A combined processing equipment for making raw materials for electric power construction accessories

A technology of electric power construction and combined processing, applied in the direction of grain processing, etc., can solve the problems of large manpower consumption, high input cost, combined processing and other problems, and achieve the effect of simple design mechanism, high input cost and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the drawings and embodiments, but this should not limit the protection scope of the present invention.

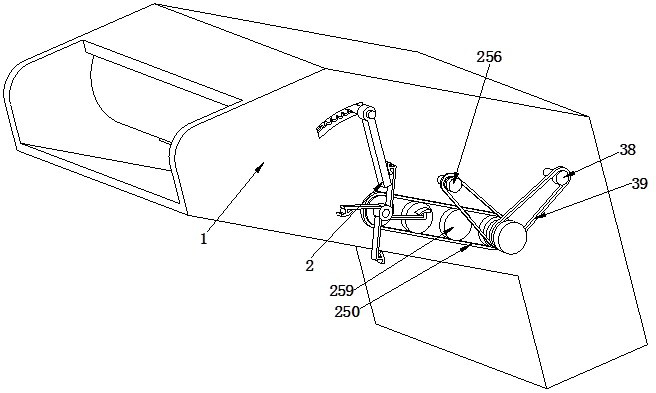

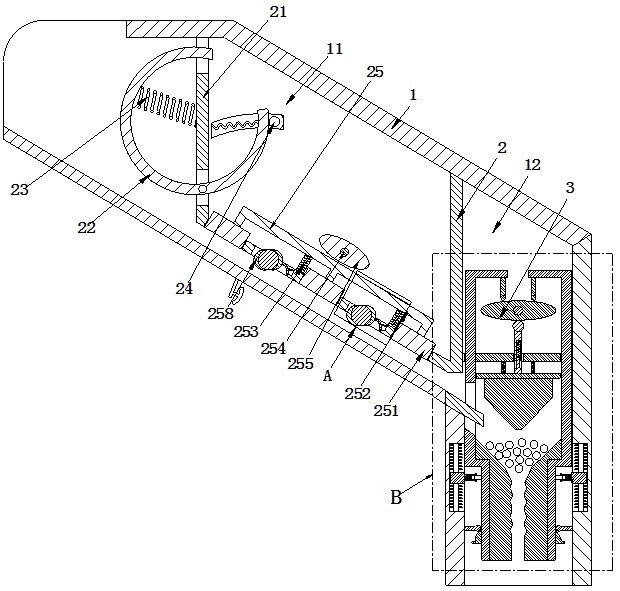

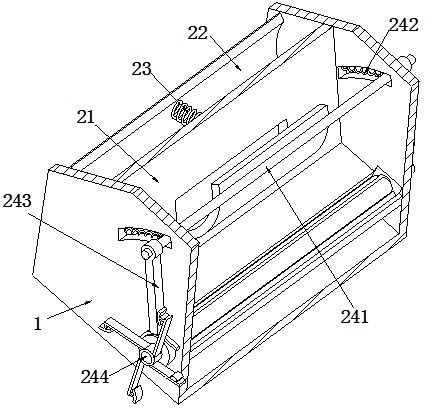

[0036] like Figure 1 to Figure 7 As shown, a combined processing equipment for making raw materials for electric power construction accessories, including a grinding frame 1, a multi-stage crushing mechanism 2 is installed on the inner wall of the left end of the grinding frame 1, and a grinding mechanism 3 is arranged on the right end of the grinding frame 1. A driving motor 4 is installed on the front end outer wall of the frame 1, and a driving column 41 is installed on the driving motor 4, and a grinding pulley 42 and a driving pulley 43 are sequentially sleeved on the driving column 41 from front to back.

[0037] Control the insulator raw material to be transported into the grinding frame 1, the driving motor 4 works to control the driving column 41 to rotate, and the driving column 41 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com