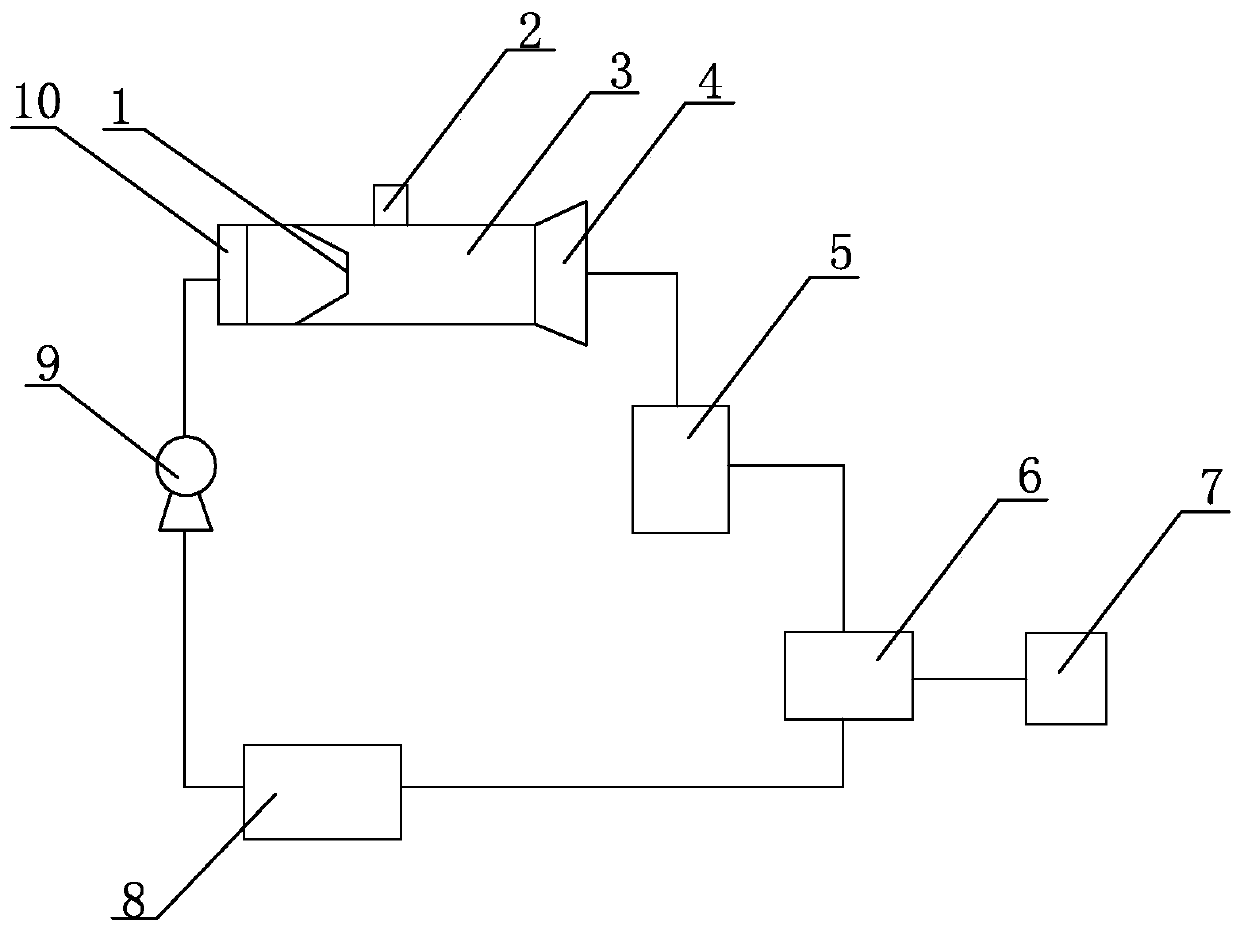

Ultra-high molecular weight polyethylene continuous water washing device and method

A technology of ultra-high molecular weight and washing equipment, which is applied in the field of continuous washing equipment for ultra-high molecular weight polyethylene, which can solve problems such as difficulties, large energy consumption, and stability impact, and achieve the effect of increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of ultra-high molecular weight polyethylene powder:

[0030] Add 600 liters of hexane oil into a stainless steel reactor with a volume of 1 cubic meter, stir and heat up to 70°C, add 50 g of aluminum alkyl, add 5 g of catalyst after 10 minutes, and feed ethylene after 10 minutes and keep the pressure at 0.7-0.9 MPa During the period, the polymerization temperature was controlled at 75°C, and the material was discharged after 5 hours of polymerization. Filter the polymer feed solution to separate the solvent, wash once with hexane oil, the mass ratio of polymer to solvent is 1:1 during solvent washing, and wash with solvent for 20 minutes, after filtering and separating, heat and dry under vacuum at a temperature of 60-80°C , taking no more solvent as the drying end point to obtain 290kg of product.

[0031] The mixing ratio of water and polyethylene powder is 1:6, and the water temperature is 60°C, and the prepared ultra-high molecular weight polyethylene p...

Embodiment 2

[0037]The preparation of ultra-high molecular weight polyethylene powder and the continuous water washing device used are the same as in Example 1, the only difference is that the mixing ratio of water and polyethylene powder is 1:6, and the water temperature is 50°C. The ultra-high molecular weight polyethylene powder is washed with water.

Embodiment 3

[0039] The preparation of ultra-high molecular weight polyethylene powder and the continuous water washing device used are the same as in Example 1, the only difference is that the mixing ratio of water and polyethylene powder is 1:6, and the water temperature is 70°C. The ultra-high molecular weight polyethylene powder is washed with water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com