Pneumatic soft gripper capable of locking joints in vacuum absorption mode

A vacuum adsorption and software technology, applied in the direction of manipulators, manufacturing tools, chucks, etc., can solve problems that affect the flexibility and adaptability of flexible drives, complex control systems, and low working reliability, so as to improve bearing capacity, stability, and rigidity The effect of obvious performance and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

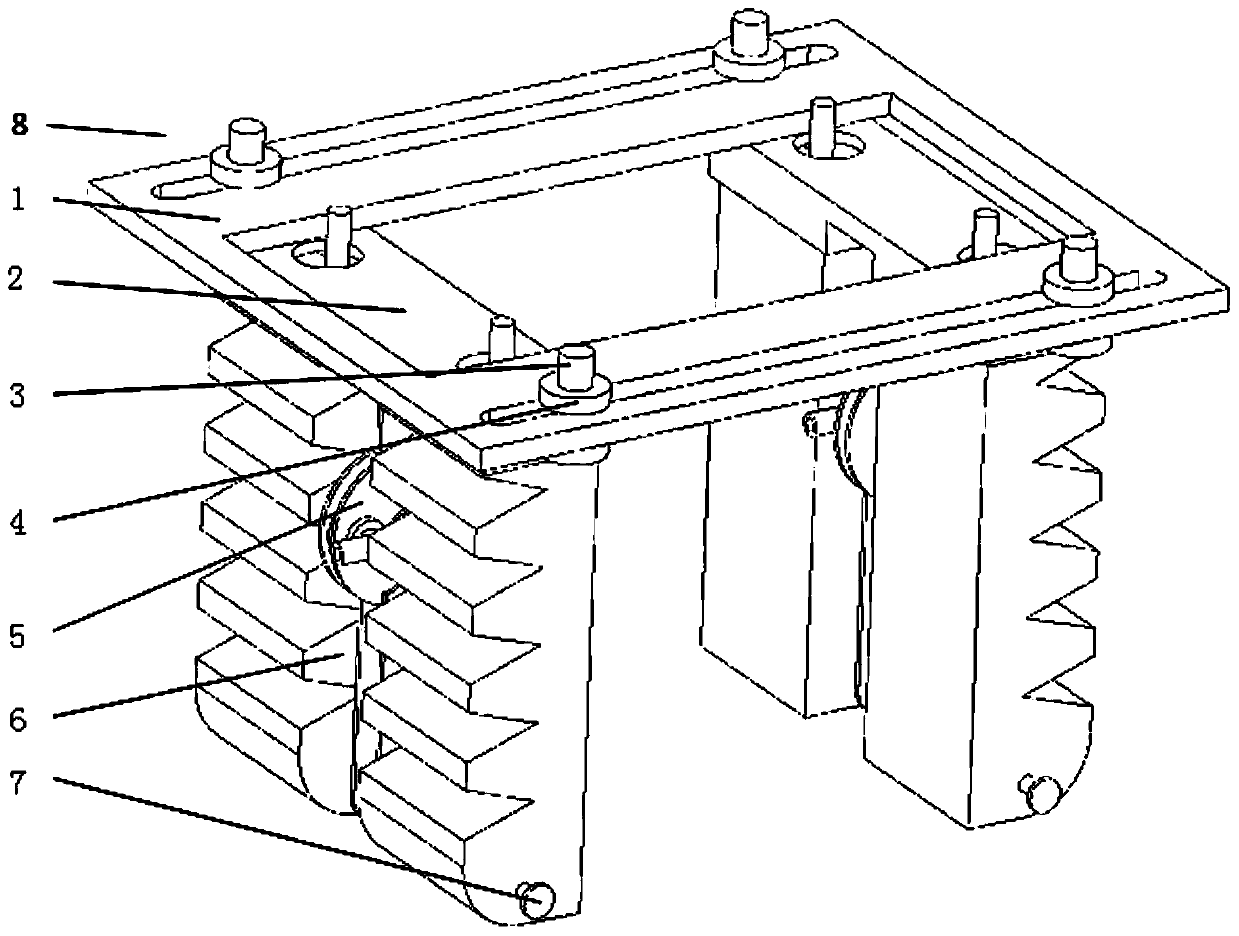

