Coupler outer box production method

A production method and coupler technology, applied in the direction of hollow objects, applications, coatings, etc., can solve problems such as the inability to meet people's needs, insufficient hardness and density of workpieces, and decreased surface density of workpieces, so as to achieve good impact, increase density, The effect of improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

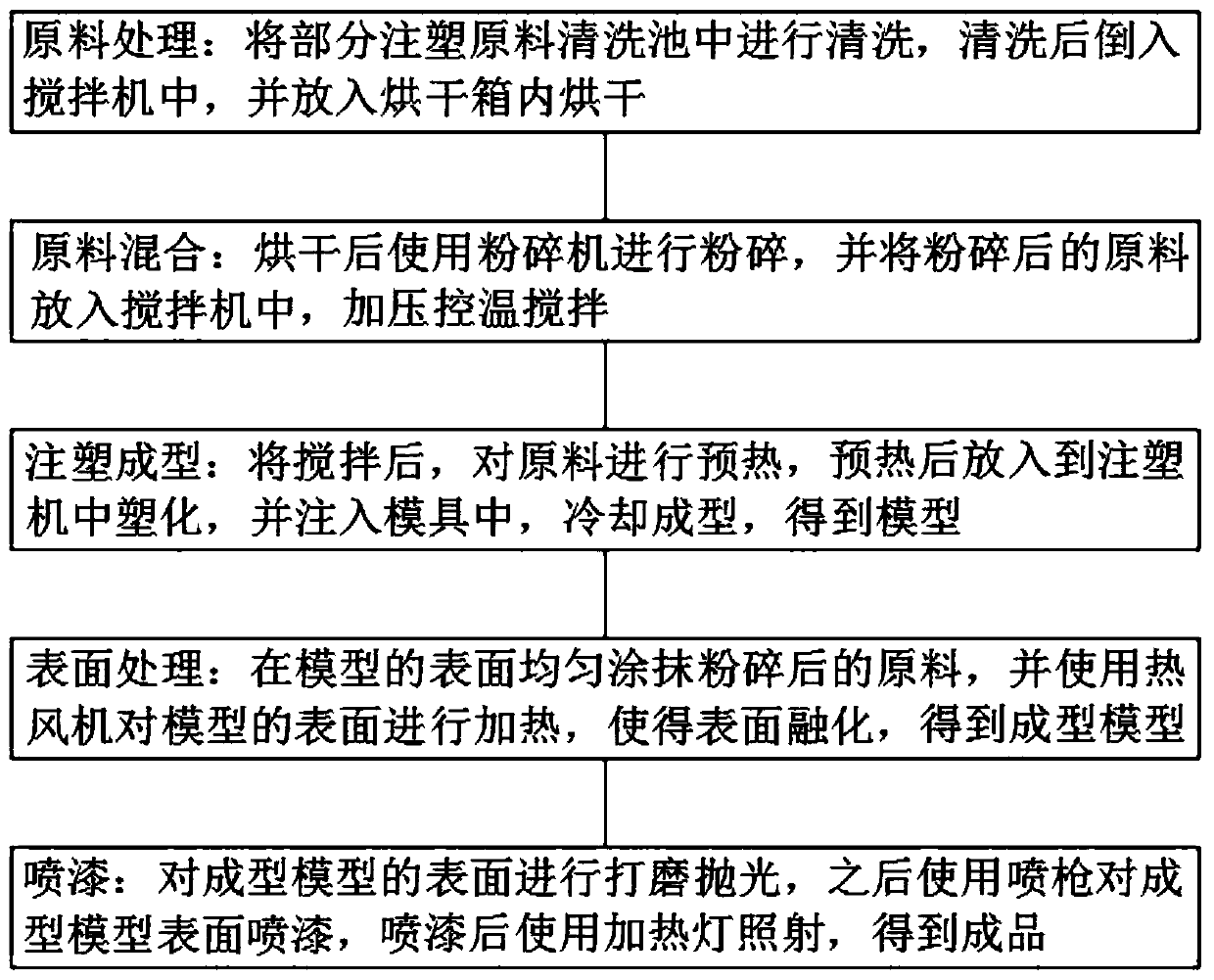

[0026] Such as figure 1 Shown, a kind of coupler outer box production method comprises the following steps:

[0027] (1) Raw material processing: Put part of the injection molding raw materials into the cleaning pool for cleaning, pour them into the mixer after cleaning, and put them into the drying box for drying. The injection molding raw materials include the following parts by weight: 7 parts of glass fiber, poly 4 parts of imide, 15 parts of epoxy resin, 8 parts of petroleum resin, 7 parts of phenolic resin, 7 parts of lignin, 32 parts of polyester chip, 4.0 parts of methyl cellulose, 7 parts of light calcium carbonate, 3 parts of ceramic fiber When cleaning, put glass fiber, petroleum resin, phenolic resin, polyester chips and ceramic fiber into the cleaning tank, the stirring speed of the agitator is 220r / min, the drying temperature is 36°C, and the drying time is 30min;

[0028] (2) Mixing of raw materials: After drying, use a pulverizer to pulverize, put the pulveriz...

Embodiment 2

[0033] Such as figure 1 Shown, a kind of coupler outer box production method comprises the following steps:

[0034] (1) Raw material processing: Put part of the injection molding raw materials into the cleaning pool for cleaning, pour them into the mixer after cleaning, and put them into the drying box for drying. The injection molding raw materials include the following parts by weight: 7 parts of glass fiber, poly 4 parts of imide, 15 parts of epoxy resin, 8 parts of petroleum resin, 7 parts of phenolic resin, 7 parts of lignin, 32 parts of polyester chip, 4.0 parts of methyl cellulose, 7 parts of light calcium carbonate, 3 parts of ceramic fiber When cleaning, put glass fiber, petroleum resin, phenolic resin, polyester chips and ceramic fiber into the cleaning tank, the stirring speed of the agitator is 220r / min, the drying temperature is 36°C, and the drying time is 30min;

[0035] (2) Mixing of raw materials: After drying, use a pulverizer to pulverize, put the pulveriz...

Embodiment 3

[0040] Such as figure 1 Shown, a kind of coupler outer box production method comprises the following steps:

[0041] (1) Raw material processing: Put part of the injection molding raw materials into the cleaning pool for cleaning, pour them into the mixer after cleaning, and put them into the drying box for drying. The injection molding raw materials include the following parts by weight: 7 parts of glass fiber, poly 4 parts of imide, 15 parts of epoxy resin, 8 parts of petroleum resin, 7 parts of phenolic resin, 7 parts of lignin, 32 parts of polyester chip, 4.0 parts of methyl cellulose, 7 parts of light calcium carbonate, 3 parts of ceramic fiber When cleaning, put glass fiber, petroleum resin, phenolic resin, polyester chips and ceramic fiber into the cleaning tank, the stirring speed of the agitator is 220r / min, the drying temperature is 36°C, and the drying time is 30min;

[0042] (2) Mixing of raw materials: After drying, use a pulverizer to pulverize, put the pulveriz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap