Patents

Literature

33results about How to "To achieve the purpose of washing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

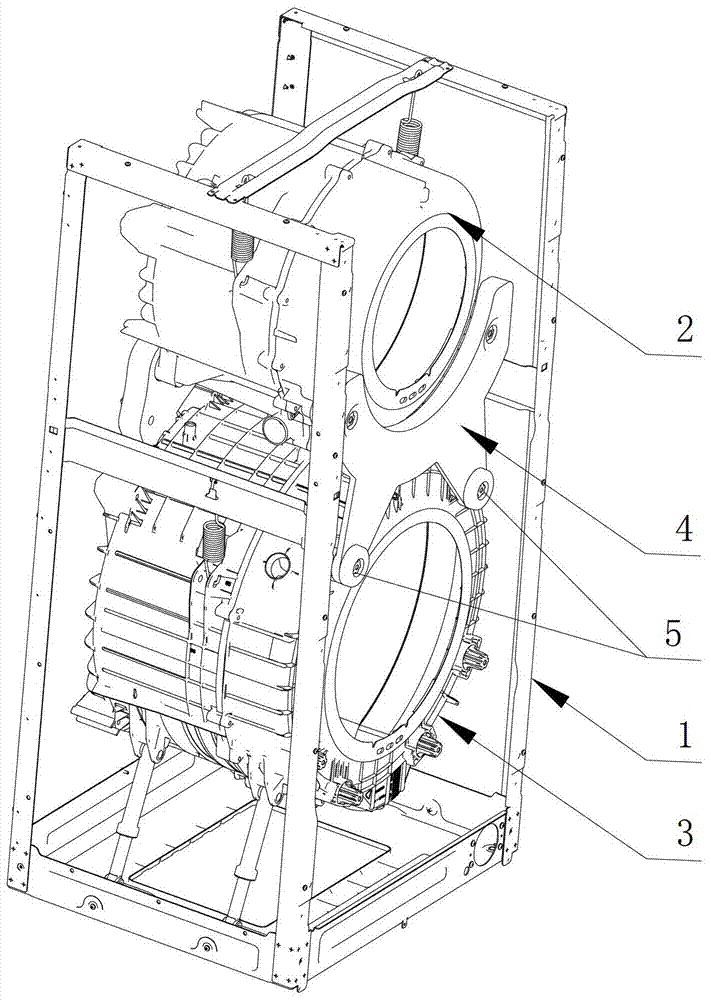

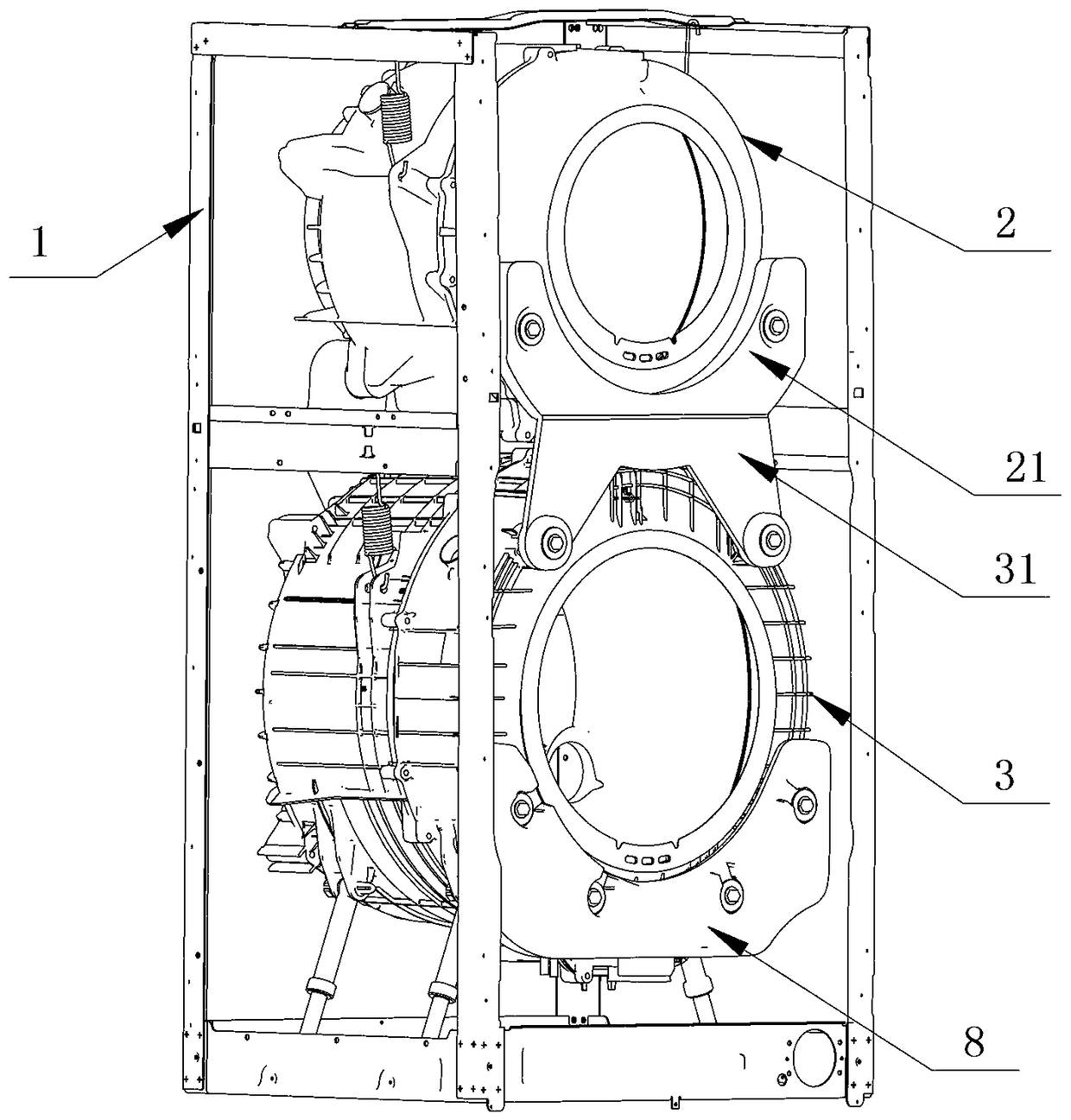

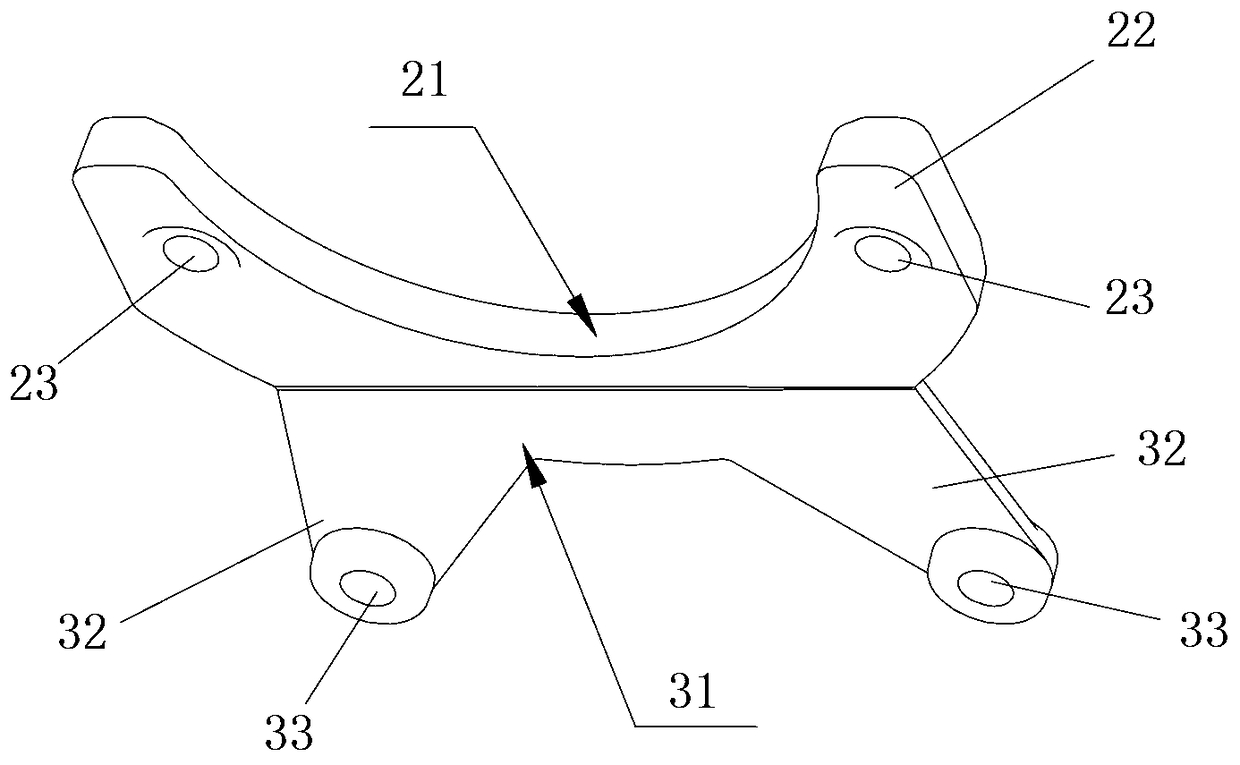

Double-drum washing machine

ActiveCN104278481AImprove compactnessTo achieve the purpose of washingOther washing machinesTextiles and paperEngineeringMechanical engineering

