Downproof nonwoven fabric for down jacket

A non-woven, anti-drilling down technology, applied in the field of down fabrics, can solve the problems such as the decrease of waterproof and air permeability of down jacket fabrics, and achieve the effect of good anti-drilling effect, reasonable design and enhanced protection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

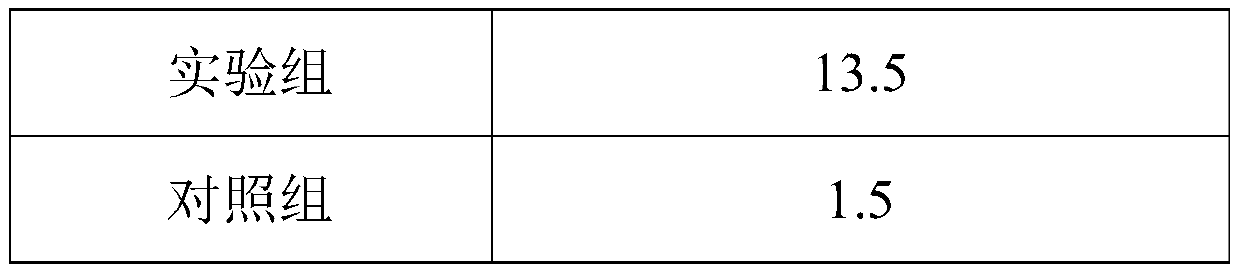

Image

Examples

Embodiment 1

[0024] An anti-drilling nonwoven fabric for a down jacket, which sequentially includes a waterproof breathable layer, a nonwoven fabric layer and an inner lining layer from outside to inside; in terms of mass percentage, the waterproof breathable layer includes 30-40% polymer waterproof breathable film and 60-70% silk fabric; in terms of mass percentage, the non-woven fabric layer includes 60-80% polyester and 20-40% conductive fiber; the inner lining layer is cotton fabric.

[0025] A preparation method for down wear anti-drilling down nonwoven fabric as described in any one of the above, comprises the following steps:

[0026] Step S1: The polymer waterproof and breathable membrane and the silk fabric are interlaced and compounded in proportion to form a multi-layer composite waterproof and breathable layer, which is ready for use;

[0027] Step S2: Arranging the polyester and the conductive fibers evenly in proportion, then fixing and bonding them to form a non-woven fabric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com