Equipment for professing milk tablets with high content of milk powder and processing method of equipment

A processing equipment and technology of milk flakes, which are applied in the direction of milk preparations, food forming, dairy products, etc., can solve the problems of no auxiliary structure for adding materials, adjustment of processing parameters, and easy cracking of milk flakes, etc., to achieve combined docking Easy to operate, increase flexibility, and use flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

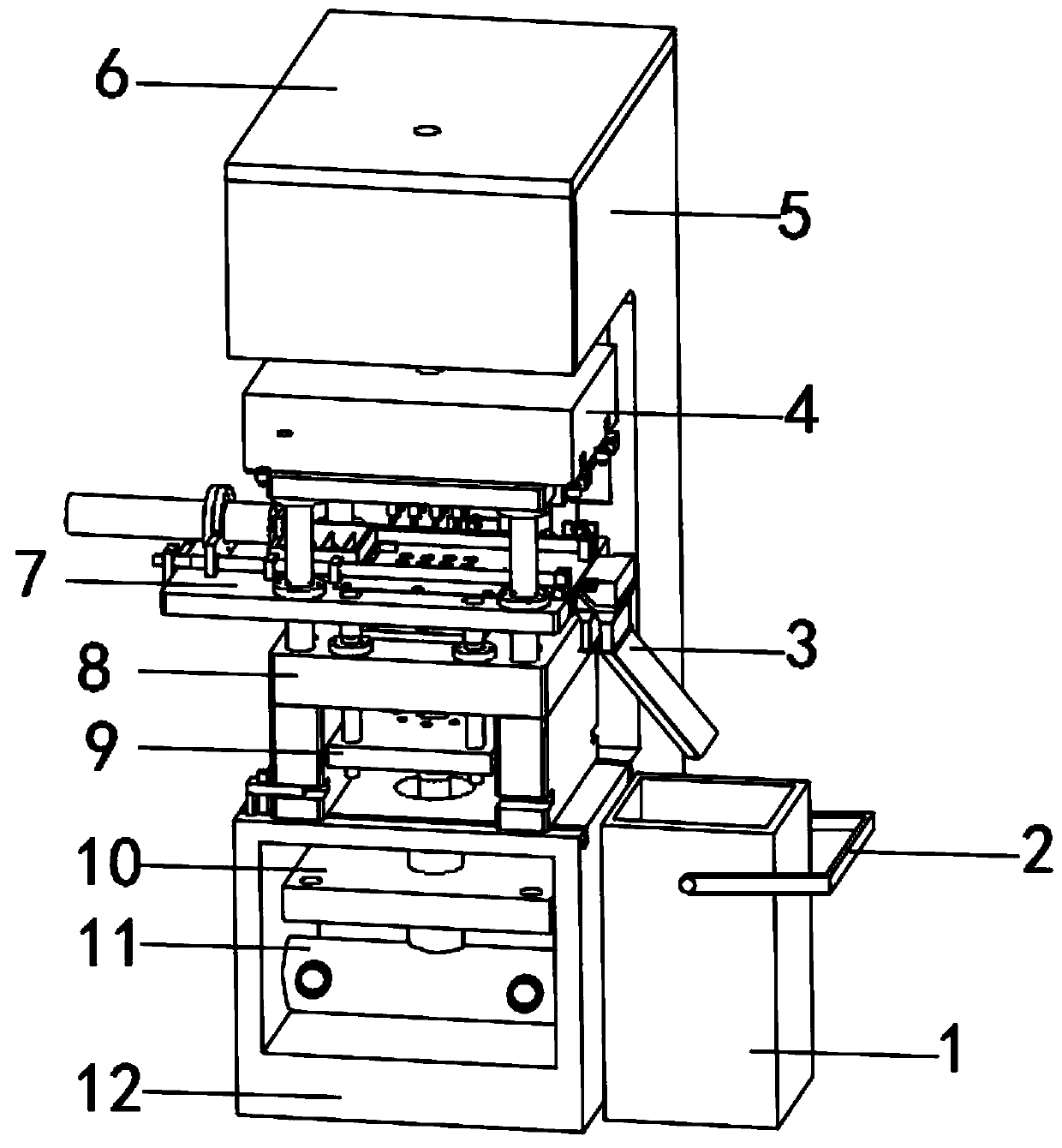

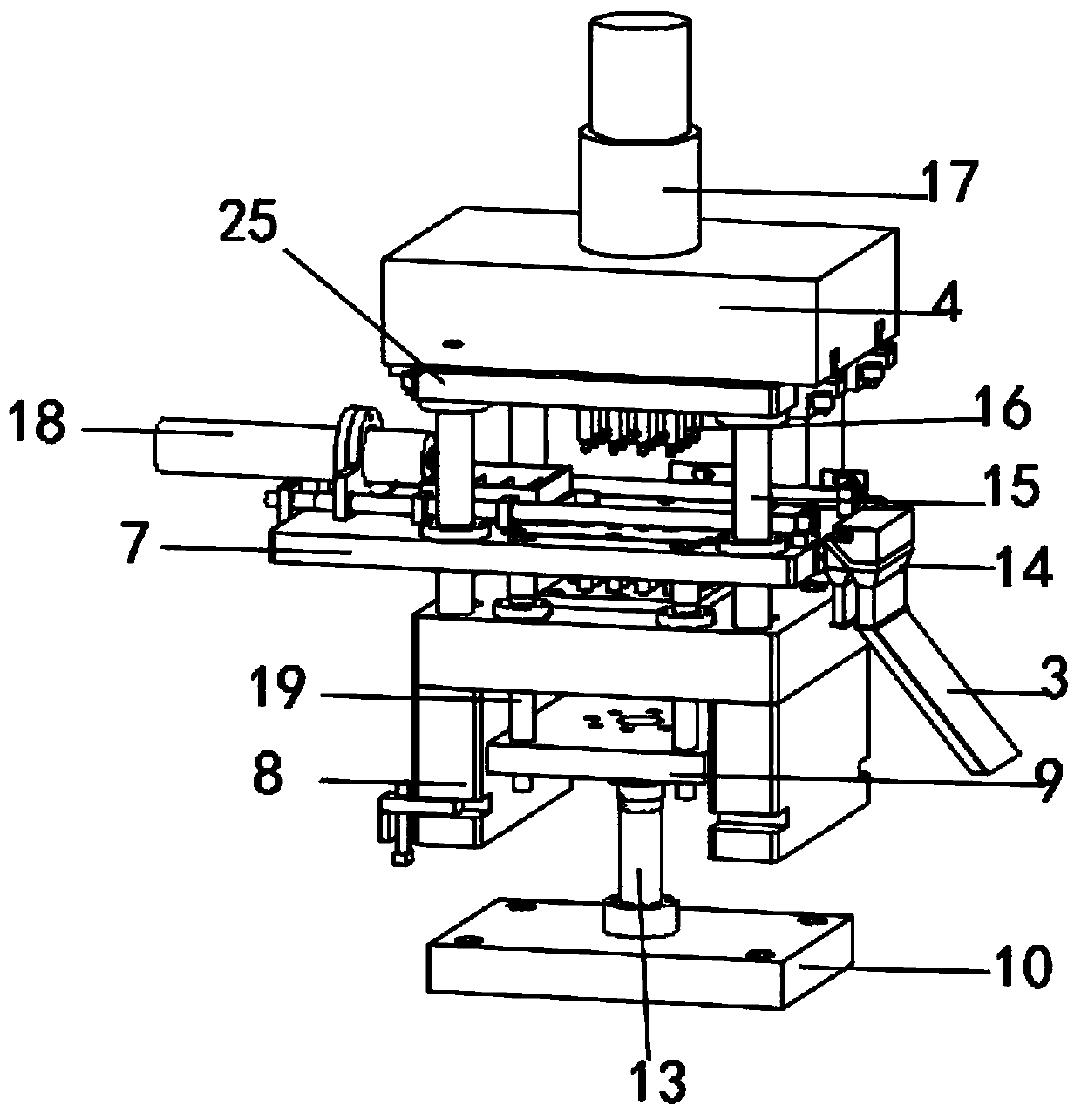

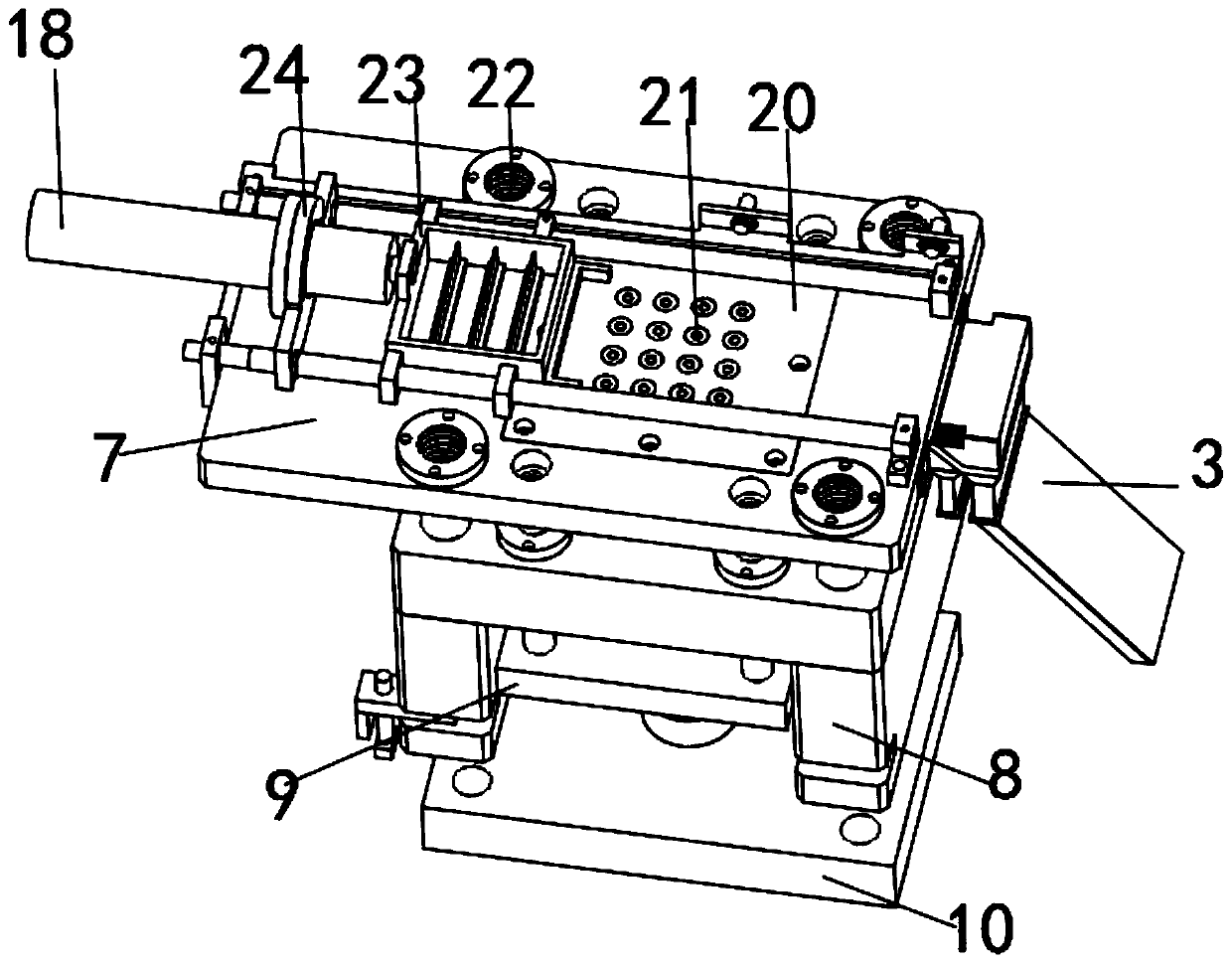

[0034] Such as Figure 1-6 As shown, a milk flake processing equipment with high content of milk powder includes a support formwork 8, a fixed base 12, a combination plate 25 and a pressing plate 7, the support formwork 8 is fixedly installed on the upper outer surface of the fixed base 12, and the pressing plate 7 It is fixedly installed on the upper part of the supporting formwork 8, and the pressing plate 7 and the supporting formwork 8 are docked and fixed through four sets of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap