Wet clutch mechanism and torque transmission module including same

A technology of wet clutch and torque transmission, applied in clutches, mechanically driven clutches, fluid driven clutches, etc., can solve the problems of harmfulness, error, and loss of cooling oil in the normal operation of the transmission system, and achieve simplified assembly, simplified installation methods, and simplified form effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] In the ensuing description and in the claims, the following terms are used in a non-limiting manner and for ease of understanding: the term "front (portion)" or "rear (portion)" along the The direction of the axial orientation determined by the main axis of rotation O, the terms "inside / inside" or "outside / outside" are oriented relative to the axis O and along a radial direction orthogonal to said axial orientation.

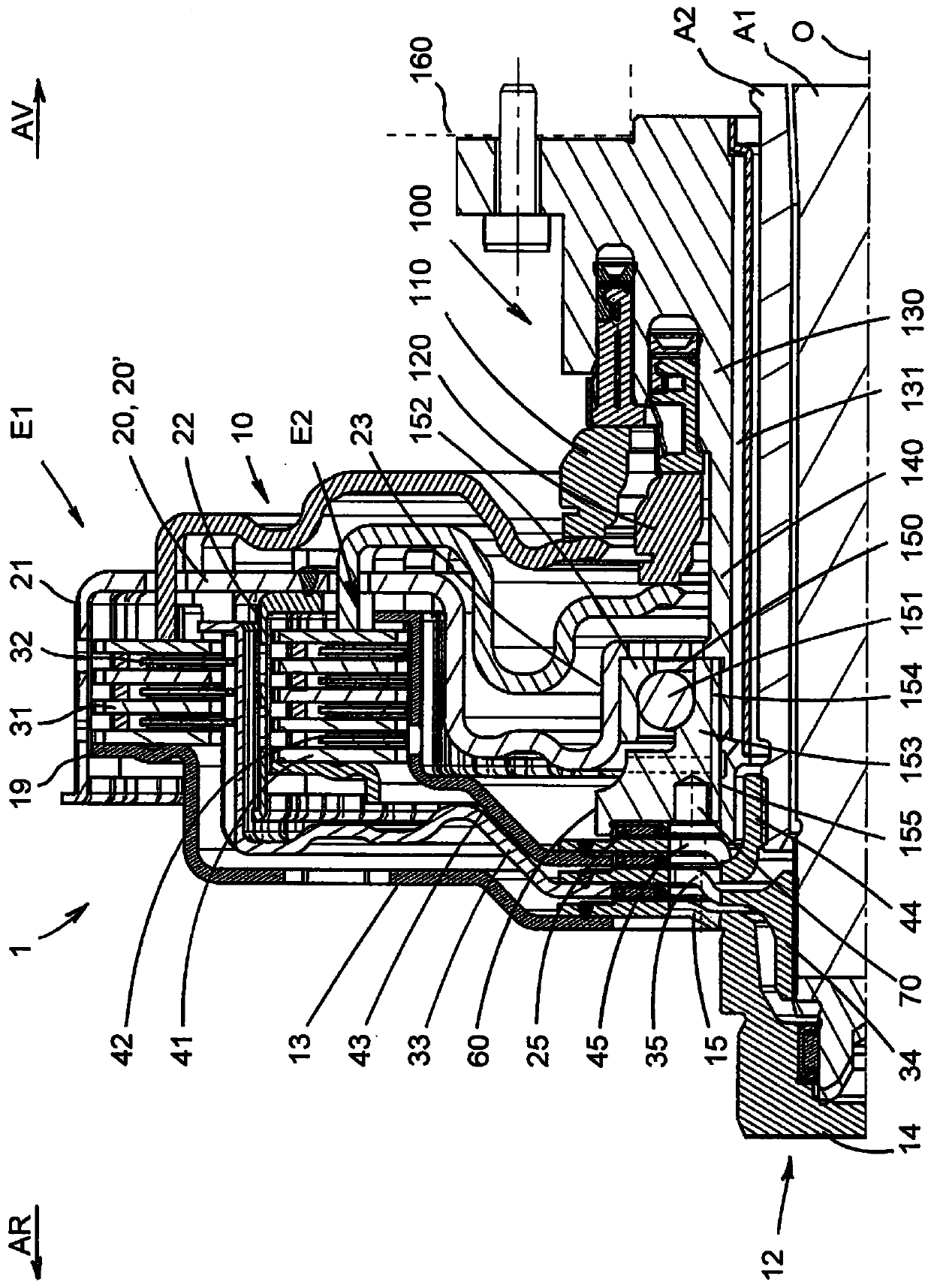

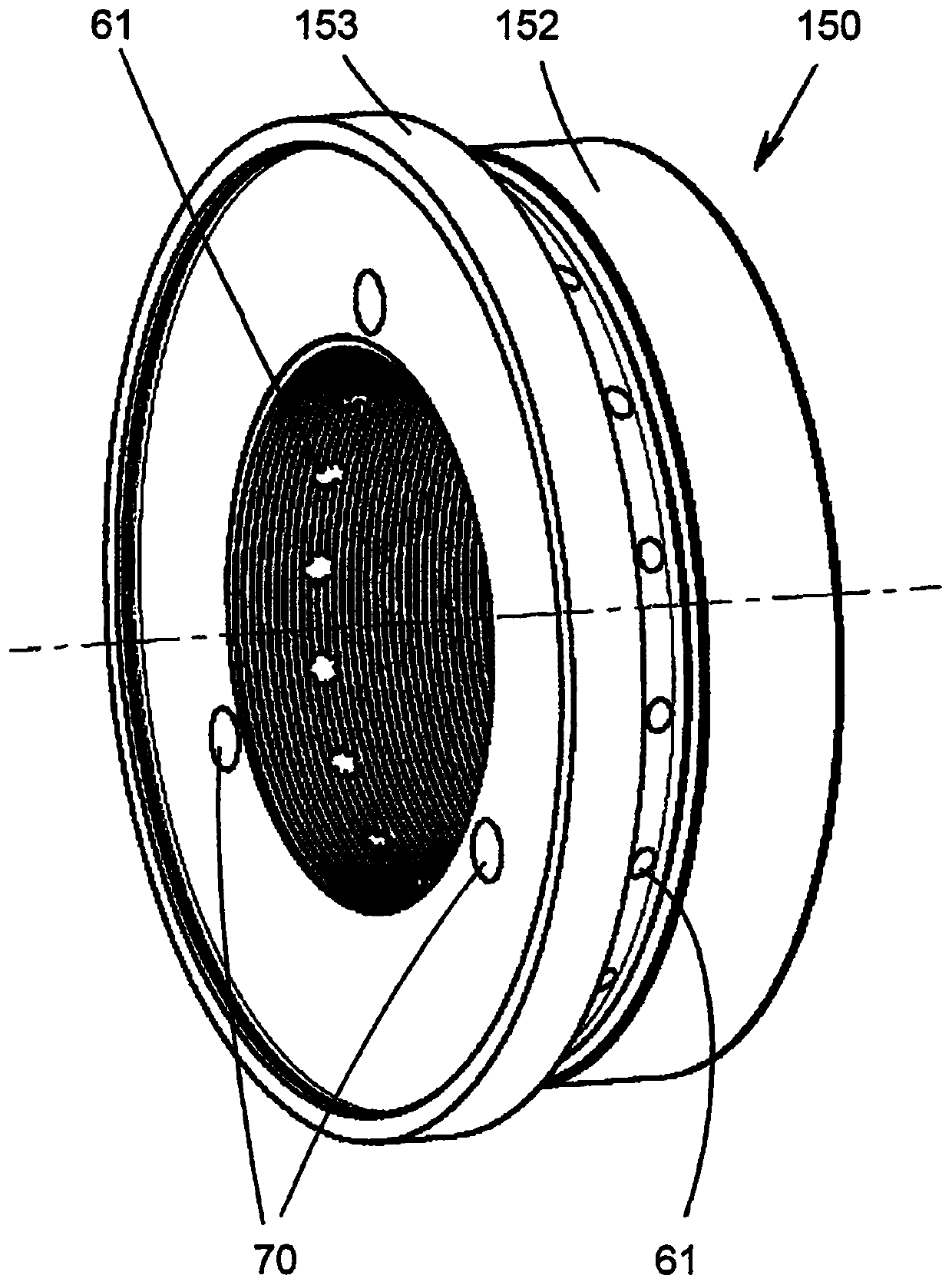

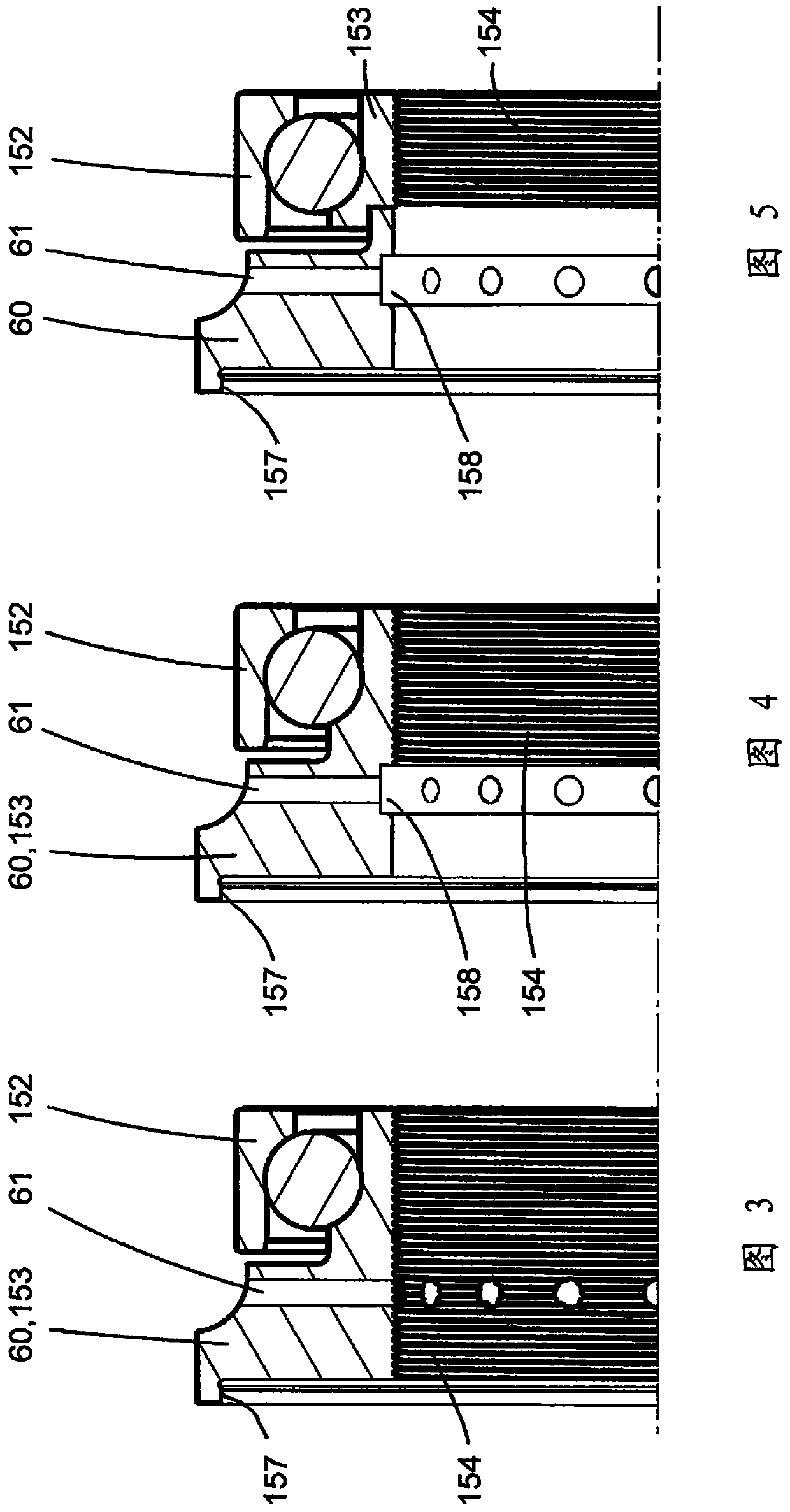

[0082] Figure 1 to Figure 3 A first embodiment of a torque transmitting module is shown. exist figure 1 In the example shown, the torque transmission module 1 is in an assembled state and comprises in particular a wet clutch mechanism 10 , having an axis of rotation O, fixed to an actuation system 100 . exist figure 1 In the example, the wet clutch mechanism 10 is a wet double clutch mechanism, including a first clutch E1 and a second clutch E2.

[0083] The wet clutch mechanism 10 comprises, about an axis O, at least one input member 12 rotationally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com