Clamping and fixing device for oil nozzle of automobile

A technology for fixing devices and fuel injection nozzles, applied in positioning devices, workpiece clamping devices, clamping, etc., can solve problems such as poor fixability of clamping fixtures, increased computing costs, and defective product rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

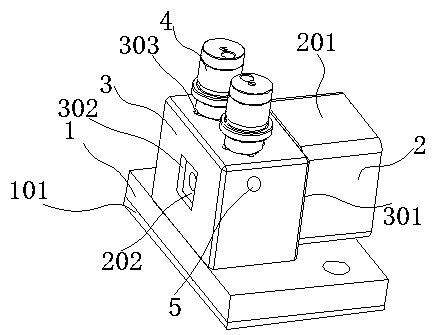

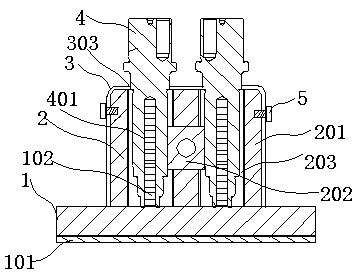

[0015] Embodiment 1: A clamping and fixing device for fuel injectors for automobiles, including a position limiting base 1, a setback fixing block 2, a positioning clamp 3 and a fuel injector workpiece 4, and the position limiting base 1 is provided with a positioning The card seat 3 is fixedly connected by welding, the nozzle workpiece 4 is sleeved in the positioning card seat 3 by the upper end and is connected with the limit base 1 in a rotating and separate manner, and the setback fixing block 2 is connected by the side end Socketed in the positioning card seat 3 and fix the fuel injection nozzle workpiece 4, the fixed block 2 and the positioning card seat 3 are fixedly connected by the fixing part 5, and the fixing part 5 is a connecting bolt, and the connecting bolt Made of alloy casting as one piece structure.

Embodiment 2

[0016] Embodiment 2: The bottom of the limiting base 1 is bonded with an anti-skid layer 101, and the anti-skid layer 101 is integrally formed by injection molding of polyurethane rubber. The limiting base 1 is equipped with a threaded protruding rod 102. The inner cavity is a threaded groove 401, and the threaded groove 401 is rotationally and fixedly connected with the threaded convex rod 102, and the rest of the technical solutions are the same as those in the first embodiment.

Embodiment 3

[0017] Embodiment 3: Make way to fix the block 2 includes a block body 201, a positioning clamp 202 and a through relief groove 203, the front end of the block body 201 is equipped with a positioning clamp 202, and the block body 201 is formed by The lower part is provided with a through relief groove 203, and the rest of the technical solutions are the same as those in Embodiments 1 and 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com