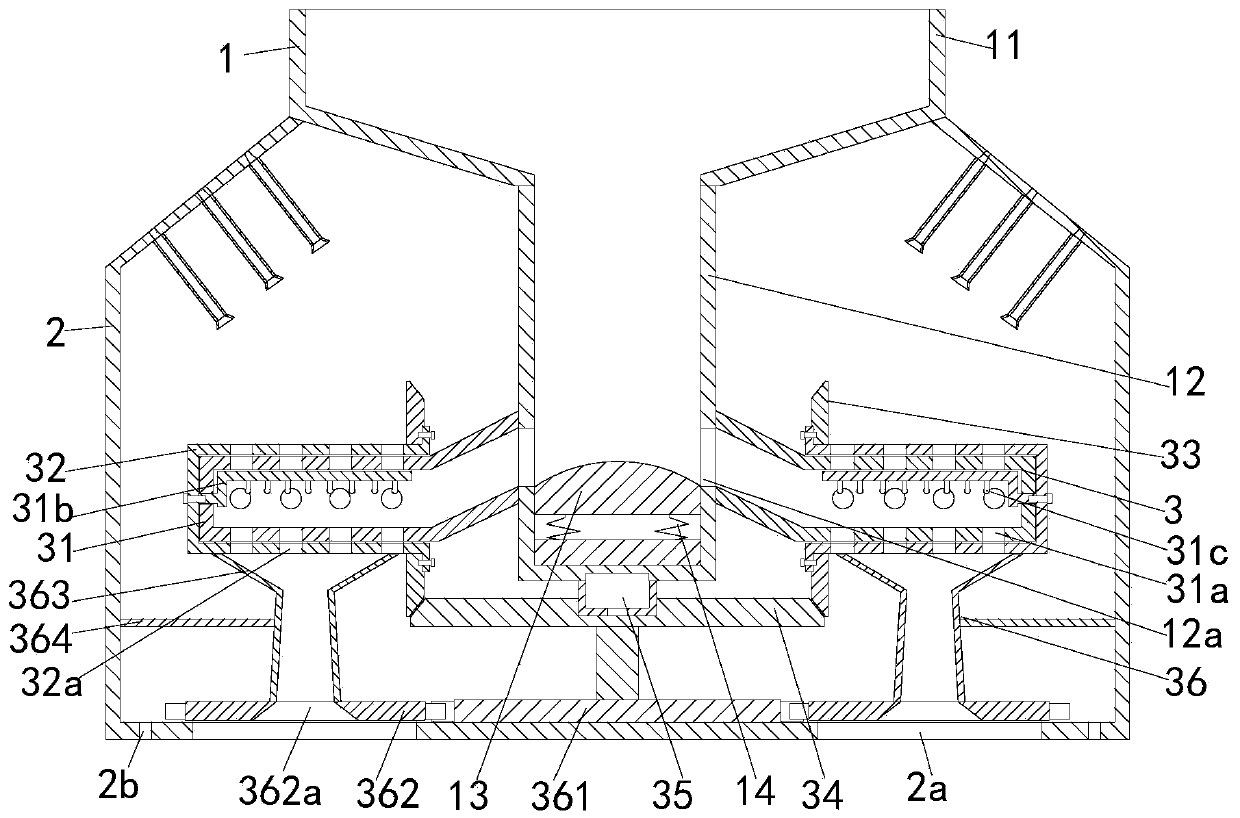

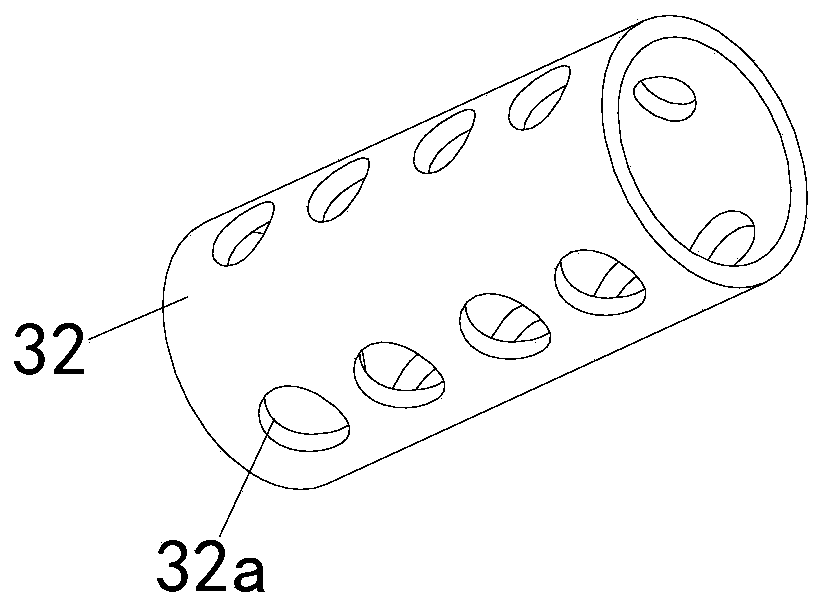

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

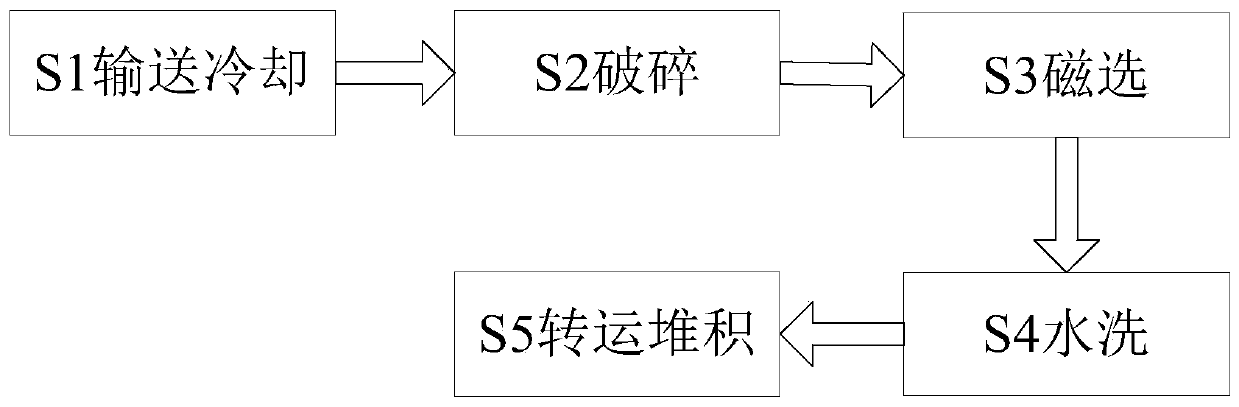

[0033] like Figure 1 to Figure 4 Shown, a kind of iron and steel smelting slag processing method mainly comprises the following steps:

[0034] S1. Conveying and cooling: the slag is conveyed by a belt conveyor, and the temperature of the slag is reduced by using air cooling equipment, and at the same time, a part of the ash adhered to the surface of the slag can be removed;

[0035] S2. Crushing: Use the jaw crusher to crush the slag initially, and then use the cone crusher to crush the slag for the second time;

[0036] S3. Magnetic separation: use a magnetic separator to separate the slag, and separate magnetic substances from the slag;

[0037] S4. Water washing: use water washing equipment to clean the separated slag to eliminate the ash adh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com