Graded punch forming method for automobile sheet metal connecting piece

A stamping forming and grading stamping technology, applied in the direction of vehicle parts, transportation and packaging, can solve the problems of slow production speed, low stamping processing efficiency, and difficulty in ensuring stamping processing accuracy in secondary clamping, and achieves improved installation simplicity, The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

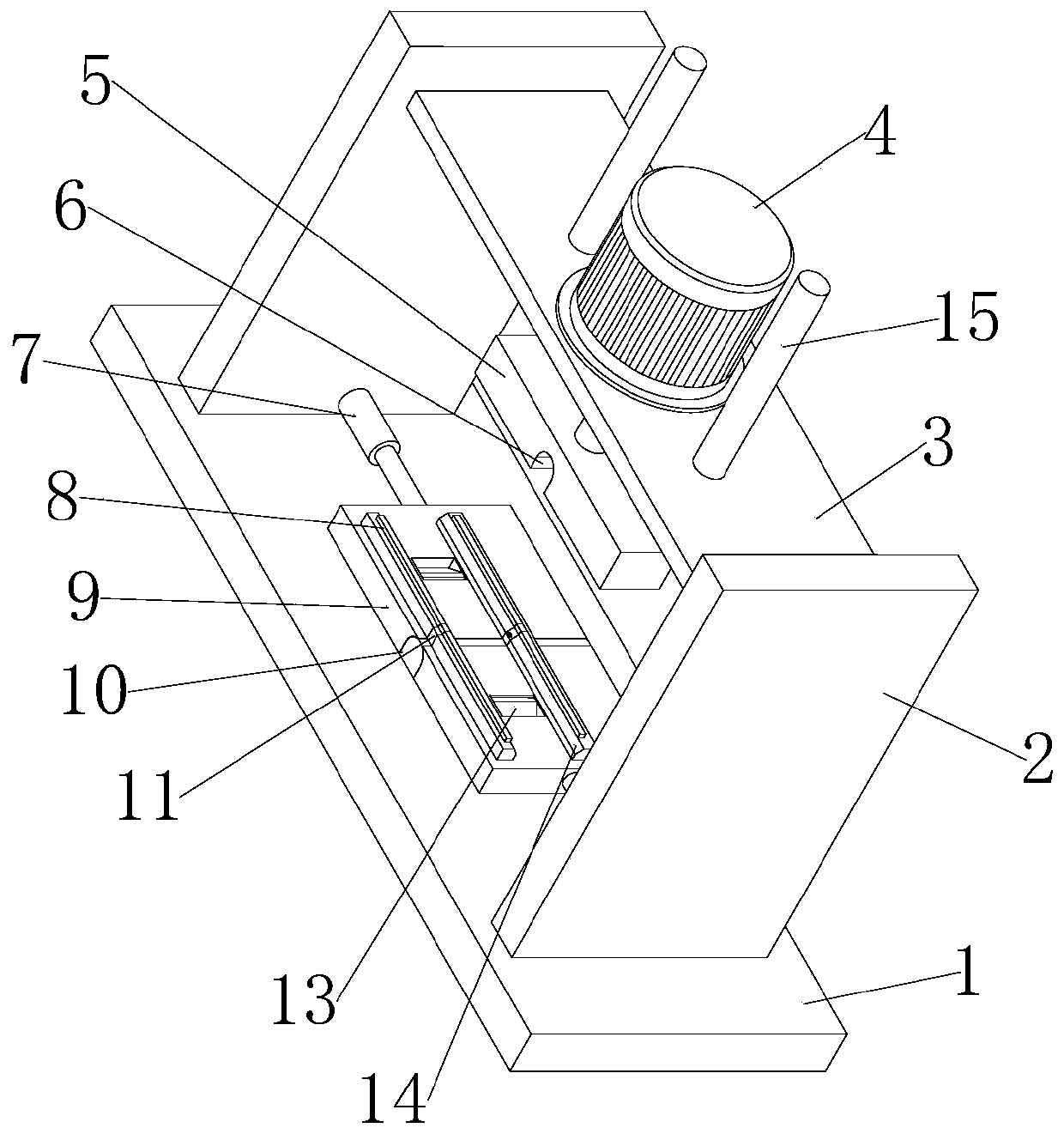

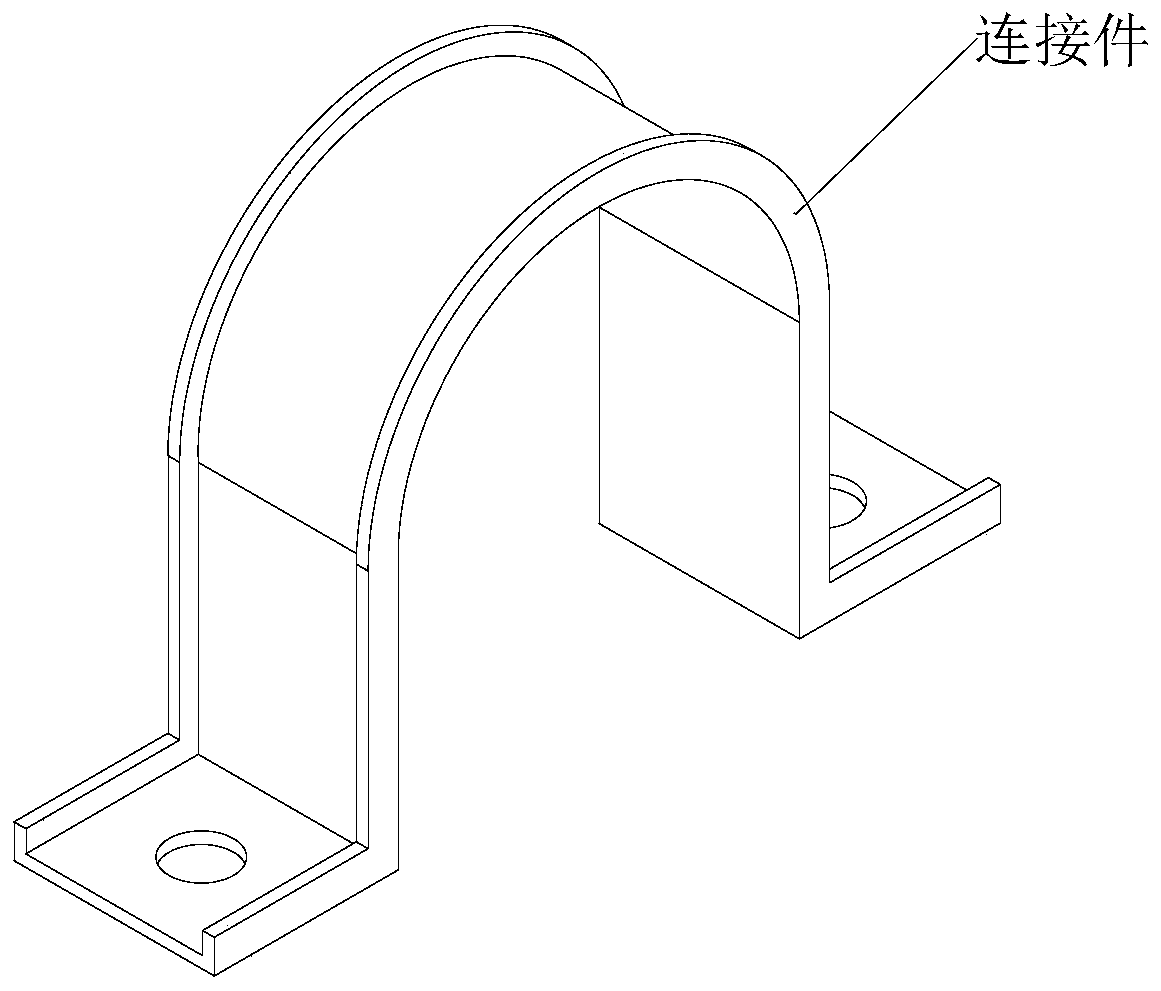

