Thermoelectric generating unit, molten salt reactor and operation method and application of molten salt reactor

A technology of temperature difference power generation and operation method, which is applied in the direction of nuclear power generation, generators using thermoelectric elements, and reduction of greenhouse gases, etc. It can solve problems such as unsatisfactory heat transfer capacity and achieve the effect of improving heat transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] (1) molten salt reactor

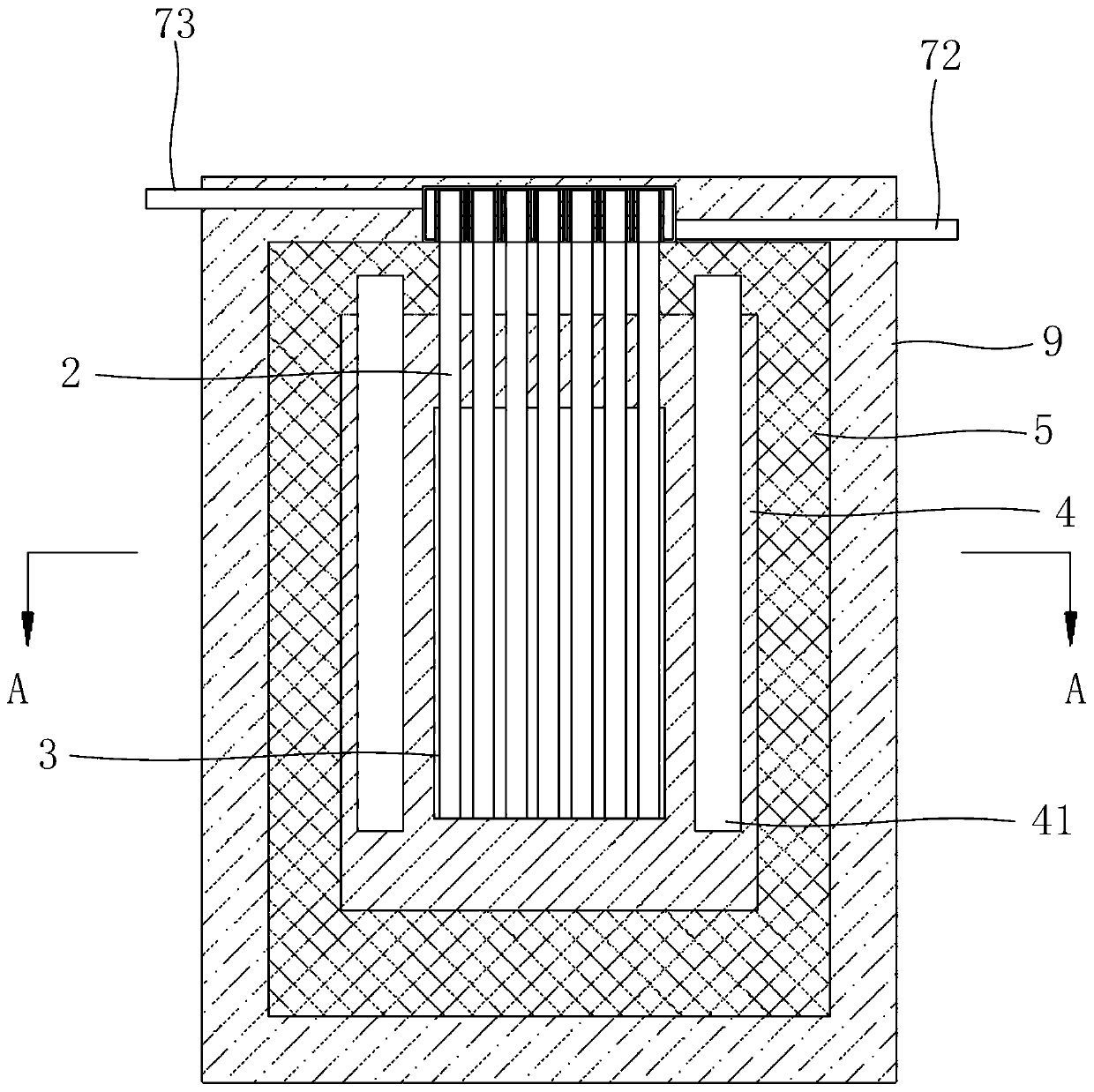

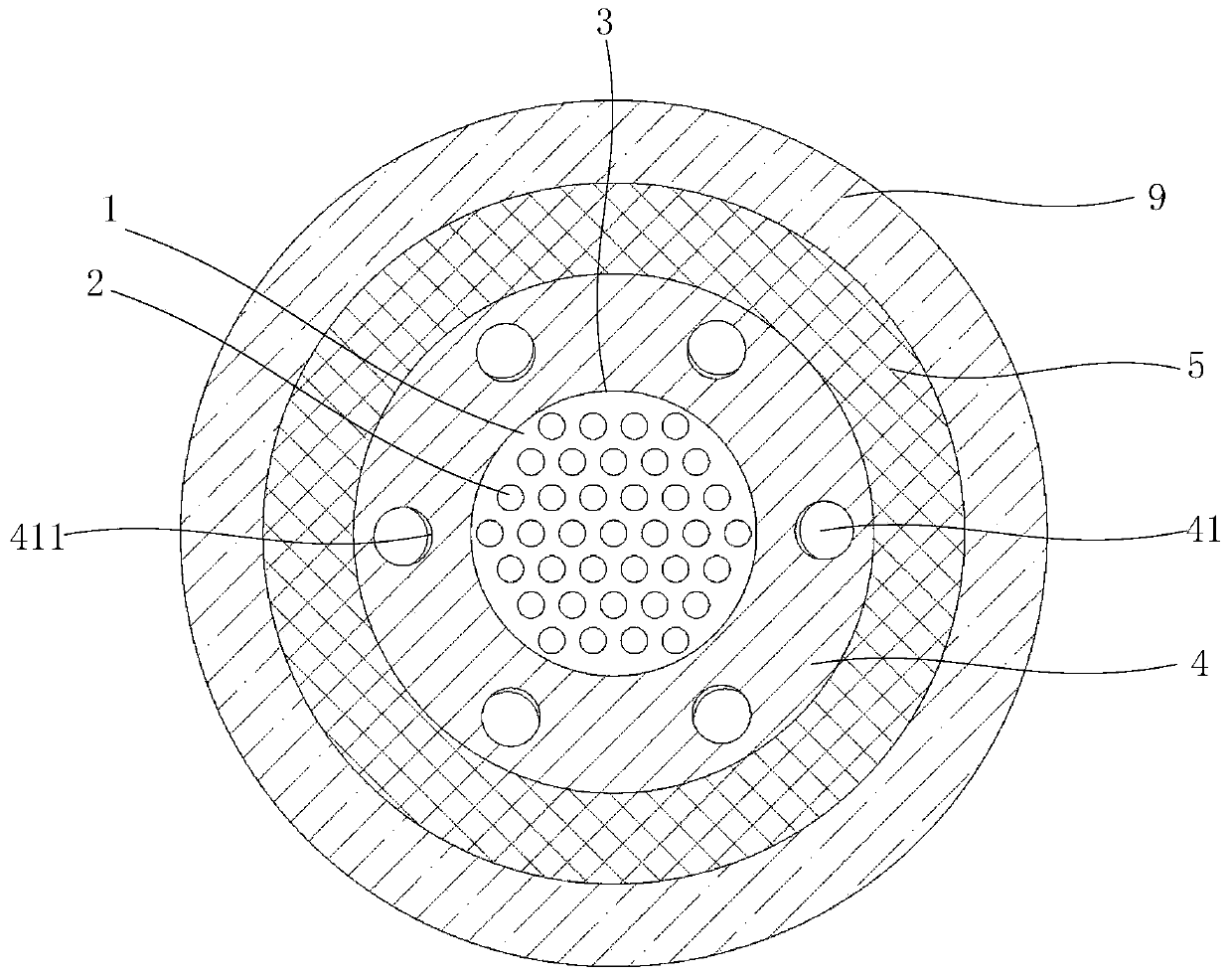

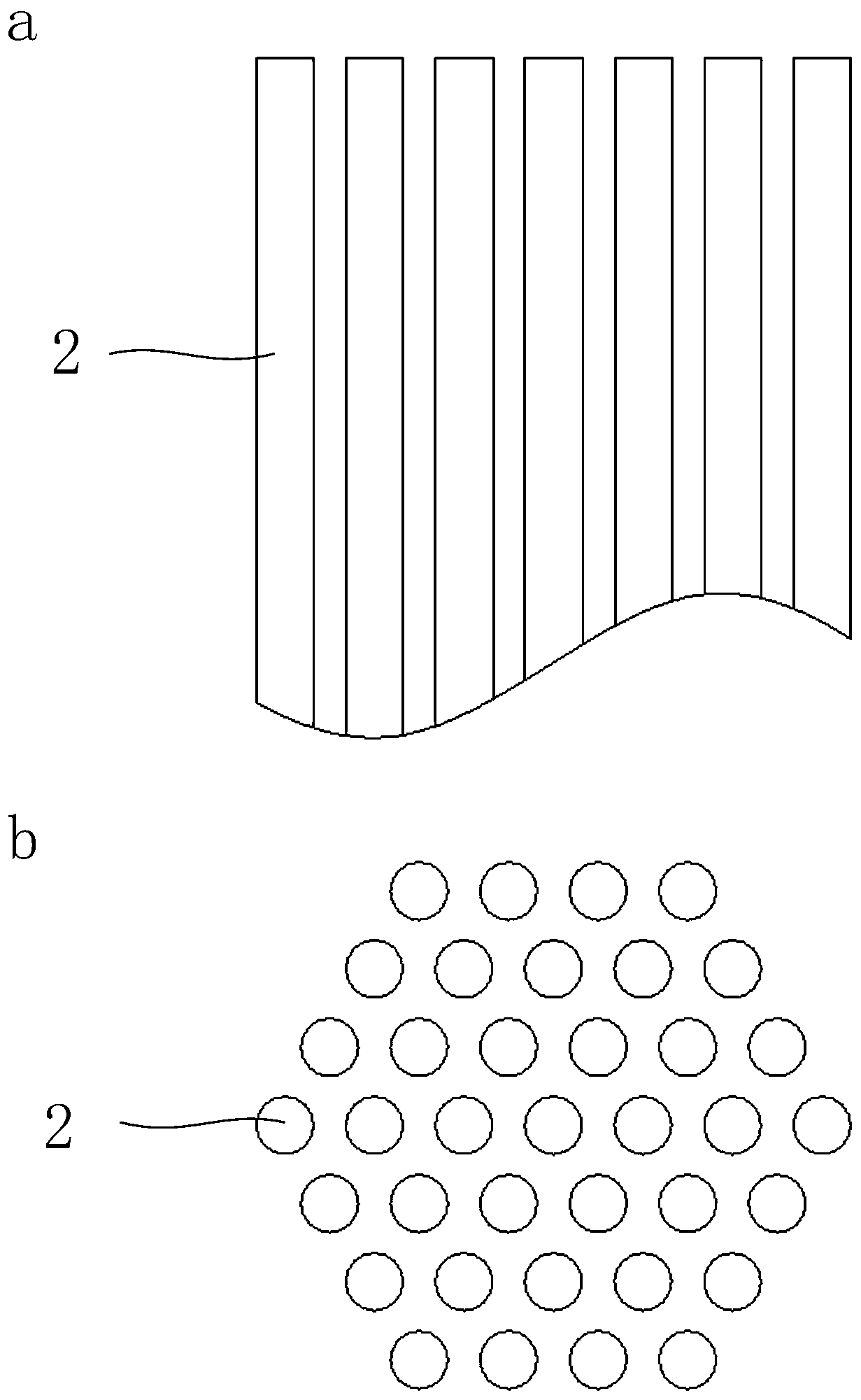

[0072] Such as Figure 1-9 As shown, the molten salt reactor includes fuel salt 1, heat pipe 2, core vessel 3, reflective layer 4 and shielding layer 5; reflective layer 4 and shielding layer 5 are arranged outside the core vessel 3 in sequence; fuel salt 1 is filled in the stack core