Cascade Utilization Process of Casting Aluminum Slag

A treatment process and technology for aluminum slag, which is applied in the field of cascade utilization treatment process of molten and cast aluminum slag, can solve the problem of not extracting high-value and useful components, and achieve the effect of realizing cascade utilization, increasing added value and increasing added value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

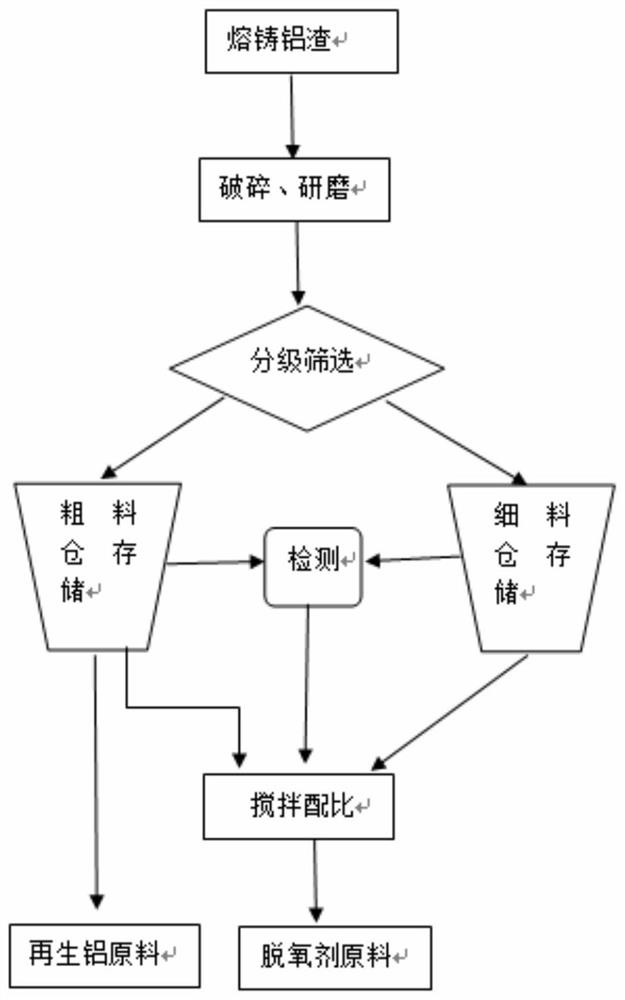

[0027] figure 1 It is a process flow diagram of an embodiment of a step utilization treatment process of molten casting aluminum slag according to the present invention. As shown in the figure, the present invention provides a step utilization treatment process of molten casting aluminum slag, which includes the following steps:

[0028] (1) Grinding molten casting aluminum slag: The molten casting aluminum slag is packed in a space bag for easy transportation, and the molten casting aluminum slag is put into a ball mill for grinding by using the space bag feeding device, so as to process the molten casting aluminum slag with irregular appearance into tiny particles, After processing, its particle diameter reaches μm level. Dust will be generated during the feeding and grinding process, so a dust collector is installed at the feed inlet of the ball mill. The dust collector generates negative pressure to absorb the flying dust into its storage hopper for recycling. In this wa...

Embodiment 2

[0036] The present invention can also detect the aluminum slag as a whole, then classify and sieve, and then detect coarse particles or fine particles, and use the proportion of coarse and fine particles according to the results of the first detection and the second detection to meet the grade requirements of aluminum slag. Qualified deoxidizer raw materials are produced, and then the remaining part of the coarse particle bin is used as recycled aluminum raw materials. Therefore, the present invention adopts the above-mentioned cascade utilization treatment process of cast aluminum slag to extract as much metal aluminum as possible under the premise of meeting the grade standard of aluminum slag, so as to meet the grade requirements of aluminum slag and extract high-value useful components.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com