A pipe gallery and construction method

A construction method and pipe gallery technology, applied in artificial islands, water conservancy projects, infrastructure engineering, etc., can solve the problems of immature connection technology between main line pipe gallery and branch line pipe gallery, high operating cost, and long construction period, etc. The construction period, the improvement of the earthquake resistance level, and the effect of strong anti-corrosion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

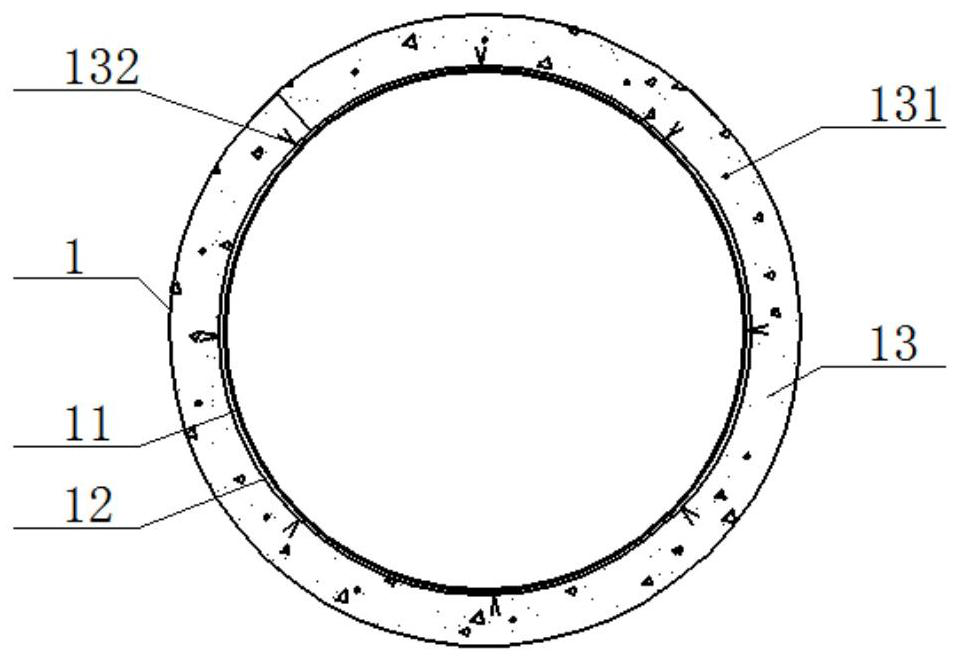

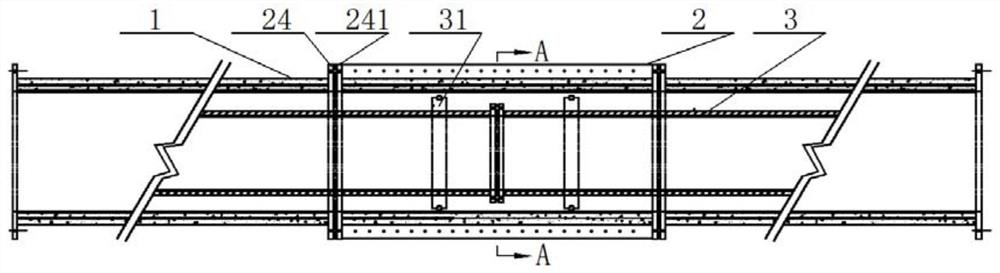

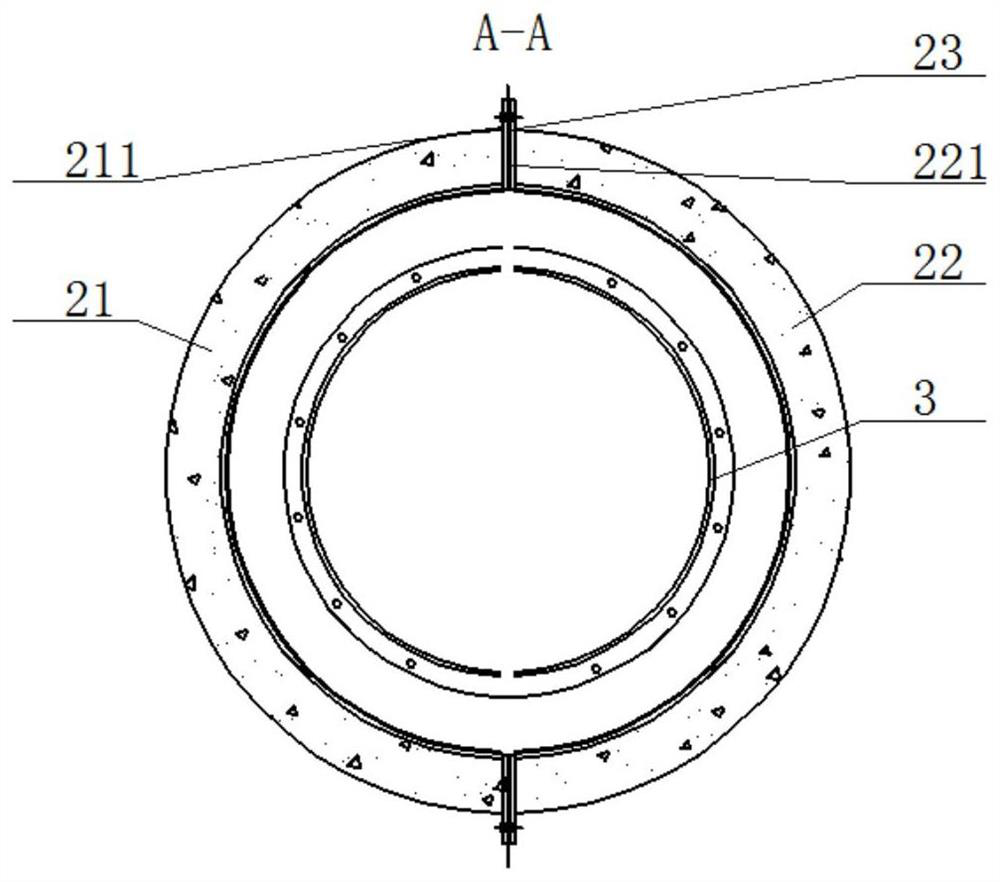

[0020] see Figure 1-Figure 6 As shown, the technical solution adopted in this specific embodiment is: a pipe gallery which is composed of reinforced concrete and steel pipe composite protection pipe body 1, protection pipe joint 2, and pipeline 3, and reinforced concrete and steel pipe composite protection pipe body 1 A steel plate 11 is set inside, a layer of anti-corrosion protection layer 12 is set on the inner surface of the steel plate 11, concrete 13 is poured on the outer periphery of the steel plate 11, threaded steel bars 131 and riveting hooks 132 are embedded inside the concrete 13, and two reinforced concrete and steel pipe composite protective pipes 1 Through the fixed installation of the protection pipe section 2, the protection pipe section 2 is composed of a first split body 21 and a second split body 22. The second rib plate 221 is set, the first split body 21 and the second split body 22 are fixedly connected by the first rib plate 211 and the second rib pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com