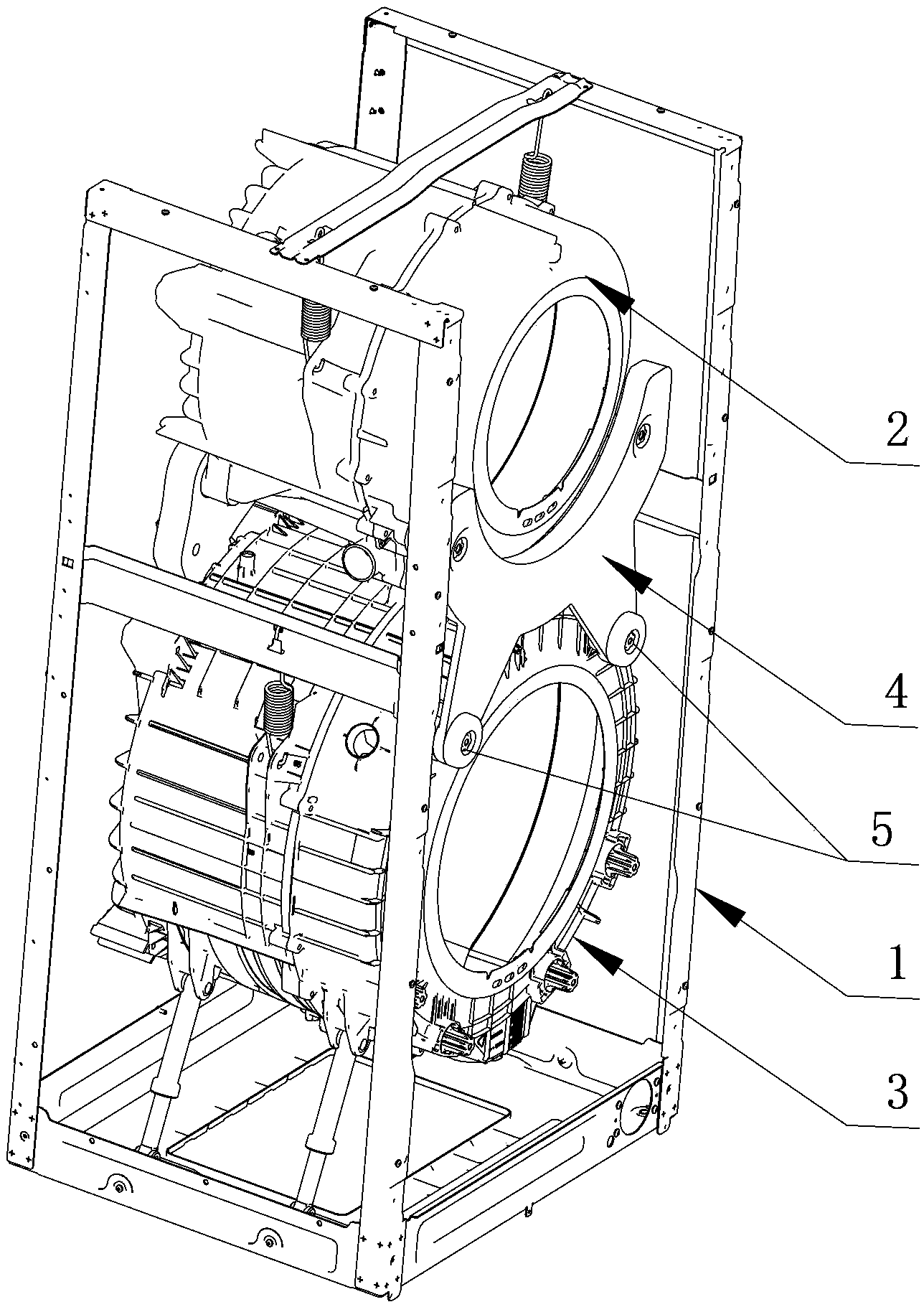

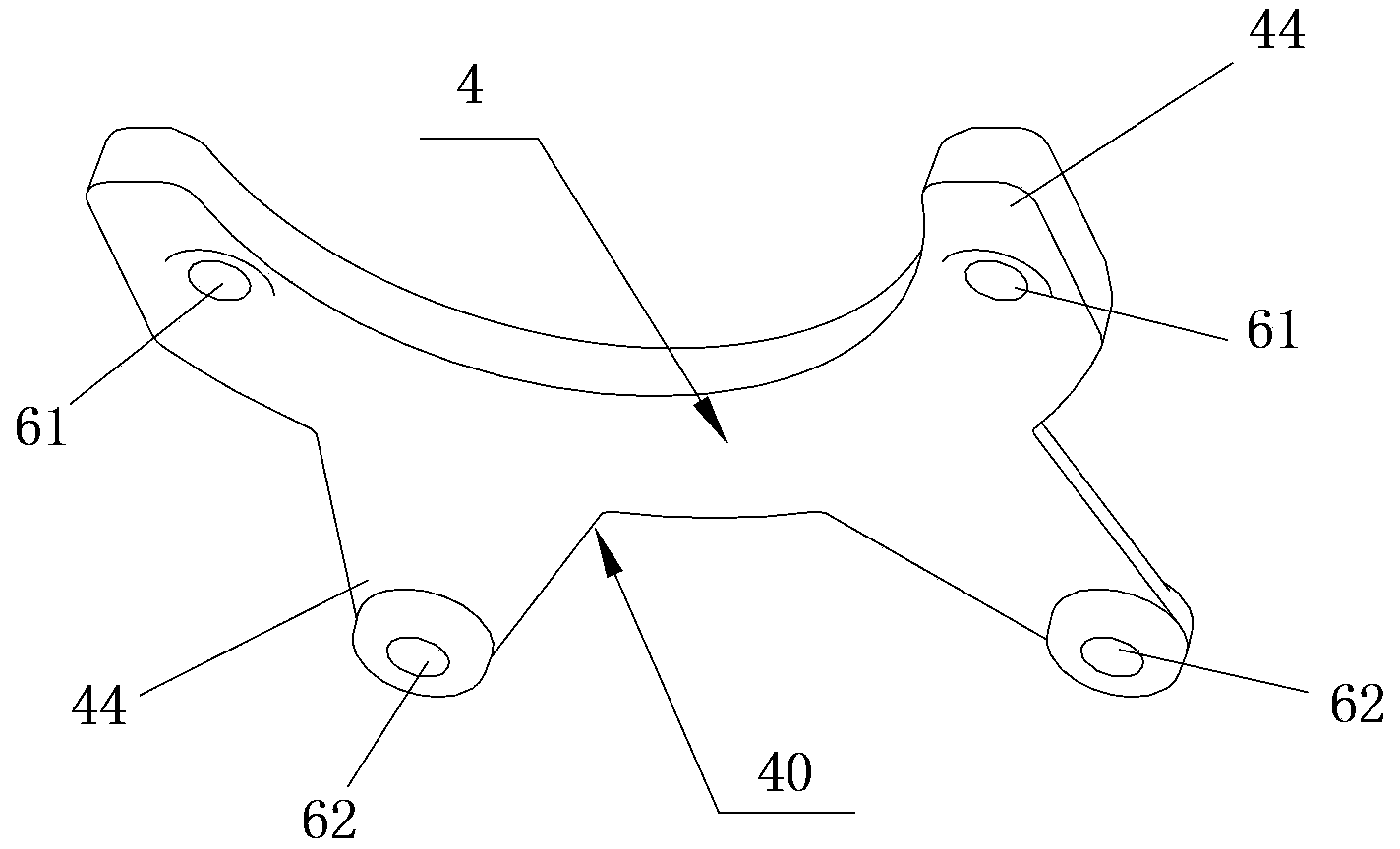

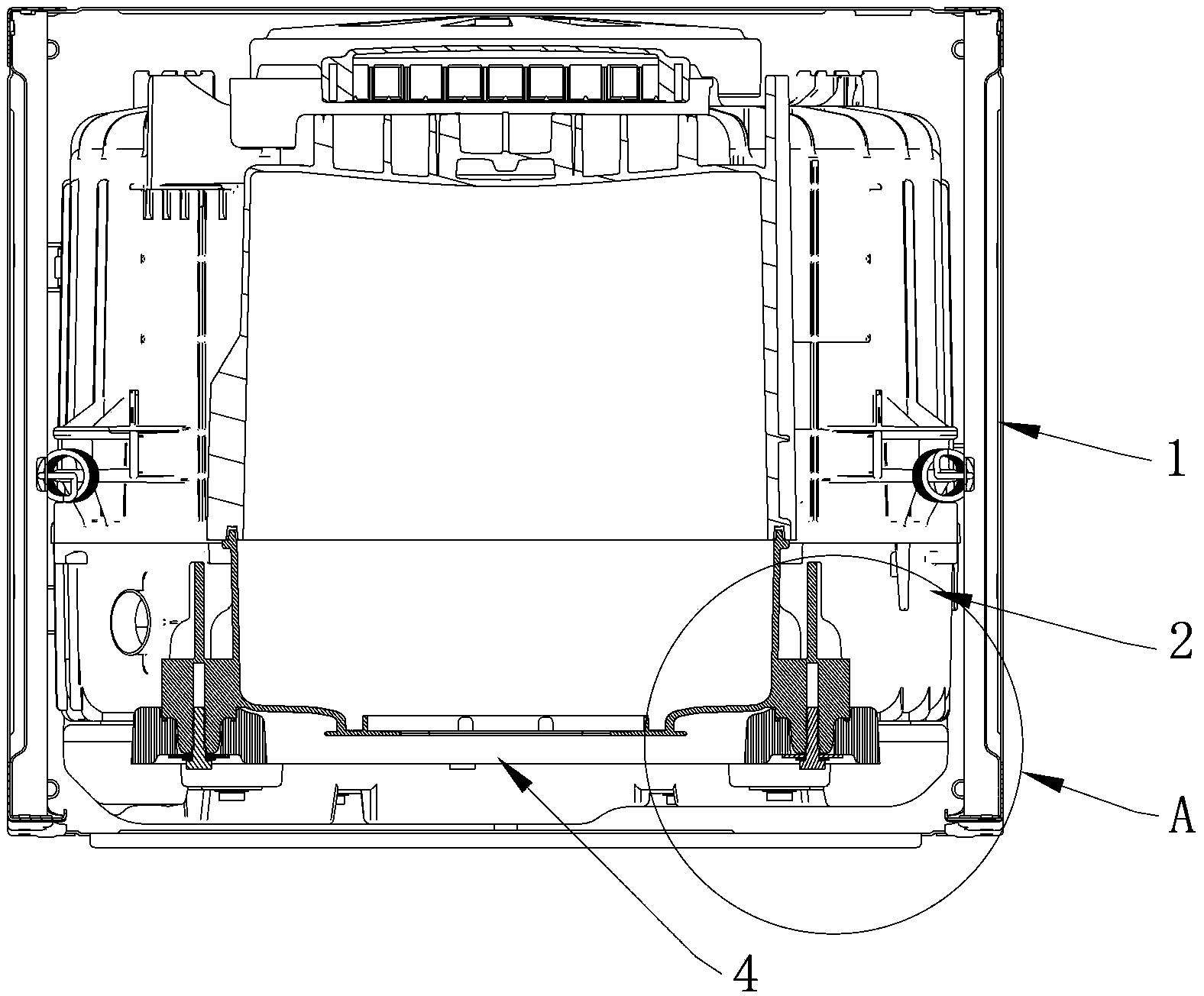

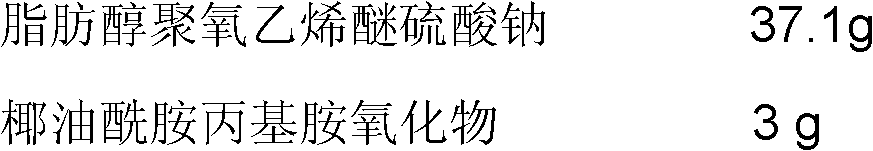

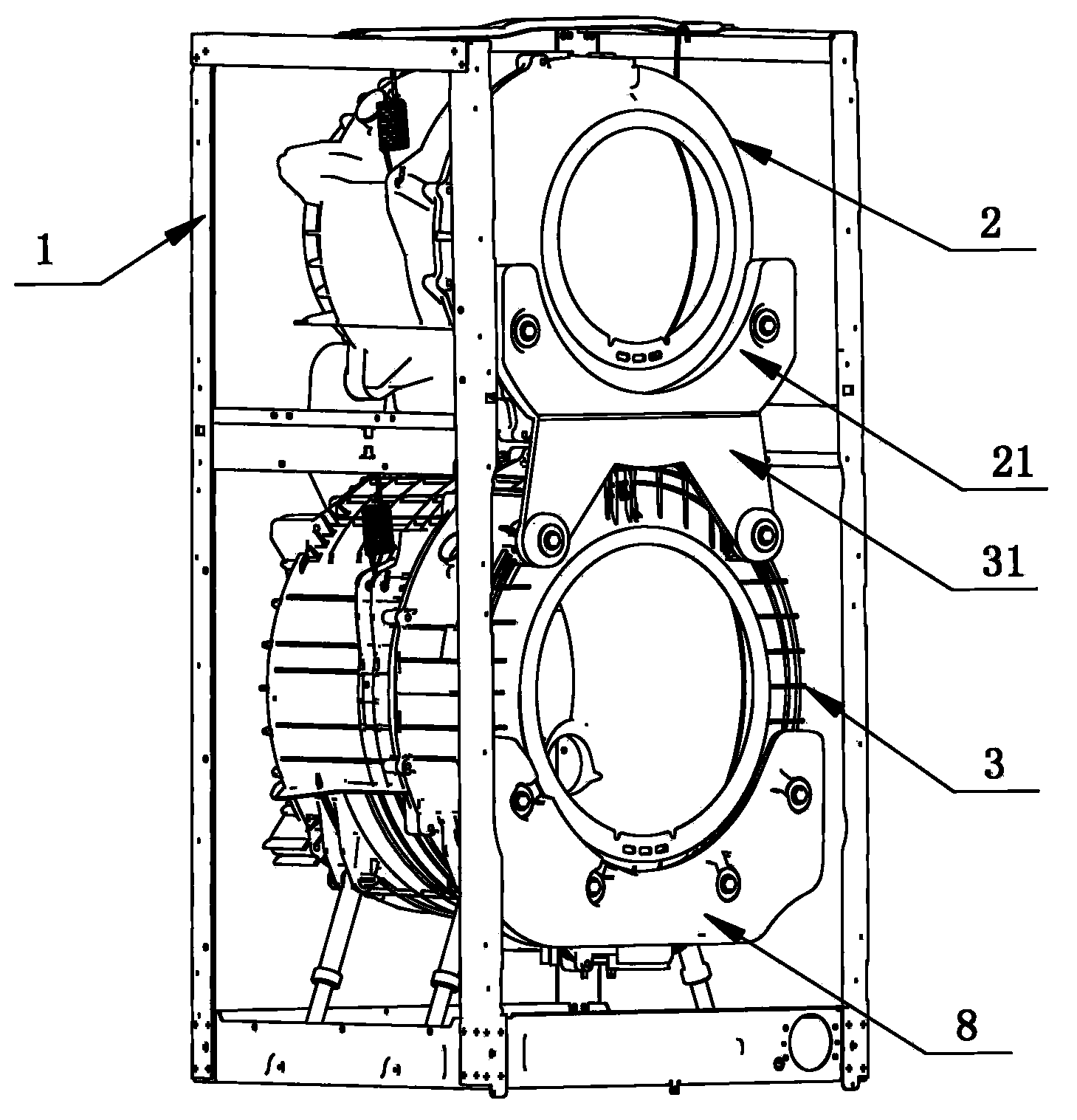

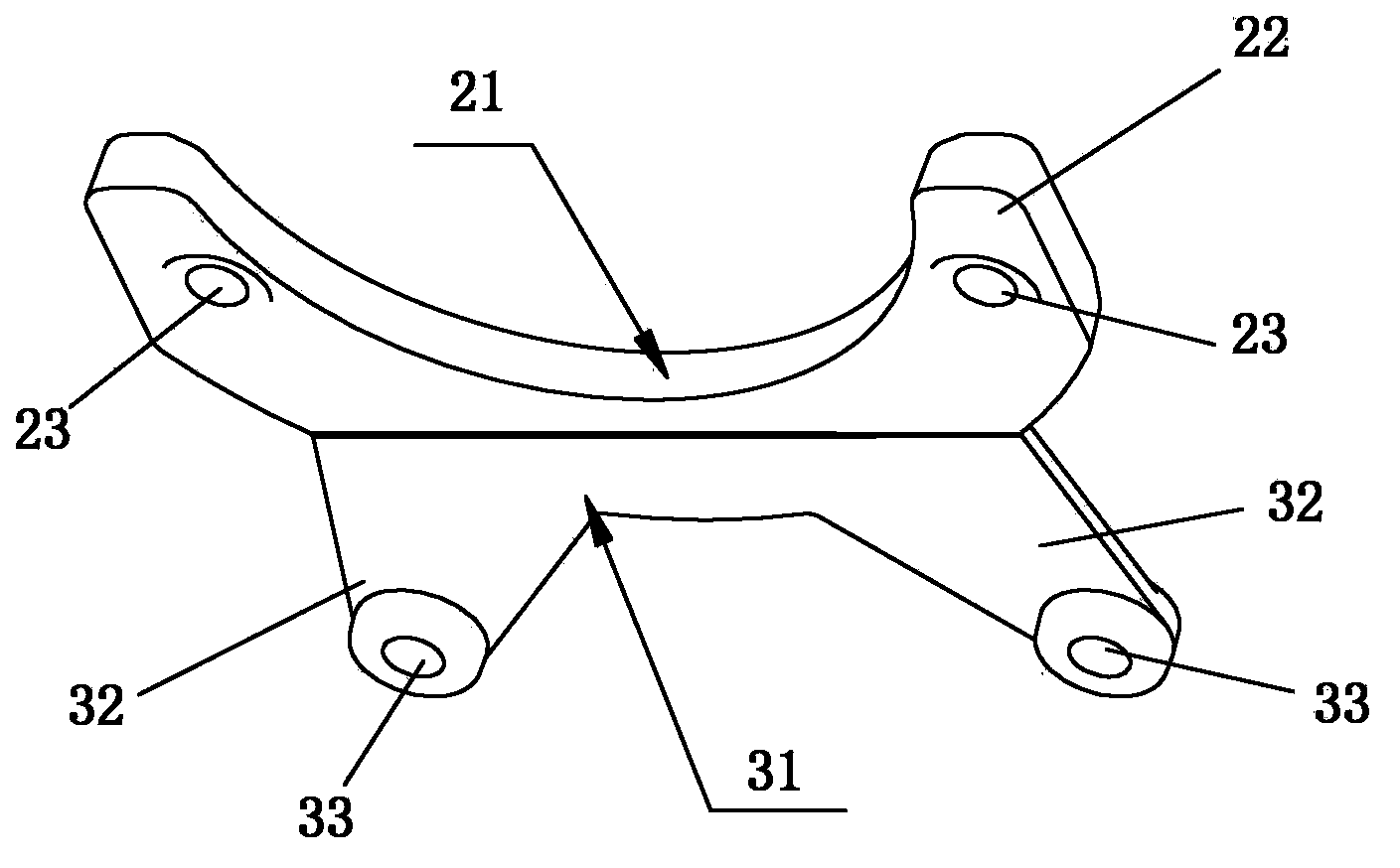

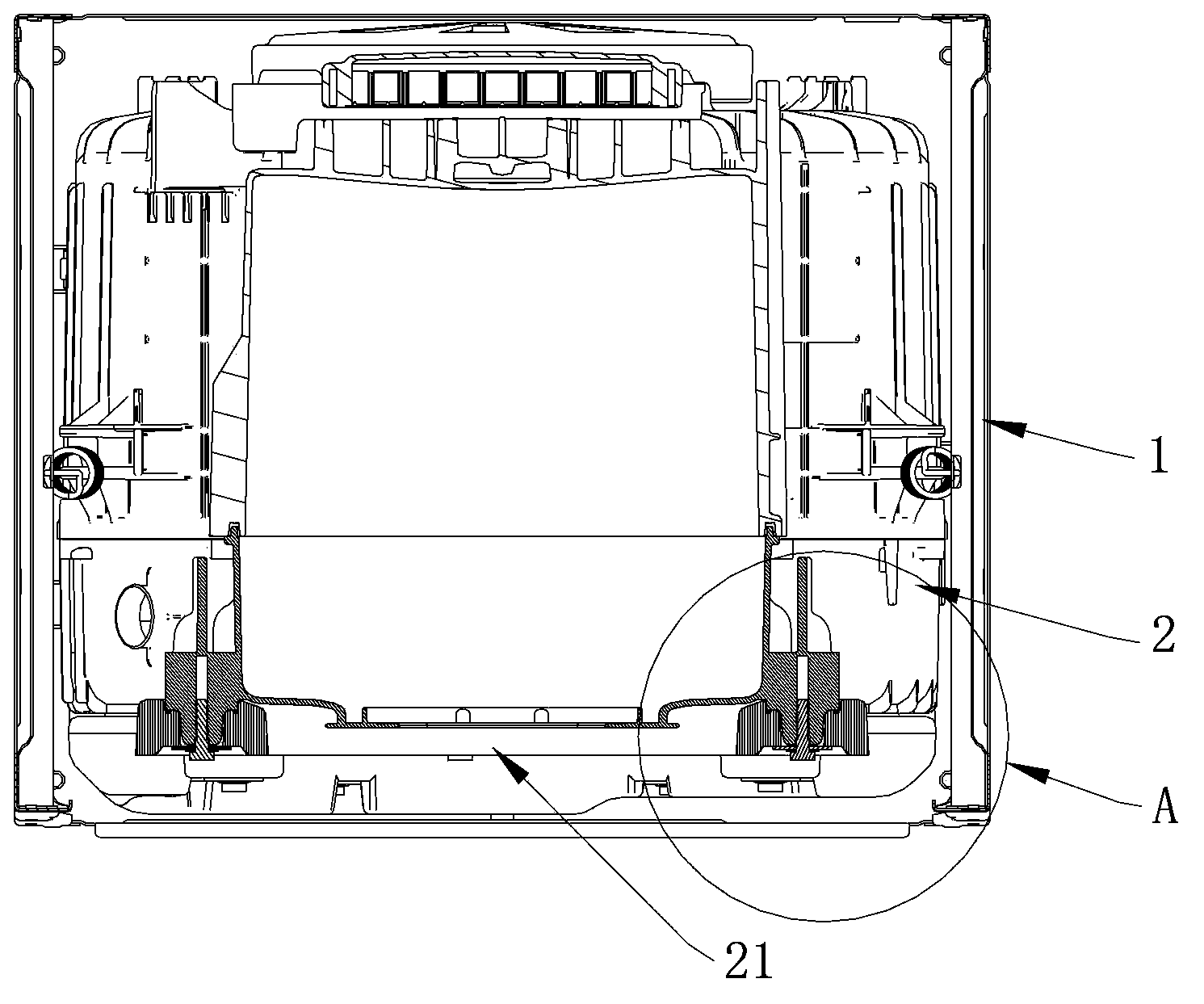

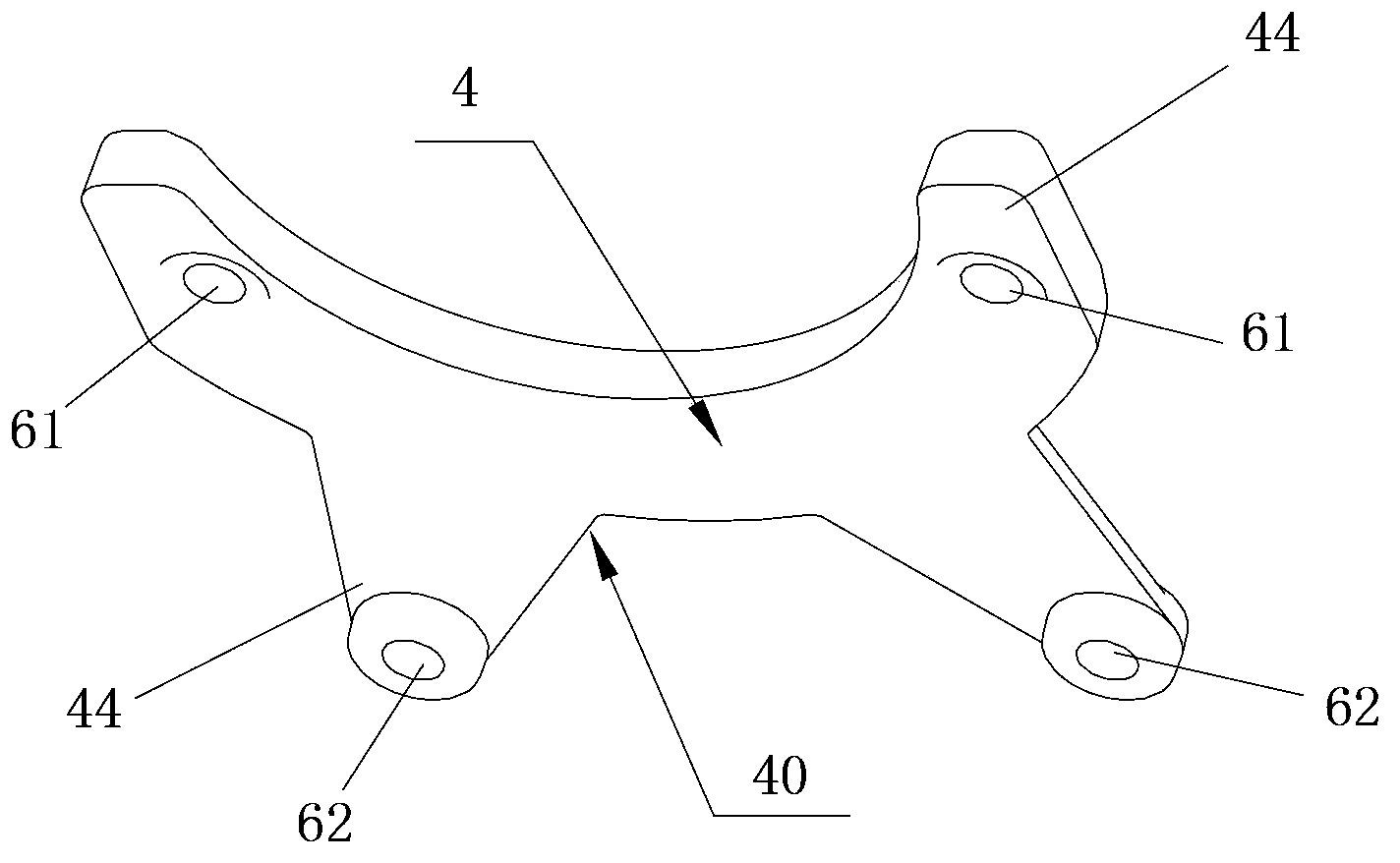

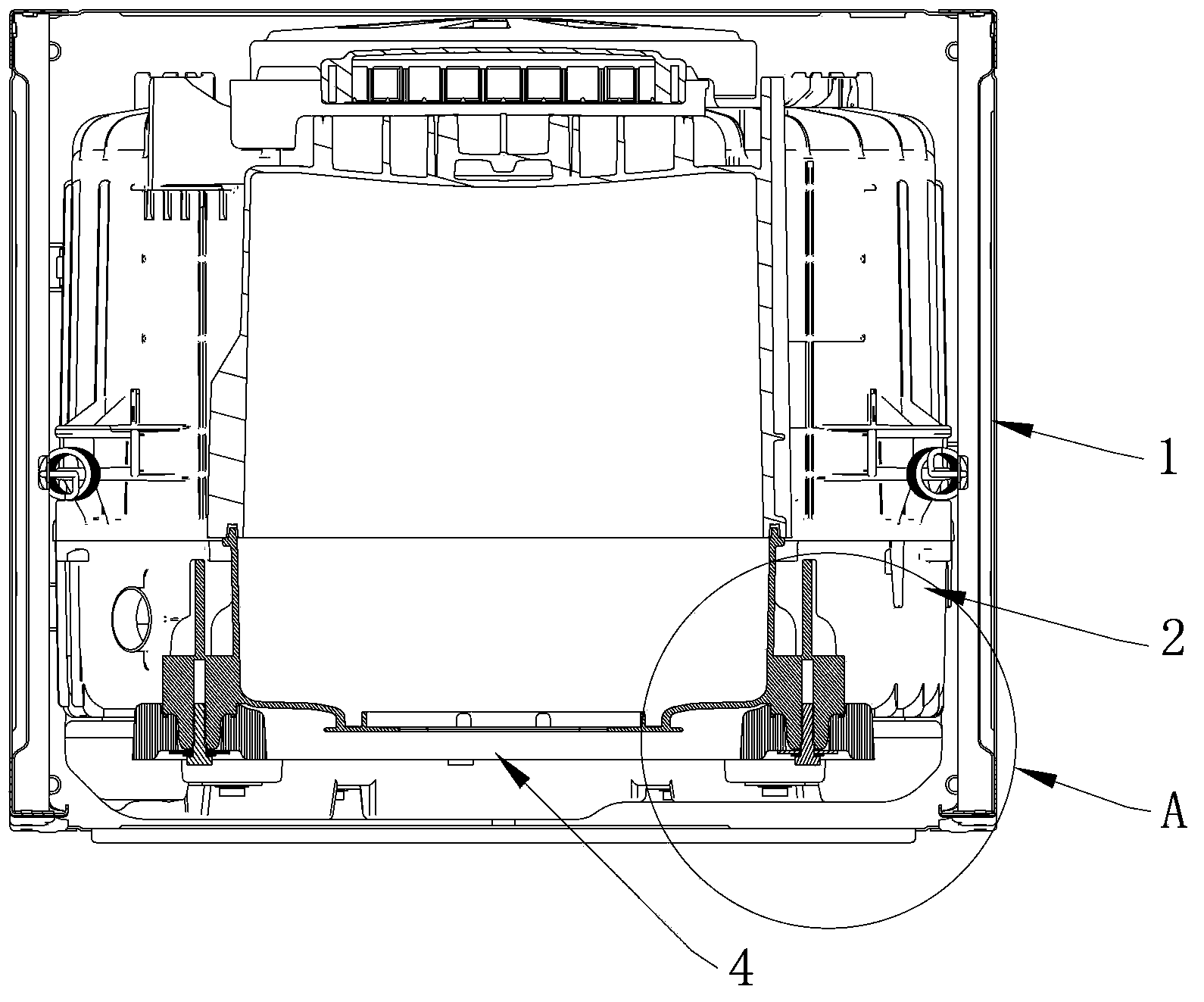

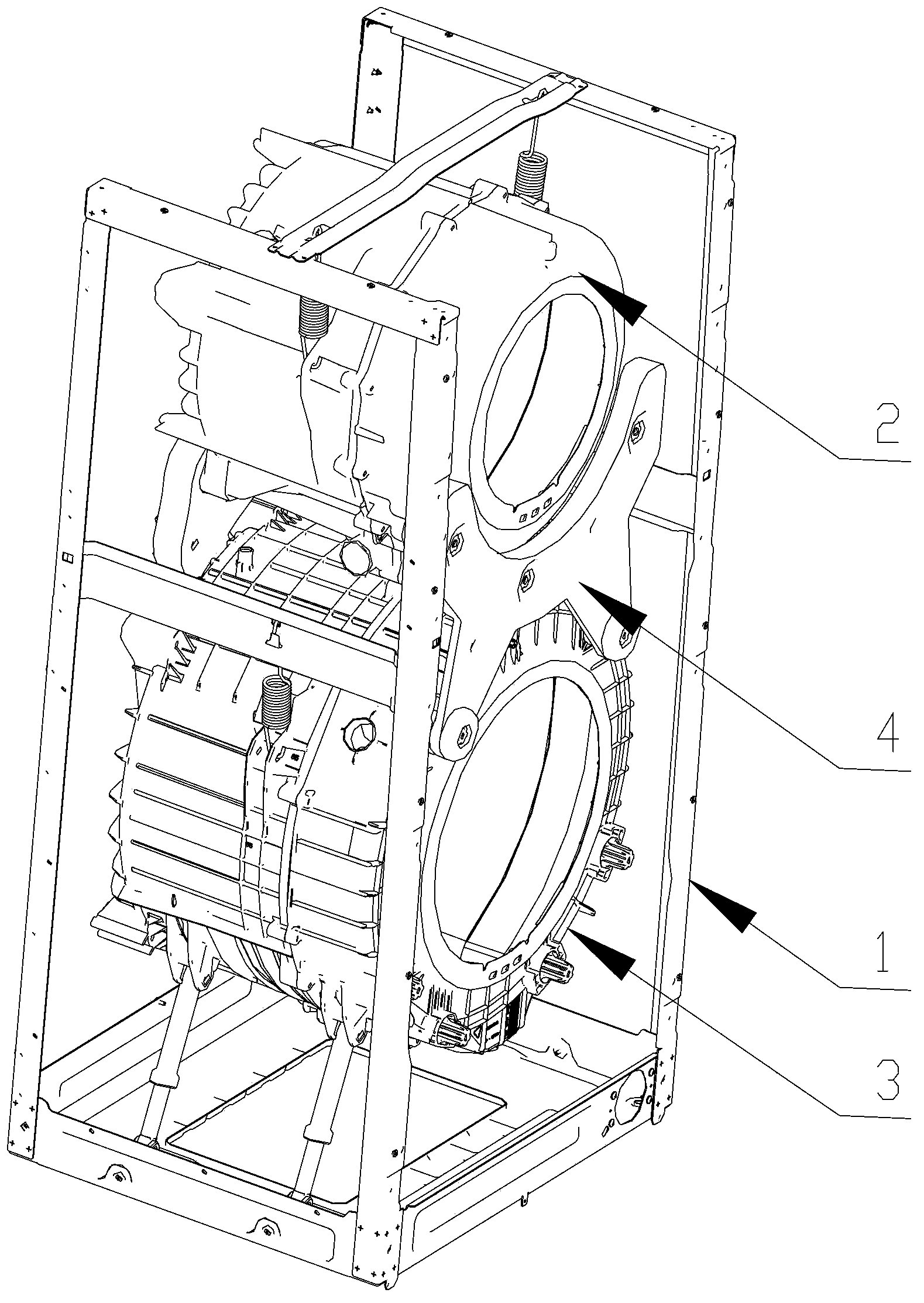

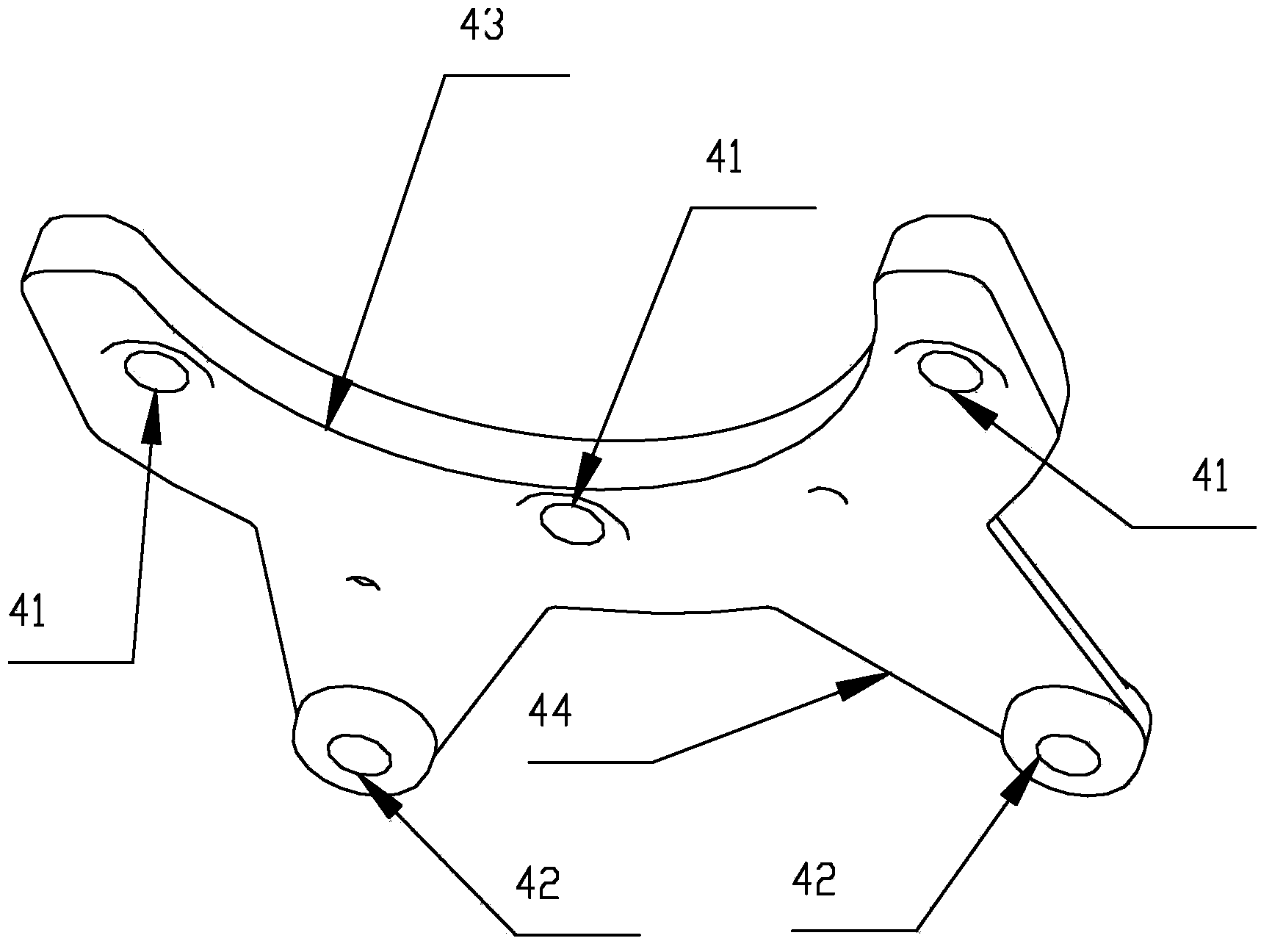

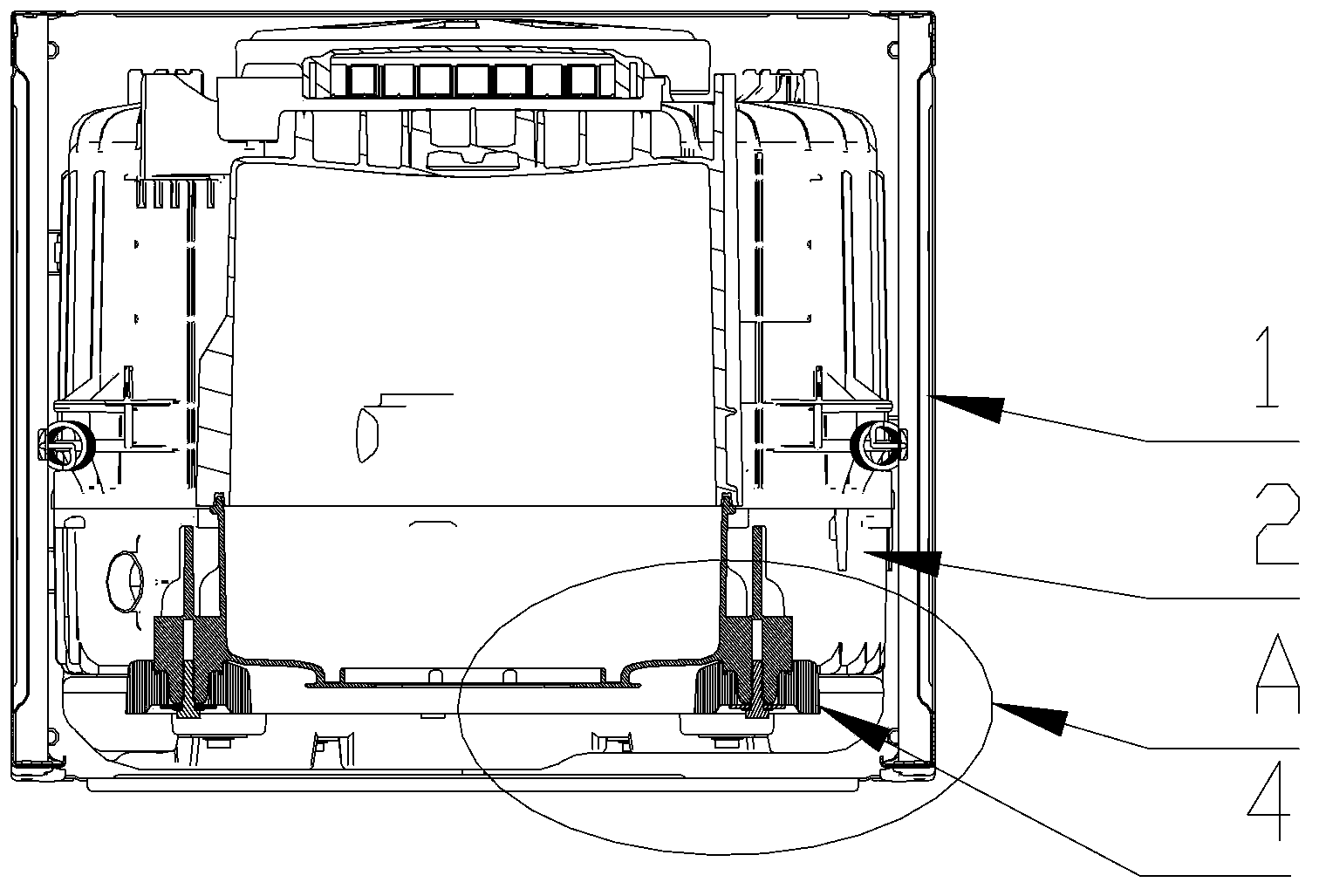

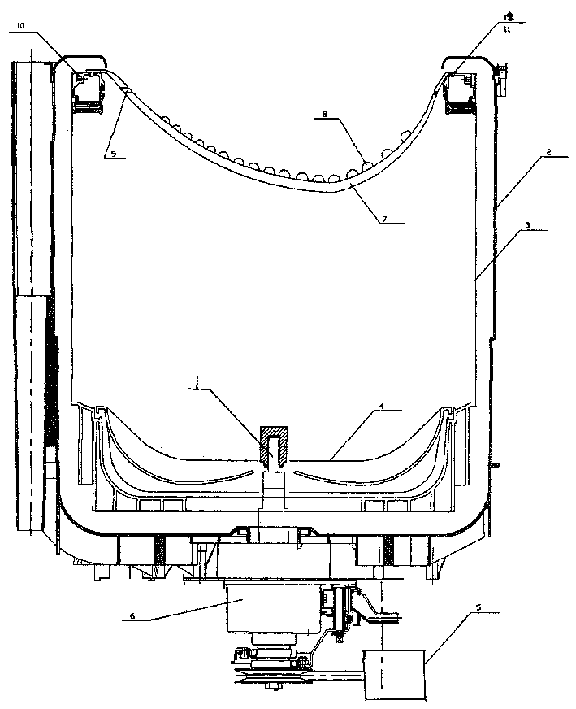

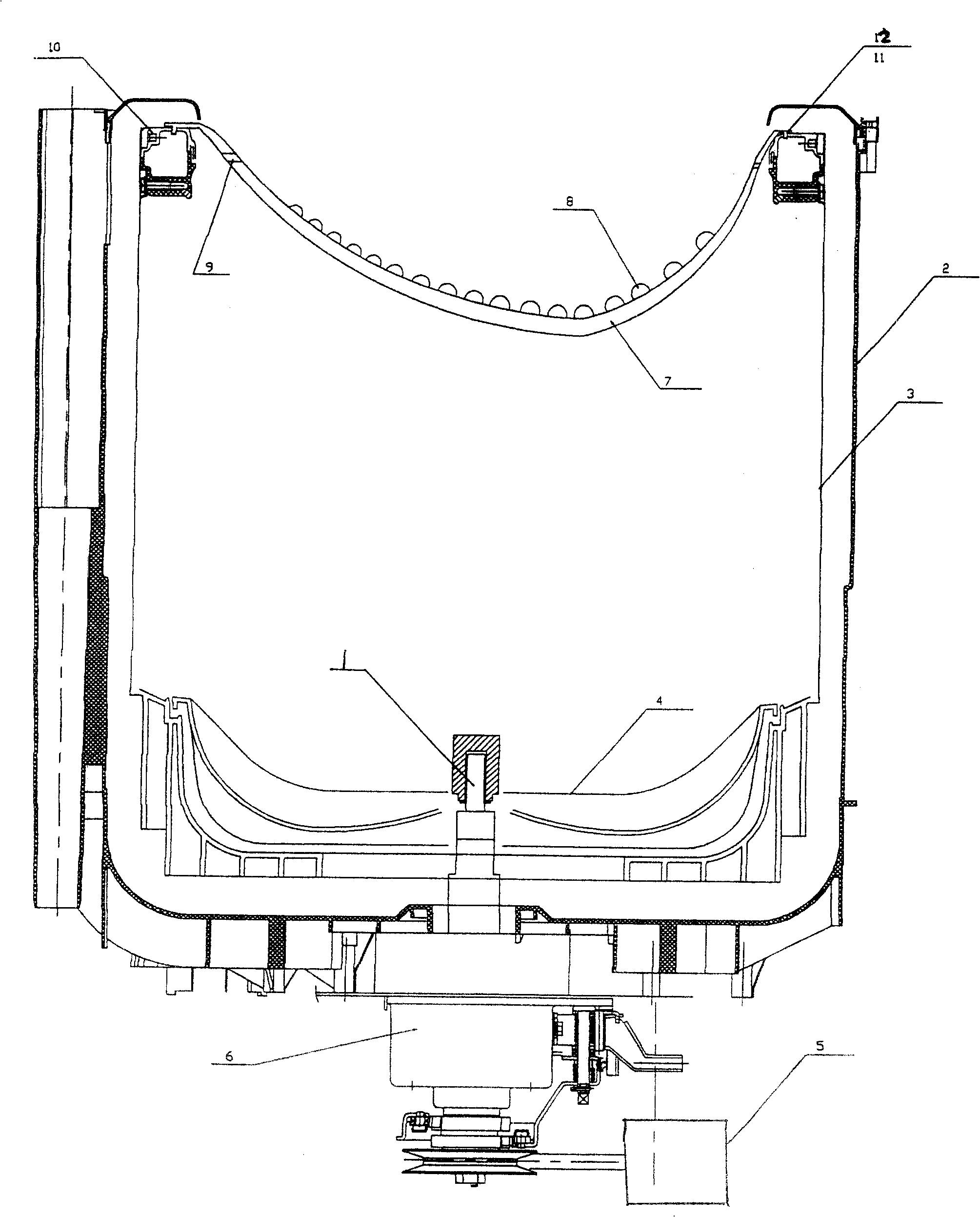

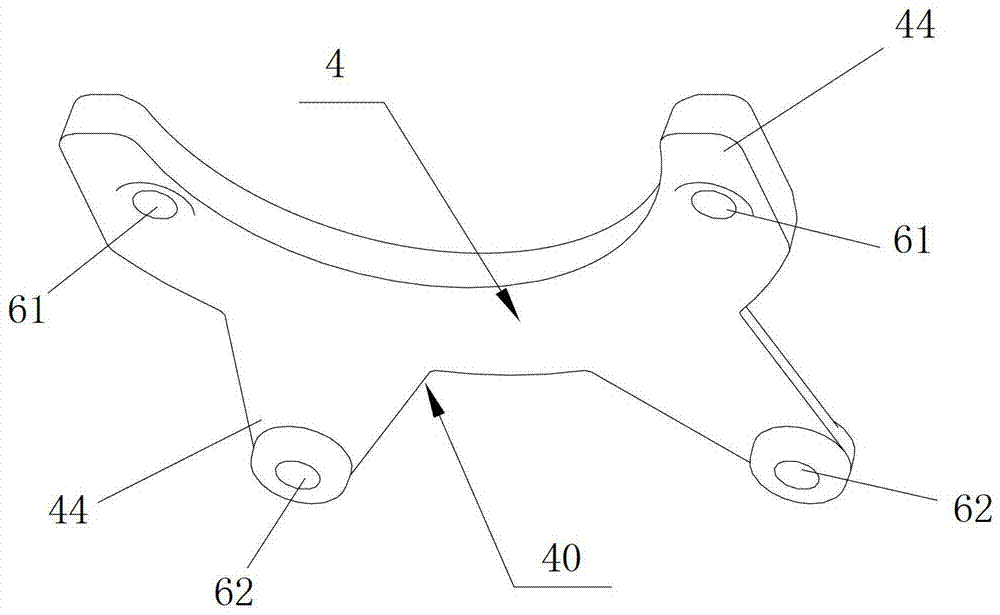

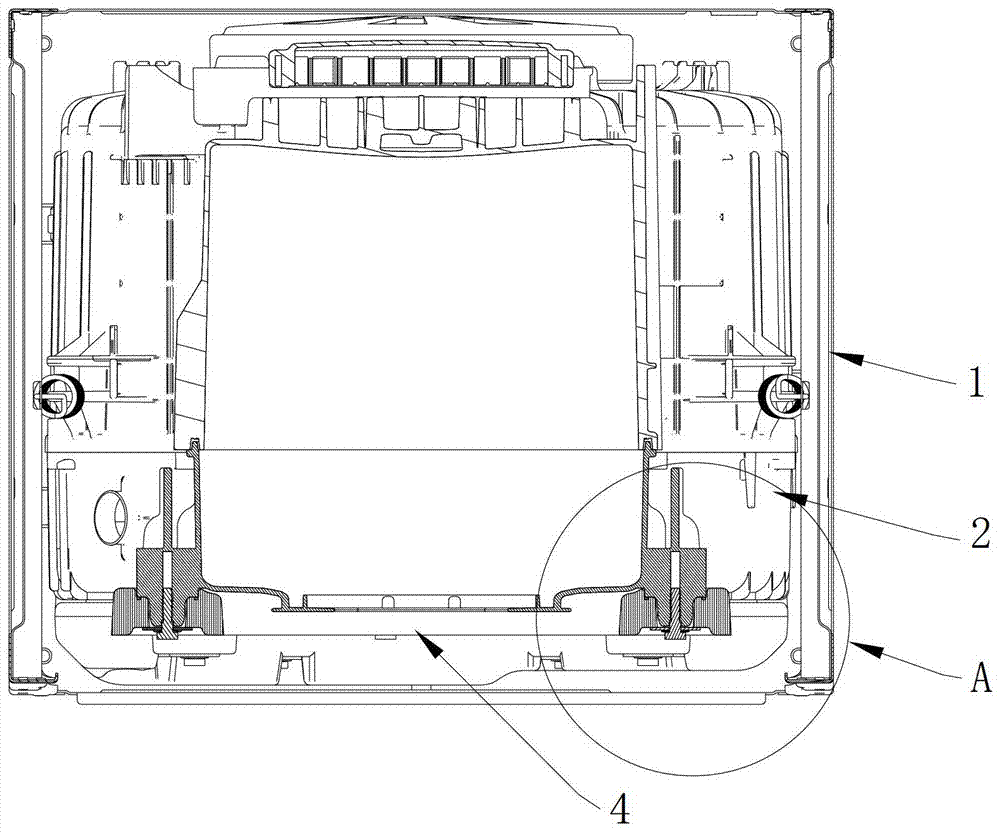

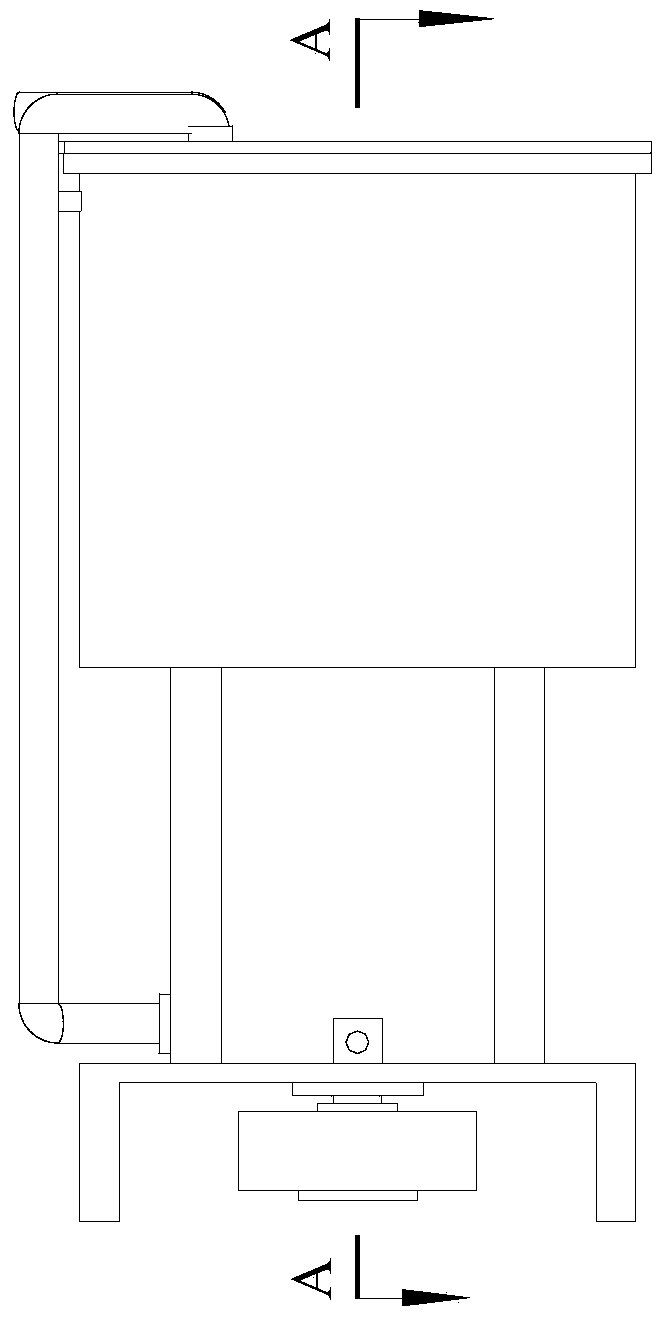

The invention discloses a double-drum washing machine, which comprises a washing machine frame, a first outer drum and a second outer drum, wherein the first outer drum and the second outer drum are arranged in the frame; the first outer drum and the second outer drum are integrally provided with balancing weight mounting columns used for mounting balancing weights; the first outer drum and the second outer drum are connected into a whole through a connecting piece; the connecting piece is fixedly connected with the balancing weight mounting columns on the first outer drum and / or the second outer drum. According to the double-drum washing machine disclosed by the invention, the first outer drum and the second outer drum are connected into an integral structure through the connecting piece so as to effectively improve the compactness of the washing machine; the connecting piece is fixedly installed and connected through the balancing weight mounting columns on the first outer drum or the second outer drum so as to increase the stability of the washing machine; moreover, a shared balancing weight is provided for the first outer drum and the second outer drum through the connecting piece; furthermore, the shared balancing weight is used by the first outer drum and the second outer drum, and the first outer drum or the second outer drum of the washing machine is used as at least one part of balancing weight of the second outer drum or the first outer drum, so that the two drums of the washing machine have an obvious damping effect, and the production cost is reduced.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

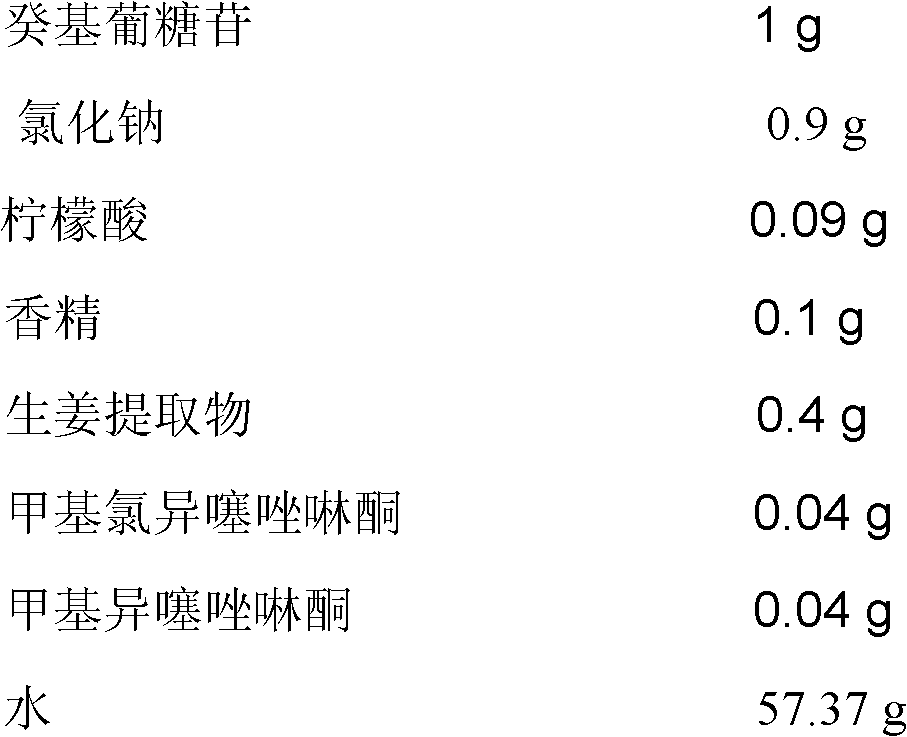

Antibacterial and peculiar-smell-removing detergent for tableware, fruits and vegetables and preparation method thereof

InactiveCN102559400AStrong antioxidant capacityKeep green freshNon-ionic surface-active compoundsDetergent compounding agentsChemistryGingerol

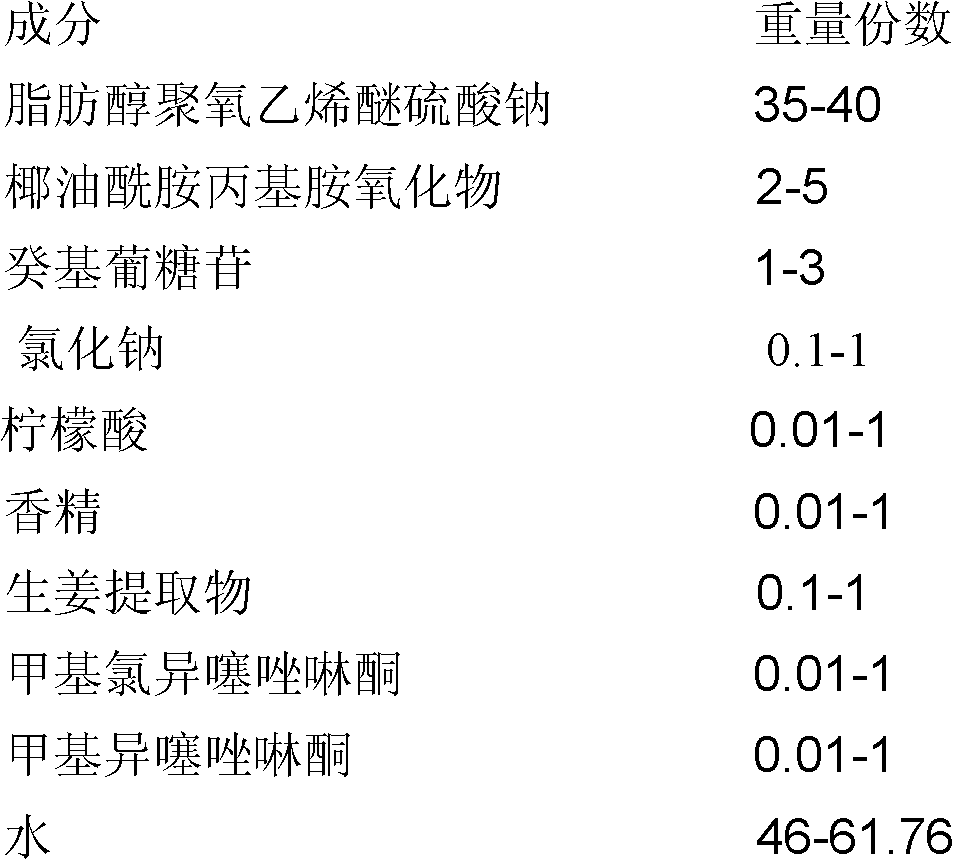

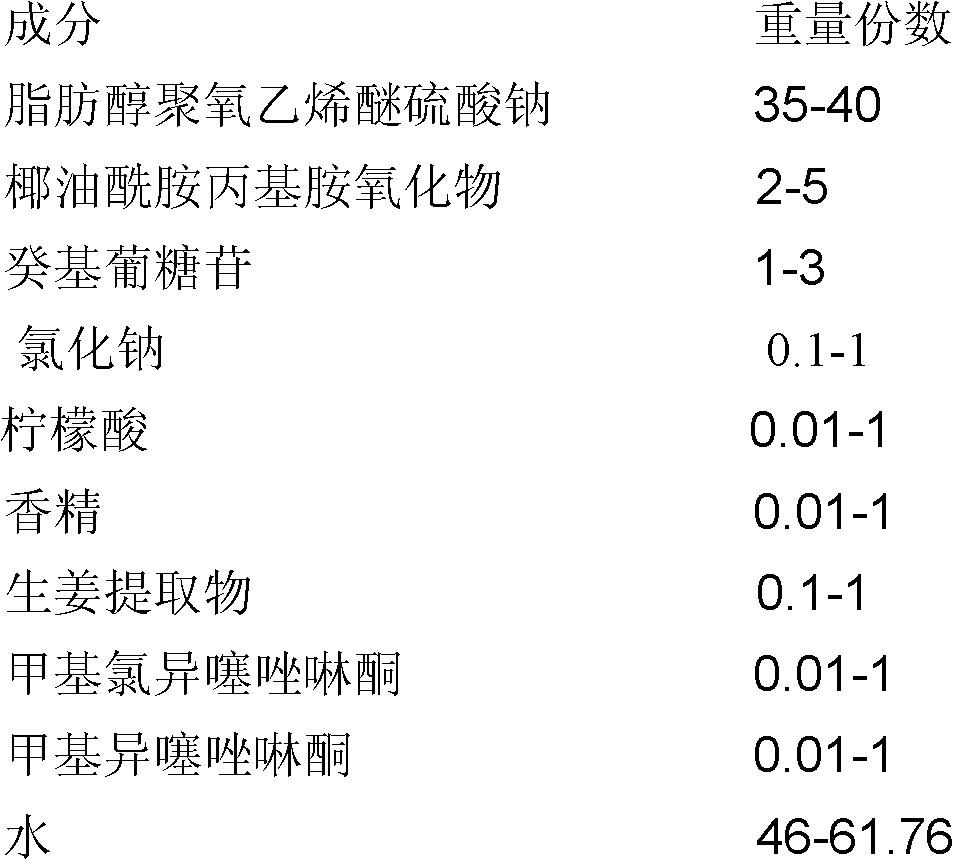

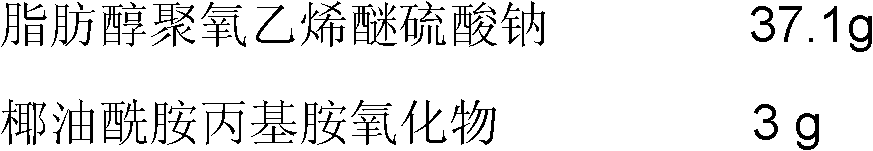

The invention discloses a detergent for tableware, fruits and vegetables and a preparation method thereof. According to a composing prescription, ginger extract is used to remove oil stains, peculiar smells and bacteria on the tableware, and microorganisms, worm eggs, ash fouling, and the like on the surfaces of the fruits and the vegetables; and meanwhile, surfactant components such as glucoside and coconut oil derivatives are used by the detergent, so that that detergent is safe for human bodies, cannot irritate skin and is harmless to the environment. The detergent has the advantages of reasonable formula, simple process and obvious use effect.

Owner:TIANJIN TIANSHI BIOLOGICAL DEV +2

Double-drum washing machine

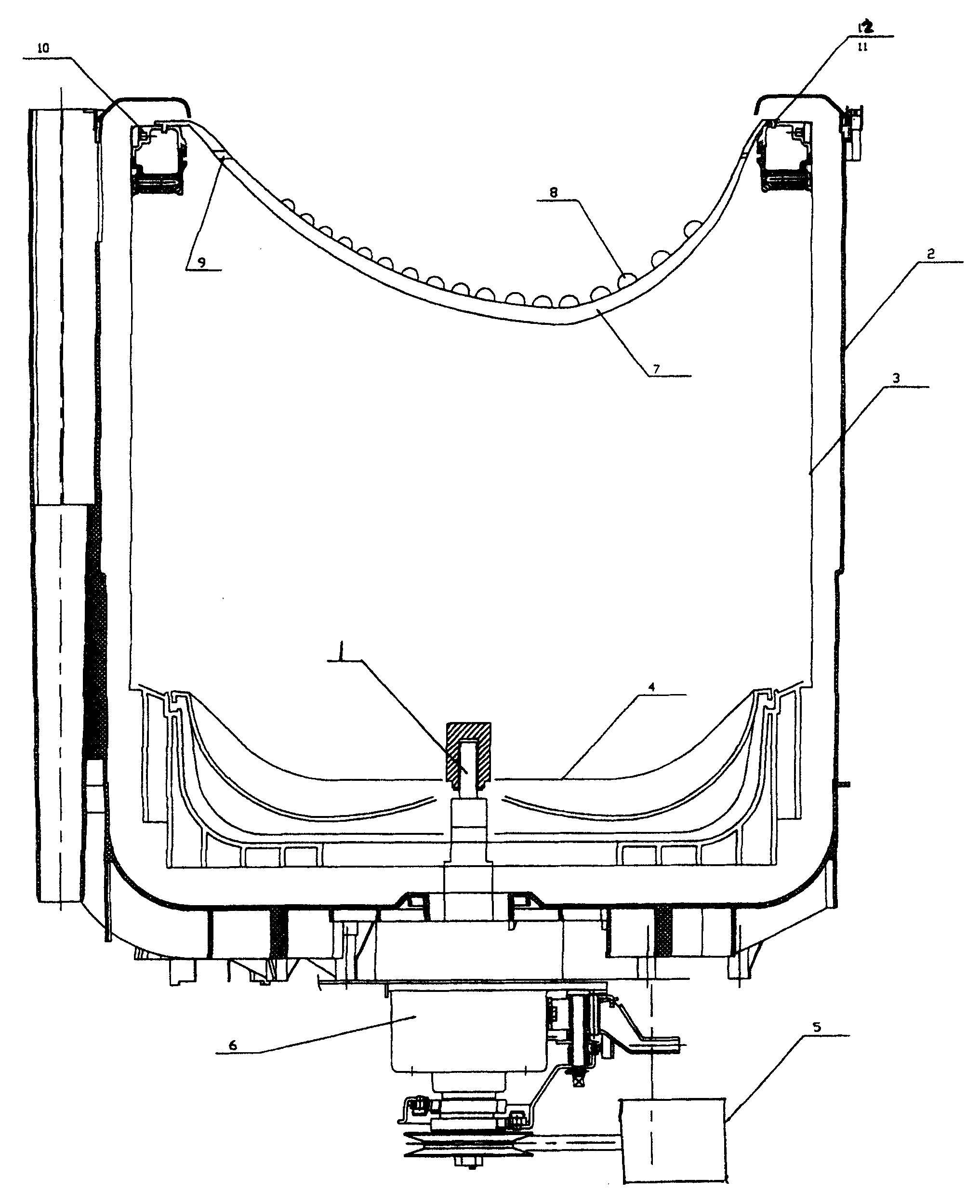

ActiveCN104278473AImprove compactnessTo achieve the purpose of washingOther washing machinesWashing machine with receptaclesLaundry washing machineMechanical engineering

The invention discloses a double-drum washing machine, which comprises a washing machine frame, a first outer drum and a second outer drum; the first outer drum and the second outer drum are arranged in the frame; the first outer drum is provided with a first balancing weight; the second outer drum is provided with a second balancing weight; the first balancing weight and the second balancing weight are connected so as to enable the first outer drum and the second outer drum to be connected into a whole. According to the double-drum washing machine disclosed by the invention, the first outer drum and the second outer drum are connected through the respective balancing weights, and therefore the two outer drums are connected into a whole and the compactness of the washing machine is effectively improved; the double-drum washing machine is simple in structure and convenient to assemble; more particularly, after the two outer drums are connected into a whole, the damping effect is remarkable, and the work noise is reduced; the double-drum washing machine disclosed by the invention is simple in structure, remarkable in effect and suitable for being popularized and used.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