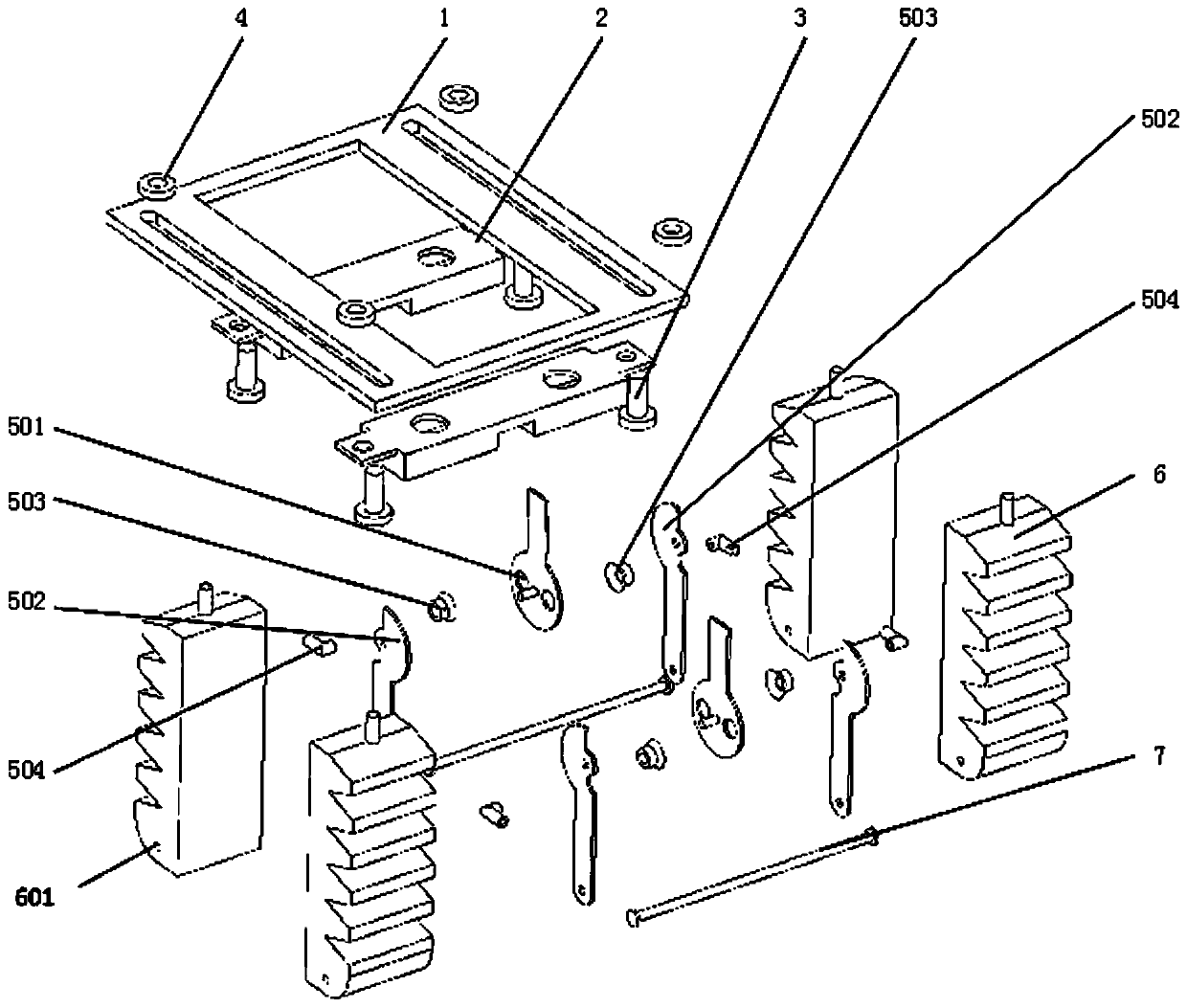

[0023] like figure 1 and figure 2 As shown, this embodiment includes: a retention structure 8, a flexible sucker spine 5 and two pairs of soft fingers 6, wherein: the soft fingers 6 are arranged on the retention structure 8, and the flexible sucker spine 5 is arranged on each pair of soft fingers 6 Between to control the relative position of the soft finger 6.

[0024] The retaining structure 8 includes: a fixing plate 1, two adjusting plates 2 and a connecting rod 7, wherein: the adjusting plate 2 is arranged in the chute 