Polyacid functionalized nitrogen-rich porous carbon as well as preparation method and application thereof

An acid-functionalized, porous carbon technology, applied in chemical instruments and methods, separation methods, inorganic chemistry, etc., can solve the problems of difficult to efficiently remove hydrogen sulfide, lose catalytic activity, affect desulfurization ability, etc. The effect of improving the utilization rate and increasing the durability of desulfurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a preparation method of polyacid functionalized nitrogen-rich porous carbon, comprising the following steps:

[0031] (1) mixing the polyacids, water and the macrocyclic compound and carrying out ultrasonication to obtain an inclusion compound;

[0032] (2) Mixing the clathrate, the nitrogen-containing compound, the activator and the carbon source to carry out a carbonization reaction to obtain a polyacid functionalized nitrogen-enriched porous carbon.

[0033] In the present invention, the polyacid compound, water and the macrocyclic compound are mixed and ultrasonicated to obtain the inclusion compound. In the present invention, the polyoxometalate preferably includes one or more of phosphotungstic acid, phosphomolybdic acid, silicotungstic acid and silico-molybdic acid; the polyoxometalate monomer preferably includes tungstic acid one or more of sodium, sodium molybdate and ammonium molybdate; the macrocyclic compound preferably includes one o...

Embodiment 1

[0045] Weigh 4 g of phosphomolybdic acid, dissolve it in 20 mL of purified water, then weigh 5 g of β-cyclodextrin, and ultrasonically treat it for 120 min to obtain an inclusion compound;

[0046] Weigh 0.5g of the clathrate, 4g of ammonium oxalate and 4g of sodium bicarbonate, mix it with 6g of rice husks, then transfer to a tube furnace, feed nitrogen, and control the nitrogen flow to be 60mL / min. The carbonization reaction was carried out in the middle, and the reaction temperature was controlled at 800 °C for 1 h to obtain the polyacid functionalized nitrogen-rich porous carbon;

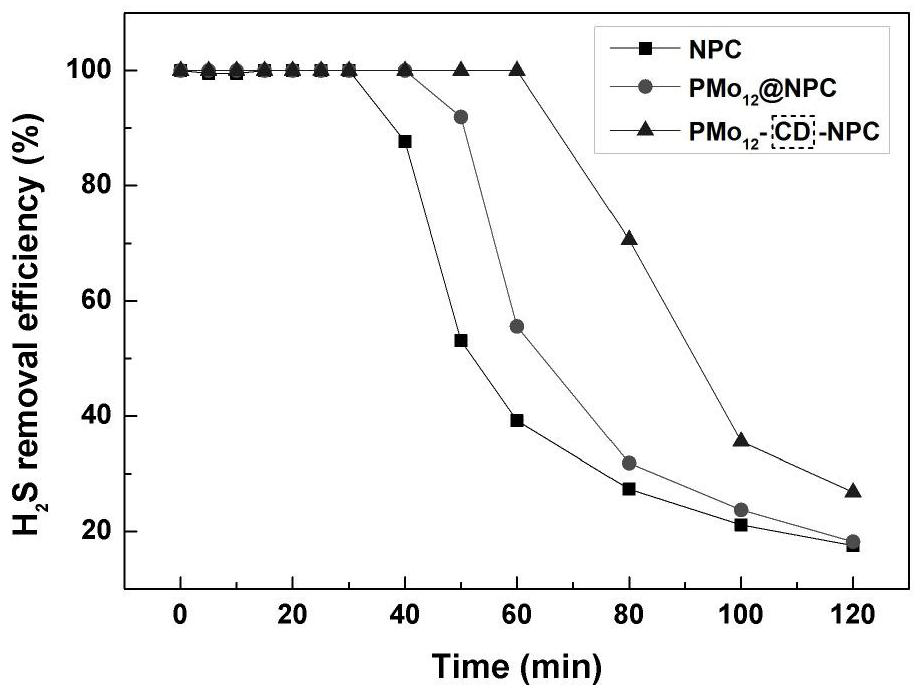

[0047] Fill 0.2 g of the polyacid functionalized nitrogen-rich porous carbon into a quartz tube with an inner diameter of 8 mm and a length of 40 cm, and under room temperature conditions, a mixed gas with a flow rate of 100 mL / min is introduced to carry out desulfurization, wherein the described The mixed gas includes hydrogen sulfide, oxygen and nitrogen, and the concentration of the hydrogen ...

Embodiment 2

[0050] Weigh 4 g of phosphomolybdic acid, dissolve it in 20 mL of purified water, weigh 5 g of β-cyclodextrin, and ultrasonically treat it for 120 min to obtain an inclusion compound;

[0051] Weigh 0.25g of the clathrate, 4g of ammonium oxalate and 4g of sodium bicarbonate, mix it with 6g of rice husks, then transfer to a tube furnace, feed nitrogen, and control the nitrogen flow to be 60mL / min. The carbonization reaction was carried out in the middle, and the reaction temperature was controlled at 800 °C for 1 h to obtain the polyacid functionalized nitrogen-rich porous carbon;

[0052] Fill 0.2 g of the polyacid functionalized nitrogen-rich porous carbon into a quartz tube with an inner diameter of 8 mm and a length of 40 cm, and under room temperature conditions, a mixed gas with a flow rate of 100 mL / min is introduced to carry out desulfurization, wherein the described The mixed gas includes hydrogen sulfide, oxygen and nitrogen, and the concentration of the hydrogen sulf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com