Auxiliary formwork removing device for vertical column bottom formwork, and formwork removing method

A column and bottom mold technology, applied in the direction of unloading devices, manufacturing tools, etc., can solve the problems of column height, weight, high cost, and inability to demould the column, and achieve the effect of simple and fast dismantling operation and auxiliary power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

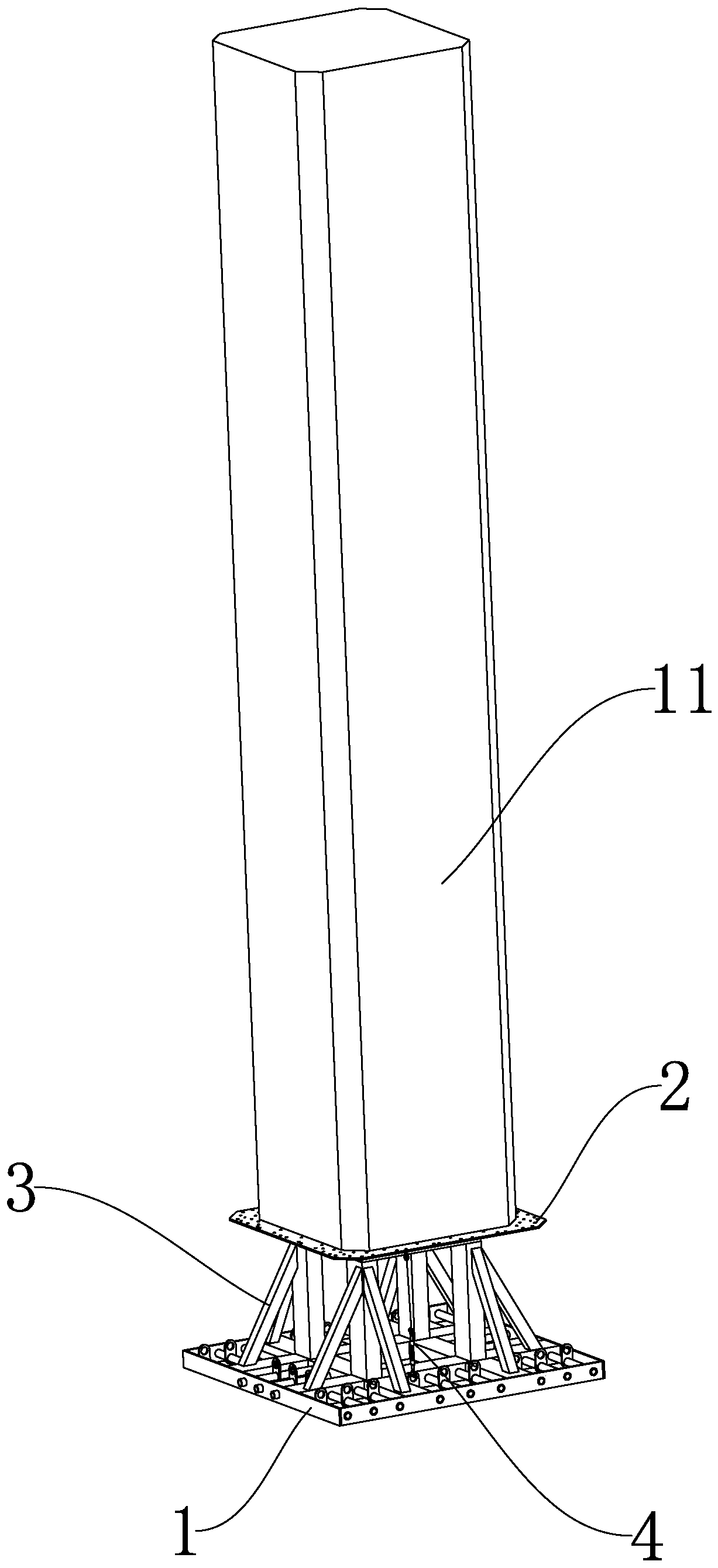

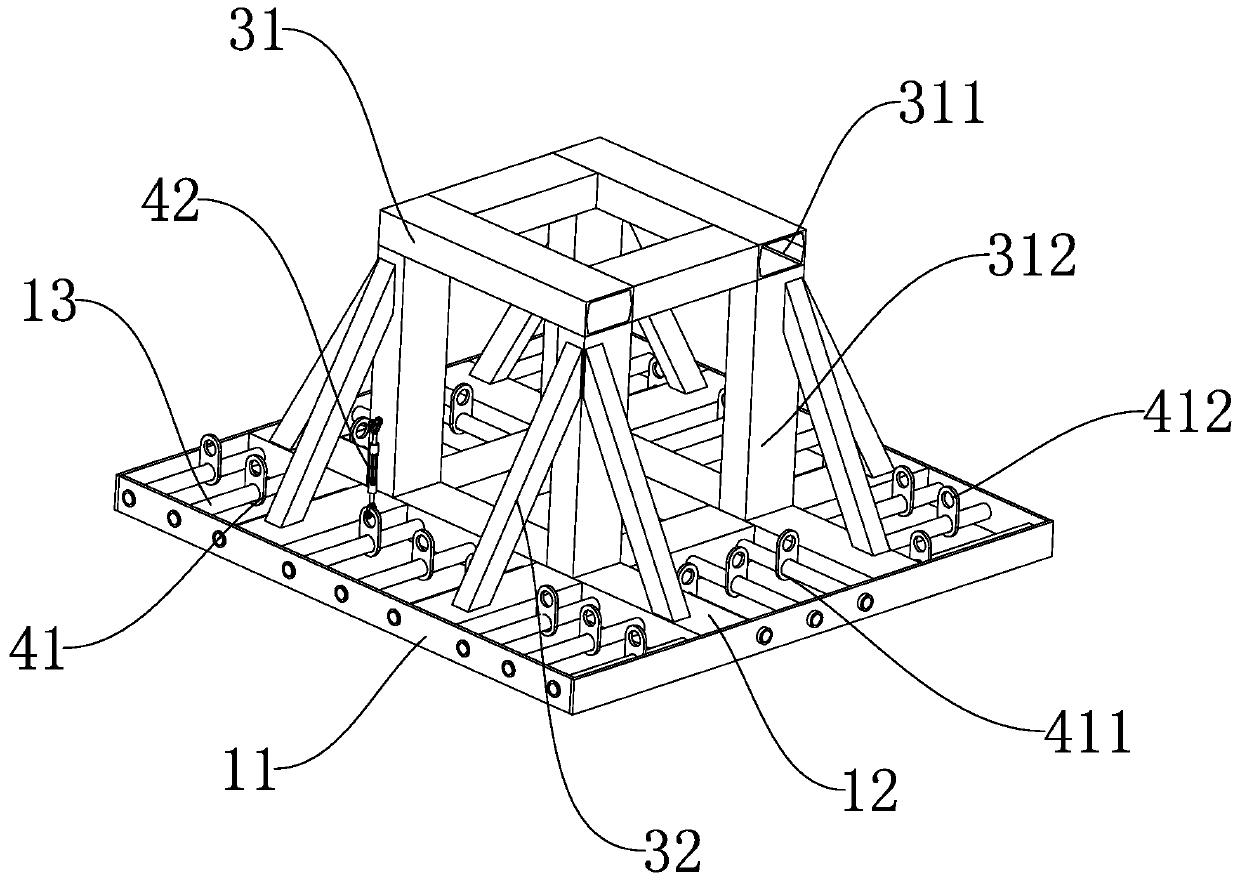