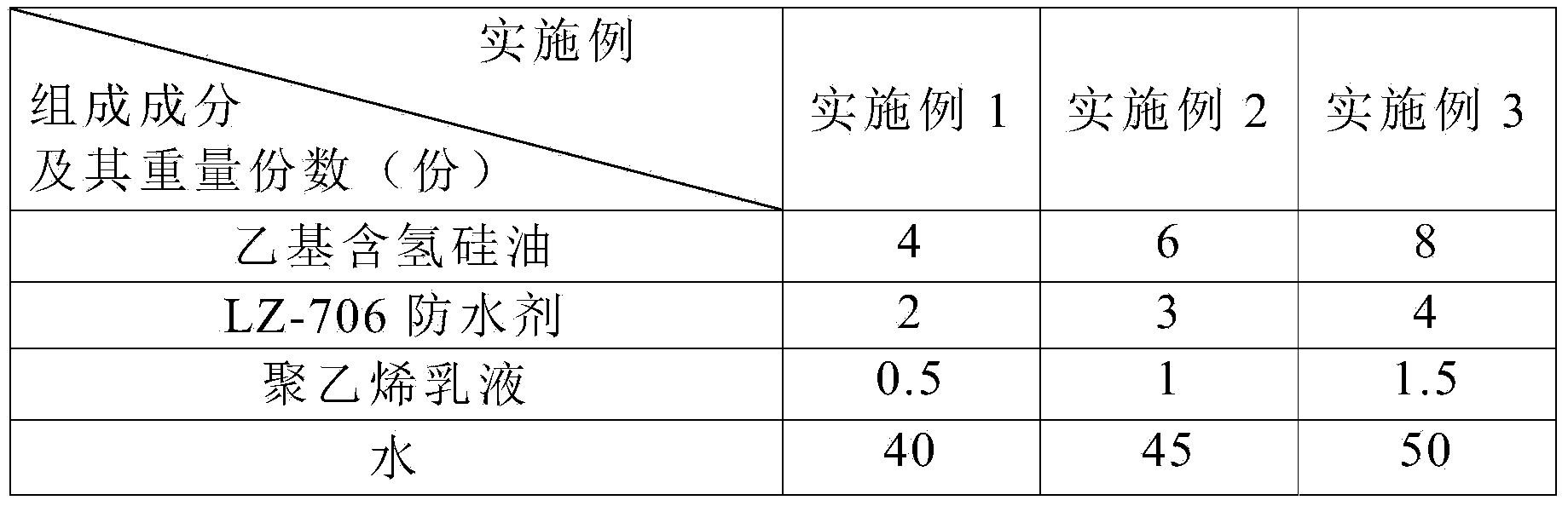

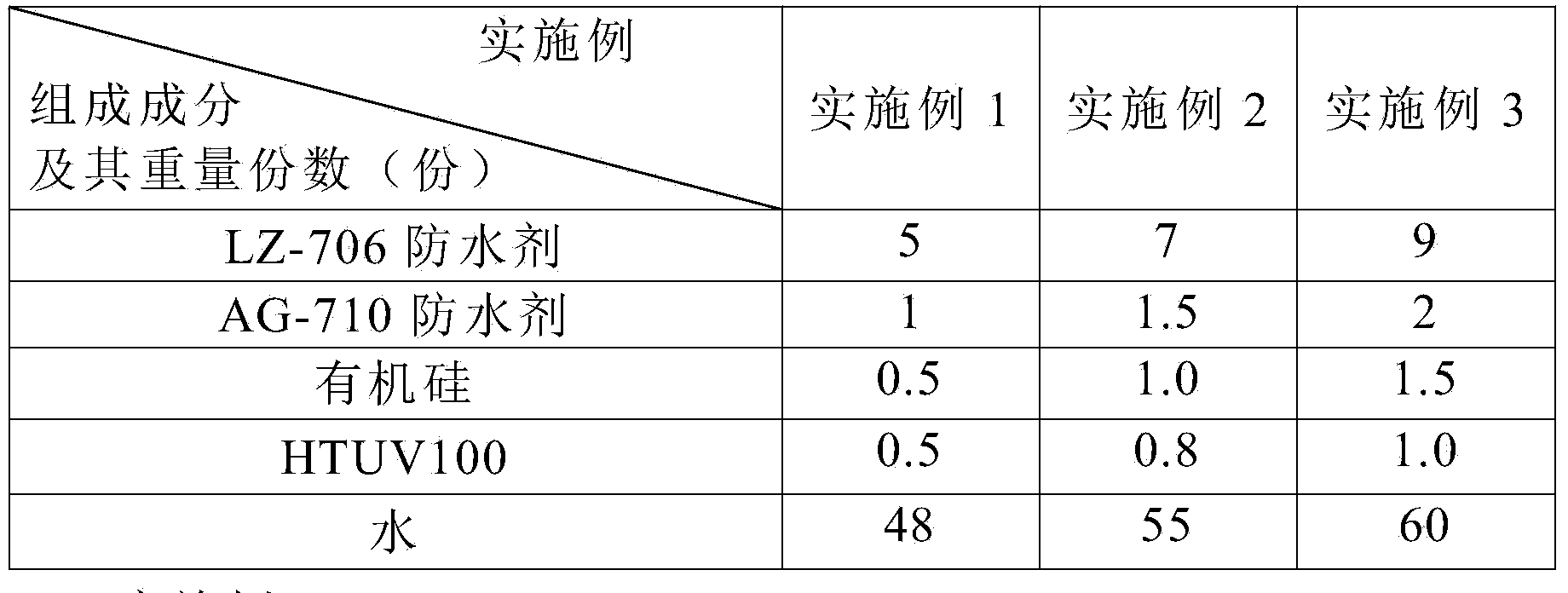

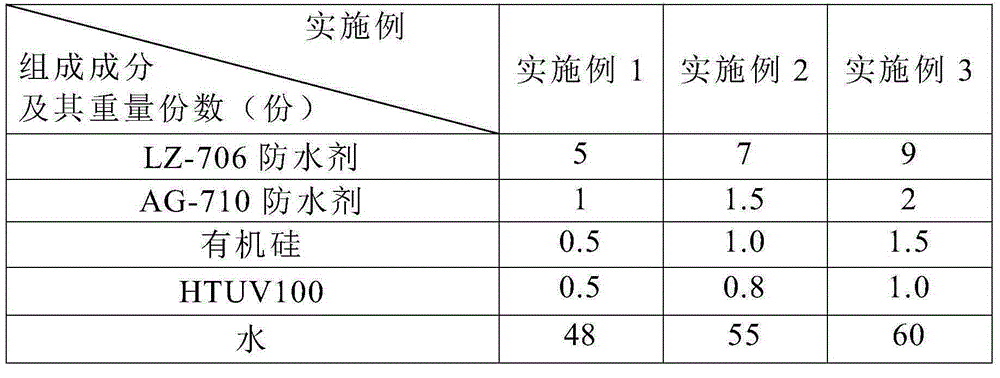

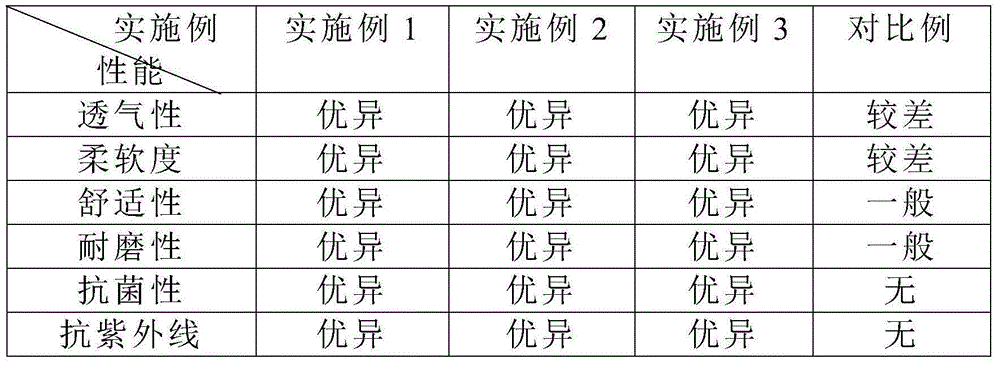

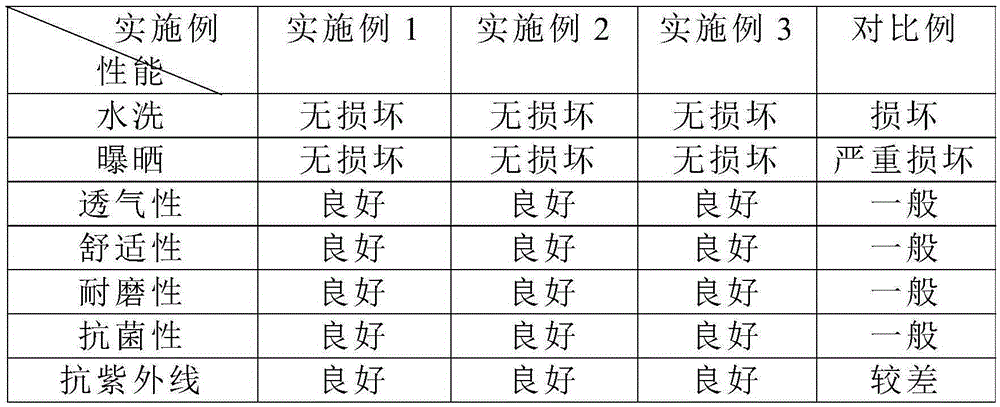

Processing technique for China-Hemp and paper straw mixed mat

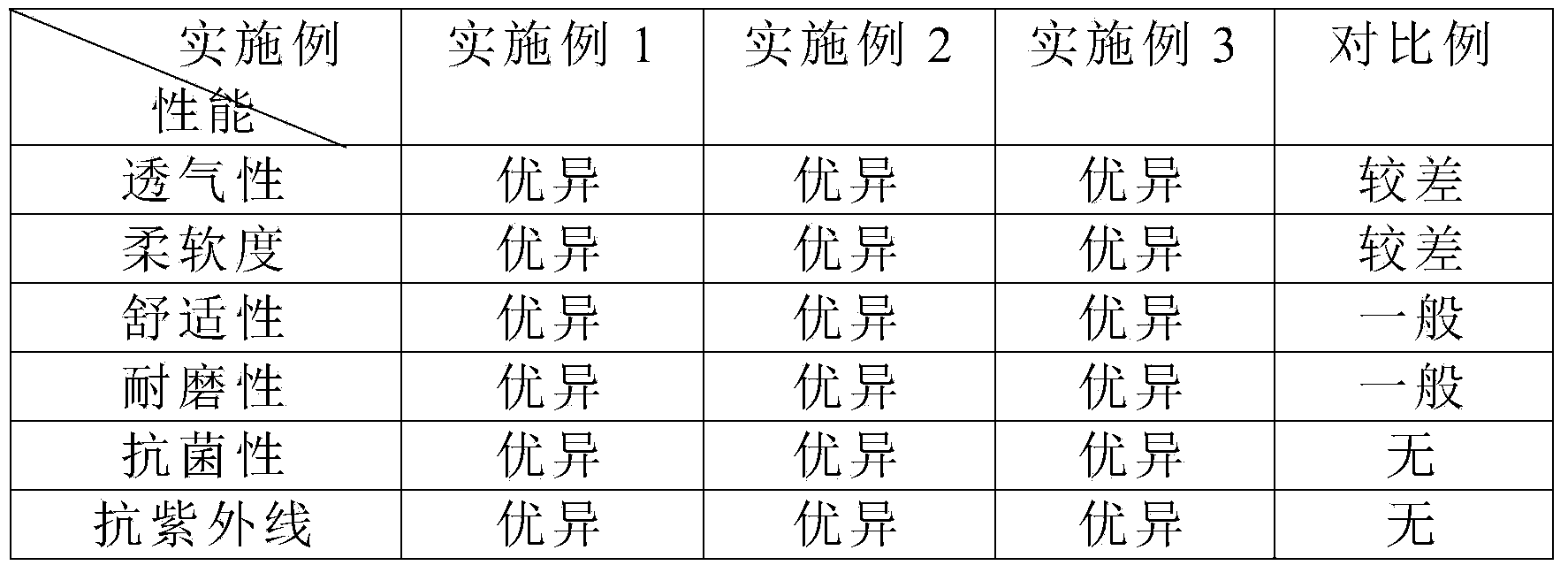

ActiveCN104207561AGood hygroscopicityImprove antibacterial propertiesBed-coversWear resistantPulp and paper industry

The invention relates to a processing technique for mats and particularly relates to a processing technique for a China-Hemp and paper straw mixed mat. The processing technique comprises the following steps: cutting waterproof paper into sheets according to specifications of the mat, then wrapping straws with sheety waterproof paper so as to form ropy paper and then reeling to form wefts, and taking China-Hemp as warps for knitting, so as to obtain a mat main body; spraying water by using an atomizer of a pressing machine, heating, pressing polish and carrying out shrinking treatment on the mat main body, so as to obtain a semi-finished mat; soaking the semi-finished mat into a waterproof agent solution with a pH value of 4.5 to 6.5, and then placing the semi-finished mat into a drying oven for drying; arranging well cut lining cloth on peripheries of the dried semi-finished mat, wrapping the semi-finished mat by using the lining cloth, enabling the lining cloth to be symmetric on upper and lower surfaces of the mat, compacting, then carrying out edge covering treatment on the mat, and finally obtaining a finished mat. The mat prepared by using the processing technique provided by the invention are not only nice and cool, air-permeable, wear-resistant, sun-proof and has soft feel, but also has the advantages of bacteriostasis, uvio-resistance and the like, and is long in service life.

Owner:宁波黄古林工艺品有限公司

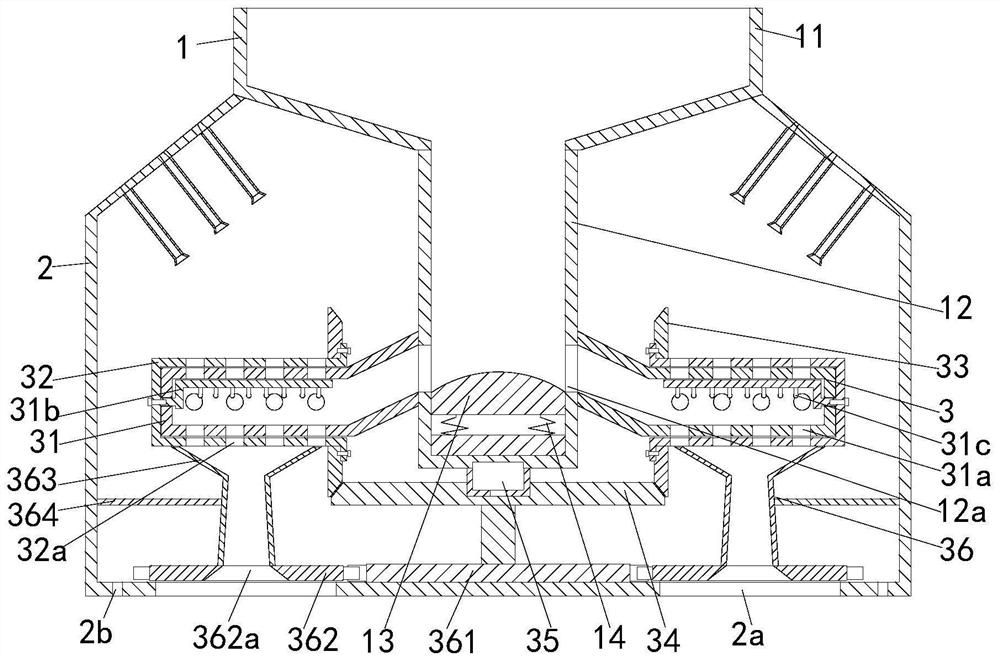

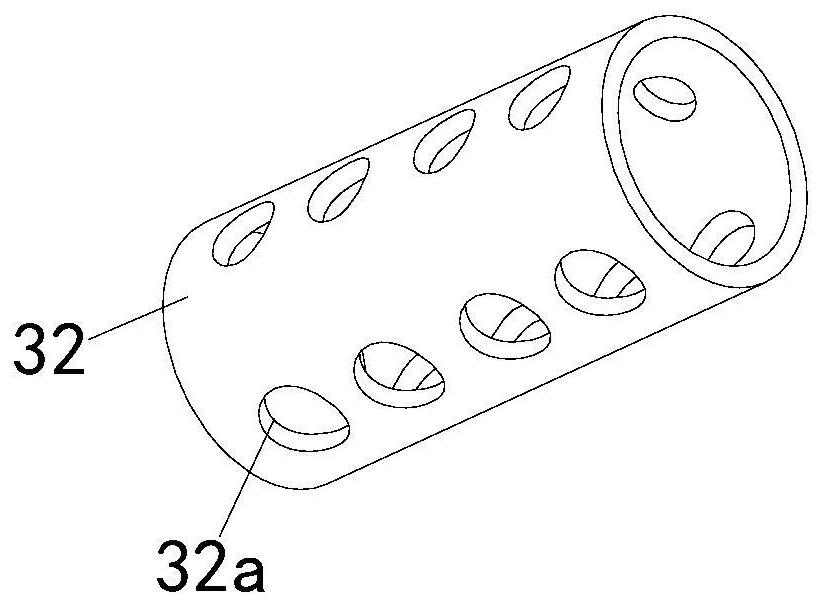

Double-roller washing machine

ActiveCN104278478AImprove compactnessTo achieve the purpose of washingOther washing machinesTextiles and paperEngineeringMechanical engineering

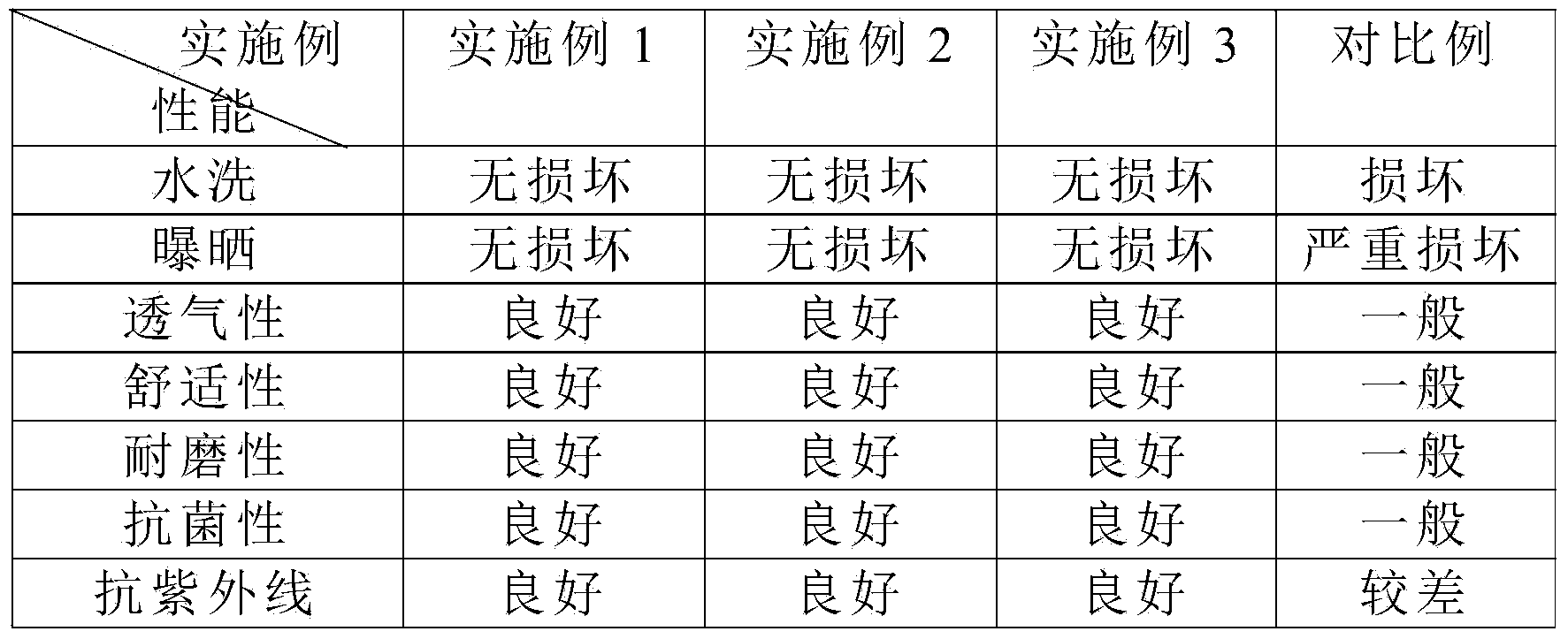

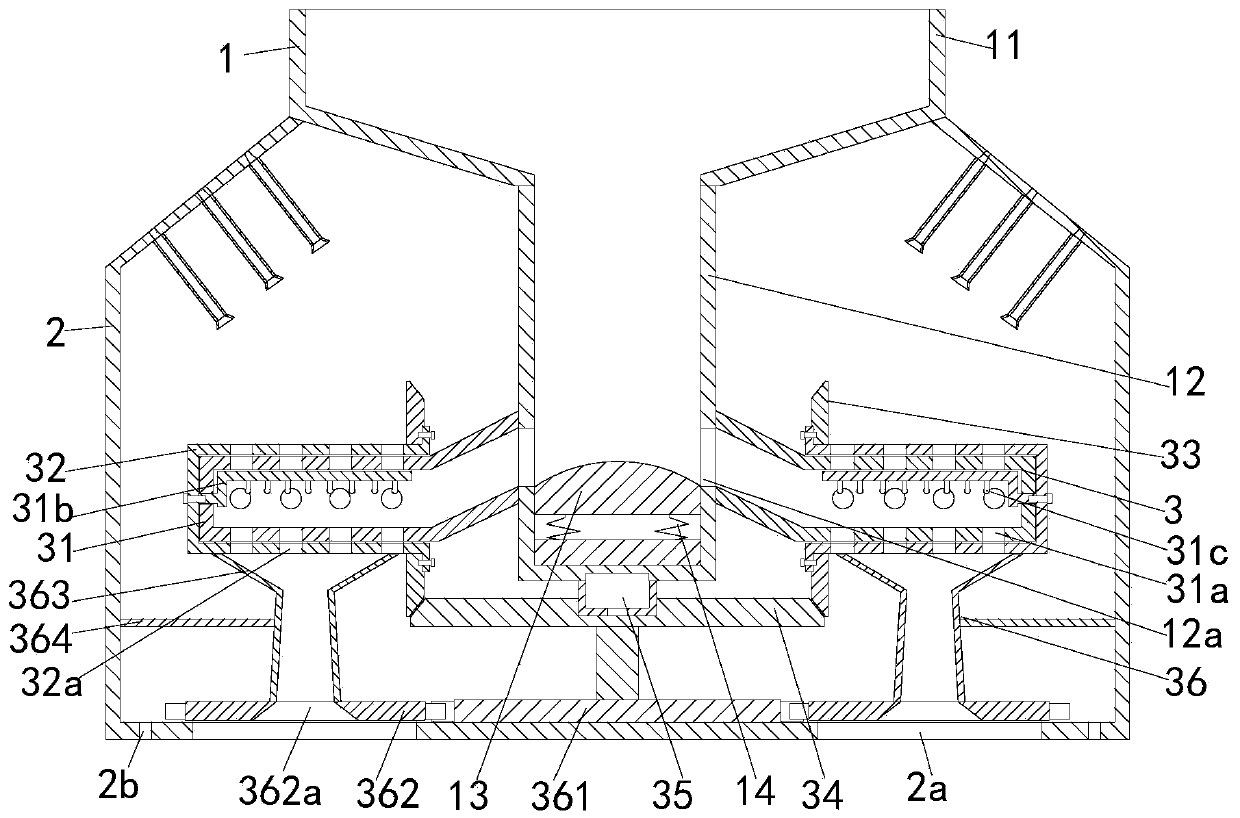

The invention discloses a double-roller washing machine. The double-roller washing machine comprises a frame of the washing machine, a first outer cylinder and a second outer cylinder, wherein the first outer cylinder and the second outer cylinder are installed in the frame, and rollers are installed in the first outer cylinder and the second outer cylinder respectively. The first outer cylinder and the second outer cylinder are connected into a whole through a connecting piece, and at least one connecting base point fixedly installed on the connecting piece is arranged on the first outer cylinder or the second outer cylinder. The first outer cylinder and the second outer cylinder are connected to be of an integrated structure through the connecting piece, so that the compactness of the washing machine is effectively improved, the connecting piece is fixedly installed and connected through the at least two connecting base points on the first outer cylinder or the second outer cylinder so that the stability can be improved, and the connecting piece supplies a balance weight shared by the first outer cylinder and the second outer cylinder to the first outer cylinder and the second outer cylinder; in addition, the first outer cylinder and the second outer cylinder share the balance weight, the first outer cylinder or the second outer cylinder of the washing machine serves as at least a part of the balance weight of the second outer cylinder or the first outer cylinder, so that the shock absorption effect on the two rollers of the washing machine is obvious, and the production cost is reduced.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

Steel smelting slag treatment method

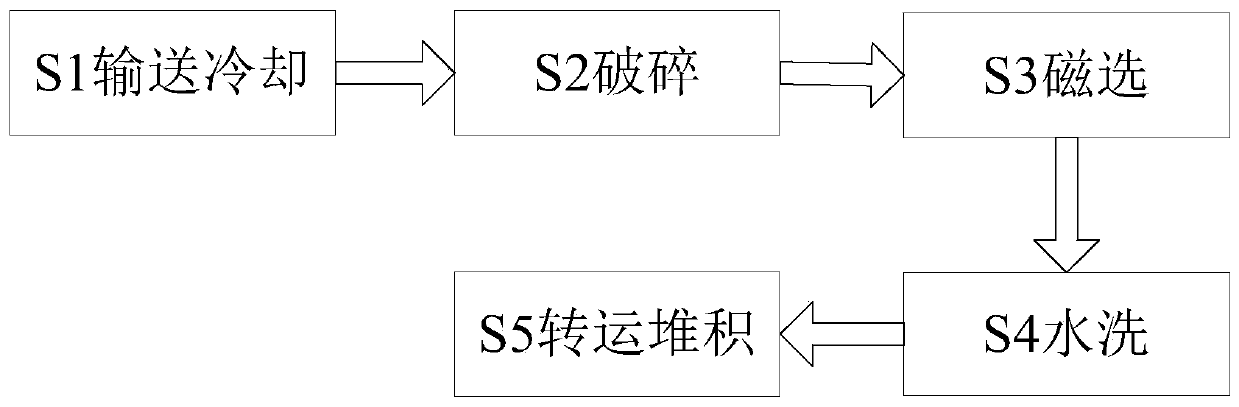

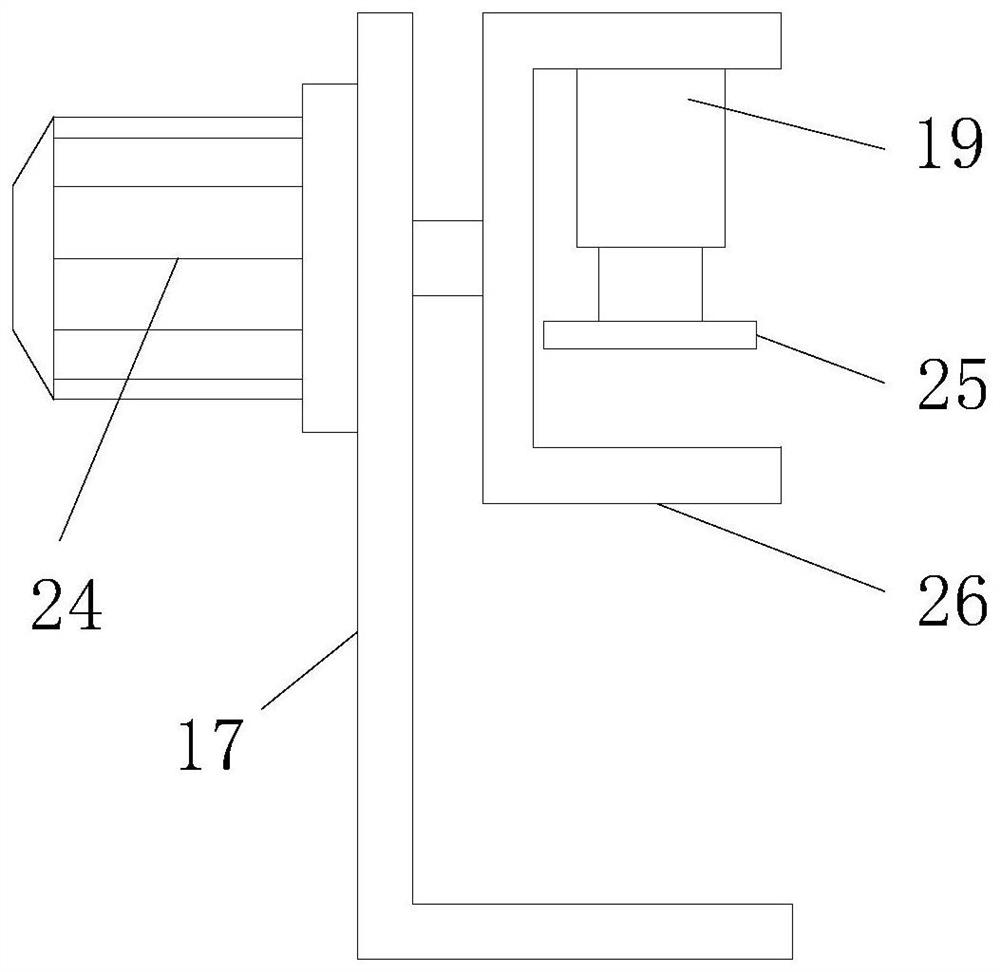

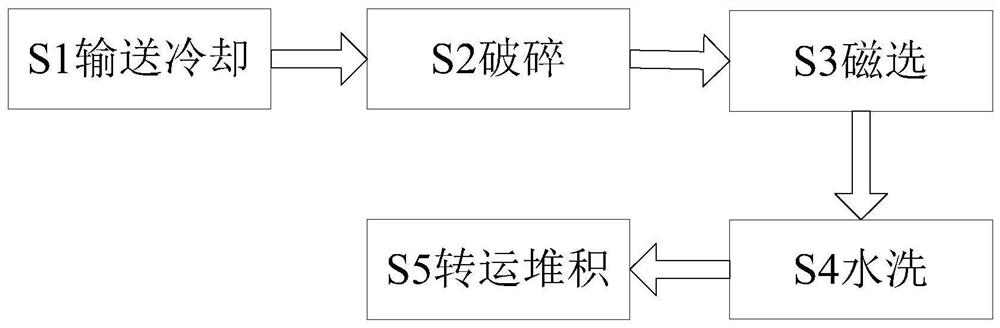

ActiveCN110779338AShorten the timeEnsure thoroughnessStirring devicesCharge manipulationSlagProcess engineering

