Device and method for producing special curing agent

A curing agent and a special technology, applied in chemical instruments and methods, transportation and packaging, chemical/physical processes, etc., can solve the problems of no large-scale development and utilization, occupying open space, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The special curing agent in this embodiment is prepared by mixing the following raw materials in parts by weight: 5-10 parts of coking desulfurization ash, 10-35 parts of slag powder, 20-30 parts of steel slag powder, and 20-30 parts of activator. The activator uses sodium silicate and sodium hydroxide, and the weight ratio of sodium silicate and sodium hydroxide is 1:3~5.

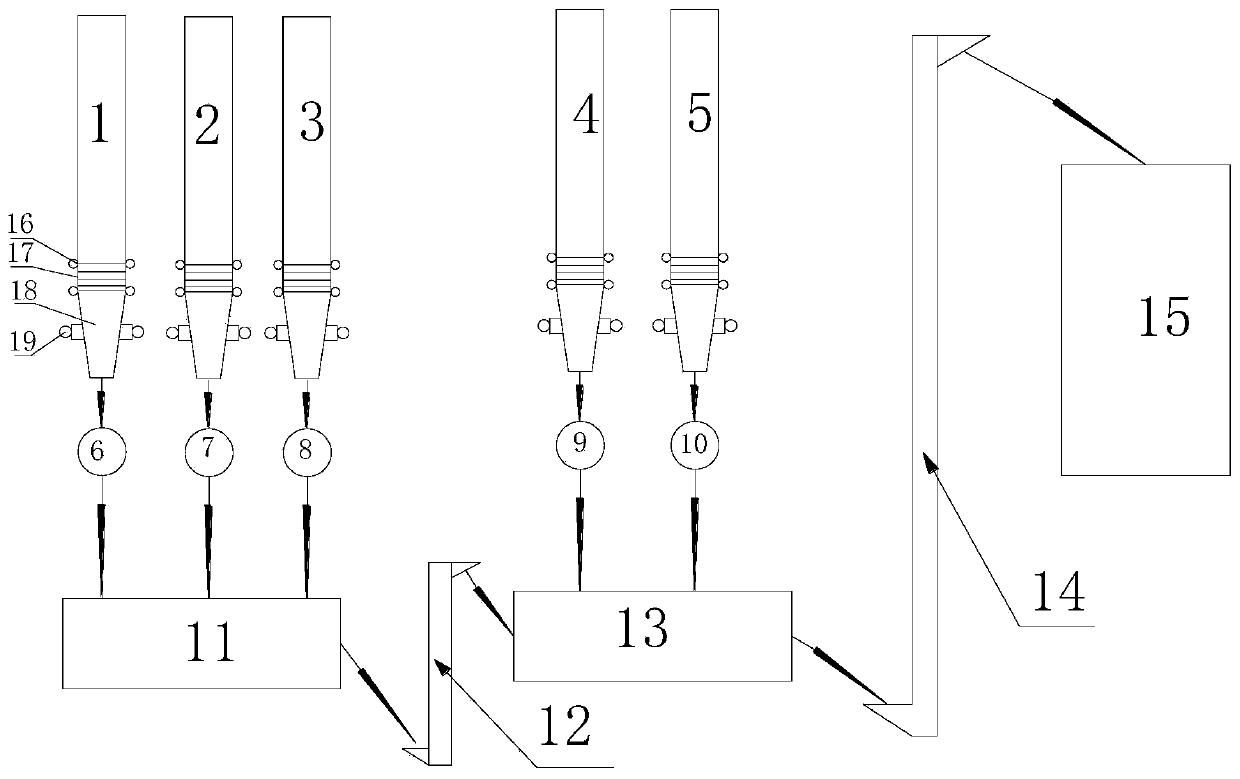

[0020] Coking desulfurization ash, slag powder, and steel slag powder are transported by tanker respectively, and transported to No. 1 raw material bin 1, No. 2 raw material bin 1, and No. 3 raw material bin 3 through pneumatic conveying devices. No. 4 raw material warehouse 4 and No. 5 raw material warehouse 5. Coking desulfurization ash is measured and weighed, conveyed to the primary mixer 11 by a screw conveyor, slag powder is measured and weighed, and conveyed to the primary mixer 11 by a screw conveyor, steel slag powder is measured and weighed, and conveyed to a primary mixer by a screw conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com