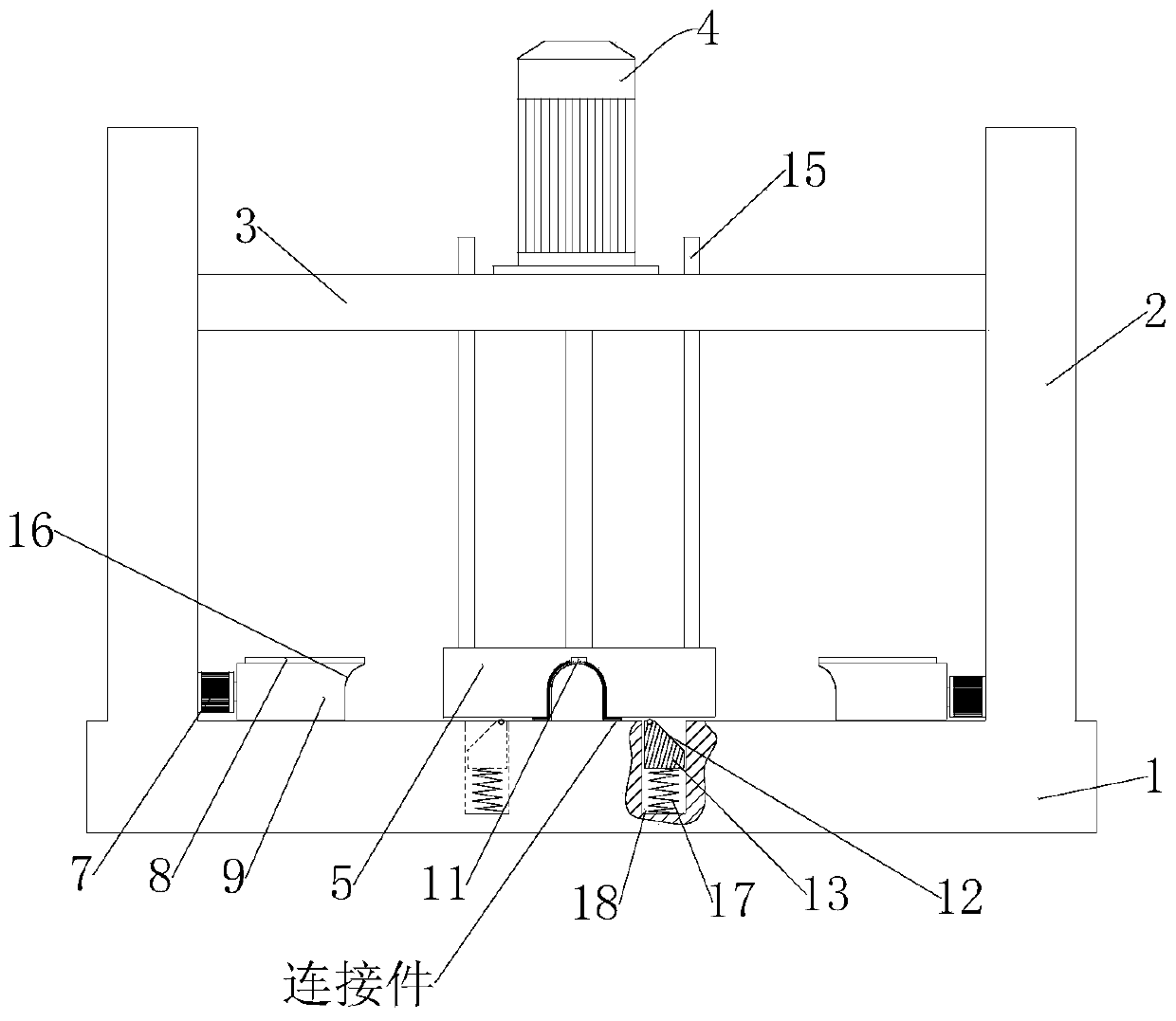

[0039] see Figure 1-8 , is a schematic diagram of the overall structure of a method for stepping stamping and forming of automobile sheet metal connectors, a method for stepping stamping and forming of automobile sheet metal connectors, including the following steps:

[0040] S1, blank installation, install the blank to be stamped and formed on the stamping forming device, install and position the blank to be stamped and formed, and wait for the stamping forming device to perform stamping and forming of the blank to be stamped and formed, wherein the stamping and forming device is provided by the present invention Automobile sheet metal connector graded stamping forming device;

[0041] S2, flanging stamping, punching both sides of the blank that has been installed and positioned in step S1, bending both sides of the blank to form flanging, and obtaining the blank after flanging;

[0042] S3, bending stamping, performing secondary stamping on the blank that has been flanged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com