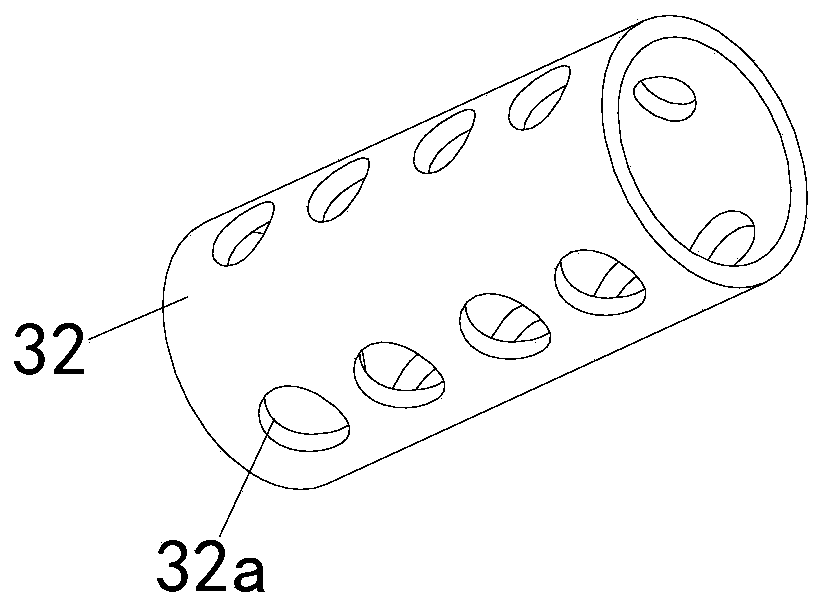

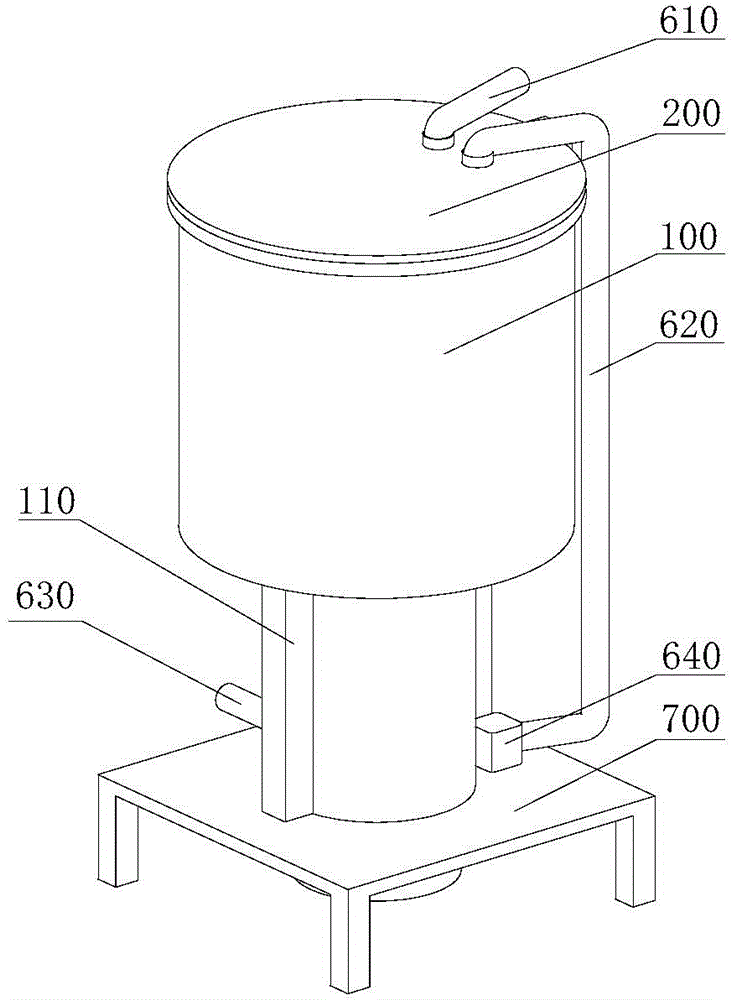

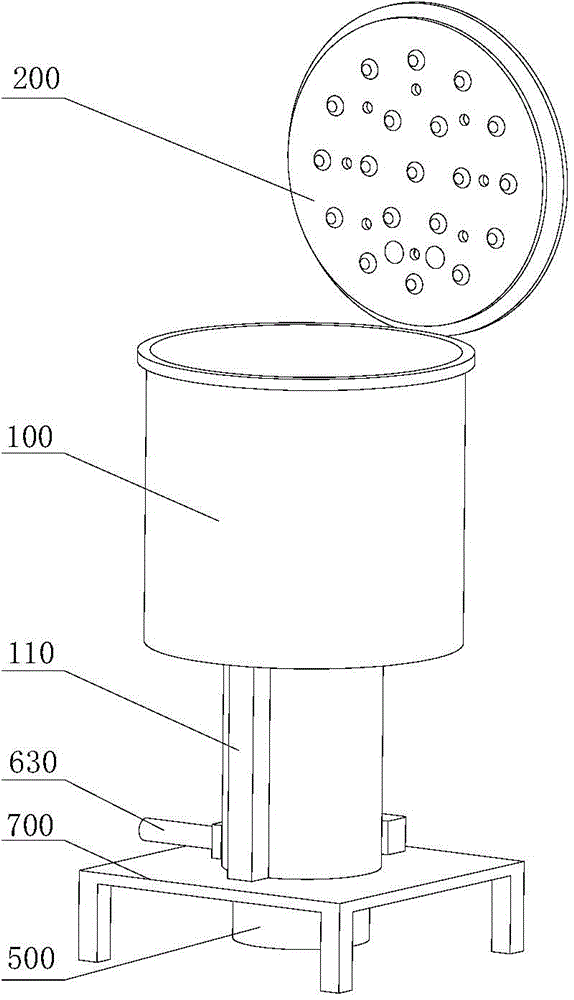

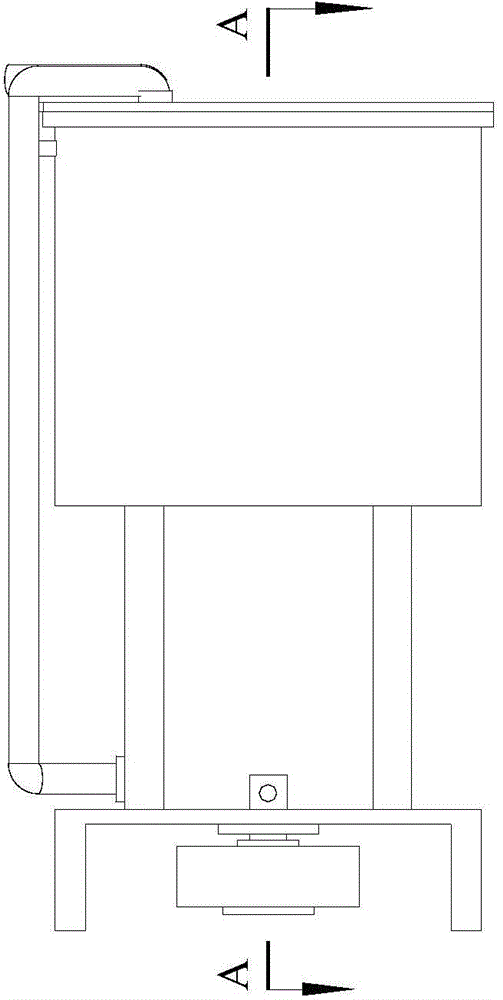

The invention relates to a steel smelting slag treatment method. The steel smelting slag treatment method mainly comprises the following steps of conveying cooling, crushing, magnetic separation, water washing and transferring accumulation, wherein water washing equipment used in the mentioned steps comprises a material falling hopper, a water washing tank and a screening device, the material falling hopper is installed at the upper end of the water washing tank, a screening device is installed in the water washing tank, the water washing tank is of a hollow cylindrical structure, and water washing spray heads are uniformly arranged on the inner wall of the water washing tank in the circumferential direction of the water washing tank; and feeding ports are uniformly formed in the bottom end of the water washing tank in the circumferential direction of the water washing tank, and a water outlet is formed in the bottom end of the water washing tank. According to the steel smelting slag treatment method, the slag can be uniformly stirred while the slag is washed, so that the water washing completeness is ensured, the slag can be subjected to preliminary screening and separate collection in a small-to-large size sequence, and the time for size sorting of the slag in the subsequent treatment process is saved.

