Battery replacement control system and method

A technology for electric control and battery replacement equipment, which is applied in charging stations, electric vehicles, electric power devices, etc., and can solve the problems of long time consumption and low efficiency of battery replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

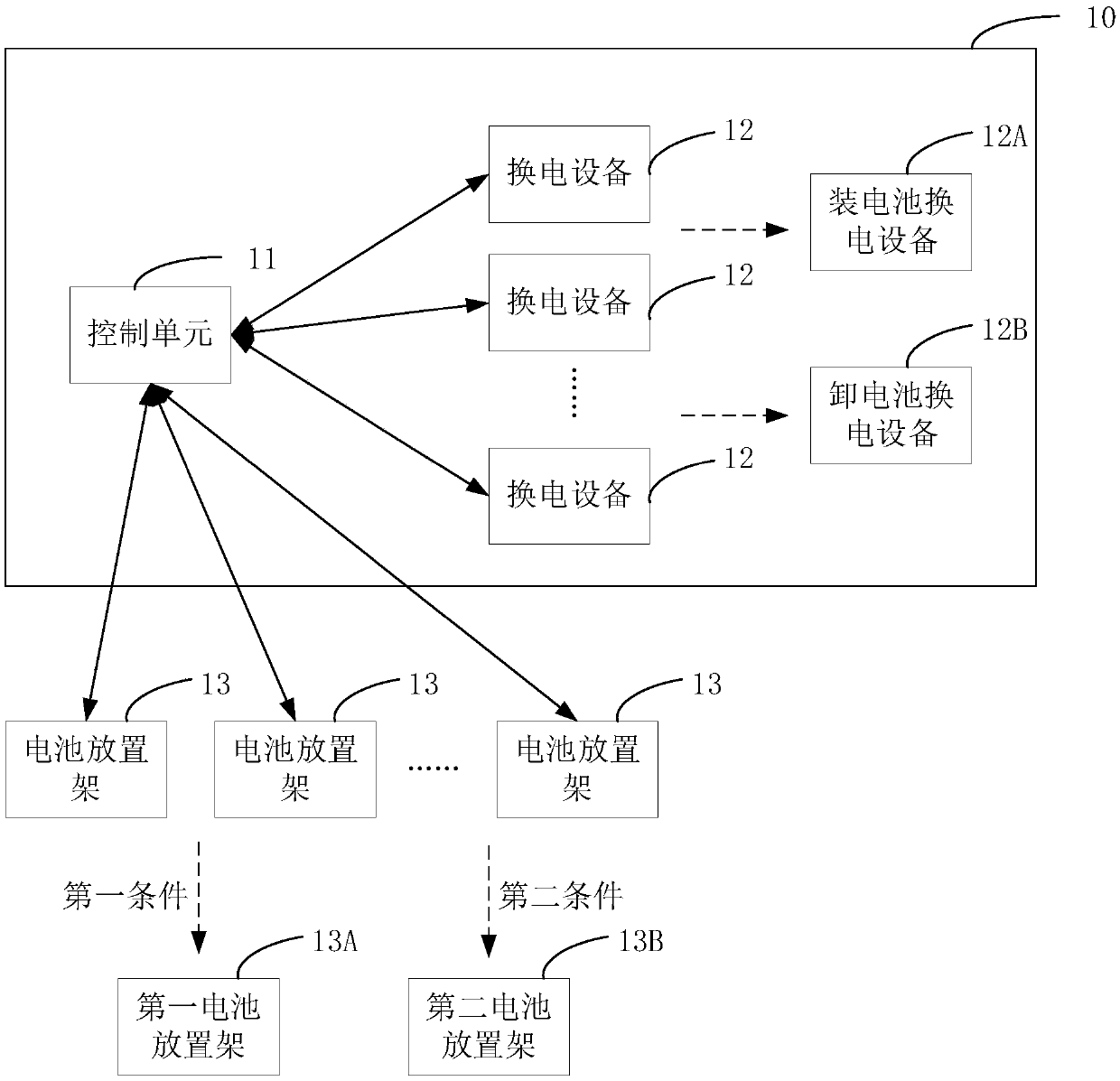

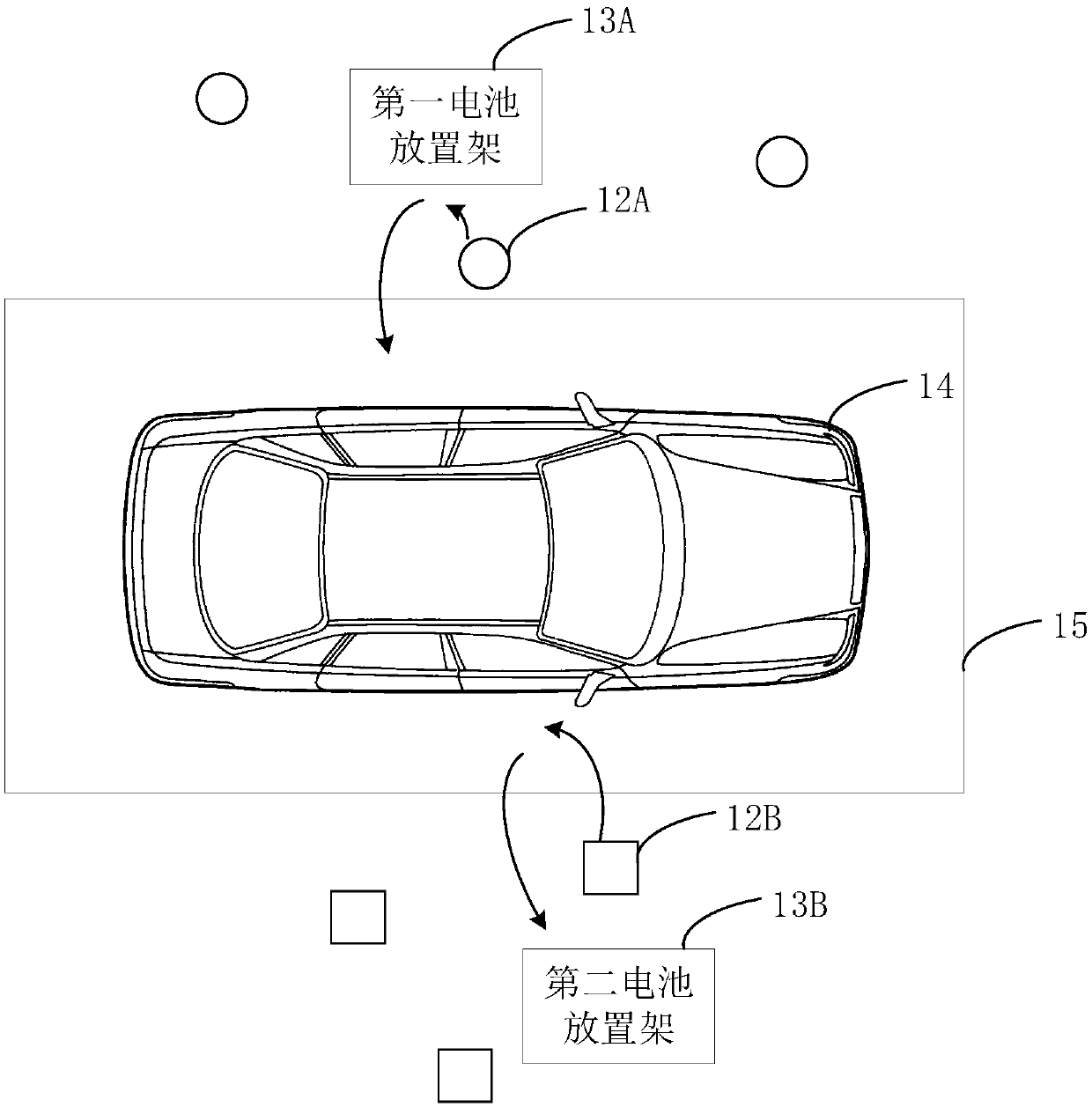

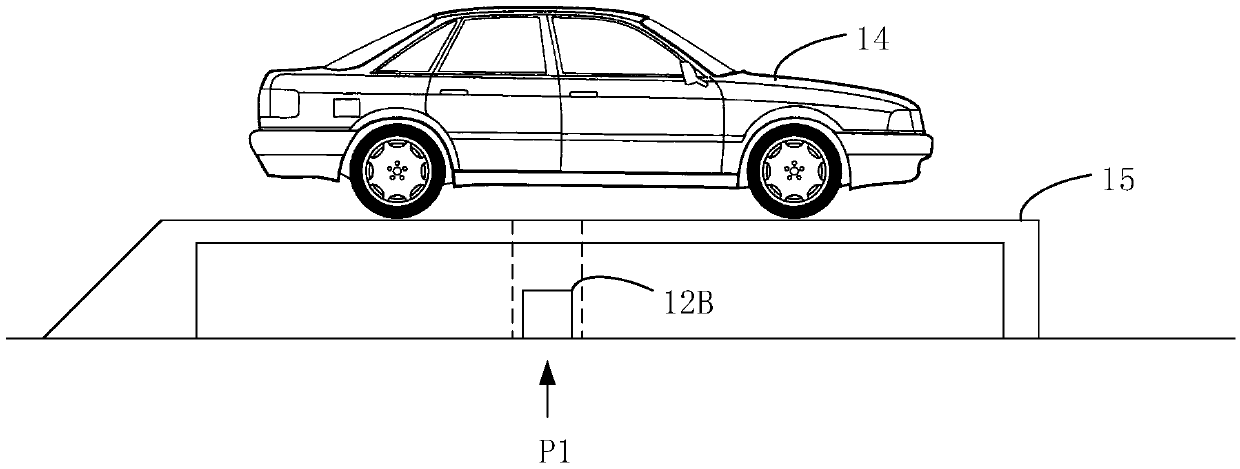

[0135] figure 1 A battery replacement control system of this embodiment is shown. The power swap control system 10 includes: a control unit 11 and at least two power swap devices 12 . Wherein, the control unit 11 is communicatively connected with each of the power exchange devices 12, and the communication connection is preferably a wireless communication connection, which can be realized through 2G, 3G, 4G, Bluetooth and other communication means. In some special cases (for example, the distance between the control unit 11 and the power exchange device 12 is very close, and the range of movement of the power exchange device 12 is small), the communication connection may also be a wired communication connection.

