Double-drum washing machine

A washing machine and double-drum technology, applied in the field of washing machines, can solve the problems of insignificant shock absorption and noise reduction effects, increase the cost of washing machines, etc., and achieve the effects of being suitable for popularization and use, obvious shock absorption effects, and reducing working noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

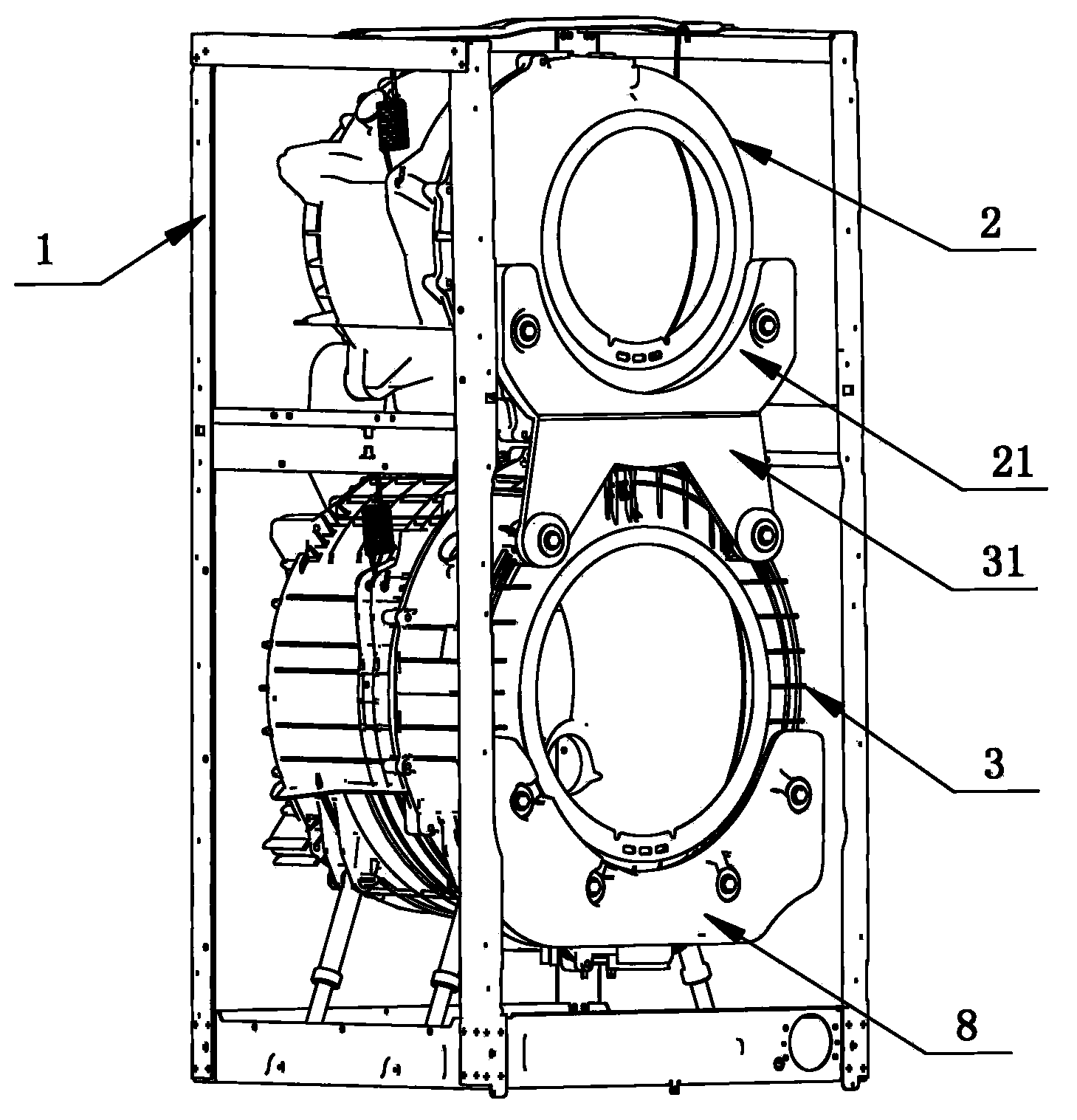

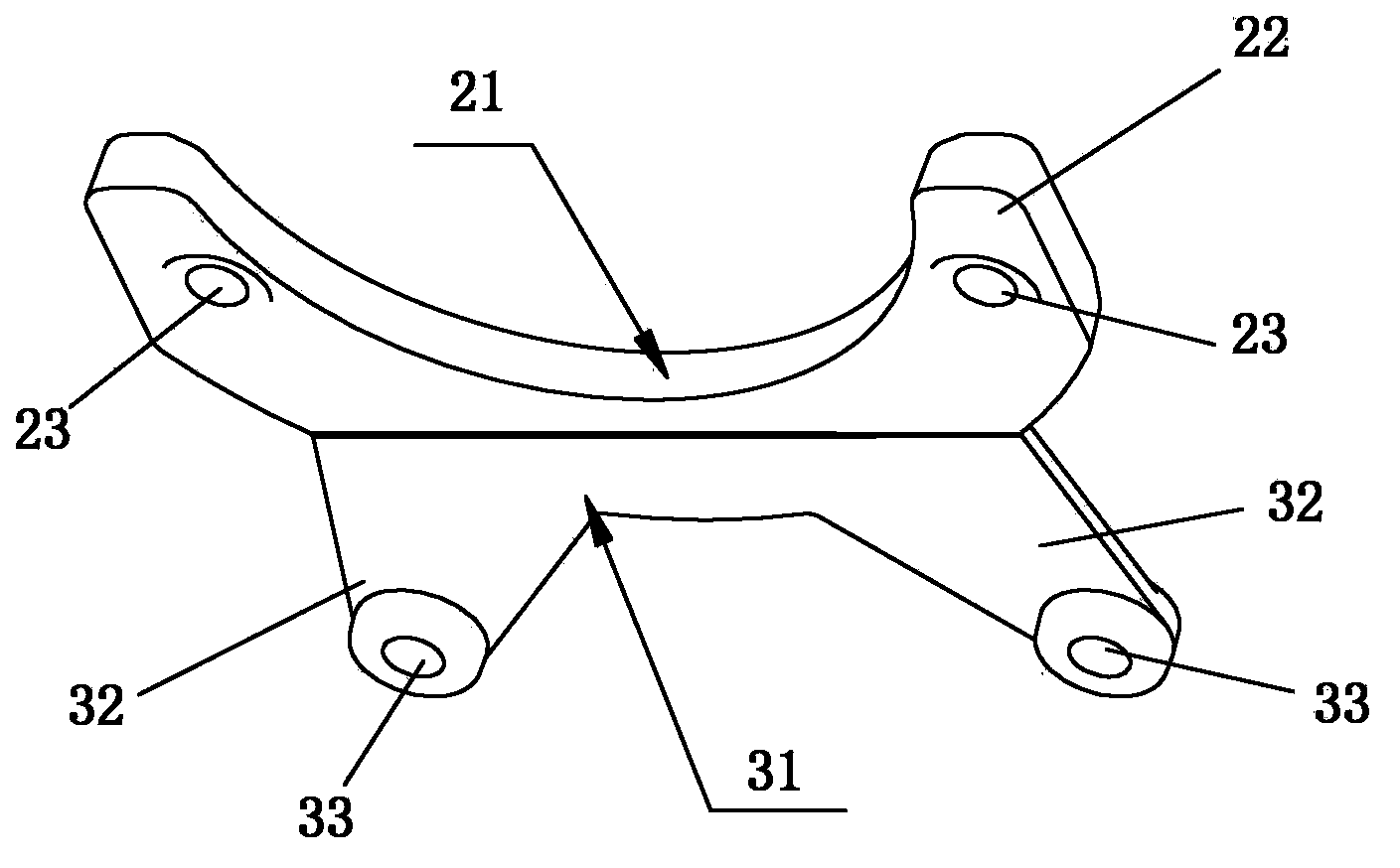

[0043] like Figures 1 to 5 As shown, the first counterweight 21 and the second counterweight 31 described in this embodiment are integrally structured, the first counterweight 21 is U-shaped, and the upper end is provided with the front end of the first outer cylinder 2 The upper mounting foot 22 matching the profile, the second counterweight 31 is an inverted U shape, and the lower end is provided with the lower mounting foot 32 matching the front end contour of the second outer cylinder 3, the first counterweight 21 and the second counterweight The weight 31 is integrally H-shaped or X-shaped.

[0044]Specifically, the first counterweight 21 is respectively provided with first upper mounting holes 23 on the upper mounting feet 22 corresponding to the front end of the first outer cylinder 2, and the first upper mounting holes 23 are installed with the counterweight at the front end of the first outer cylinder 2. The column 5 is correspondingly connected by the bolt 7; simil...

Embodiment 2

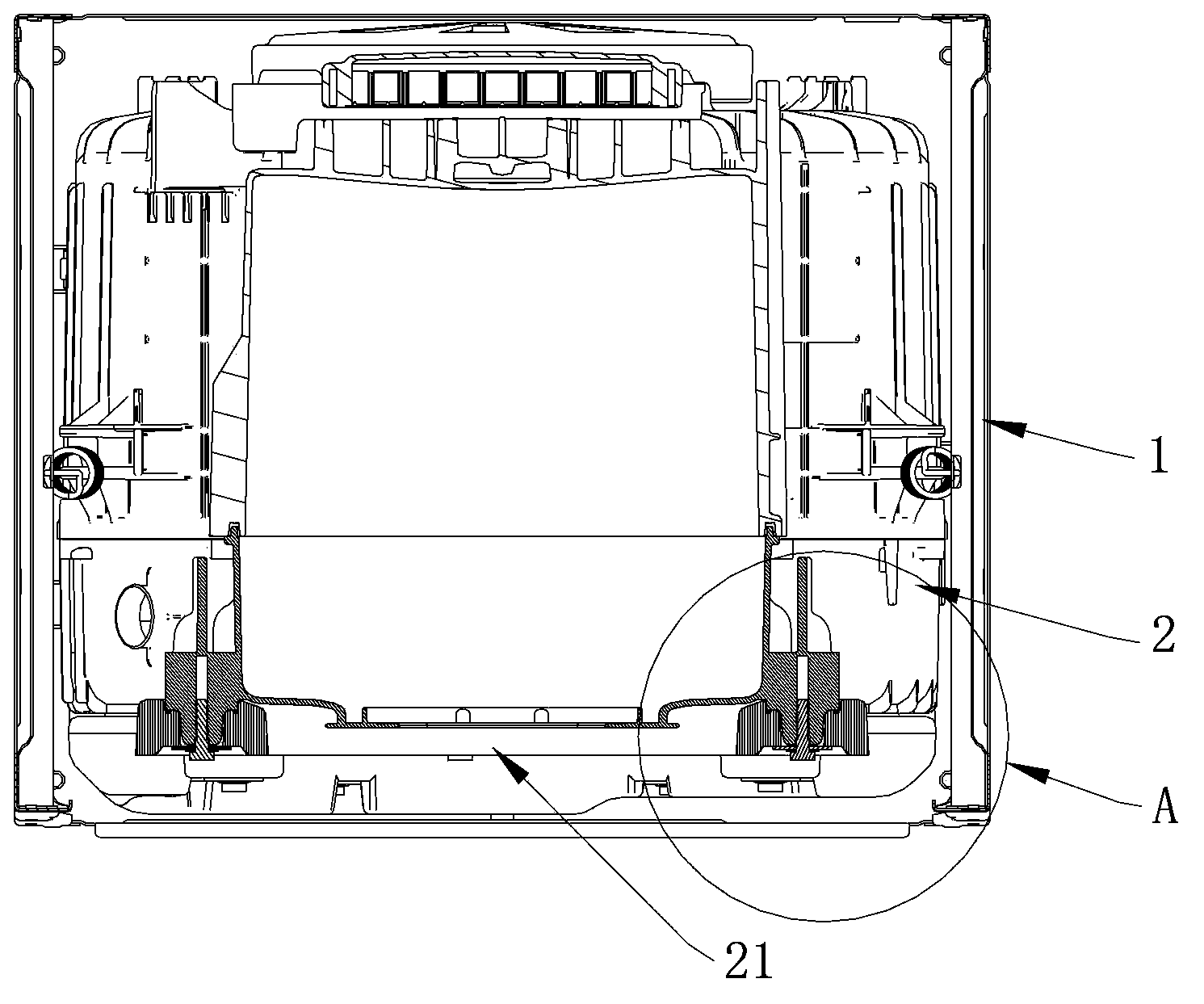

[0046] like Figure 6 and Figure 7 As shown, the first counterweight 21 described in this embodiment and the second counterweight 31 are connected as an integral structure through the connecting piece 4, and the connecting piece 4 is connected with the first counterweight 21 and the second counterweight respectively. Block 31 bolted connection.

[0047] like Figure 6 As shown, the connecting piece 4 is a plate structure, and the first counterweight 21 and the second counterweight 31 are connected through a connecting piece; Figure 7 As shown, the connector is a rod-shaped structure, and the first counterweight 21 and the second counterweight 31 are connected by two sets of rod-shaped connectors.

Embodiment 3

[0049] This embodiment makes further improvements on the basis of Embodiment 2: for the convenience of assembly, the weight of the first counterweight 21 and the second counterweight 31 can be reduced, and the connecting piece 4 is made for the first outer cylinder 2 and the second counterweight 31. Additional counterweight shared by the second outer cylinder 3 (see Figure 8 ), or an additional counterweight (not shown in the figure) shared by the first outer cylinder and the second outer cylinder is installed on the connecting member 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com