Owner:SHANDONG HUASHUN RARE METAL

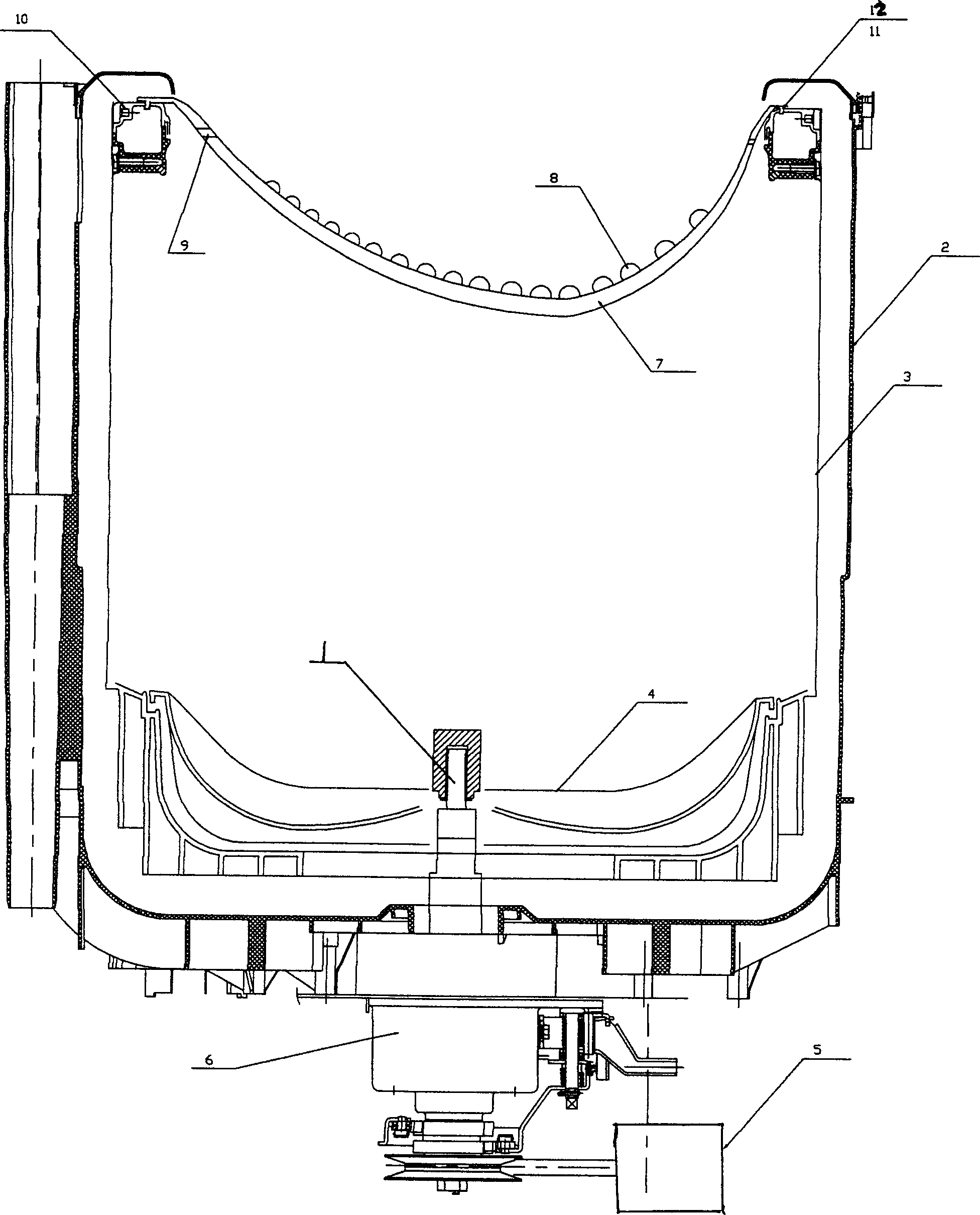

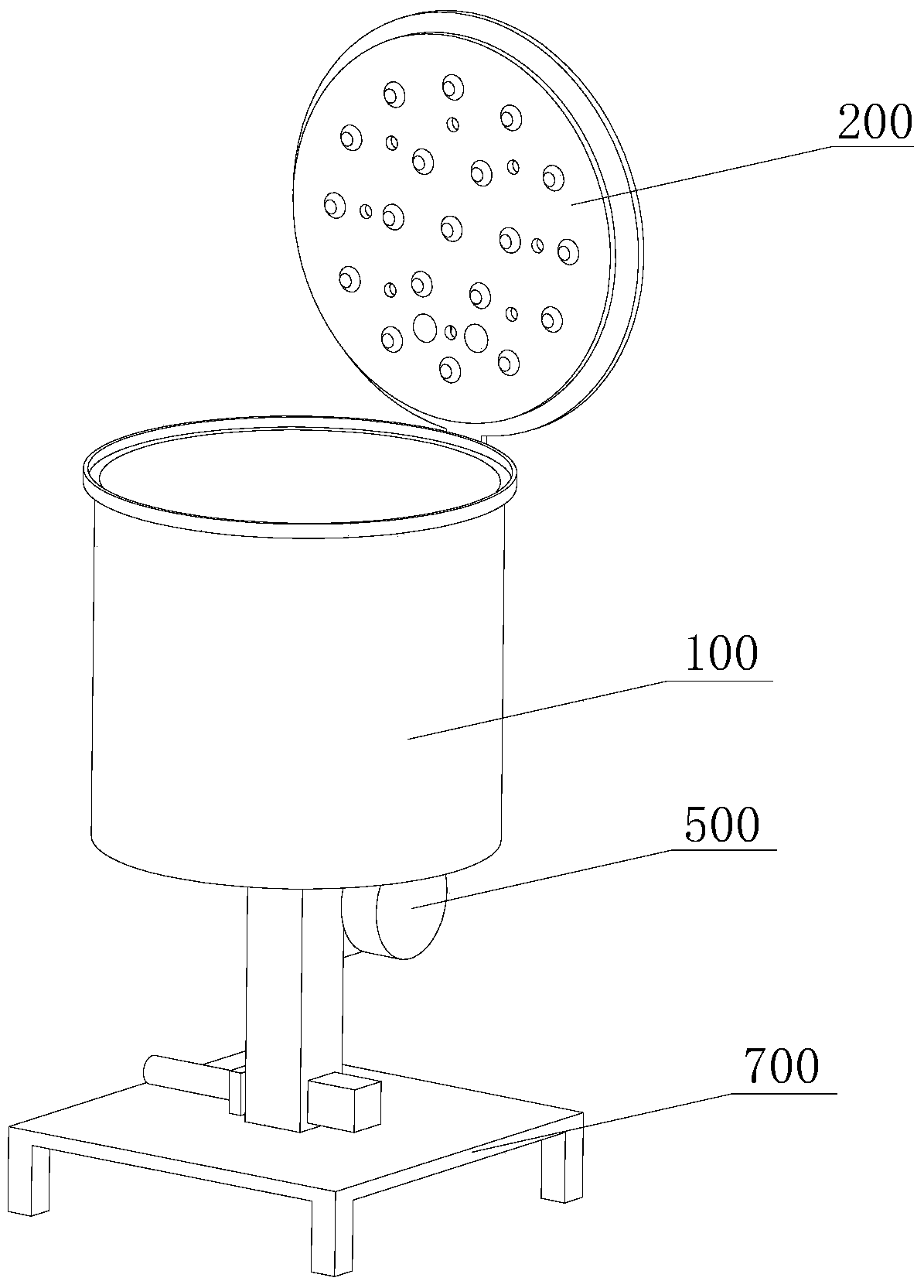

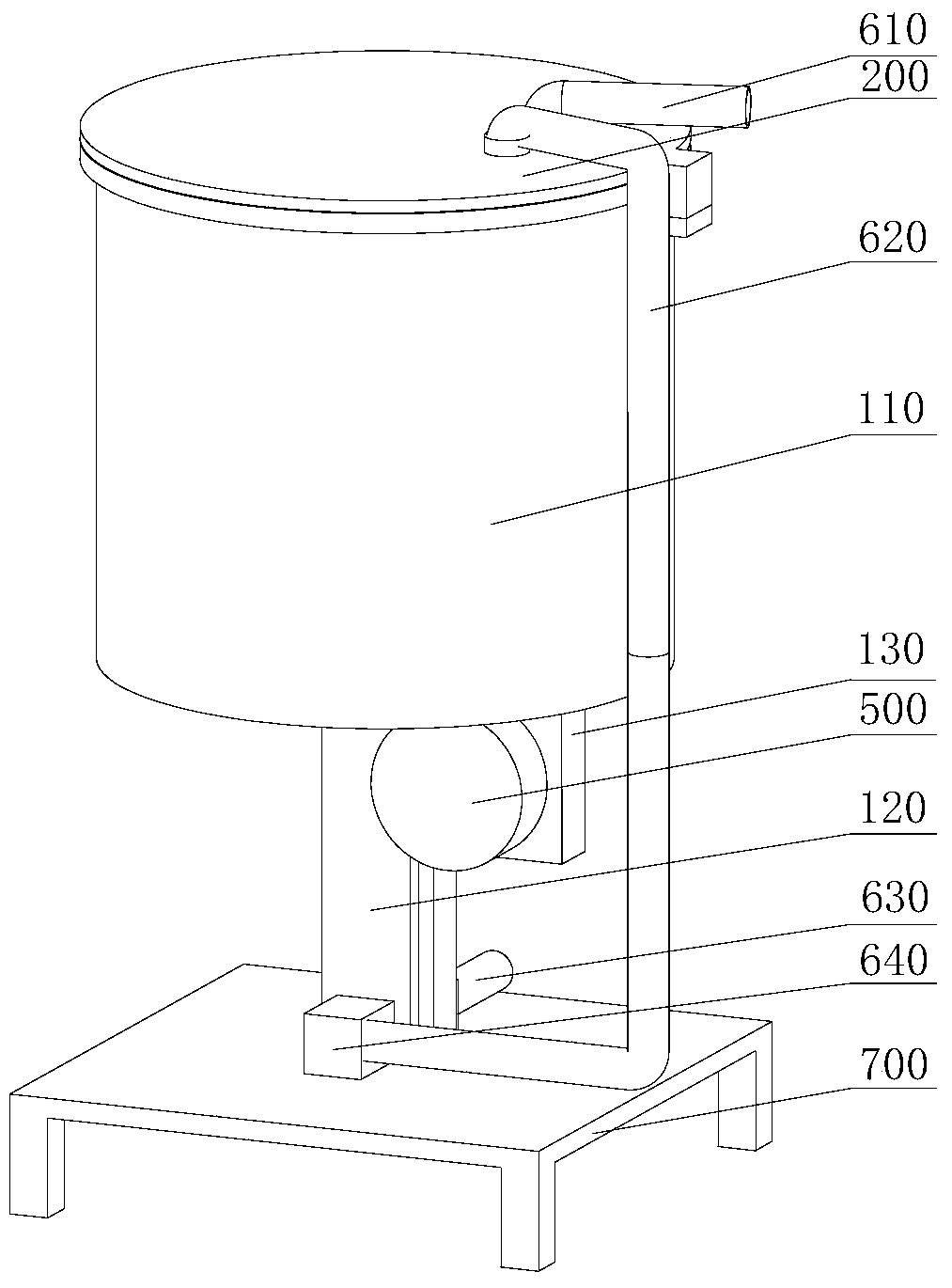

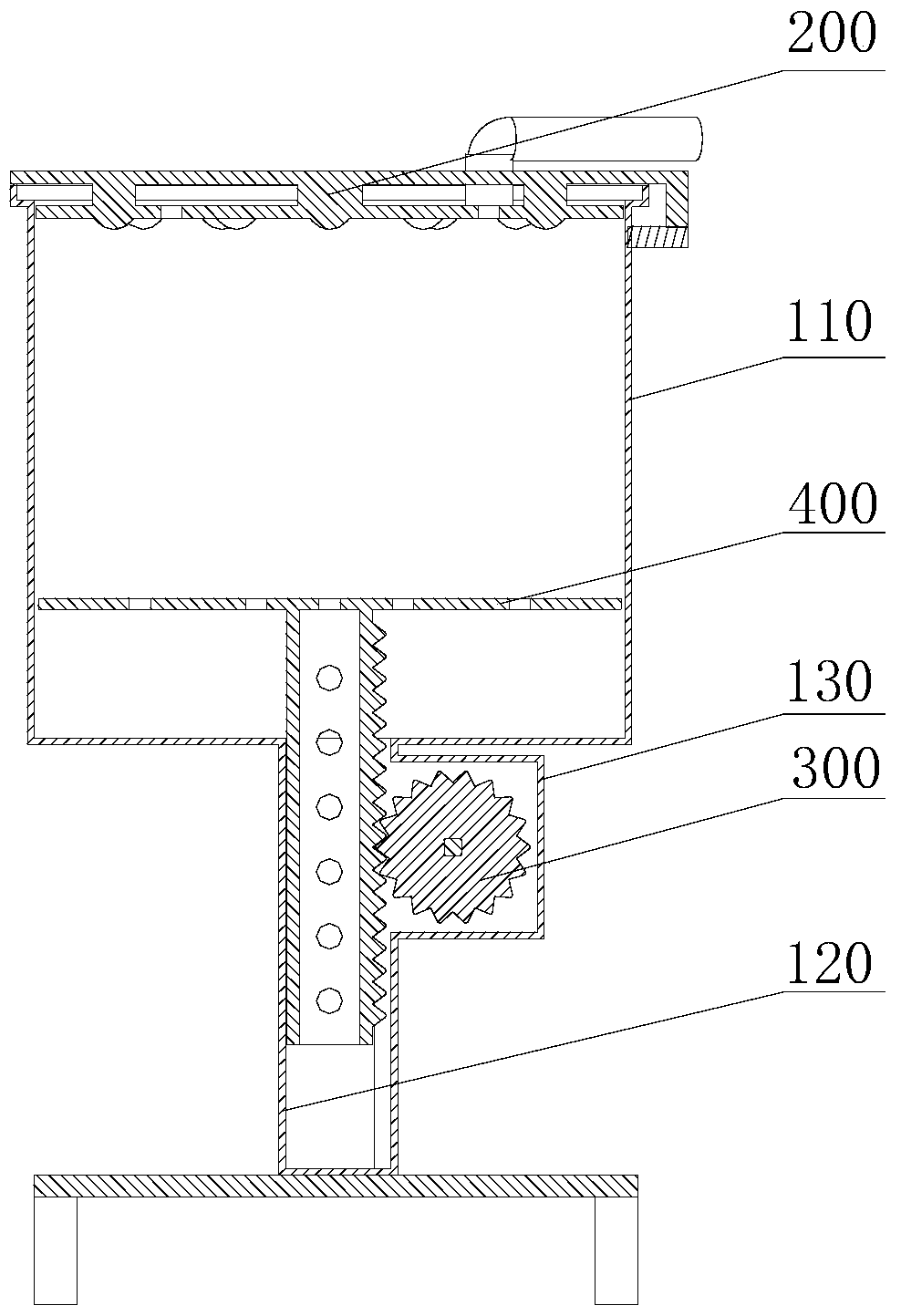

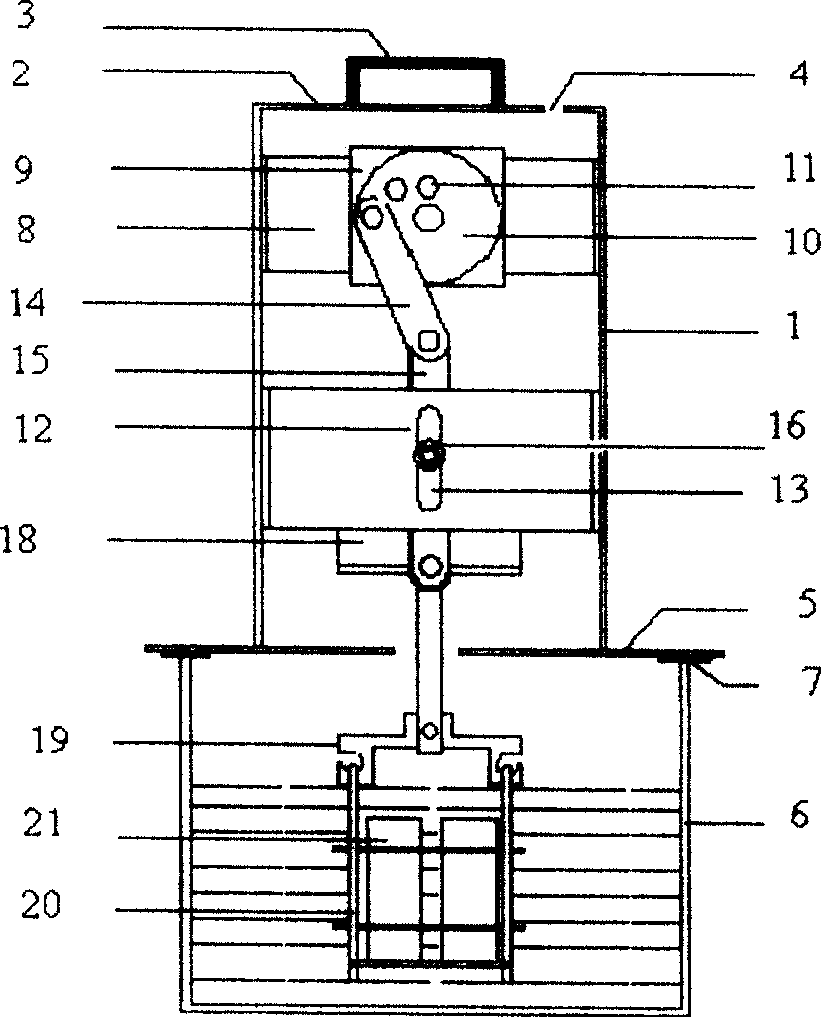

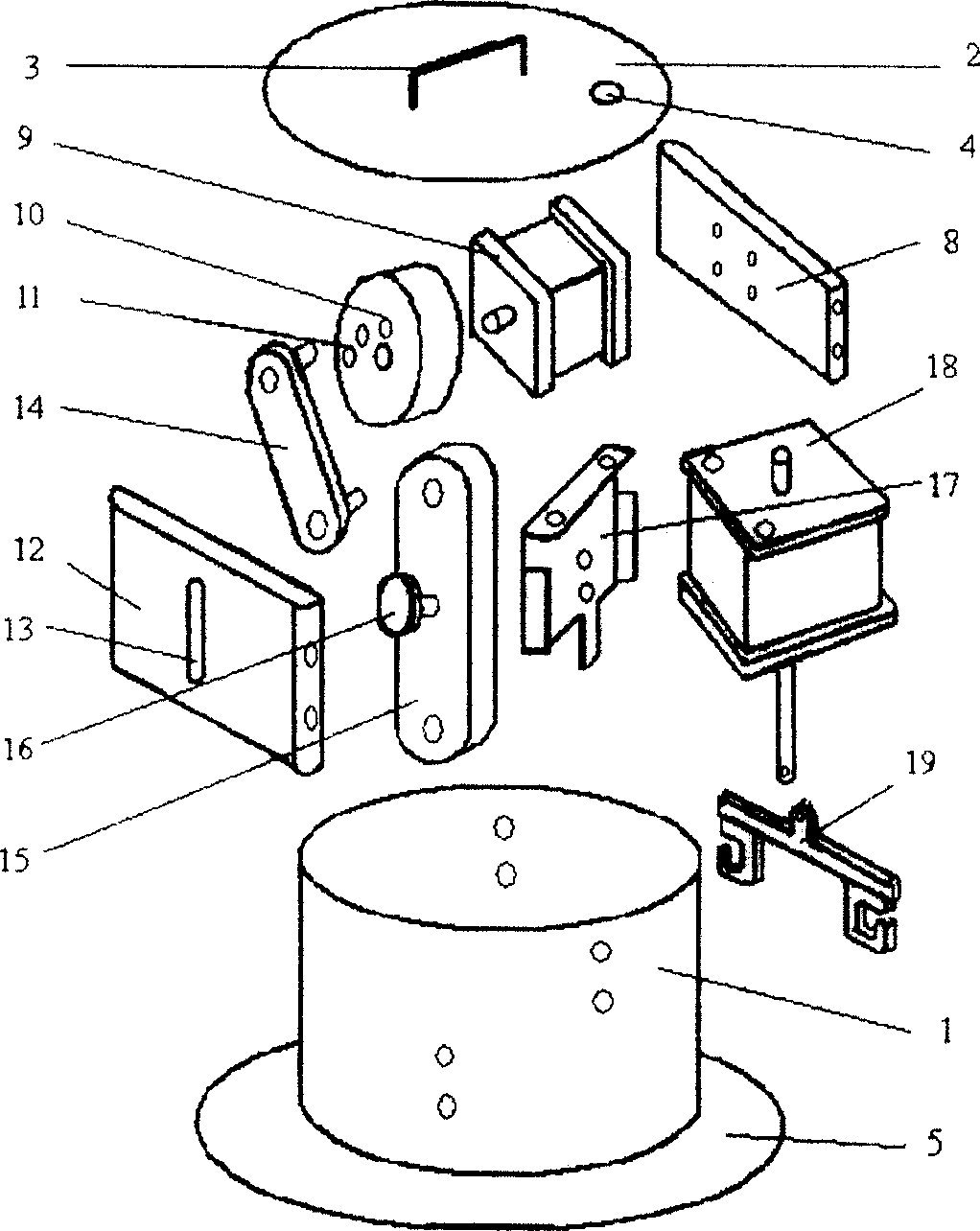

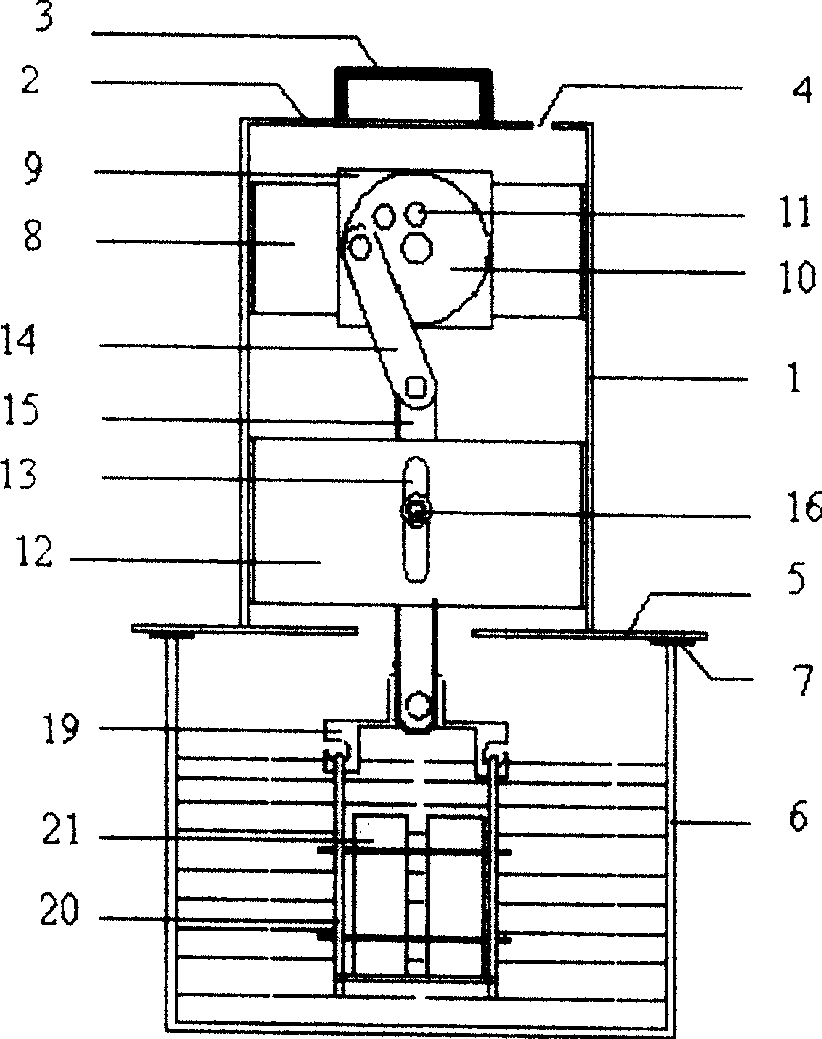

Reciprocating type washing machine

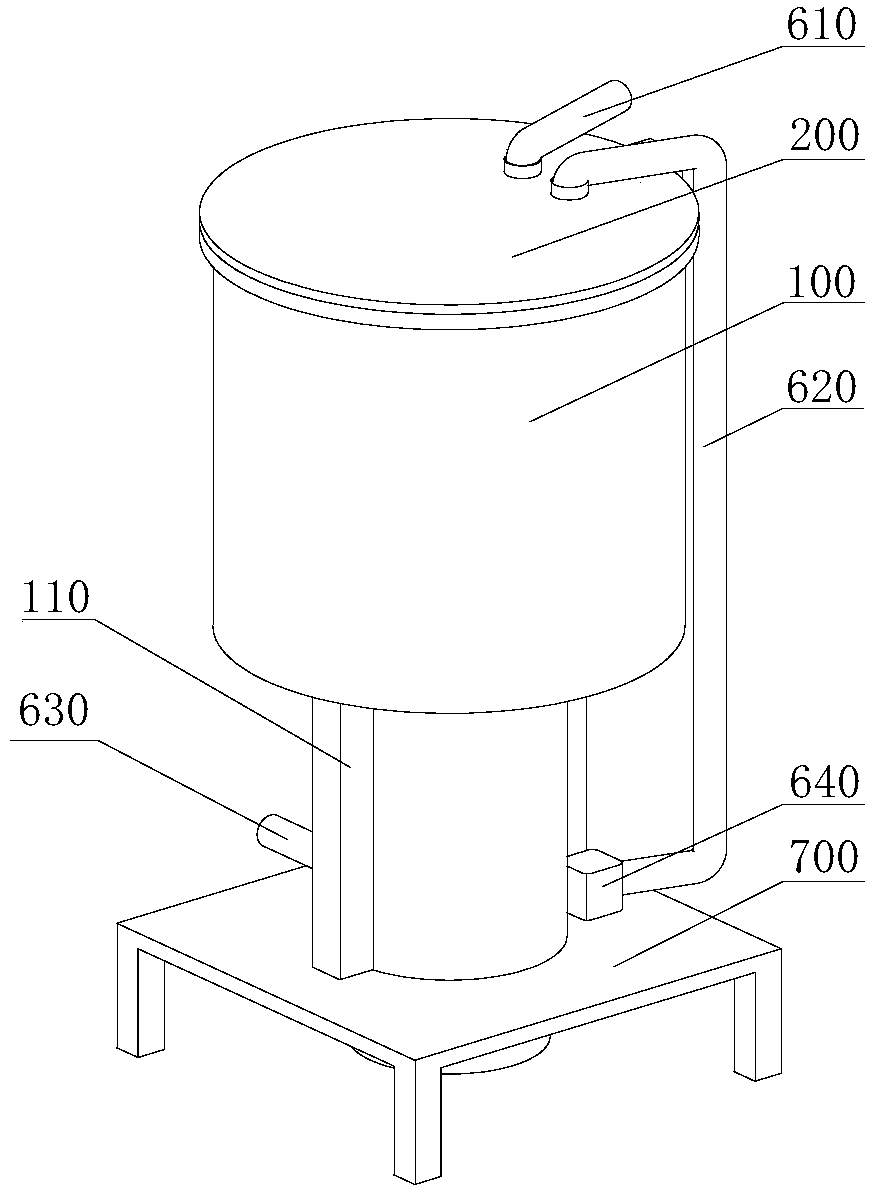

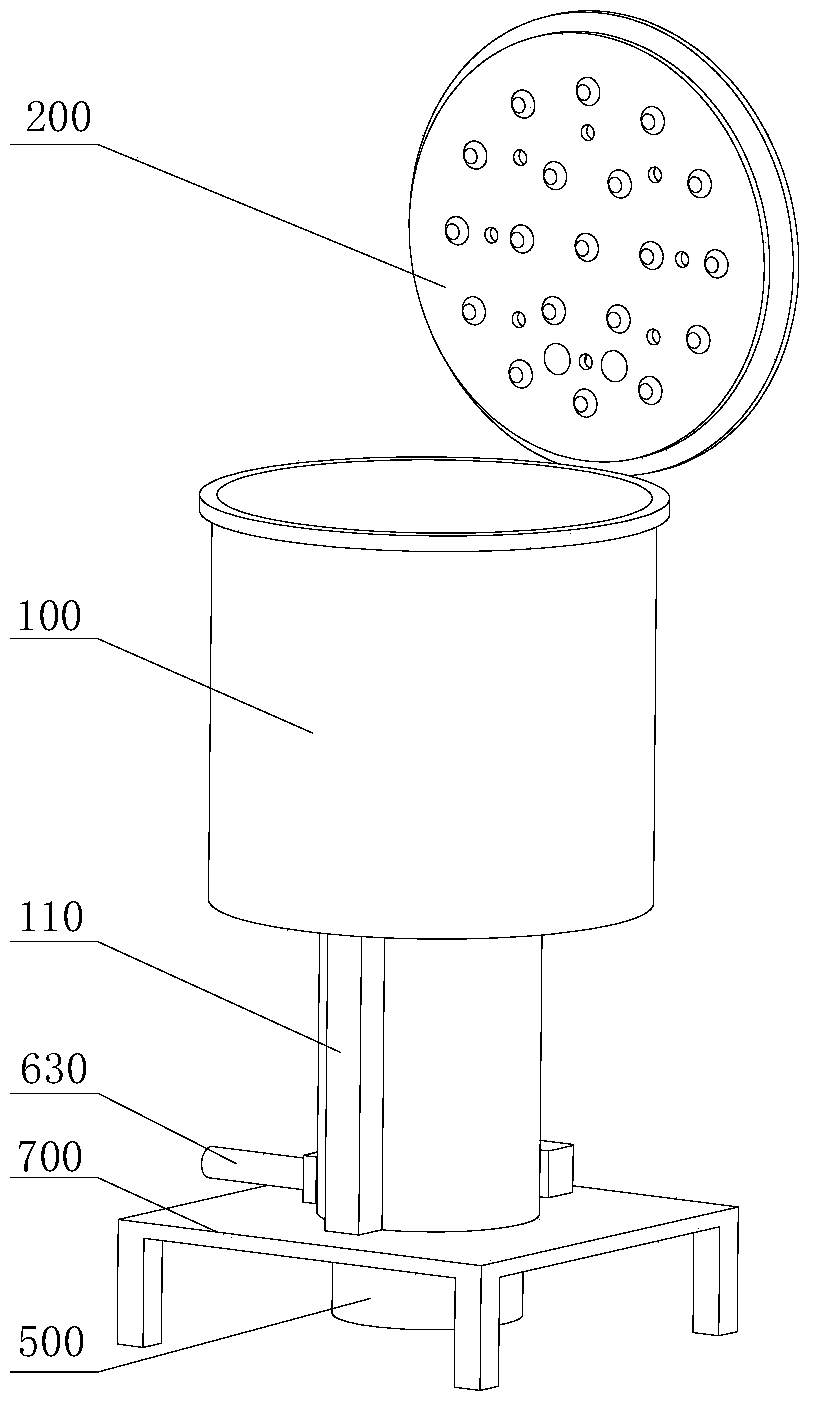

ActiveCN104975458AOvercome the disadvantages of large wear and large water consumptionImprove washing effectOther washing machinesTextiles and paperImpellerReciprocating motion

The invention provides a reciprocating type washing machine. The reciprocating type washing machine comprises a washing bucket, an upper cover, a transmission mechanism, a piston and a driving device, wherein the upper cover is movably connected to an opening of the washing bucket, the washing bucket comprises an upper portion and a lower portion, the upper portion of the washing bucket is used as a washing cavity for containing / washing clothes, the piston is arranged in the washing cavity, the lower portion of the washing bucket is used as a control cavity, the transmission mechanism is arranged in the control cavity, the input end of the transmission mechanism is connected with the driving device, the transmission mechanism and the piston are in screw transmission, and the driving device drives the piston to perform up-down reciprocating motion in the washing bucket through the transmission mechanism. According to the reciprocating type washing machine, washing is performed through reciprocating extrusion on the clothes by the piston, the defects that an existing impeller type washing machine and a tumbling-box washing machine are serious in wear of the clothes and large in water consumption are overcome, and the better washing effect is achieved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Double-roller washing machine

ActiveCN104278479AImprove compactnessRealize comprehensive utilizationOther washing machinesTextiles and paperAbsorption effectMechanical engineering

The invention discloses a double-roller washing machine. The double-roller washing machine comprises a frame of the washing machine, a first outer cylinder and a second outer cylinder, wherein the first outer cylinder and the second outer cylinder are installed in the frame, and rollers are installed in the first outer cylinder and the second outer cylinder respectively. The first outer cylinder and the second outer cylinder are connected into a whole through a connecting piece and provided with a balance weight mechanism shared by the first outer cylinder and the second outer cylinder. The first outer cylinder and the second outer cylinder are connected into an integrated structure through the connecting piece, so that the compactness of the washing machine is effectively improved, and the connecting piece supplies a balance weight shared by the first outer cylinder and the second outer cylinder to the first outer cylinder and the second outer cylinder; in addition, the first outer cylinder and the second outer cylinder share the balance weight, the first outer cylinder or the second outer cylinder of the washing machine serves as at least a part of the balance weight of the second outer cylinder or the first outer cylinder, so that the shock absorption effect on the two rollers of the double-roller washing machine is obvious, and the production cost is reduced.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

Two-washing-tube double-power laundry machine

InactiveCN1414165AEasy to removeIncrease frictionOther washing machinesWashing machine with receptaclesEngineeringPower transmission

A dual-power dual-drum washer is composed of external drum washing drum, waving wheel, motor, and dual-power transmission unit. It features that a small washing drum is installed to the mouth of washing drum for waving the clothes in it as the washing drum and waving wheel are rotating in different directions.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Processing method for enabling fabrics containing cotton to have enduring luster

InactiveCN101736590BAvailable in easy-iron and even non-iron gradesEasy to iron or even non-iron levelVegetal fibresTextile shapingFiberCross-link

The invention discloses a processing method for enabling fabrics containing cotton to have enduring luster, which is characterized in that after being processed by the traditional technology which comprises singeing, desizing and mercerizing, the woven grey fabric is padded by a forming machine, calendered by a NIPCO L three-roller calender, and rolled. The invention has the advantages that the fabric containing cotton by the method has an appearance with bright luster; the grey fabric is baked and preshrunk after being calendered, so that the cross-linking reaction occurs between the fibers in the grey fabric and the resin, thereby enabling the fabric to achieve the standard of easy-ironing and even no-ironing and ensuring that the face fabric washed with water has a flat appearance without affecting the surface luster; and the brightener can be enduringly fixed on the surface and the interior of the fibers, thereby achieving the goal of wash bearing.

Owner:浙江盛泰服装集团股份有限公司

Chitosan type Schiff base, preparing method thereof and feather cleaning deodorant based on same

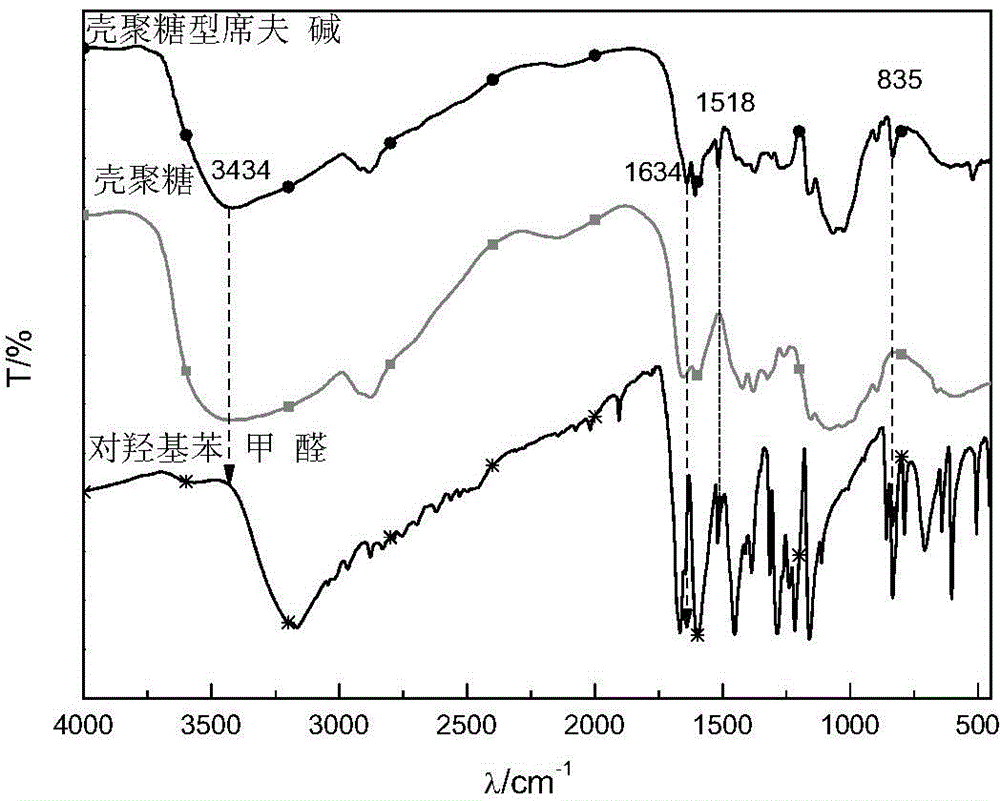

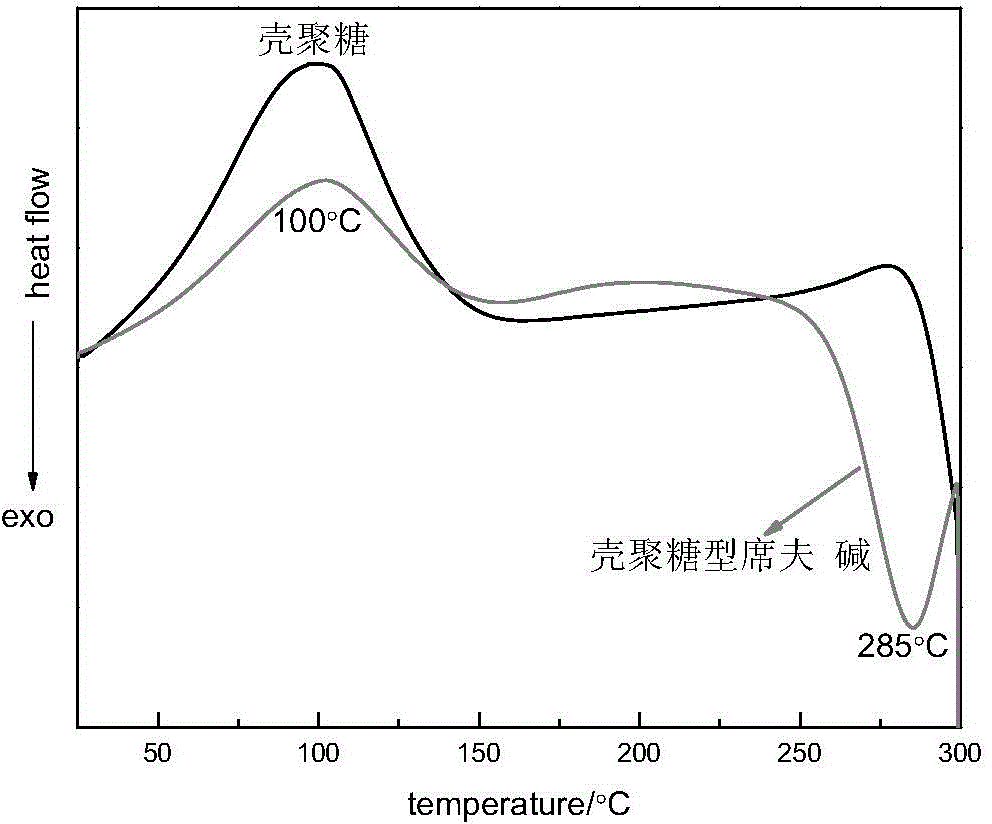

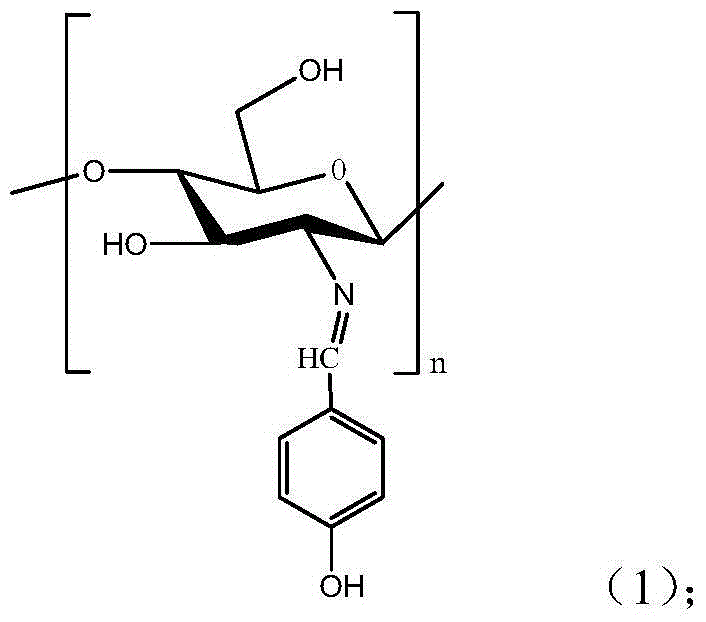

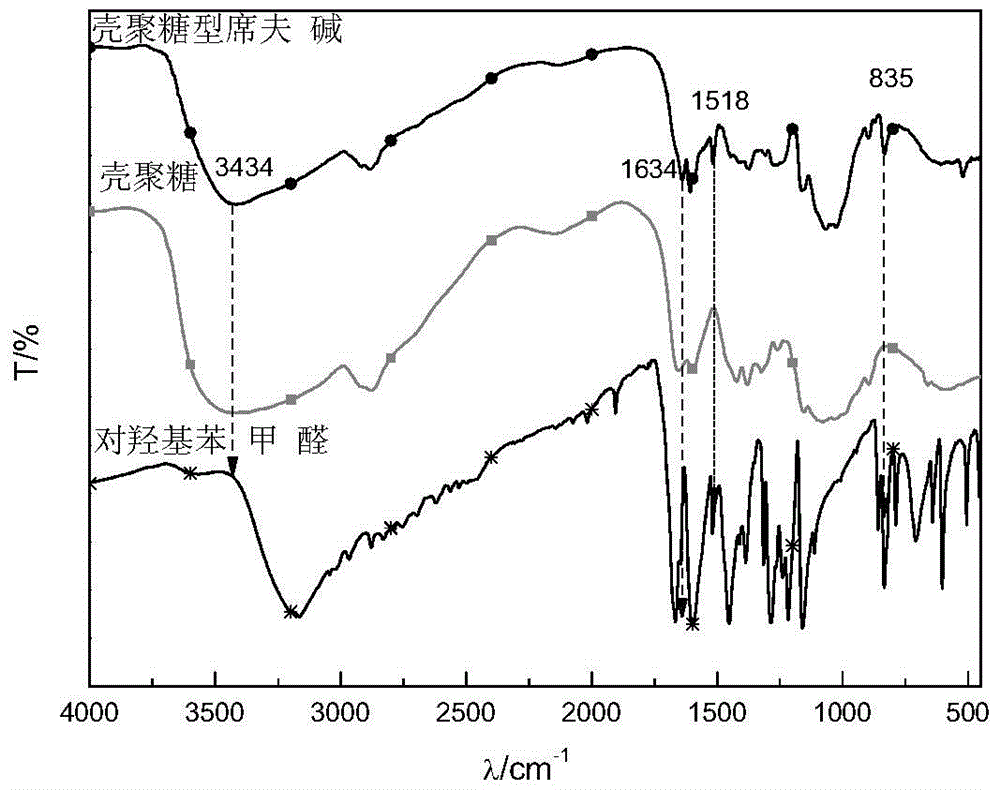

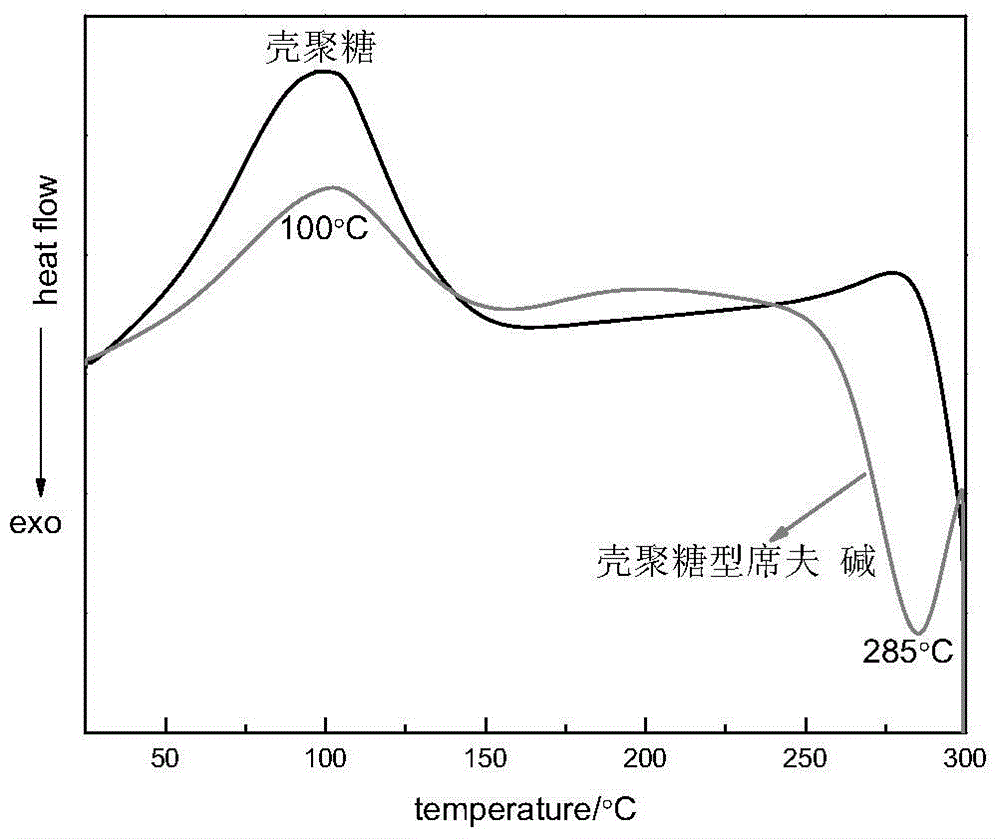

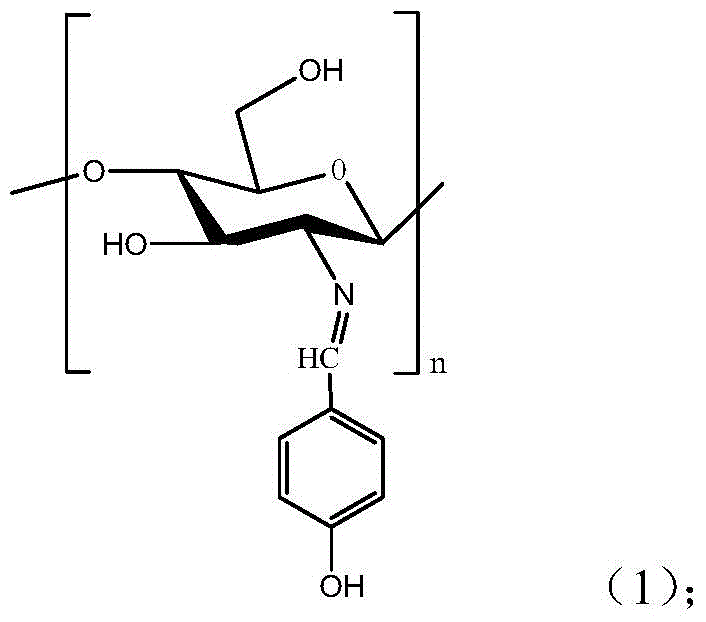

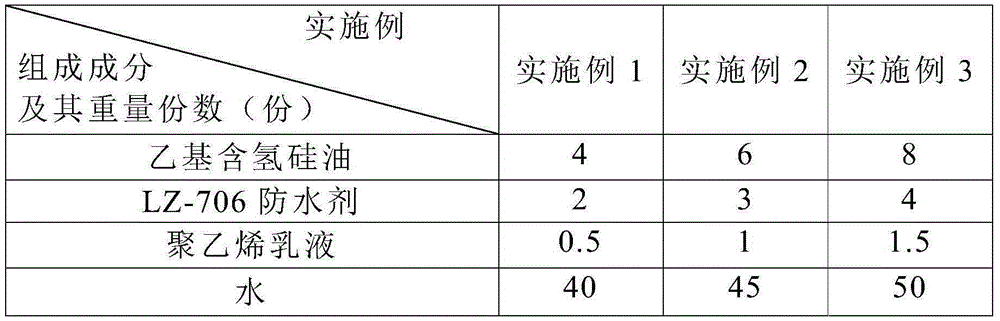

ActiveCN104530259AImprove solubilityReduce usageSurface-active detergent compositionsDetergent compounding agentsOrganic solventBenzaldehyde

The invention discloses a chitosan type Schiff base, a preparing method of the Schiff base and feather cleaning deodorant based on the Schiff base. The Schiff base is characterized in that natural biomass chitosan is used as a main raw material, and reacts with p-hydroxy benzaldehyde in an organic solvent to prepare the chitosan type Schiff base; the chitosan type Schiff base obtained through preparation is mixed with water and OP-10 according to different ratios to prepare the detergent. The feather cleaning deodorant is adopted for cleaning feathers in an ultrasonic mode in ultrasounds, and the cleaned feathers are pure white without extraneous odor; the preparing method of the chitosan-based feather cleaning deodorant is simple, the raw material is safe and free from poison, sources are sufficient, the price is low, and use of poisonous chemical reagents is reduced.

