Method for recycling wastewater containing high-concentration ammonia nitrogen

An ammonia nitrogen wastewater, high concentration technology, applied in chemical instruments and methods, water pollutants, hydrogen production and other directions, can solve problems such as the inability to achieve harmless ammonia nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

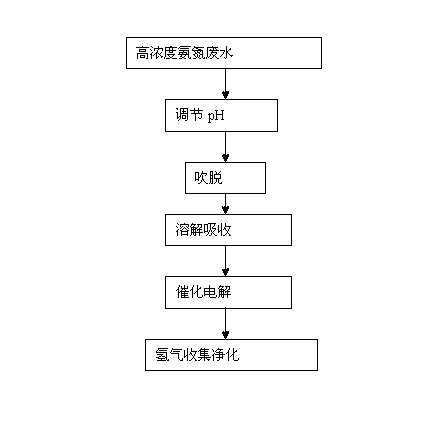

Image

Examples

Embodiment 1

[0040] The concentration of ammonia nitrogen in the wastewater is 1000-10000mg / L, and the pH is controlled between 9 and 11. The lye and electric energy are consumed, and the air is blown off to blow off more than 90% of the high-concentration ammonia nitrogen from the wastewater, followed by lye Absorb the ammonia nitrogen blown out to complete the concentration and purification of ammonia nitrogen;

[0041] The design parameters of the electrolytic reaction device used in the ammonia nitrogen electrolytic hydrogen production test are: the appearance size is 190mm×110mm×180mm; the iron plate and the graphite electrode are 2 pieces each, and the size is 100mm×100mm×5mm; the DC output voltage of the current regulator 1-15V, current 1-10A. Table 1 shows the results of the electrolysis of two ammonia nitrogen solutions with different concentrations under the conditions of a voltage of 5V and a distance between the plates of 1.5cm.

[0042] time (min) Ammonia nitrogen...

Embodiment 2

[0046] The concentration of ammonia nitrogen in the wastewater is 1000-10000mg / L, and the packing blow-off tower is used to control the pH between 9-11, and the air is blown off for 1.5-2 hours to blow off the high-concentration ammonia-nitrogen above 70-95% from the waste water. The lye is used to absorb the stripped ammonia nitrogen to complete the concentration and purification of ammonia nitrogen; the electrolytic reaction device used in the ammonia nitrogen electrolytic hydrogen production test uses a modified electrode coated with Pt, Rh and Ir precious metals on the surface; the voltage is 1-15V, Current 1-10A. Under the conditions of a voltage of 5V and a distance between plates of 1.5cm, the concentration of electrolyzed ammonia nitrogen is between 5000 and 10000mg / L, and the conversion rate of ammonia nitrogen is 91.4%.

Embodiment 3

[0048] The concentration of ammonia nitrogen in the wastewater is 5000-8000mg / L, and the packed stripping tower controls the pH between 10 and 13, air blows off for 2 hours, and blows off more than 90% of the high-concentration ammonia nitrogen from the wastewater at a temperature of 30-50 °C out, and then use lye to absorb the stripped ammonia nitrogen to complete the concentration and purification of ammonia nitrogen; the electrolytic reactor adopts modified electrodes coated with Ti, Rh and Ir precious metals on the surface; the voltage is 7.5V, and the current is 5A. Under the condition that the distance between the plates is 2cm, the concentration of electrolytic ammonia nitrogen is between 5000 and 10000 mg / L, and the conversion rate of ammonia nitrogen is greater than 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com