Automatic ultrasonic coupling agent smearing device

An ultrasonic coupling agent and automatic technology, which is applied in the field of ultrasonic medicine, can solve the problems of insufficient automaticity, single application method, and inability to fit the skin surface well, so as to achieve the effect of good automation and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

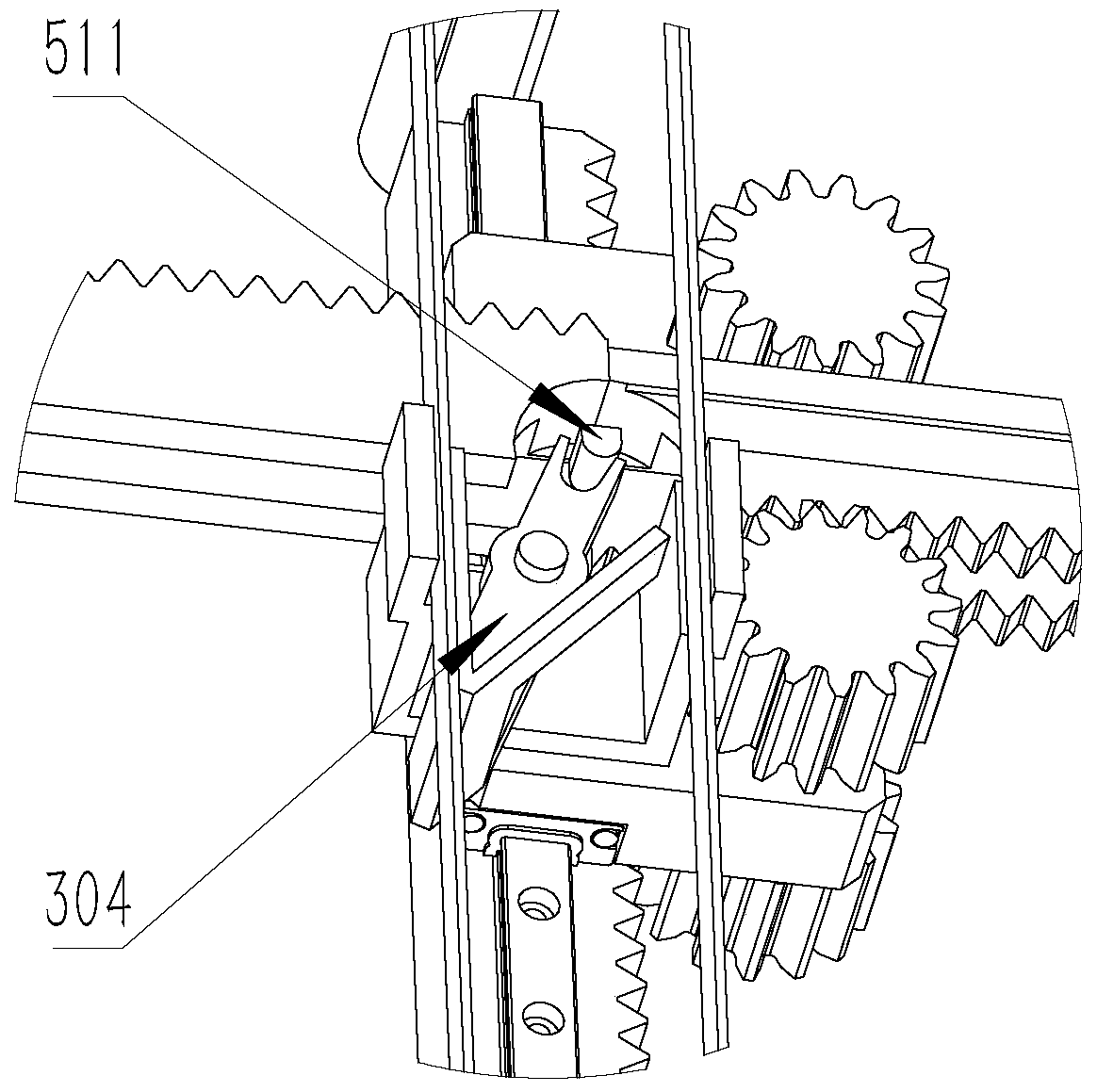

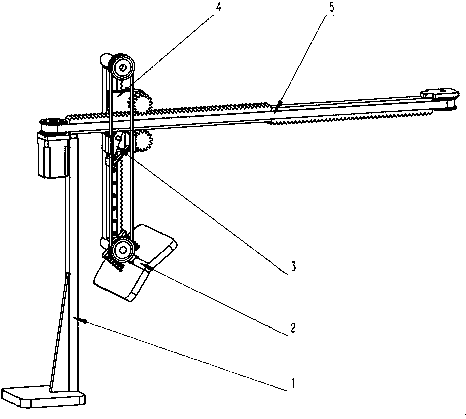

[0027] Embodiment 2: The rest of this embodiment is the same as the previous embodiment. When the lower end of the reversing lever 304 swings to the left, cooperate with the timing belt stopper 303 to fix the left side of the second synchronous belt 302; the reversing lever When the lower end of 304 swings to the right, cooperate with the synchronous belt limit block 303 to fix the second synchronous belt 302 right side.

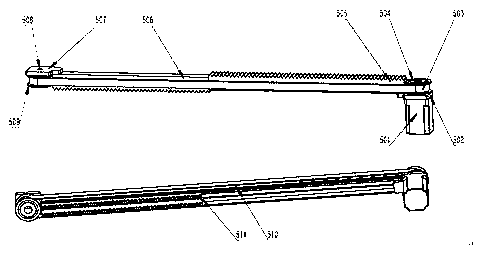

[0028] The transverse driving mechanism 5 comprises a motor 501, a first synchronous wheel 504, a second synchronous wheel 509, a second synchronous wheel shaft 508, a first synchronous belt 503, a motor fixed plate 502, a pulley fixed plate 507, a long slotted rack 505, Short slotted rack 506, reversing limit head 511, horizontal guide rail 510; long slotted rack 505 has a groove on one plane side, and one side is fixed to the side of short slotted rack 506; short slotted rack The 506 tooth surface side has a groove; the motor fixing plate 502 is fixed on o...

Embodiment 3

[0029]Embodiment 3: the remainder of this embodiment is the same as the previous embodiment, and the smearing mechanism 2 includes a smearing panel 203, a smearing bracket 204, a support shaft 201, and a panel spring 202; the lower end of the smearing bracket 204 is connected with the smearing panel 203; the smearing panel 203 can Swing around the smearing bracket 204, the upper side of the smearing panel 203 is connected to one side of the panel spring 202; one side of the panel spring 202 is connected to the smearing panel 203, and the other side is connected to the protruding ends of the smearing bracket 204; the bracket shaft 201 is connected to the smearing bracket The upper end of 204 is fixed and fixed with the fourth synchronous wheel 305; it is connected with the lower end of the vertical rack 402 and can rotate freely; the smearing panel can provide a certain number of couplant output holes as required. The bottom panel of the support 1 is fixed on other surfaces, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com