[0136] The control unit 11 is used to determine the battery model applicable to the electric vehicle to be replaced.

[0137] The control unit 11 is also used to select a battery storage rack that meets the first condition from at least one battery storage rack 13 ...

Embodiment 2

[0143] The battery replacement control system in this embodiment is a further improvement on the basis of Embodiment 1, mainly reflected in the setting of the first condition. The first condition is used as the basis for selecting the first battery storage rack 13A. In addition to the battery of the battery type must be placed, other preferred matching conditions can be further set. In this embodiment, the matching condition is mainly related to the power of the battery, and the control unit 11 is also used to monitor the power of the battery placed on each of the battery racks.

[0144] Specifically, the first condition may be set as a fully charged battery that is placed with the battery type. Correspondingly, the control unit 11 is configured to determine whether there is a battery storage rack meeting the first condition in the at least one battery storage rack, and if so, select one of them as the first battery storage rack 13A. If there is no battery storage rack meetin...

Embodiment 3

[0150] The battery replacement control system of this embodiment is a further improvement on the basis of Embodiment 1 or 2, which is mainly reflected in the selection of the first battery placement rack 13A and the second battery placement rack 13B by the control unit 11 . When the number of battery storage racks is two or even more, it is likely that two or more battery storage racks meet the first condition or the second condition at the same time. The control unit 11 can further set selection requirements of the first battery placement rack 13A and the second battery placement rack 13B according to requirements.

[0151] In this embodiment, in order to deal with the situation that two or more battery storage racks meet the first condition at the same time, the control unit 11 can be used to determine whether there are more than one battery storage racks that meet the first condition , if then:

[0152] From the battery storage racks meeting the first condition, randomly s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com