101 of the fixing plate 1 through the cooperation of the bolt 3 and the nut 4, and each adjusting plate The plate 2 is fixedly connected with the roots of a pair of juxtaposed soft fingers 6 , and the connecting rod 7 runs through the spine 5 of the flexible suction cup and the circular hole 601 at the end of the soft fingers 6 .

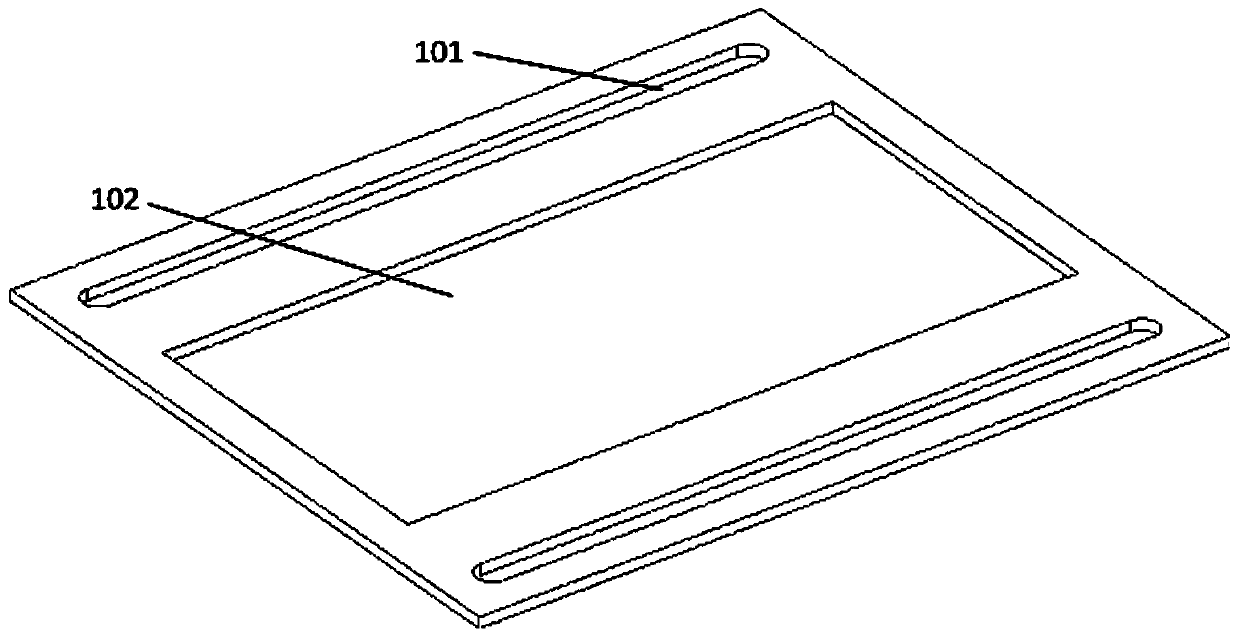

[0025] like image 3 As shown, the two sides of the fixed plate 1 are provided with sliding grooves 101 to change the relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com