Owner:WEST ANHUI UNIV

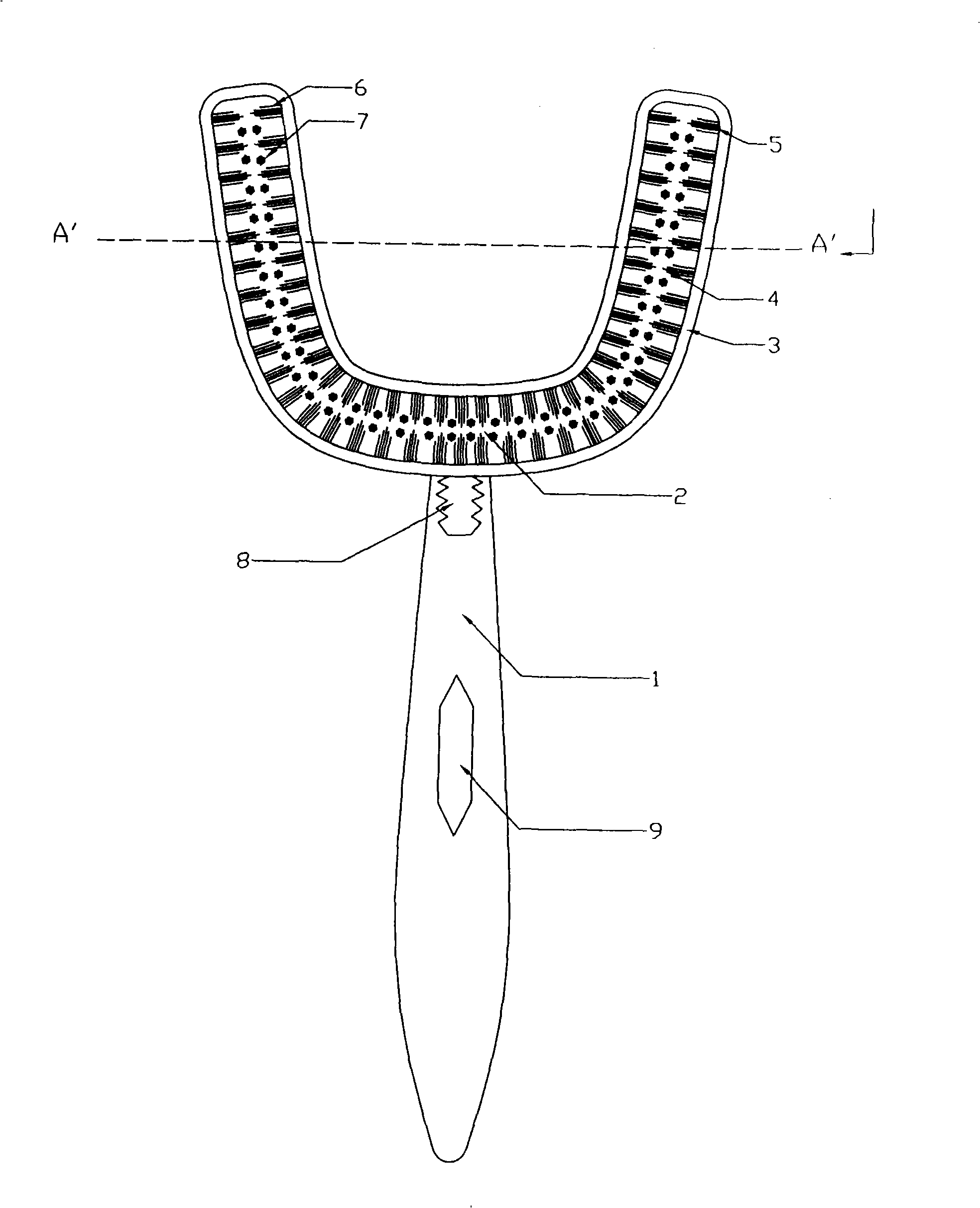

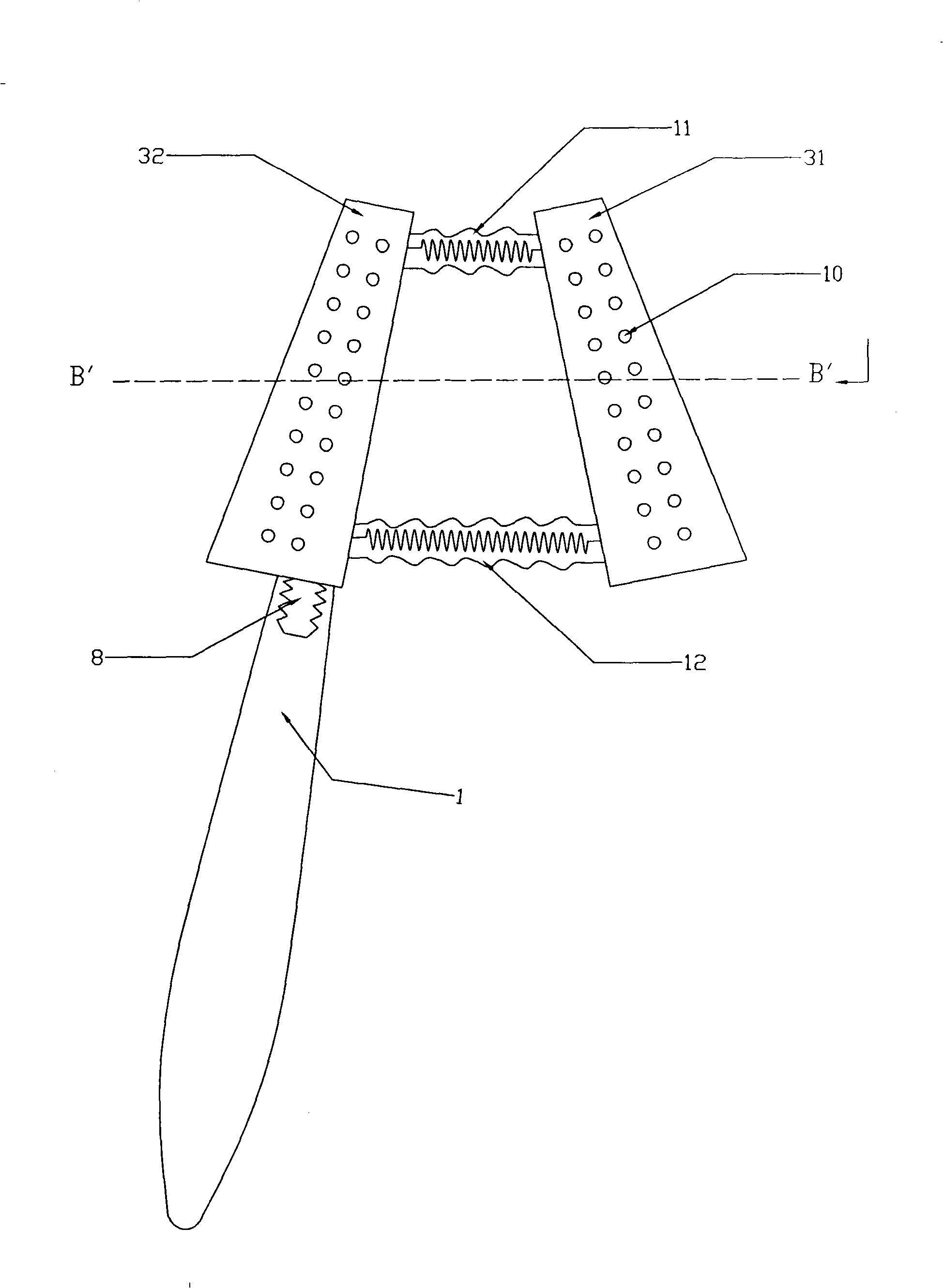

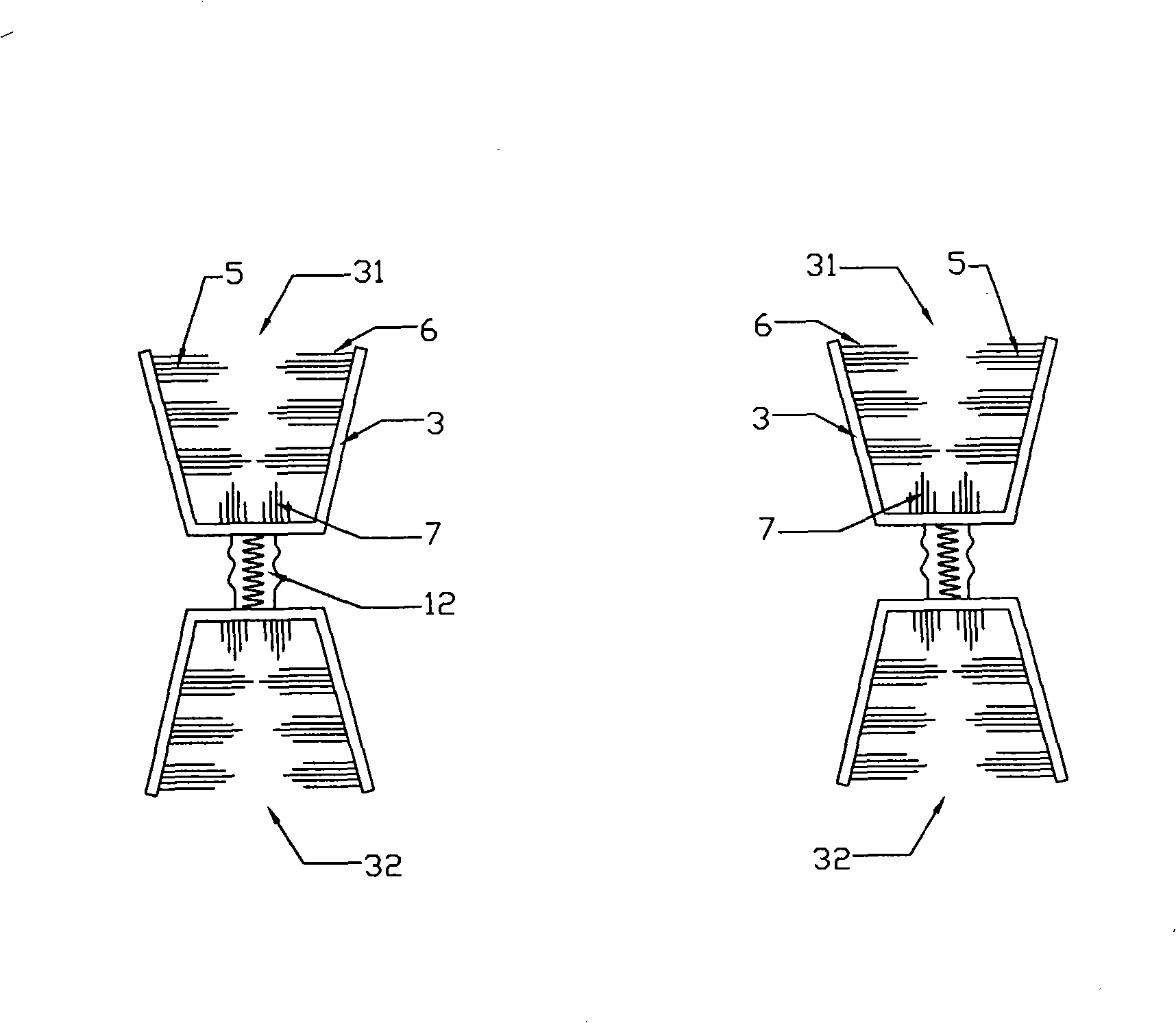

Full-mouth toothbrush with elastic fixing pole

The invention relates to a full-mouth tooth brush provided with an elastic connecting post, which consists of a tooth brush handle and a tooth brush main body. The tooth brush main body is provided with a tooth brush holder and brush hairs, wherein the tooth brush holder consists of an upper tooth brush holder and a lower tooth brush holder, and the bottom of the upper tooth brush holder and the bottom of the lower tooth brush holder are provided with the elastic connecting post to be connected into a whole. The brush hairs are sequentially arranged on the outside, the inside and the bottom surface of the U-shaped tooth brush holder, and the tooth brush hairs are matched with full-mouth teeth. The full-mouth tooth brush has the advantages that when the teeth make up-down chewing, under the action of the elastic connecting post arranged on the bottom of the upper tooth brush holder and the bottom of the lower tooth brush holder, the tooth brush can achieve washing aim, and is quick and sanitary; meanwhile, the tooth brush has the function of massaging gum, simple structure, convenient use and good reliability.

Owner:周之海

Ramie and paper straw mix-woven mat and processing technology thereof

InactiveCN104382430AStrong adsorption capacityEliminate bad smellHeating/cooling textile fabricsWoven fabricsAnti bacterialCotton thread

The invention relates to a mat and a processing technology thereof, in particular to a ramie and paper straw mix-woven mat and the processing technology thereof. The ramie and paper straw mix-woven mat is formed by weaving ramie and paper straws in a mixed way. The processing technology of the ramie and paper straw mix-woven mat comprises the following steps of firstly manufacturing the paper straws into paper, cutting the paper into pieces according to the specification of the ramie and paper straw mix-woven mat, then taking the pieces as weft threads by rolling the pieces into rope shapes or core-spun cotton threads in the pieces to form the rope shapes, obtaining ramie fiber by carrying out chemical degumming on the ramie, soaking the ramie fiber by nano-silver antibiotic finishing agent solution of which the PH is 5.0-6.5, and taking the ramie fiber as warp threads for weaving after the ramie fiber is dried, so as to obtain a mat main body; obtaining a mat semi-finished product by carrying out water spraying, heating, press polishing and shrinkage treatment on the mat main body by a press atomizer; finally, drying the mat semi-finished product after soaking the mat semi-finished product is soaked in a waterproof agent of which the PH is 4.3-6.2 for 5-10 minutes, and obtaining a mat finished product by carrying out edge covering treatment. According to the ramie and paper straw mix-woven mat and the processing technology, disclosed by the invention, the processing technology is simple, and the ramie and paper straw mix-woven mat which is obtained through the processing technology not only has excellent performance of moisture-absorption air permeability, anti-bacterial deodorization performance, health and environment protection performance and the like, but also is comfortable in hand feeling, is washable and foldable and is long in service life.

Owner:NINGBO YINZHOU LIMING ARTS & CRAFTS

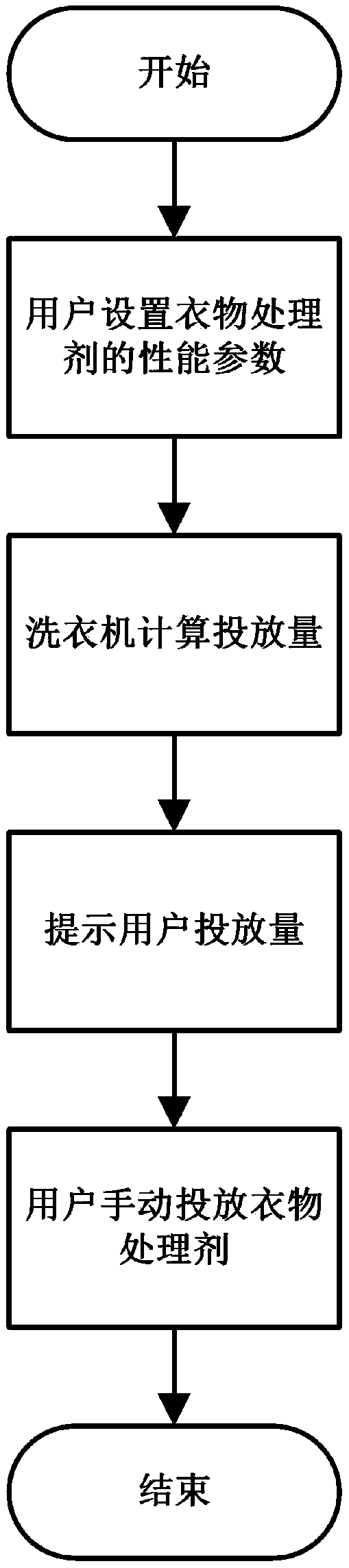

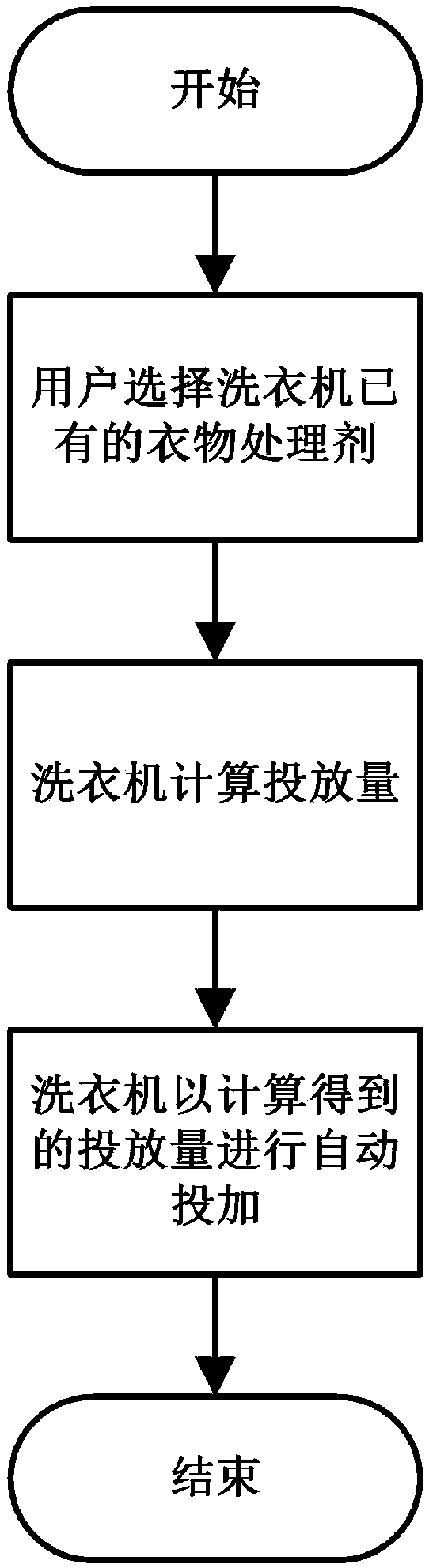

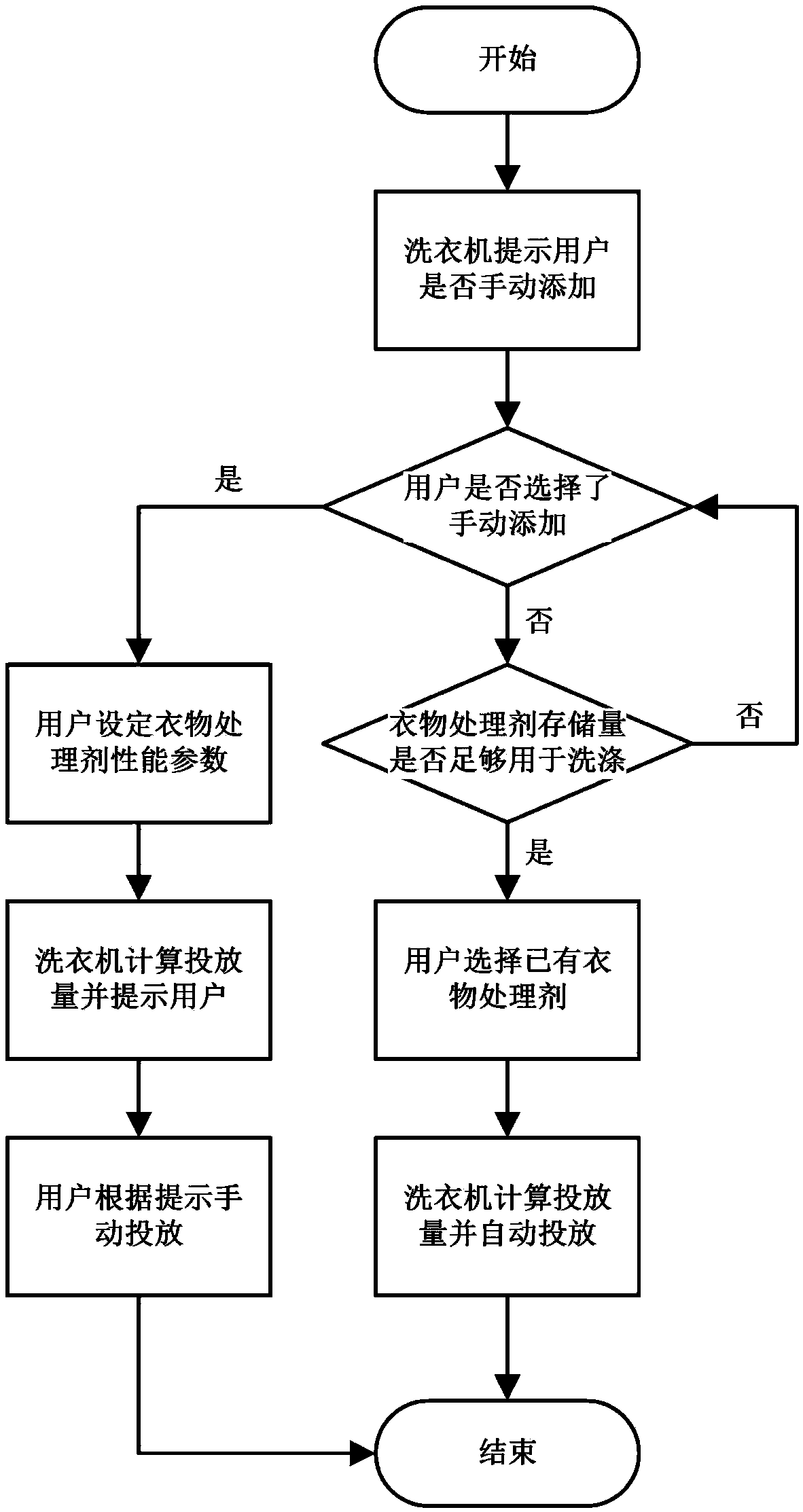

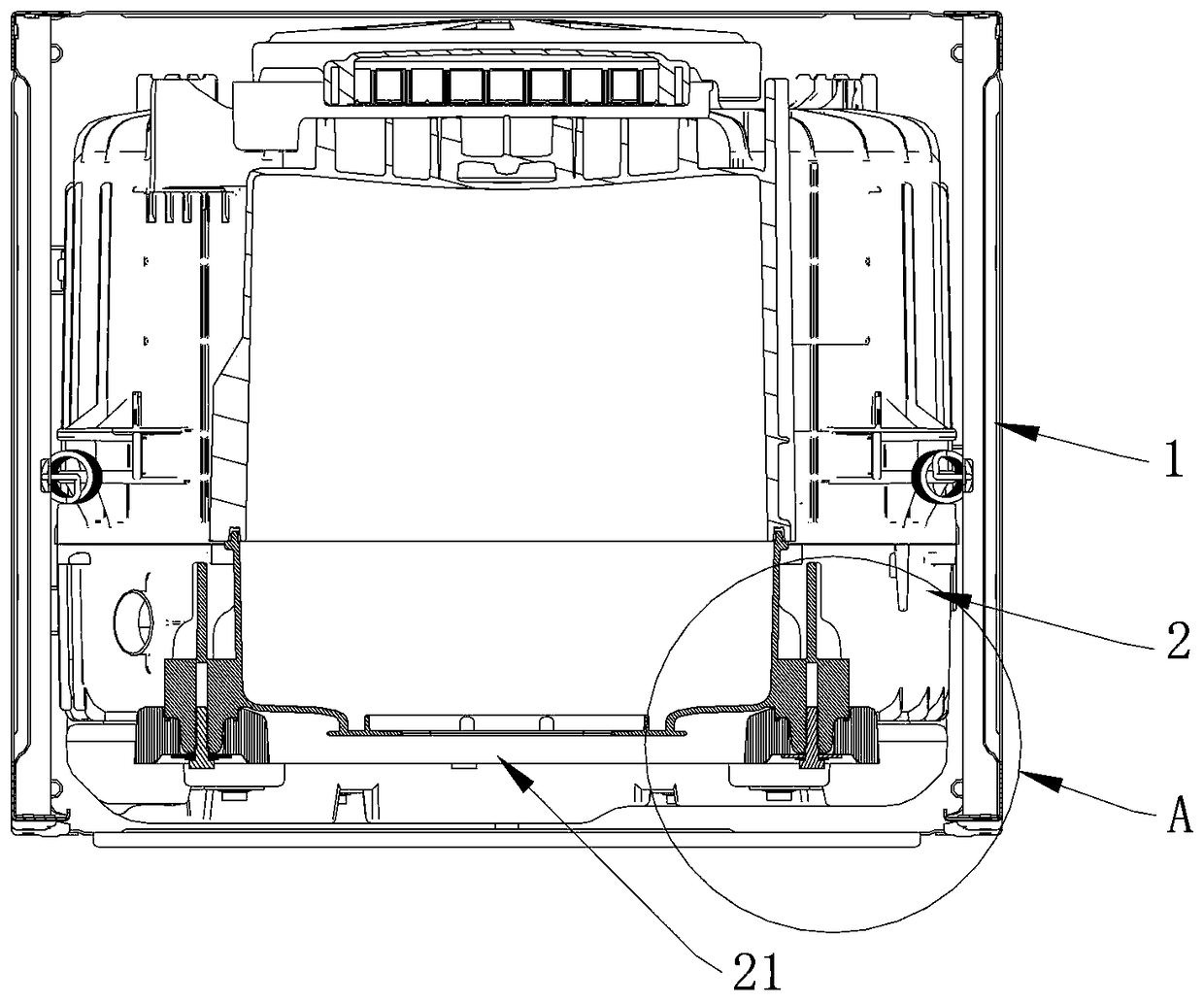

Control method of washing machine and washing machine

PendingCN111434838ADoes not affect storageTo achieve the purpose of washingOther washing machinesControl devices for washing apparatusLaundry washing machineProcess engineering

The invention discloses a control method of a washing machine and the washing machine. The washing machine controls putting of a clothes treating agent according to performance parameters, set by a user, of the clothes treating agent. The washing machine can support manual putting of the clothes treating agent and / or automatic putting of the clothes treating agent. The washing machine uses the control method and supports manual putting of the clothes treating agent and / or is provided with an automatic putting device to put the clothes treating agent. The user can select different clothes treating agents according to requirements of current washing, and storage in the automatic putting device is not affected by manual addition of the clothes treating agent. When the quantity of the clothestreating agent stored in the automatic putting device is insufficient, the user can directly put laundry detergents into an inner barrel more conveniently and more quickly. The washing machine performs conversion on laundry detergents with different concentrations according to the concentrations and precisely puts the laundry detergents before washing according to choices of the user, and waste and pollution environment caused by an excessively large quantity of laundry detergents with high concentrations are avoided.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Two-washing-tube double-power laundry machine

InactiveCN100412256CTo achieve the purpose of washingEasy to removeOther washing machinesWashing machine with receptaclesEngineeringMechanical engineering

A dual-power dual-drum washer is composed of external drum washing drum, waving wheel, motor, and dual-power transmission unit. It features that a small washing drum is installed to the mouth of washing drum for waving the clothes in it as the washing drum and waving wheel are rotating in different directions.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Washing method for groove etching device parts

ActiveCN103084984ALow raw material costReduce environmental costsBlast gunsAbrasive feedersUltrapure waterEngineering

The invention relates to a washing method of groove etching device parts. The invention relates to a washing method of groove etching device parts. The method comprises the steps that: resin sand is selected as a main sand material; sandblasting machine blasting working pressure is adjusted to 0.35-0.5Mpa; the sand blasting head of the sandblasting machine is aimed at an attachment area on a groove etching device part to be washed, and sand blasting is carried out; attachment attached to the groove etching device part is impacted off by using a sand material; and the attachment is removed through ultrapure water fine washing. With the washing method provided by the invention, base material and anode film layer are not damaged, and a part washing purpose is achieved. Also, working time cost can be saved, and production efficiency can be improved.

