Low-temperature resistant light-cured inkjet printing gloss oil for LED and preparation and application of gloss oil

An inkjet printing and photocuring technology, which is applied in applications, inks, household appliances, etc., can solve problems such as surface cracking, low temperature resistance, poor flexibility and bending properties, and improve low temperature resistance and bending resistance Good, good anti-yellowing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044]This embodiment provides an LED light-curable inkjet printing varnish, the formula of which is shown in Table 1.

[0045] Table 1

[0046]

[0047] According to the formulations of the components listed in Table 1, first the prepolymer resin GU3030Z, GU8100W and aldehyde and ketone resin CT-120 are added to the active diluent (monofunctional monomer isobornyl methacrylate and difunctional Monomer diethanol dimethacrylate), stirred at a high speed of 4000rad / min for 50min to completely dissolve the resin, then added initiator, leveling agent, polymerization inhibitor and ultraviolet absorber under the condition of avoiding light, to Stir at a speed of 3000rad / min for 60min to obtain low temperature resistant LED photocurable inkjet printing varnish. The varnish has a viscosity of 10.12cp at 40°C and a surface tension of 28.02mN / m. It has good printing fluency on the printer. It can be completely cured after being irradiated with LED light with an emission wavelength o...

Embodiment 2

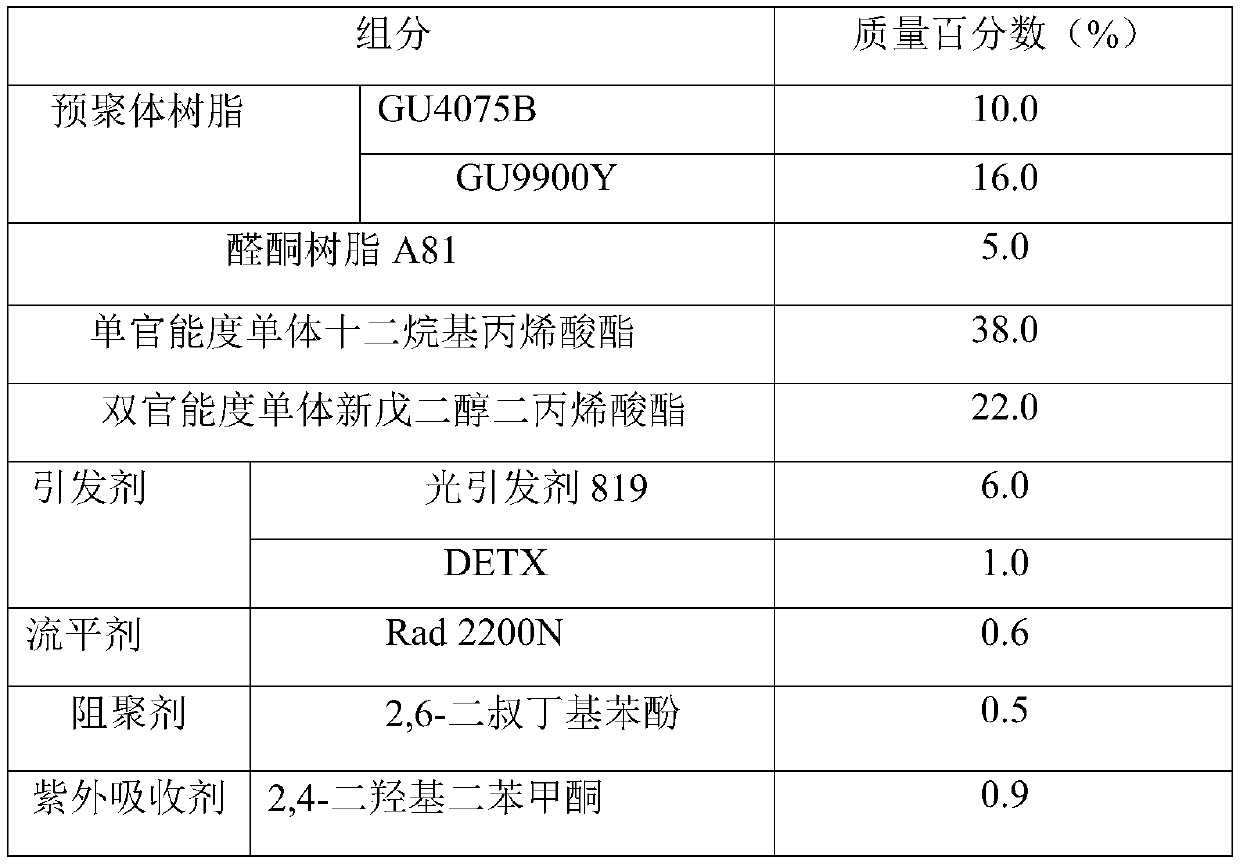

[0049] This embodiment provides an LED light-curable inkjet printing varnish, the formula of which is shown in Table 2.

[0050] Table 2

[0051]

[0052] According to the formulations of the components listed in Table 2, first the prepolymer resin GU4075B, GU9900Y and aldehyde and ketone resin A81 are added to the reactive diluent (monofunctional monomer lauryl acrylate and difunctional monomer In neopentyl glycol diacrylate), stir at a high speed of 3800rad / min for 55min to make the resin dissolve completely, then add initiator, leveling agent, polymerization inhibitor and ultraviolet absorber under the condition of avoiding light min at a speed of stirring for 65 min to obtain low temperature resistant LED photocurable inkjet printing varnish. The varnish has a viscosity of 10.08cp at 40°C and a surface tension of 28.30mN / m. It has good printing fluency on the printer. It can be completely cured after being irradiated with LED light with an emission wavelength of 395nm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap