Novel cement mortar stirring device

A cement mortar and mixing device technology, applied in cement mixing devices, measuring devices, clay preparation devices, etc., can solve problems such as waste of materials, impact on accuracy, unreasonable structural design, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

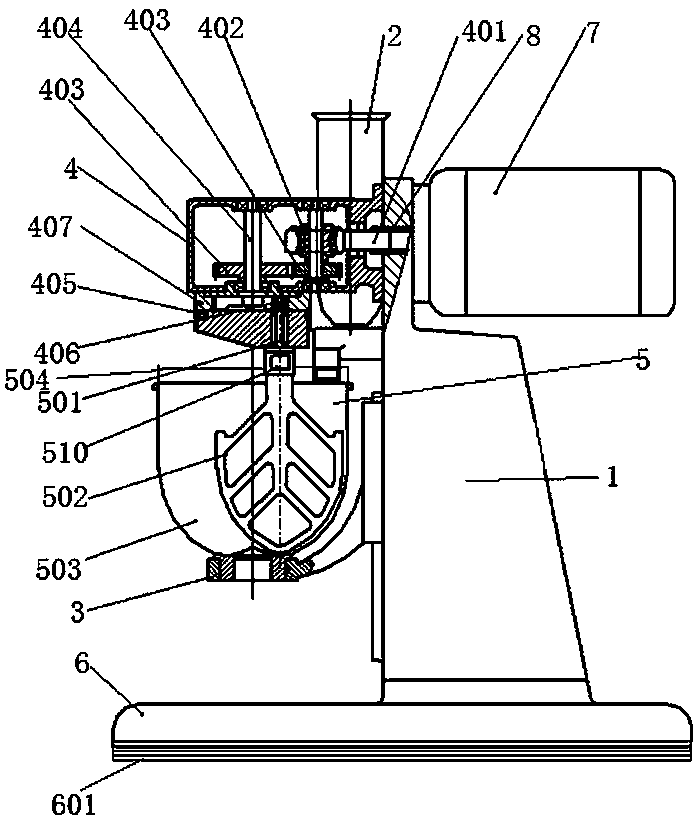

[0016] Embodiment 1: A new type of cement mortar mixing device, including a fuselage 1, a feeding box 2, a transmission box assembly 4, a stirring assembly 5 and a base 6, and the side end of the fuselage 1 is fixedly equipped with a feeding box 2, so One end of the fuselage 1 is provided with a transmission box assembly 4 , and the bottom end of the transmission box assembly 4 is provided with a stirring assembly 5 and is in transmission connection with it. The fuselage 1 is arranged on a base 6 .

Embodiment 2

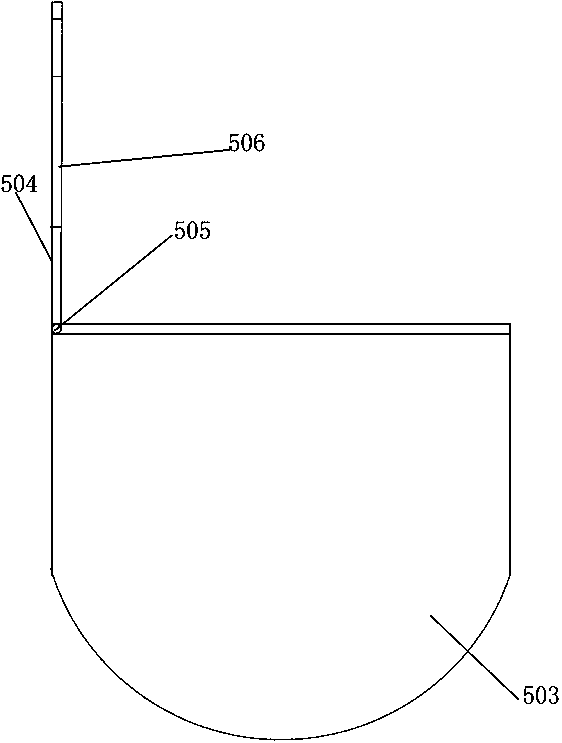

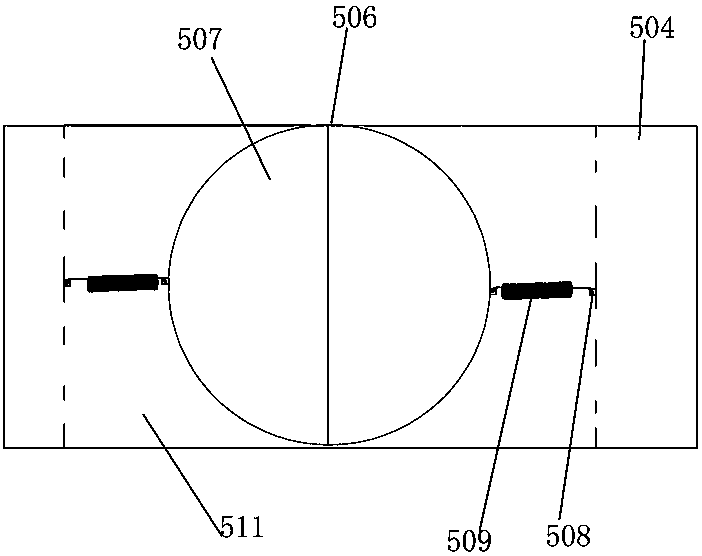

[0017] Embodiment 2: the stirring assembly 5 includes a stirring shaft 501, a stirring paddle 502 and a stirring box 503, the bottom end of the stirring shaft 501 is equipped with a stirring paddle 502, and the upper end of the stirring box 503 is communicated with the charging box 2 through a delivery pipeline, The mixing box 503 is equipped with a protective box cover 504, the mixing box 503 is located on the support 3, the protective box cover 504 is closed and connected with the mixing box 503 through a pin 505, and the protective box cover 504 is opened There is a relief hole 506, the relief hole 506 is equipped with a relief clip cover 507, the two sides of the relief hole 506 are provided with cavity grooves 511, and the side ends of the protective case cover 504 and the inner wall of the cavity groove 511 are both A positioning hook 508 is installed, and a telescopic spring 509 runs through the positioning hook 508 and is hooked to it. The stirring shaft 501 is equipped...

Embodiment 3

[0018] Embodiment 3: An anti-slip layer 601 is installed at the bottom of the base 6, and the anti-slip layer 601 is integrally formed by injection molding of polyurethane rubber. The rest of the technical solutions are the same as those in Embodiments 1 and 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com