On-line monitoring system and monitoring method of submarine cable all-fiber temperature

A submarine cable and monitoring system technology, applied in the field of monitoring, can solve problems such as potential safety hazards and inaccurate temperature monitoring of submarine cables, and achieve the effects of avoiding maintenance equipment, avoiding accidents such as electric shock, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

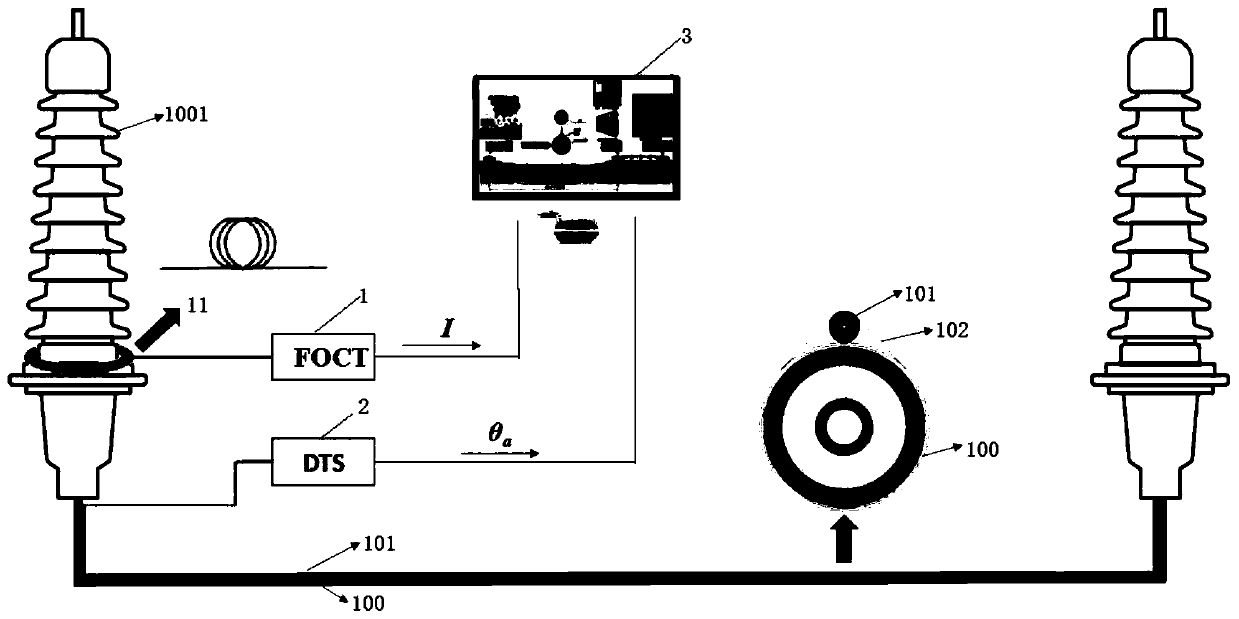

[0021] Such as figure 1 As shown, the existing submarine cable 100 is bundled with an optical cable 101 or has an optical fiber inside. In this implementation, the submarine cable 100 is bundled with the optical cable 101 through a binding band 102 . However, the submarine cable all-fiber temperature on-line monitoring system provided in this embodiment is mainly composed of three parts, namely an optical fiber current transformer 1 , a distributed optical fiber sensor 2 and an online monitoring terminal 3 .

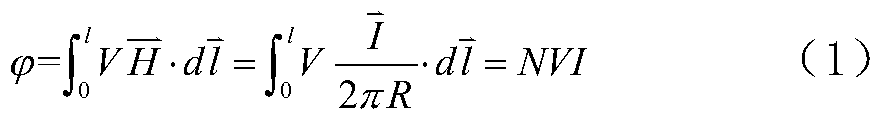

[0022] Among them, the optical fiber current transformer 1 is used to be installed at the position of the submarine cable terminal 1001 to measure and obtain the current flowing through the submarine cable conductor; the distributed optical fiber sensor 2 is used to monitor the real-time temperature distribution of the surface of the submarine cable; the online The monitoring terminal 3 is used to receive the current parameters measured by the optical fiber current trans...

Embodiment 2

[0044] This embodiment provides a method for on-line monitoring of the temperature of all optical fibers in a submarine cable. The submarine cable is bound with an optical cable or is compounded with an optical fiber inside. The method includes:

[0045] The optical fiber sensing ring of the optical fiber current transformer is installed on the flange of the lower part of the submarine cable terminal. Before installation, the armor and lead sheath of the submarine cable have been stripped at the installation position to avoid the induction of the external metal layer. Power interference, to ensure the accuracy of detection.

[0046] Use distributed optical fiber sensors to monitor the real-time temperature distribution of the surface of the submarine cable on the bundled optical cable or the composite optical fiber of the submarine cable;

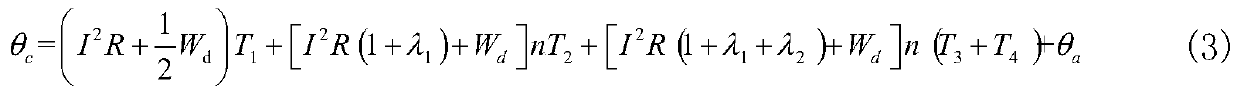

[0047] Receive the current parameters measured by the optical fiber current transformer and the real-time distribution parameters of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com