Owner:湖州科秉电子科技有限公司

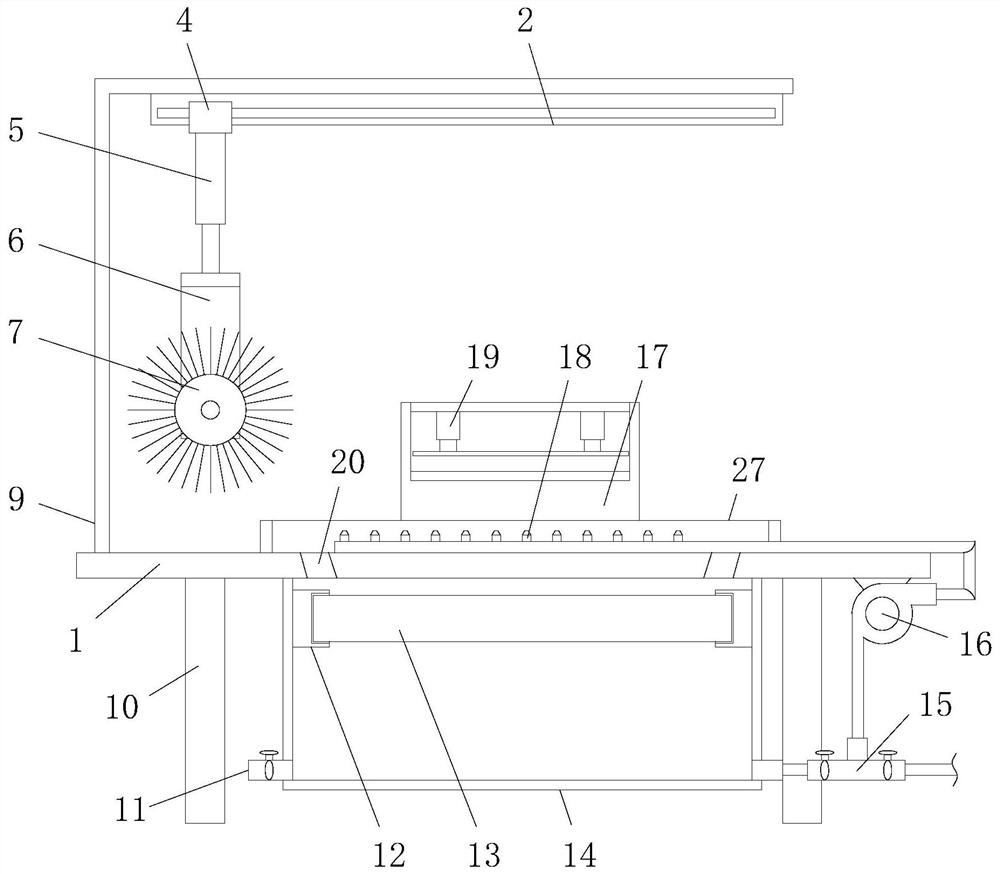

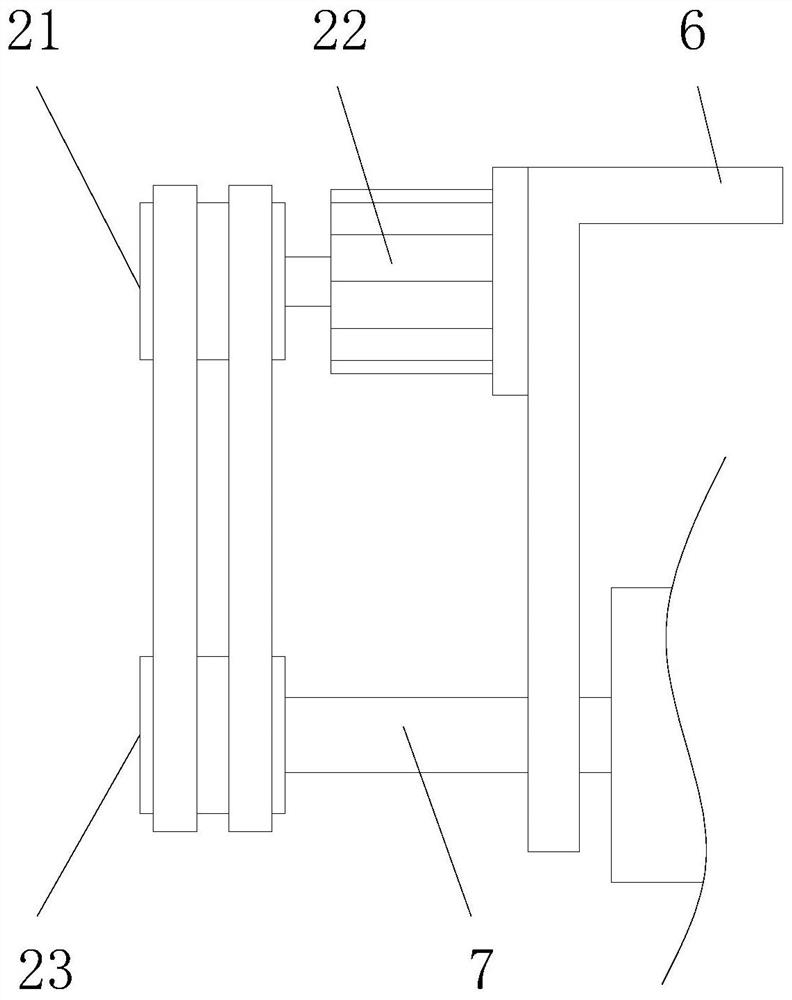

Cleaning device for production and machining of metal protective fences

InactiveCN113967619AReach the purpose of recyclingAchieve the purpose of clampingCleaning using toolsCleaning using liquidsWater storageActivated carbon filtration

The invention discloses a cleaning device for production and machining of metal protective fences. The cleaning device comprises a workbench and a three-way communicating vessel, a water storage tank is fixedly connected to the middle end of the bottom of the workbench, a clamping seat is fixedly connected to the upper end of the inner surface of the water storage tank, meanwhile, an activated carbon filtering layer is clamped to the inner surface of the clamping seat, second connecting plates are fixedly connected to the middle ends of the front side and the rear side of the workbench, a second motor is fixedly mounted on the back side of the second connecting plate located at the rear end of the workbench, and a rotating shaft is movably connected to the upper end of the back surface of the second connecting plate located at the front end of the workbench through a bearing. The device is provided with a first connecting plate, a sliding seat, a sliding device, a first electric telescopic rod, a third connecting plate, a first belt pulley, a first motor, a second belt pulley, a brush roller, the three-way communicating vessel, a pump machine, a spray head, the activated carbon filtering layer, a second electric telescopic rod, a pressing plate, a fourth connecting plate, a second connecting plate and the second motor, the cleaning effect of the device on the metal protective fences is effectively improved.

Owner:赣州市桐鑫金属制品有限公司

A method for treating iron and steel smelting slag

ActiveCN110779338BShorten the timeEnsure thoroughnessStirring devicesCharge manipulationThermodynamicsSlag

The invention relates to a treatment method for iron and steel smelting slag, which mainly includes the following steps: conveying and cooling, crushing, magnetic separation, water washing and transfer accumulation. The water washing equipment used in the above steps includes a falling hopper, a water washing box and a screening device. The hopper is installed on the upper end of the washing box, and a screening device is installed in the washing box. The washing box is a hollow cylindrical structure, and the inner wall of the washing box is uniformly equipped with washing nozzles along its circumferential direction, and the bottom of the washing box is evenly provided with feeding nozzles along its circumferential direction. There is a water outlet at the bottom of the washing box. While washing the slag with water, the present invention evenly stirs the slag to ensure the thoroughness of water washing, and then can preliminarily screen and classify the slag according to the sequence from small to large, saving the need for subsequent processing of the slag. Time for size sorting.

Owner:SHANDONG HUASHUN RARE METAL

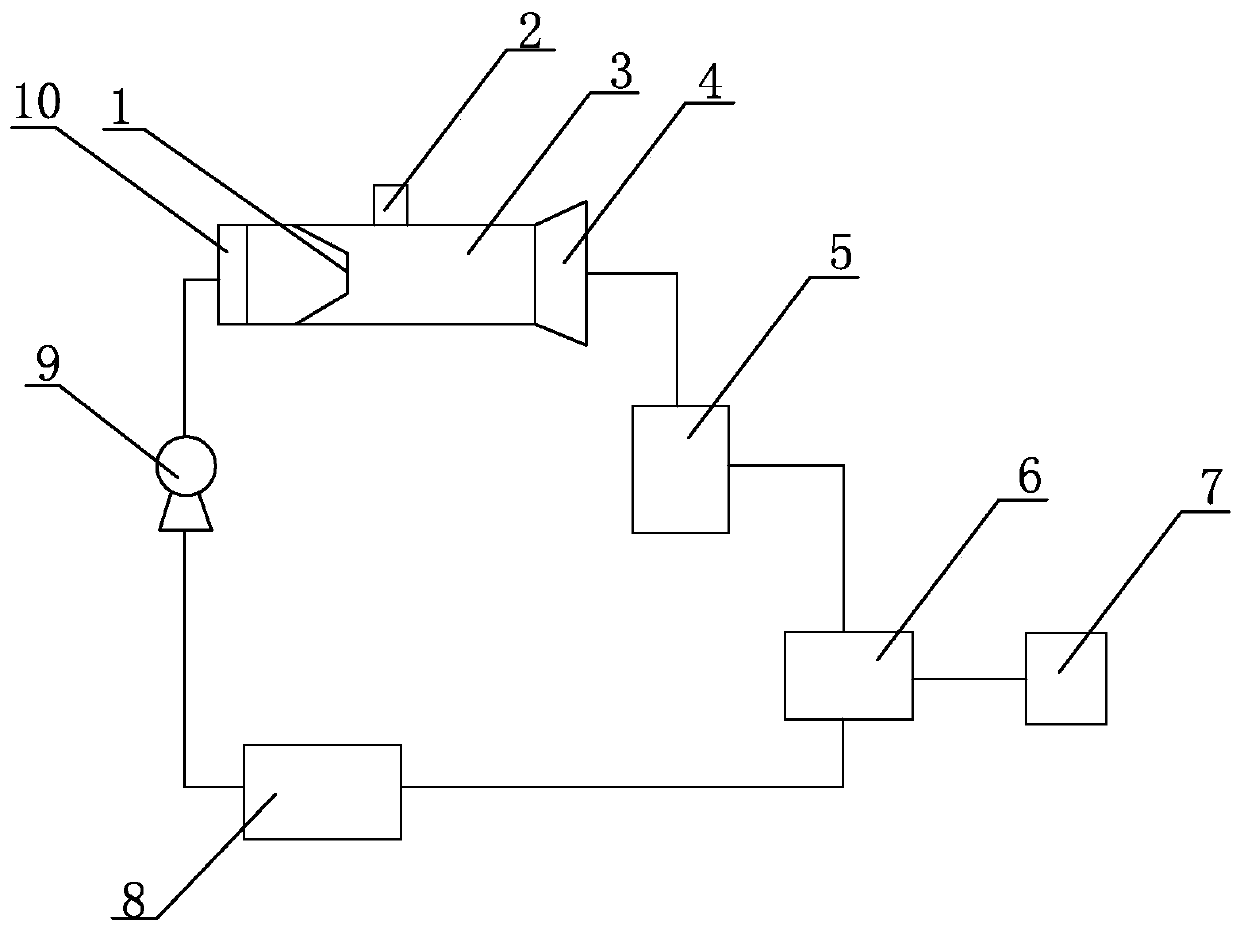

Ultra-high molecular weight polyethylene continuous water washing device and method

The invention belongs to the technical field of macromolecular chemical engineering, and particularly relates to a continuous washing device and method for polyethylene with an ultrahigh molecular weight. The continuous washing device comprises a jet mixer, wherein a washing material outlet of the jet mixer is connected with an inlet of a buffer tank; an outlet of the buffer tank is connected witha centrifugal machine; the centrifugal machine is connected with a dryer and a hot water tank; the hot water tank is connected with a material inlet of the jet mixer. The jet mixer comprises the material inlet; the material inlet and the washing material outlet are respectively located at two ends of a mixing chamber; a nozzle is arranged inside the mixing chamber; a material inlet is formed in the wall, which is located between the nozzle and the washing material outlet, of the mixing chamber. The continuous washing method comprises the step of washing polyethylene powder with water according to a mass ratio of 1:(2-30) at water temperature of 10 to 100 DEG C. The jet mixer is used as washing equipment; by adjustment of the water temperature and the ratio of the water to the powder, thewater and the powder can be fully mixed; after the powder is washed, the performance of the powder is equivalent to that of kettle type washed powder; furthermore, a breakthrough from an intermittentmode to a continuous mode is achieved, and the quality stability of the powder is improved.

Owner:CHINA PETROLEUM & CHEM CORP

A kind of ramie and flax mixed mat and its processing technology

InactiveCN104382430BGood anti-mildew effectImprove wear resistanceHeating/cooling textile fabricsWoven fabricsFiberPolymer science

The invention relates to a mat and its processing technology, in particular to a ramie and flax mixed mat and its processing technology. The mat is made of mixed ramie and flax, and its processing technology includes the following steps: first make the flax into paper, cut it into sheets according to the specifications of the mat, and then roll it into a rope or core-spun cotton into a rope for use as a mat. Weft thread, ramie is chemically degummed to obtain ramie fiber, soaked in a nano-silver antibacterial finishing agent solution with a pH of 5.0-6.5, dried, and made into a warp thread to weave to obtain the main body of the mat; the main body of the mat is sprayed with water through a press atomizer, The semi-finished mat is obtained by heating, calendering and shrinking; finally, it is soaked in a water repellent with a pH of 4.3-6.2 for 5-10 minutes, dried and edge-wrapped to obtain a finished mat. The mat of the invention has a simple processing technology, and the prepared mat not only has excellent moisture absorption and air permeability, antibacterial and deodorizing properties, health and environmental protection, etc., but also has comfortable hand feeling, can be washed and folded, and has a long service life.

Owner:NINGBO YINZHOU LIMING ARTS & CRAFTS

A reciprocating extrusion washing machine

ActiveCN104975455BReduce wearReduce water consumptionOther washing machinesTextiles and paperImpellerLaundry washing machine

Owner:QINGDAO HAIER WASHING MASCH CO LTD

A double-drum washing machine

ActiveCN104278481BImprove compactnessTo achieve the purpose of washingOther washing machinesTextiles and paperEngineeringMechanical engineering

The invention discloses a double-drum washing machine, which comprises a washing machine frame, a first outer drum and a second outer drum, wherein the first outer drum and the second outer drum are arranged in the frame; the first outer drum and the second outer drum are integrally provided with balancing weight mounting columns used for mounting balancing weights; the first outer drum and the second outer drum are connected into a whole through a connecting piece; the connecting piece is fixedly connected with the balancing weight mounting columns on the first outer drum and / or the second outer drum. According to the double-drum washing machine disclosed by the invention, the first outer drum and the second outer drum are connected into an integral structure through the connecting piece so as to effectively improve the compactness of the washing machine; the connecting piece is fixedly installed and connected through the balancing weight mounting columns on the first outer drum or the second outer drum so as to increase the stability of the washing machine; moreover, a shared balancing weight is provided for the first outer drum and the second outer drum through the connecting piece; furthermore, the shared balancing weight is used by the first outer drum and the second outer drum, and the first outer drum or the second outer drum of the washing machine is used as at least one part of balancing weight of the second outer drum or the first outer drum, so that the two drums of the washing machine have an obvious damping effect, and the production cost is reduced.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

A reciprocating washing machine

ActiveCN104975458BReduce wearReduce water consumptionOther washing machinesTextiles and paperImpellerReciprocating motion

The invention provides a reciprocating type washing machine. The reciprocating type washing machine comprises a washing bucket, an upper cover, a transmission mechanism, a piston and a driving device, wherein the upper cover is movably connected to an opening of the washing bucket, the washing bucket comprises an upper portion and a lower portion, the upper portion of the washing bucket is used as a washing cavity for containing / washing clothes, the piston is arranged in the washing cavity, the lower portion of the washing bucket is used as a control cavity, the transmission mechanism is arranged in the control cavity, the input end of the transmission mechanism is connected with the driving device, the transmission mechanism and the piston are in screw transmission, and the driving device drives the piston to perform up-down reciprocating motion in the washing bucket through the transmission mechanism. According to the reciprocating type washing machine, washing is performed through reciprocating extrusion on the clothes by the piston, the defects that an existing impeller type washing machine and a tumbling-box washing machine are serious in wear of the clothes and large in water consumption are overcome, and the better washing effect is achieved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Antibacterial and odor-removing tableware fruit and vegetable cleaning agent and preparation method thereof

InactiveCN102559400BKeep green freshTo achieve the purpose of washingNon-ionic surface-active compoundsDetergent compounding agentsMicroorganismCoconut oil

The invention discloses a detergent for tableware, fruits and vegetables and a preparation method thereof. According to a composing prescription, ginger extract is used to remove oil stains, peculiar smells and bacteria on the tableware, and microorganisms, worm eggs, ash fouling, and the like on the surfaces of the fruits and the vegetables; and meanwhile, surfactant components such as glucoside and coconut oil derivatives are used by the detergent, so that that detergent is safe for human bodies, cannot irritate skin and is harmless to the environment. The detergent has the advantages of reasonable formula, simple process and obvious use effect.

Owner:TIANJIN TIANSHI BIOLOGICAL DEV +2

Washing method for groove etching device parts

ActiveCN103084984BTo achieve the purpose of washingLow costBlast gunsAbrasive feedersSand blastingEngineering

The invention relates to a washing method of groove etching device parts. The invention relates to a washing method of groove etching device parts. The method comprises the steps that: resin sand is selected as a main sand material; sandblasting machine blasting working pressure is adjusted to 0.35-0.5Mpa; the sand blasting head of the sandblasting machine is aimed at an attachment area on a groove etching device part to be washed, and sand blasting is carried out; attachment attached to the groove etching device part is impacted off by using a sand material; and the attachment is removed through ultrapure water fine washing. With the washing method provided by the invention, base material and anode film layer are not damaged, and a part washing purpose is achieved. Also, working time cost can be saved, and production efficiency can be improved.

Owner:湖州科秉电子科技有限公司

Chitosan-type Schiff base, preparation method thereof, and feather cleaning deodorant based thereon

ActiveCN104530259BImprove solubilityReduce usageSurface-active detergent compositionsDetergent compounding agentsOrganic solventBenzaldehyde

The invention discloses a chitosan type Schiff base, a preparing method of the Schiff base and feather cleaning deodorant based on the Schiff base. The Schiff base is characterized in that natural biomass chitosan is used as a main raw material, and reacts with p-hydroxy benzaldehyde in an organic solvent to prepare the chitosan type Schiff base; the chitosan type Schiff base obtained through preparation is mixed with water and OP-10 according to different ratios to prepare the detergent. The feather cleaning deodorant is adopted for cleaning feathers in an ultrasonic mode in ultrasounds, and the cleaned feathers are pure white without extraneous odor; the preparing method of the chitosan-based feather cleaning deodorant is simple, the raw material is safe and free from poison, sources are sufficient, the price is low, and use of poisonous chemical reagents is reduced.

Owner:WEST ANHUI UNIV

A processing technology of hemp and flax mixed mat

The invention relates to a processing technique for mats and particularly relates to a processing technique for a China-Hemp and paper straw mixed mat. The processing technique comprises the following steps: cutting waterproof paper into sheets according to specifications of the mat, then wrapping straws with sheety waterproof paper so as to form ropy paper and then reeling to form wefts, and taking China-Hemp as warps for knitting, so as to obtain a mat main body; spraying water by using an atomizer of a pressing machine, heating, pressing polish and carrying out shrinking treatment on the mat main body, so as to obtain a semi-finished mat; soaking the semi-finished mat into a waterproof agent solution with a pH value of 4.5 to 6.5, and then placing the semi-finished mat into a drying oven for drying; arranging well cut lining cloth on peripheries of the dried semi-finished mat, wrapping the semi-finished mat by using the lining cloth, enabling the lining cloth to be symmetric on upper and lower surfaces of the mat, compacting, then carrying out edge covering treatment on the mat, and finally obtaining a finished mat. The mat prepared by using the processing technique provided by the invention are not only nice and cool, air-permeable, wear-resistant, sun-proof and has soft feel, but also has the advantages of bacteriostasis, uvio-resistance and the like, and is long in service life.

Owner:宁波黄古林工艺品有限公司

A double-drum washing machine

ActiveCN104278473BImprove compactnessTo achieve the purpose of washingOther washing machinesWashing machine with receptaclesEngineeringMechanical engineering

The invention discloses a double-drum washing machine, which comprises a washing machine frame, a first outer drum and a second outer drum; the first outer drum and the second outer drum are arranged in the frame; the first outer drum is provided with a first balancing weight; the second outer drum is provided with a second balancing weight; the first balancing weight and the second balancing weight are connected so as to enable the first outer drum and the second outer drum to be connected into a whole. According to the double-drum washing machine disclosed by the invention, the first outer drum and the second outer drum are connected through the respective balancing weights, and therefore the two outer drums are connected into a whole and the compactness of the washing machine is effectively improved; the double-drum washing machine is simple in structure and convenient to assemble; more particularly, after the two outer drums are connected into a whole, the damping effect is remarkable, and the work noise is reduced; the double-drum washing machine disclosed by the invention is simple in structure, remarkable in effect and suitable for being popularized and used.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

Method for treating pure cotton fabric with aromatic odor

InactiveCN104420229AAvoid many disadvantages such as oil spotsAchieve long-term effectVegetal fibresPolyvinyl alcoholReaction temperature

The invention discloses a method for treating a pure cotton fabric with aromatic odor. The method comprises the following steps: adding a monomeric substance polyvinyl alcohol and 2,4-toluene diisocynate between which a reaction is carried into a solvent acetone in advance, stirring under the designed reaction temperature, reacting to a certain viscosity, stopping the reaction, and preparing a prepolymer; adding essence into the prepolymer, uniformly mixing, and taking the solution as an oil phase; adding an emulsifier, a water-soluble polymer monomer into water, stirring to be uniform, and preparing an aqueous phase; and dripping the oil phase into the aqueous phase, and preparing a colloidal solution. The pure cotton fabric is finished by utilizing the colloidal solution, so that the aroma of the pure cotton fabric can be released for a long time, and a phenomenon that the quality of the fabric is influenced by the produced oil patches is effectively avoided.

Owner:QINGDAO SINGAO TEX NEW TECH COMPOSITE MATERIAL

A chip washing device

ActiveCN100464877CSmall driving forceConveniently achieve the purpose of washingGearingFlexible article cleaningMotor driveEngineering

One kind of chip washing method and device are disclosed. The method includes setting a motor driven conveyer over a washing container, immobilizing the washing container and driving the chip to be washed with the conveyer to move relatively to the washing container. The chip washing device includes: one outer barrel, one bottom plate fixed to the bottom of the outer barrel, one fixing board fixed inside the outer barrel, one motor fixed onto the fixing board, one slipway board fixed inside the outer barrel, one conveyer set on the slipway with input connected to the output of the motor; and one frame for holding the chip and connected to the output of the conveyer. The present invention can wash great amount of chips in identical washing effect and may be used widely in washing various kinds of electronic chips and biochips.

Owner:CAPITALBIO CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com