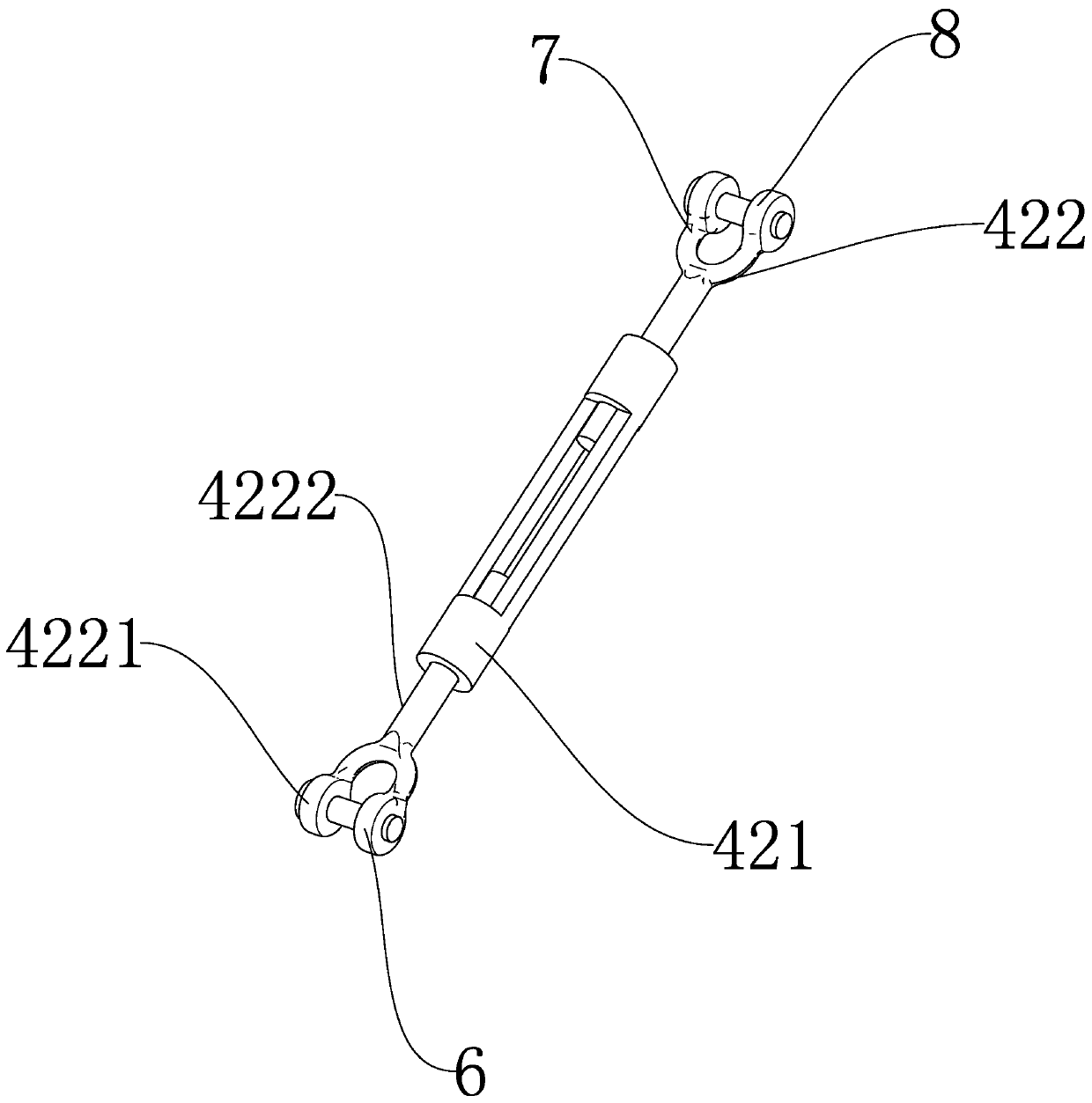

[0040] Such as Figure 1 to Figure 6 Shown, a kind of auxiliary demolition device of column base mold, comprises the fixed member 1 that is fixedly connected with ground, is characterized in that, is connected with support member 3 in order to support column base mold 2 on described fixation member, and column base form is in Under the action of the supporting member, it is separated from the ground. A pre-tensioning member 4 is provided between the bottom mold of the column and the fixed component. It can be separated from the bottom mold of the column under driving; the bottom mold of the column is in the shape of a beveled rectangular plate, and the bottom mold of the column is provided with a number of positioning holes 21 and installation holes 22 penetrating along its thickness direction. The arrangement of the positioning holes and the installation holes is rectangular. shape, the positioning hole is located on the first inner offset line 2a of the outer edge of the col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com