Device for preparing non-frozen model ice with columnar texture characteristics

A texture feature and model technology, applied in the field of non-freezing model ice generation and preparation for simulating sea ice in alpine regions, can solve problems such as differences in mechanical characteristics, non-freezing model ice does not have natural sea ice, does not have natural sea ice characteristics, etc. , to achieve the effect of shortening the test period, reducing the test cost and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with examples.

[0020] 1. Prepare the paraffin wax mixture solution. In order to effectively simulate the density of natural sea ice, paraffin wax with a density similar to sea ice was selected as the base material. Heat the solid paraffin until it completely melts into liquid paraffin. In order to improve the brittleness of non-frozen model ice and make it more similar to natural sea ice in terms of mechanical properties, 1% gypsum powder, 3% quartz powder and 1.5% silicon powder were added to liquid paraffin, and stirred evenly for later use.

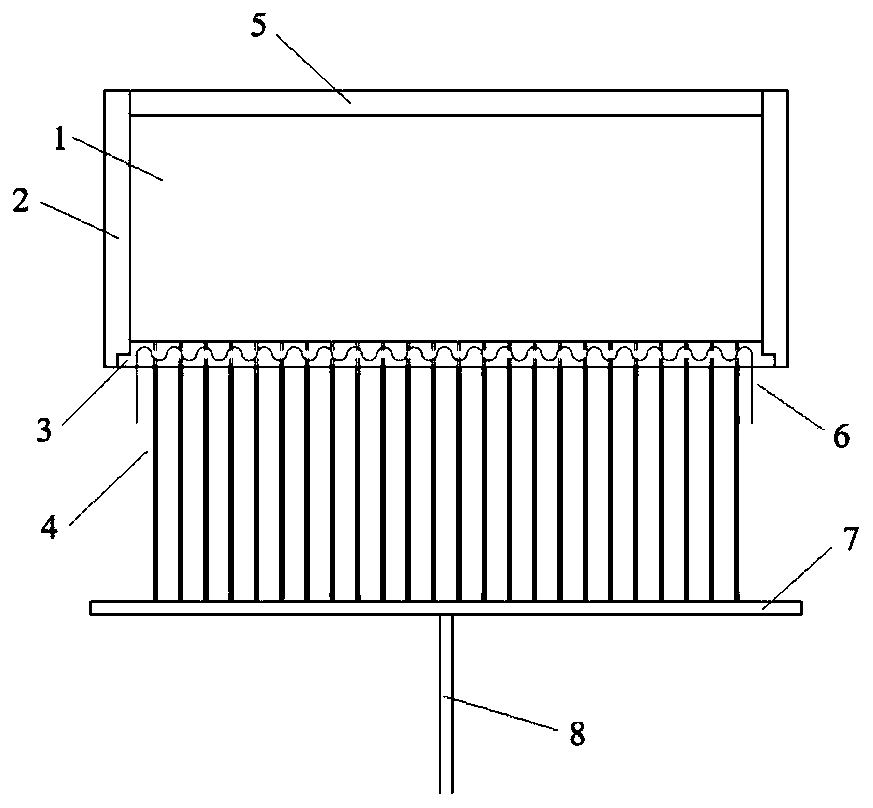

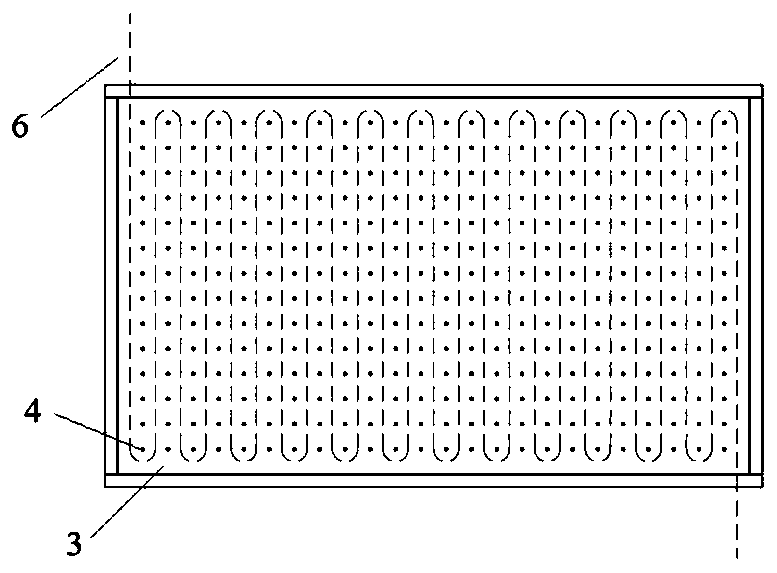

[0021] 2. Assemble the non-frozen model ice preparation mold and gas injection device. Use prefabricated ABS panels according to figure 1 and figure 2 Styles shown are spliced and assembled with non-frozen model ice preparation molds, and the outside of the sheet is secured with tape to facilitate removal of the mold when removing the model ice. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com