container 3; one end of the heat pipe 2 is inserted into the fuel salt 1, and the other end of the heat pipe 2 protrudes from the shielding layer 5 of the molten salt pile as the heat pipe condensing end; each heat pipe condensing end is sleeved with a suitable Hot end sleeve 61, the outer wall of hot end sleeve 61 is a plane, the bottom of each hot end sleeve is connected with the bottom of its adjacent hot end sleeve to form a hot end sleeve 6; A suitable cold end sleeve 71 with an internal cavity is sleeved, and the bottom of each cold end sleeve communicates with the bottom of the adjacent cold end sleeve to form a cold end sleeve 7 with an internal cavity. ...

Embodiment 2

[0084] (1) molten salt reactor

[0085] The power of the molten salt reactor is 10kw, the inner diameter of the core vessel is 30cm, the distance between heat pipes is adjusted to 60mm, and the number of heat pipes is 19, and the rest are the same as the molten salt reactor in embodiment 1.

[0086] (2) Operation method

[0087] It is carried out in the above molten salt reactor, wherein the cooling water flow rate is 0.2kg / s, the inlet water temperature of the cooling water inlet is 300K, and the outlet water temperature of the cooling water outlet is 330.2K; the core temperature is 873K, and the temperature of the hot end of the thermoelectric power generation sheet is 833.2K, the temperature of the cold end of the thermoelectric power generation sheet is 517.3K, the temperature difference between the hot end and the cold end of the thermoelectric power generation sheet is 325.9K, and the rest are the same as the operation method of embodiment 1.

[0088] Technical effect: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat transfer coefficient | aaaaa | aaaaa |

| Heat transfer coefficient | aaaaa | aaaaa |

| Heat transfer coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com